Zinc alloy material for degradable cardiovascular stent and preparation method of zinc alloy material

A zinc alloy and cardiovascular technology, applied in the field of materials, can solve the problems of unsatisfactory mechanical properties, medical metal use requirements, zinc alloy structure, etc., to reduce the risk of infection, improve strength, and weaken the effect of galvanic corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The composition of the zinc-magnesium-manganese alloy contains Mg 0.03%, Mn 0.03%, unavoidable impurities ≤ 10ppm, and Zn as the balance.

[0029] (1) Prepare metal zinc, metal magnesium, metal manganese and phosphorus as raw materials for smelting according to the composition, first heat metal zinc to 600±5° C., add metal magnesium, metal manganese and phosphorus (boiling point 350 ℃), after it is completely melted, stir evenly. Cool it down to 550±5°C, use a graphite bell jar to pass hexachloroethane into the molten metal, make it fully contact with the molten metal, and let it stand at 550±5°C for 15-20 minutes; melt the metal The body is lowered to 500±10°C, cast into a water-cooled iron mold and cooled to obtain an ingot;

[0030] (2) Secondary magnetic levitation smelting: the ingot is subjected to secondary magnetic levitation smelting to make the component uniformity deviation less than ±0.02wt.%, and the structure is uniform;

[0031] (3) Homogenization treat...

Embodiment 2

[0038] The composition of the zinc-magnesium-manganese alloy contains 0.05% of Mg, 0.05% of Mn, unavoidable impurities ≤ 10ppm, and the balance of Zn.

[0039] (1) Prepare metal zinc, metal magnesium, metal manganese and phosphorus as raw materials for smelting according to the composition, first heat metal zinc to 600±5° C., add metal magnesium, metal manganese and phosphorus (boiling point 350 ℃), after it is completely melted, stir evenly. Cool it down to 550±5°C, use a graphite bell jar to pass hexachloroethane into the molten metal, make it fully contact with the molten metal, and let it stand at 550±5°C for 15-20 minutes; melt the metal The body is lowered to 500±10°C, cast into a water-cooled iron mold and cooled to obtain an ingot;

[0040] (2) Secondary magnetic levitation smelting: the ingot is subjected to secondary magnetic levitation smelting to make the component uniformity deviation less than ±0.02wt.%, and the structure is uniform;

[0041] (3) Homogenization...

Embodiment 3

[0046] The composition of the zinc-magnesium-manganese alloy contains 0.07% of Mg and 0.07% of Mn by weight percentage, unavoidable impurities ≤ 10ppm, and the balance of Zn.

[0047] (1) Prepare metal zinc, metal magnesium, metal manganese and phosphorus as raw materials for smelting according to the composition, first heat metal zinc to 600±5° C., add metal magnesium, metal manganese and phosphorus (boiling point 350 ℃), after it is completely melted, stir evenly. Cool it down to 550±5°C, use a graphite bell jar to pass hexachloroethane into the molten metal, make it fully contact with the molten metal, and let it stand at 550±5°C for 15-20 minutes; melt the metal The body is lowered to 500±10°C, cast into a water-cooled iron mold and cooled to obtain an ingot;

[0048] (2) Secondary magnetic levitation smelting: the ingot is subjected to secondary magnetic levitation smelting to make the component uniformity deviation less than ±0.02wt.%, and the structure is uniform;

[00...

