a l1 2 Precipitation-strengthened high-entropy alloy and preparation method thereof

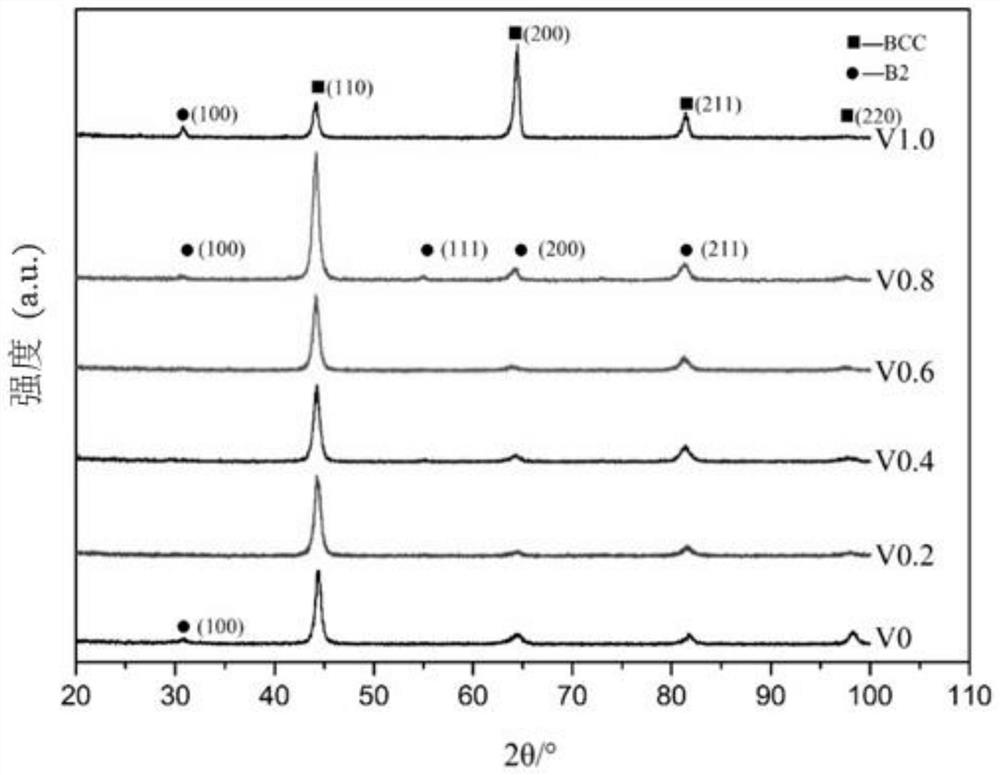

A high-entropy alloy and precipitation strengthening technology, applied to high-strength and wear-resistant parts, L12 type precipitation-strengthening high-entropy alloy and its preparation field, can solve the problems of high brittleness, influence of final alloy properties, difficult control of particle shape and size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

