Preparation method of silver-metallic oxide electrical contact material

A technology of oxide electrodes and contact materials, which is applied in the direction of silver compounds, silver compounds, contact materials, etc., can solve the problems of Ag-MeO materials that are difficult to oxidize fully, shorten the production process, and the production process is long, so as to shorten the oxidation time , improve comprehensive performance, and solve the effect that is difficult to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

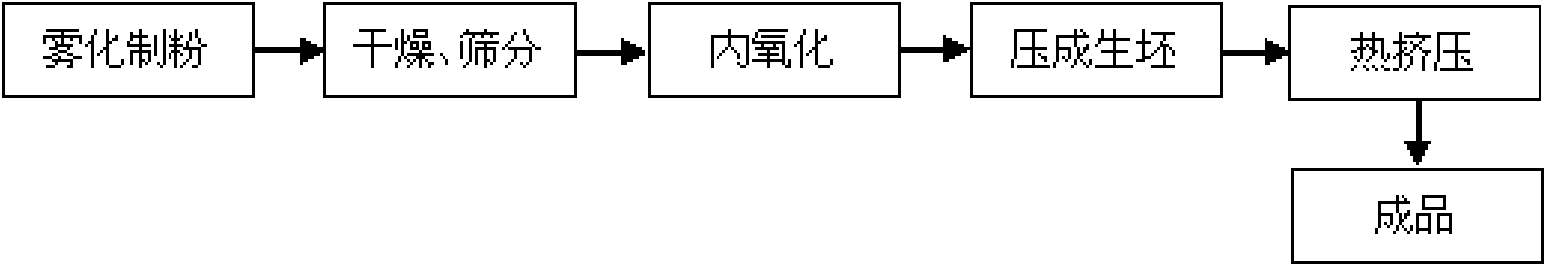

Method used

Image

Examples

Embodiment 1

[0025] Take 2004 grams of silver, 112.5 grams of tin, and 76.5 grams of antimony, put them in an intermediate frequency induction furnace and melt them, then atomize the alloy with compressed air in the atomization equipment, and sieve the alloy powder after atomization, and the particle size is -325 mesh The powder is oxidized in an oxidation furnace, the oxidation temperature is controlled at 800°C, the oxygen pressure is kept at 50atm, and the oxidation is taken out for 6 hours, and molded into a green body with a diameter of 28mm and a relative density of 70%, and then the green body heated to 800°C is placed Put it into a mold that has been preheated to 500°C, and perform hot extrusion to obtain a product with a diameter of 4mm.

Embodiment 2

[0027] Take 2000 grams of silver, 223 grams of zinc, 105 grams of lanthanum, and 25 grams of yttrium. After melting in an intermediate frequency induction furnace, the alloy is atomized with compressed air in the atomization equipment. After atomization, the alloy powder is screened to determine the particle size. Put the -325 mesh powder into an oxidation furnace for oxidation, control the oxidation temperature at 400°C, keep the oxygen pressure at 10atm, take it out after oxidation for 3 hours, mold it into a green body with a diameter of 28mm and a relative density of 75%, and then heat it to 600°C Put the green body into the mold that has been preheated to 450 ℃, and after hot extrusion, a product with a diameter of 8 mm can be obtained.

Embodiment 3

[0029] Take 2000 grams of silver, 110.5 grams of copper, 82.9 grams of antimony, and 20 grams of cerium. After melting in an intermediate frequency induction furnace, the alloy is atomized with compressed air in the atomization equipment. After atomization, the alloy powder is screened to determine the particle size Put the -325 mesh powder into an oxidation furnace for oxidation, control the oxidation temperature at 700°C, keep the oxygen pressure at 25atm, take it out after oxidation for 5 hours, mold it into a green body with a diameter of 28mm and a relative density of 80%, and then heat it to 830°C Put the green body into the mold that has been preheated to 300 ℃, and after hot extrusion, a product with a diameter of 4 mm can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com