Method for preparing TiAl-based composite material sheet material

An aluminum-based composite material and a composite material technology, which are applied in the field of composite material sheet preparation, can solve the problems of poor tissue density, poor tissue uniformity, internal oxidation, etc., and achieve good tissue density, good tissue uniformity, and dense interface bonding. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

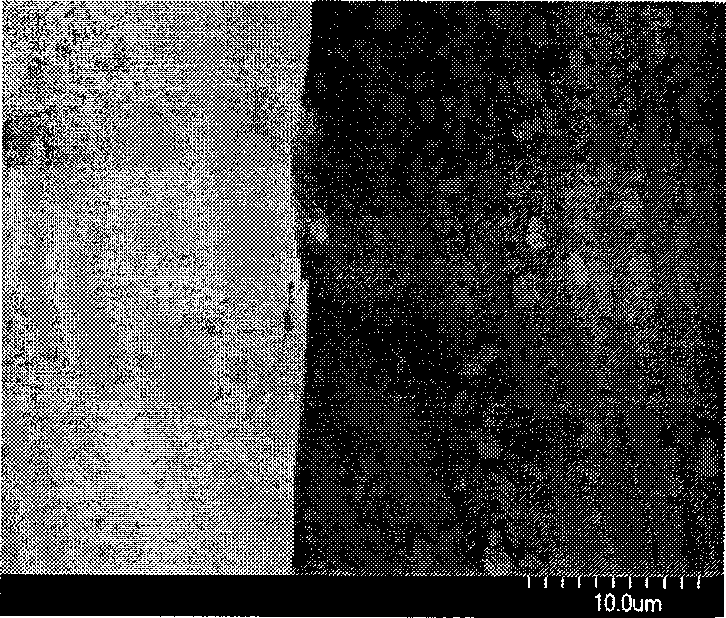

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: The preparation method of the TiAl-based composite material plate in this embodiment is carried out according to the following steps: 1. Heat the alternately laminated aluminum-based composite material plate and pure titanium plate under the conditions of 200-500°C and 28-32MPa Press for 0.5-3 hours, and then hot-roll at 200-500°C to obtain a multi-layer composite sheet; 2. The multi-layer composite sheet obtained in step 1 is heat-treated at 500-700°C for 5-25 hours, Then heat treatment at 800-1000° C. for 5-25 hours to obtain a TiAl-based composite material plate.

[0011] In the first step of this embodiment, the hot pressing and rolling is carried out until the pressing amount of the plate reaches 20% to 80%.

[0012] When the deformation of the TiAl-based composite material plate prepared in this embodiment is 58-62%, the deformation of pure titanium is 56-64%, and the deformation of the aluminum-based composite material is 60-64%.

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the number of alternately laminated layers of aluminum-based composite material plates and pure titanium plates is 2n+1 layers, n is a positive integer, and n≤50; The outermost layer is pure titanium plate. Other steps and parameters are the same as those in Embodiment 1.

[0014] The thickness of the TiAl-based composite material plate produced in this embodiment is 1-9 mm.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the thickness of the aluminum-based composite material plate in step 1 is 0.05-0.3 mm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com