Oversized high-strength heatproof magnesium alloy ingot blank semicontinuous casting technique

An ultra-large-scale, casting process technology, applied in the field of magnesium alloy casting, can solve the problems of increased shrinkage, increased thermal stress of casting, and difficult ingot casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

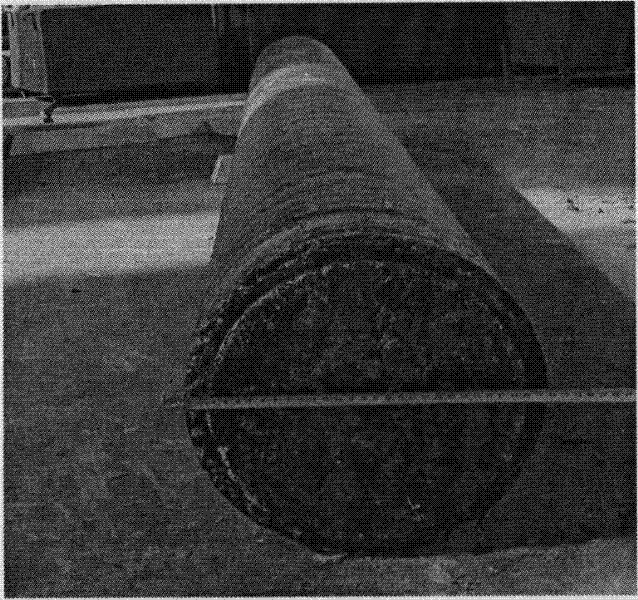

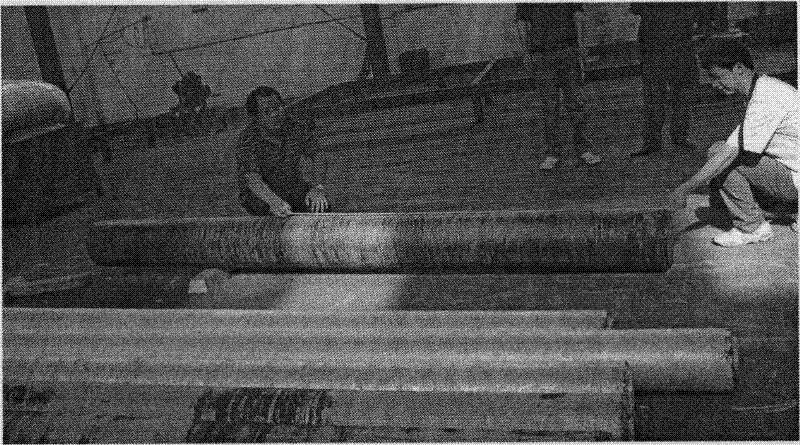

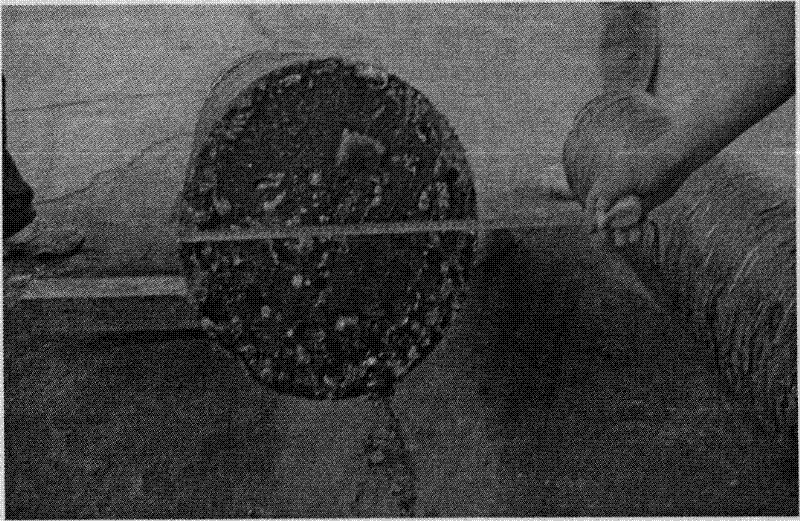

Image

Examples

Embodiment 1

[0022] In this embodiment, various process parameters of semi-continuous casting are adjusted to obtain high-quality super-large-sized high-strength magnesium alloy ingots. After the magnesium alloy melt is refined and left to stand, the low-pressure transfer technology and flow control technology of the melt are used to realize the micro-controllable flow of the alloy liquid during the pouring process. The specific process steps are as follows:

[0023] a. Melting magnesium, melting the high-purity magnesium ingot in an iron crucible, the melting temperature is 720°C, and adding 5# flux at the same time;

[0024] b. When the magnesium ingot is completely melted, add Mg-Gd, Mg-Y, and Mg-Zr master alloys in sequence, the temperature is 790°C, and sprinkle 5# flux in an appropriate amount to protect the melt;

[0025] c. When the alloy is completely melted, stir, and remove slag after degassing with argon;

[0026] d. The temperature drops to 700°C, and the temperature is kept...

Embodiment 2

[0029] In this embodiment, various process parameters of semi-continuous casting are adjusted to obtain high-quality super-large-sized high-strength magnesium alloy ingots. After the magnesium alloy melt is refined and left to stand, the low-pressure transfer technology and flow control technology of the melt are used to realize the micro-controllable flow of the alloy liquid during the pouring process. The specific process steps are as follows:

[0030] a. Melting magnesium, melting the high-purity magnesium ingot in an iron crucible, the melting temperature is 720°C, and adding 5# flux at the same time;

[0031] b. When the magnesium ingot is completely melted, add Mg-Gd, Mg-Y, and Mg-Zr master alloys in sequence, the temperature is 790°C, and sprinkle 5# flux in an appropriate amount to protect the melt;

[0032] c. When the alloy is completely melted, stir, and remove slag after degassing with argon;

[0033] d. The temperature is lowered to 700 ° C, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com