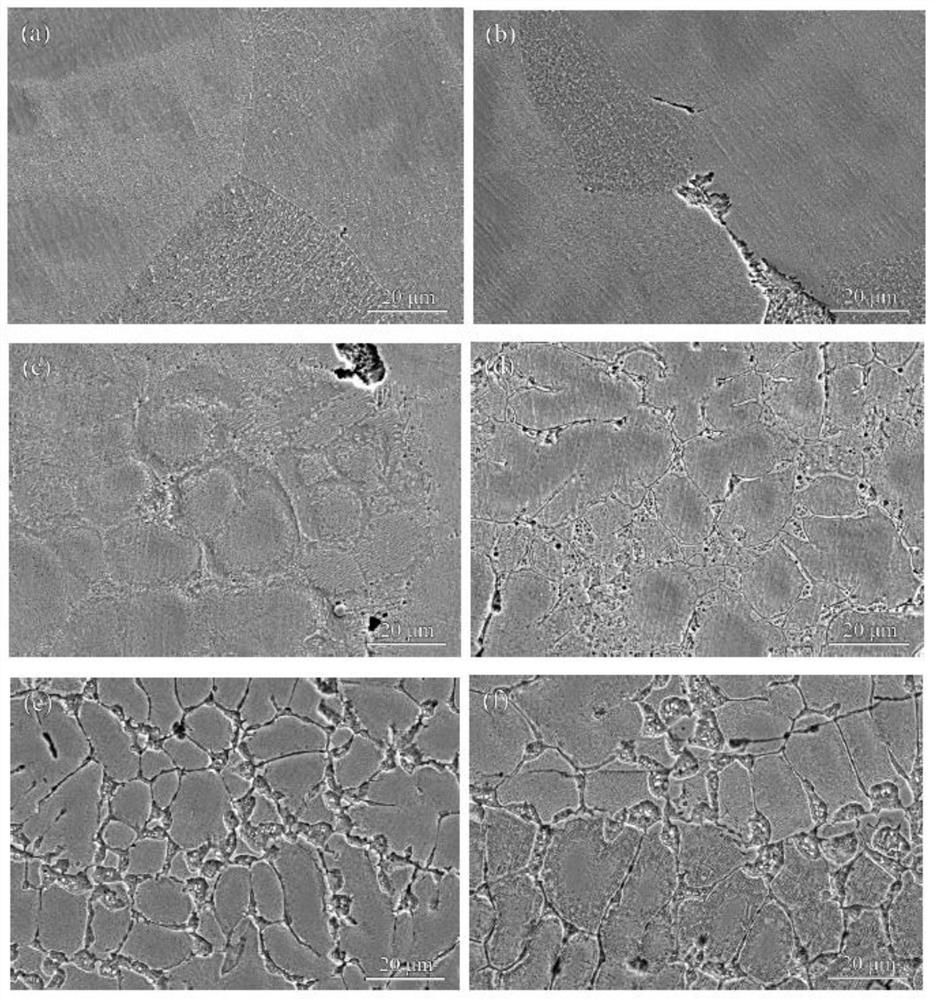

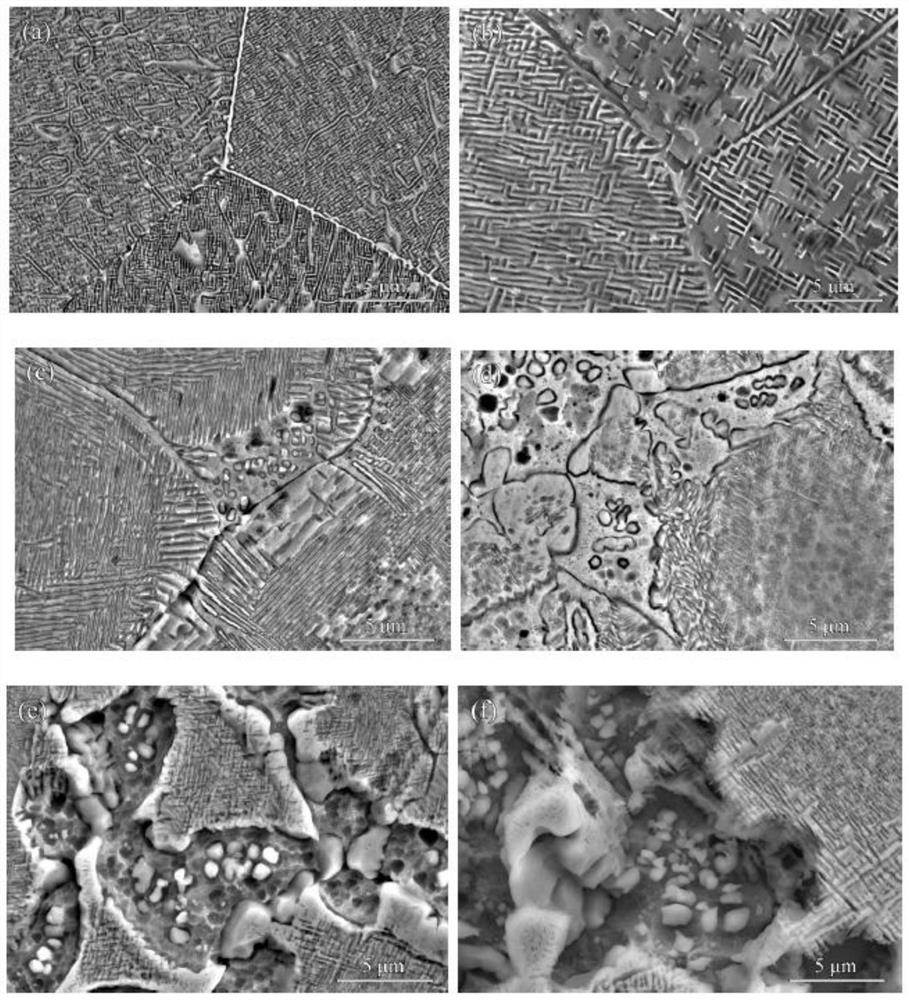

Examples

Embodiment 1

[0032] 1) Raw material preparation:

[0033] Al, Co, Cr, Fe, Ni feedstock of purity above 99.9% is mole than AlcoCrfeni (TiN) in accordance with alloy ingredients 0.2 Formulated, the quality required to convert the alloy ingot, using electronic balance accurately, pretreatment of each group of raw materials before smelting; pretreatment is to remove the oxide treatment for each group of raw materials, and then in ultrasonic cleaning instrument Perform ultrasound cleaning treatment, and finally naturally dried.

[0034] 2) Equipment cleaning:

[0035] Wipe the vacuum electric arc furnace using a gauze dipped in anhydrous ethanol, a fine sandpaper is used to polish tungsten poles until the tungsten pointer occurs and the surface is smooth, and the spare group of raw materials is placed in the sample tank in the arc furnace. In the order of the melting point from the low to high, it is sequentially placed in the sample tank in the furnace, and there is a titanium ingot of the sample ...

Embodiment 2

[0039] Al, Co, Cr, Fe, Ni, Tin feedstock of purity above 99.9% is mole than AlcoCrfeni (TiN) in accordance with alloy components 0.4 Formulated, the quality required to convert the alloy ingot, using electronic balance accurately, pretreatment of each group of raw materials before smelting; pretreatment is to remove the oxide treatment for each group of raw materials, and then in ultrasonic cleaning instrument Ultrasound cleaning treatment, finally naturally dried, and then step in the first embodiment.

Embodiment 3

[0041] Al, Co, Cr, Fe, Ni, Tin feedstock of purity above 99.9% is mole than AlcoCrfeni (TiN) in accordance with alloy components 0.6 Formulated, the quality required to convert the alloy ingot, using electronic balance accurately, pretreatment of each group of raw materials before smelting; pretreatment is to remove the oxide treatment for each group of raw materials, and then in ultrasonic cleaning instrument Ultrasound cleaning treatment, finally naturally dried, and then step in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com