PUM

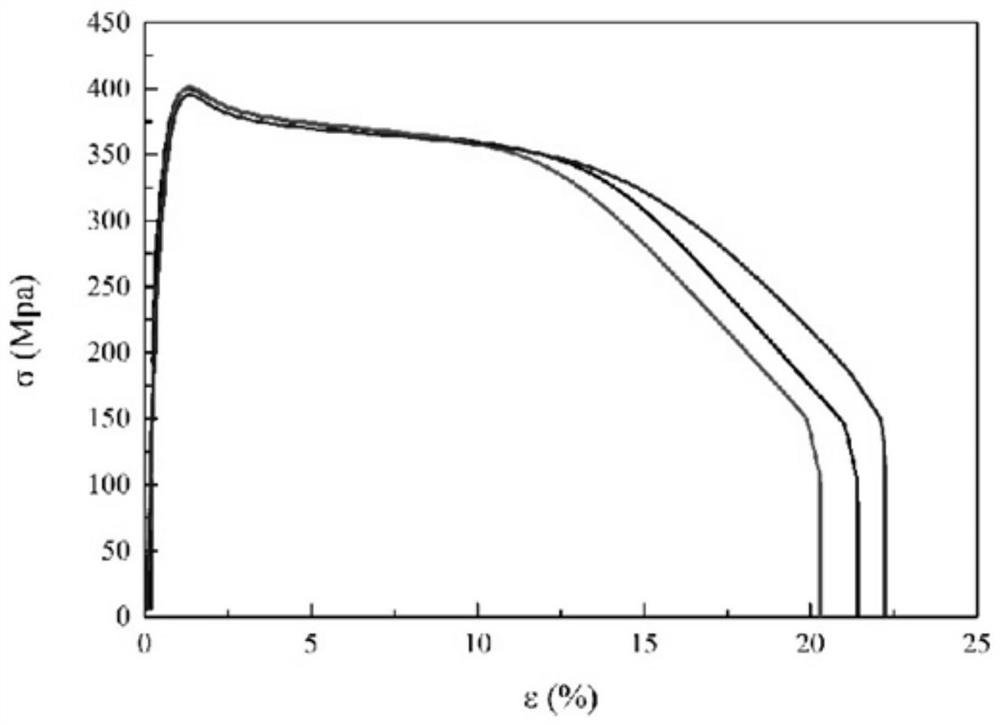

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

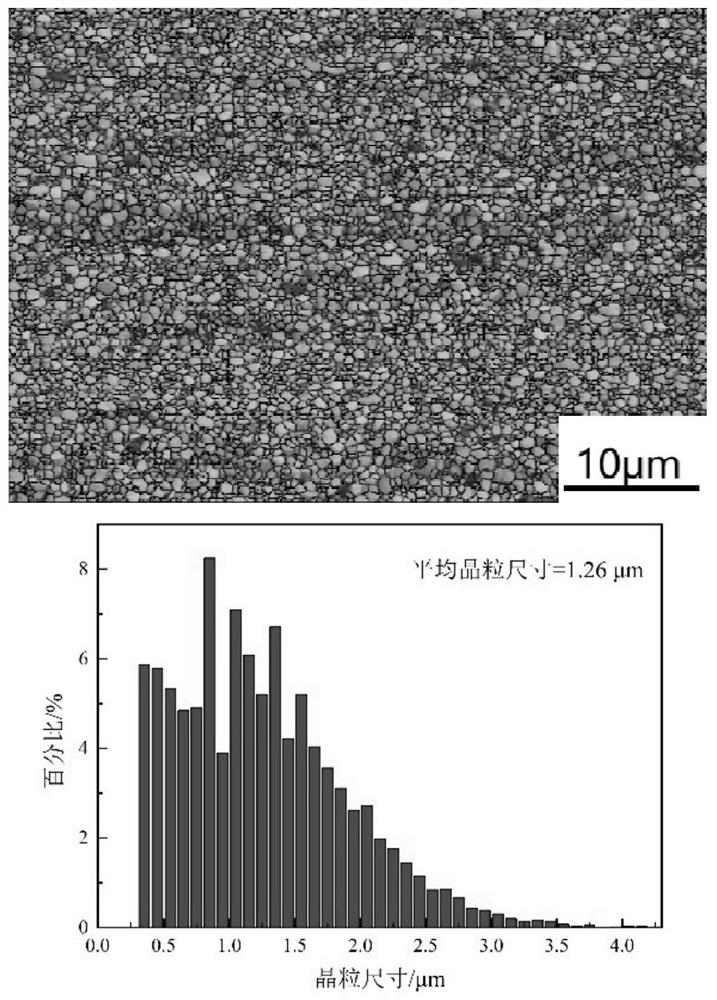

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com