High-strength high-conduction strengthened dispersion copper alloy and preparation method thereof

A technology for dispersion strengthening of copper and copper alloys, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of uniform and stable suspension of particles in the composite electrodeposition method that is difficult to control, and the size limit of composite material products, etc., to achieve Excellent anti-high temperature softening ability, shorten production cycle, high anti-softening temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, 0.14wt% Al is added to the Cu-copper alloy base material.

[0030] The process for preparing the above-mentioned copper alloy material includes:

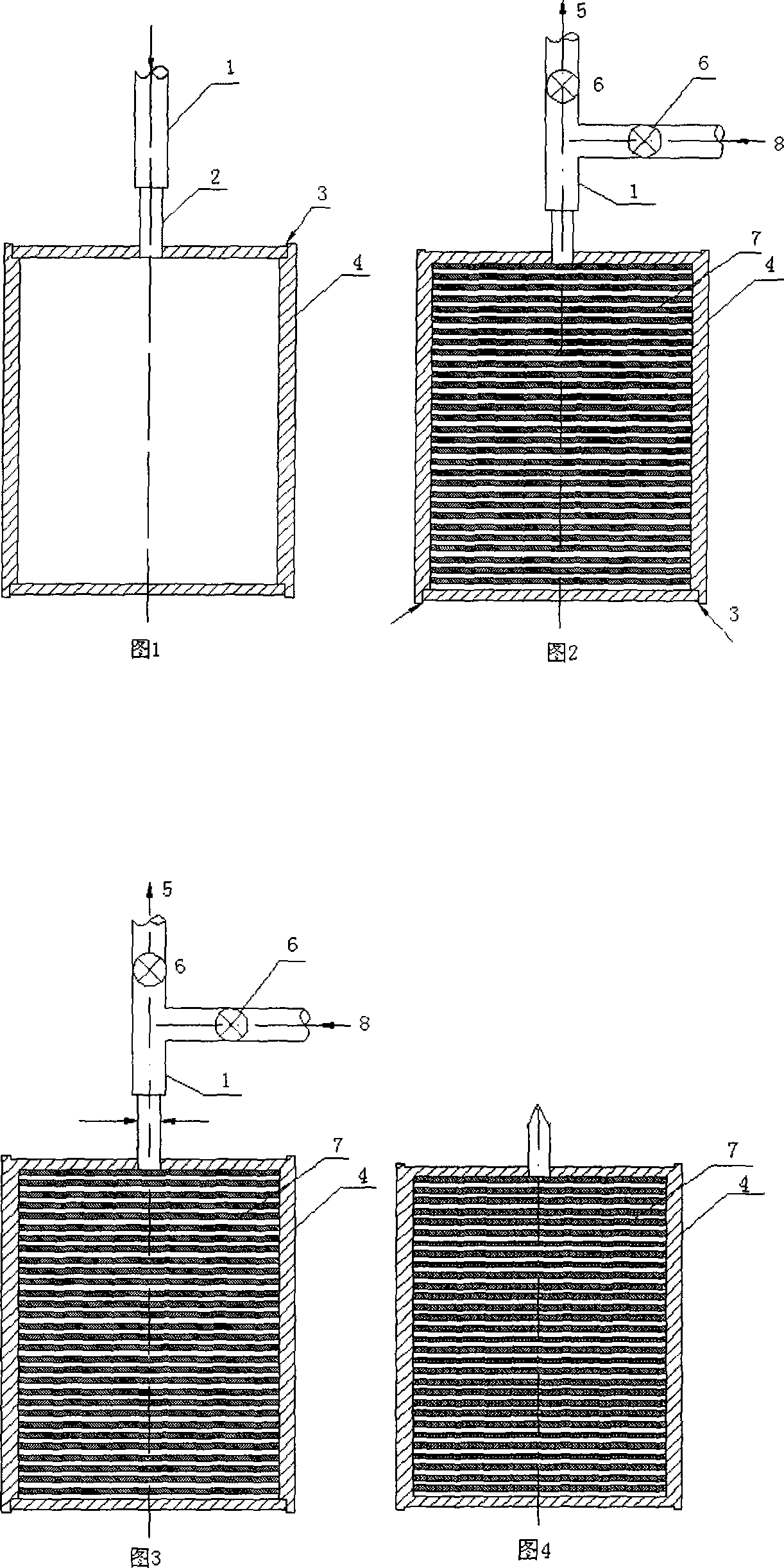

[0031] ①Smelting of alloys ②Hot rolling or cold rolling (or wire cutting) of alloys to prepare sheets ③Internal oxidation of alloy sheets ④Lamination of internally oxidized sheets with hot pressing ⑤Alloy processing.

[0032] Among them: the melting of the alloy is carried out in an intermediate frequency induction furnace in an atmospheric environment, and the Cu-Al alloy is made of high-purity cathode copper (Cu≥99.90wt%) and electrolytic aluminum (Al≥99.90wt%) as raw materials. It is Φ80mm×150mm.

[0033] Hot rolling or cold rolling (or wire cutting) of the alloy to prepare thin plates is to remove the defects on the surface and ends of the ingot, forge it into a billet with a rectangular cross-sectional size of 15mm×100mm (forging temperature is 800°C), and then heat it at 900°C×10h Heating under the...

Embodiment 2

[0039] In this embodiment, the addition content of Cu copper alloy base material is 0.30wt%.

[0040] The process for preparing the above-mentioned copper alloy material includes:

[0041] ①Smelting of alloys ②Hot rolling or cold rolling (or wire cutting) of alloys to prepare sheets ③Internal oxidation of alloy sheets ④Lamination of internally oxidized sheets and hot extrusion ⑤Alloy processing.

[0042] Among them: alloy smelting means that the alloy is smelted in an intermediate frequency induction furnace in a traditional atmospheric environment, and the Cu-Al alloy is smelted by using high-purity cathode copper (Cu≥99.90wt%) and electrolytic aluminum (Al≥99.90wt%) as raw materials Pouring, ingot size is Φ80mm×150mm. The Al content is 0.30 wt%.

[0043] Wherein: the smelting of alloy is with embodiment 1.

[0044] The hot rolling or cold rolling (or wire cutting) of the alloy to prepare the thin plate is to remove the defects on the surface and both ends of the ingot, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com