Method for preparing sliver-tin oxide and indium oxide electrical contact material by gradient internal oxidation method and material thereof

An electrical contact material, silver tin oxide technology, applied in contacts, circuits, electric switches, etc., can solve the problems of increasing silver consumption, prolonging the process, increasing production costs, etc., to improve the yield, suppress outward diffusion, Effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment one: take by weighing 1.3 kilograms of Sn ingots, 0.6 kilograms of In ingots, and 18.1 kilograms of Ag ingots, and melt them into silver-tin-indium alloy ingots in an intermediate frequency furnace. After turning, silver-tin-indium alloy ingots remove surface impurities and oil stains. ℃, extrusion ratio of 250 when extruded into φ6.0 alloy wire. The alloy wire rod becomes a φ1.55 wire rod after being drawn many times, and the wire segment with a length of about 10 mm to 15 mm is cut on a cutting machine and loaded into a material tray.

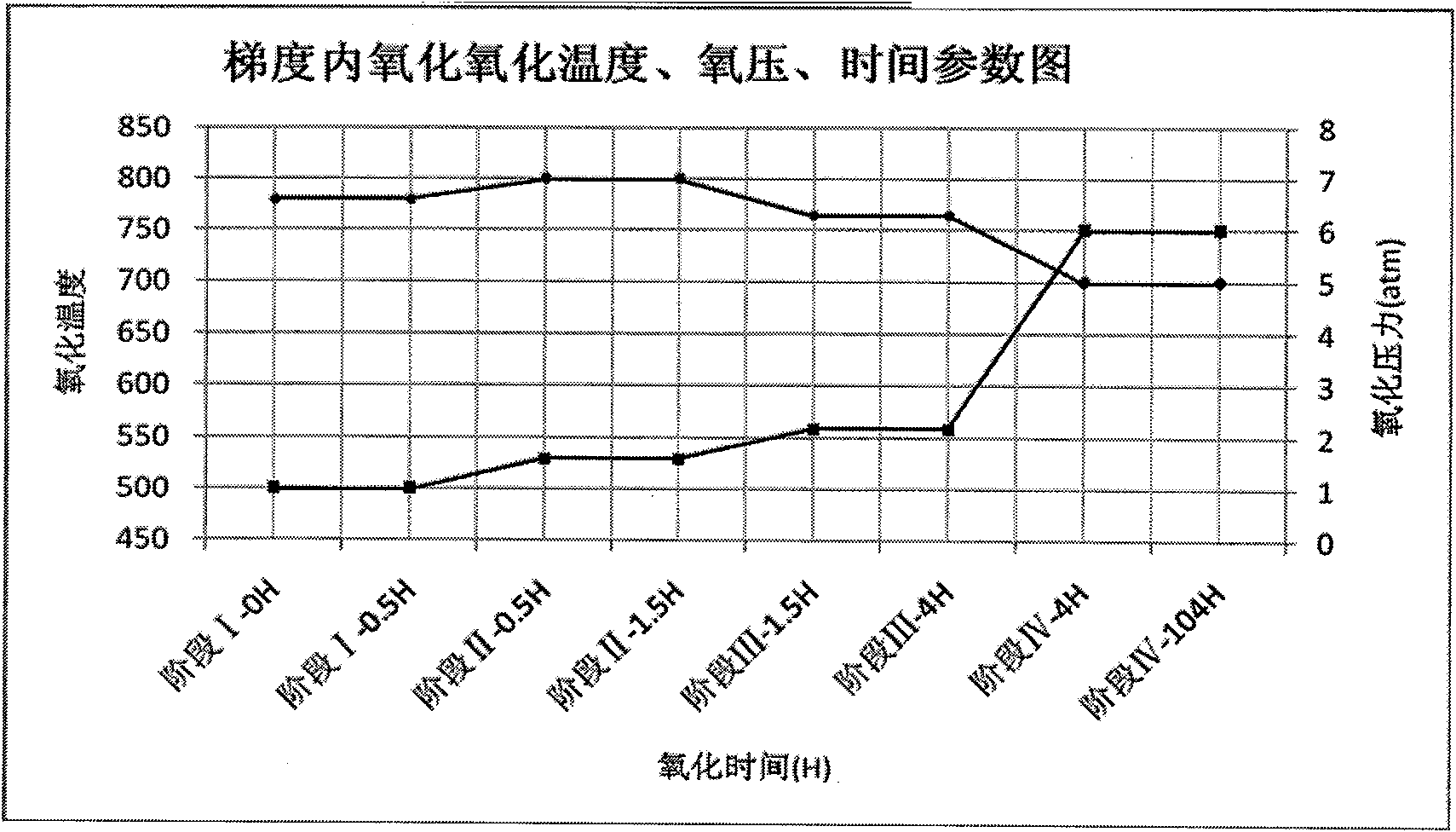

[0057] Then carry out alloy gradient internal oxidation. In the internal oxidation stage of normal pressure and temperature rise, the silver-tin-indium alloy charge is hoisted into the internal oxidation furnace when the temperature of the internal oxidation furnace reaches 780 ° C. The furnace cover is closed, the vent valve is opened, and pure oxygen is charged. After 2 minutes to 3 minutes, close the vent valve to keep th...

Embodiment 2

[0064] Example 2 Weigh 1.64 kilograms of Sn ingots, 0.7 kilograms of In ingots, and 17.66 kilograms of Ag ingots, melt them into silver-tin-indium alloy ingots in an intermediate frequency furnace, and extrude them into φ6.0 alloys at 740°C and an extrusion ratio of 250 wire. The silver-tin-indium alloy wire rod is drawn into a φ1.45 wire rod, and the oxidation temperature is 760°C in the normal pressure heating internal oxidation stage, and the oxidation temperature is 780°C in the low pressure internal oxidation stage, and the others are the same as in Example 1.

[0065] Ten different parts of the wire product were sampled for chemical composition analysis, the average silver content was 85.80%, and the relative standard deviation was 0.15%, indicating that the composition of the product was uniform

[0066] The metallographic examination and rivet processing performance analysis of the wire products show that the prepared silver tin oxide indium oxide wire products with hi...

Embodiment 3

[0067] Example 3 Weigh 1.36 kg of Sn ingots, 0.54 kg of In ingots, 0.04 kg of Ni ingots, 0.05 kg of Bi ingots, and 18.10 kg of Ag ingots, and melt them into silver tin indium bismuth nickel alloy ingots in an intermediate frequency furnace. The gold ingots are removed after turning Surface impurities and oil stains are extruded into alloy sheets of 5×10 mm at 710°C and extrusion ratio of 250. The alloy sheet is broken into 3×5×1.5 alloy sheets after repeated rolling, and loaded into the material tray. Others are with embodiment 1.

[0068] The silver tin oxide indium oxide alloy sheet after internal oxidation was sampled for metallographic analysis, and no pure silver layer was enriched on the surface of the wire rod, and the size and distribution of oxide particles were uniform at the same time.

[0069] The rivet processing performance test is carried out on wire products with a diameter of φ1.4. The rivet specification is F3.0×1.5 (0.3), the cracking rate of the rivet is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com