Method for preparing AgTiB2 contact material

A technology of contact material and process control agent, applied in contacts, electrical components, electrical switches, etc., can solve the problems of low density, poor electrical conductivity and arc erosion resistance of Ag-based contact materials, and achieve excellent resistance. Arc erosion performance, effect of increasing density and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

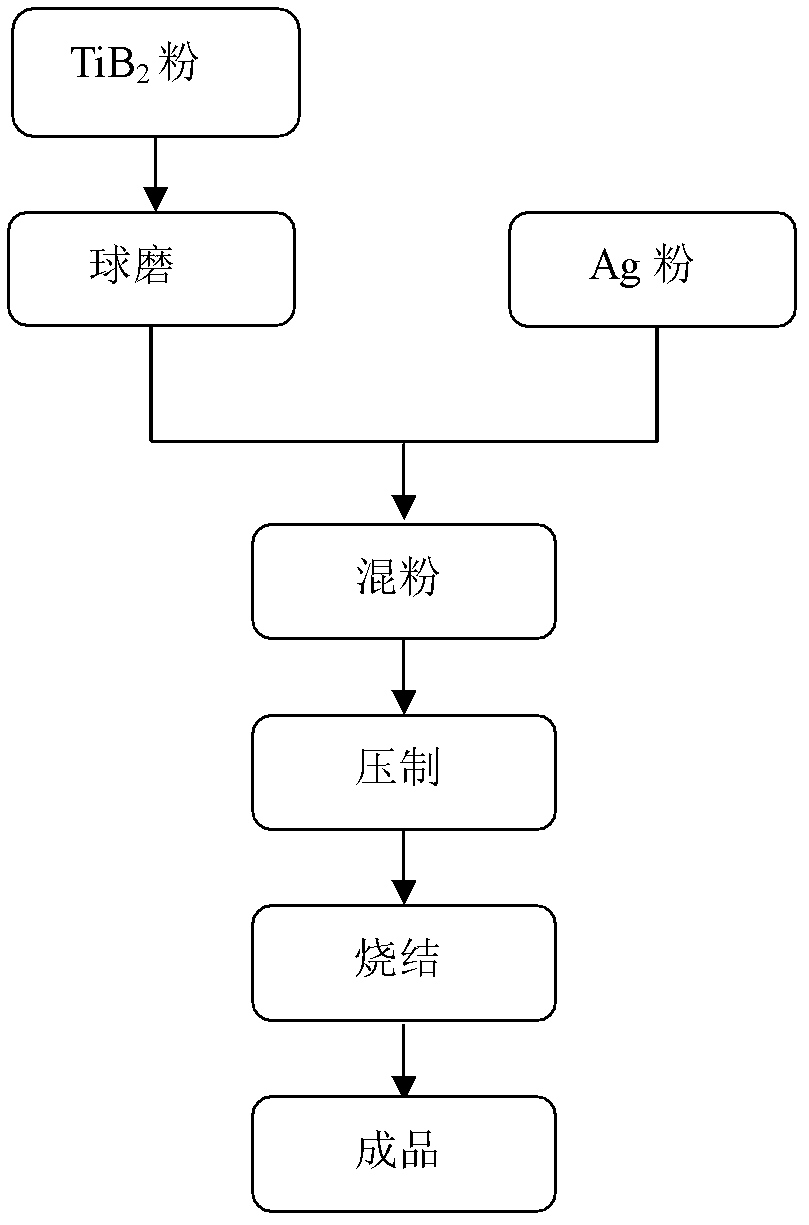

[0025] The invention provides a kind of preparation method of AgTiB2 contact material, such as figure 1 As shown, follow the steps below to implement:

[0026] Step 1, ball milling

[0027] TiB with an average particle size of 1-10 μm and a purity of not less than 99.9% 2 The particles are ball-milled in a high-energy ball mill, the balls are agate balls, the ball-to-material ratio is 20:1-60:1, and anhydrous ethanol is added as a process control agent in the ball mill, and the addition amount is TiB 2 2% to 5% of the total powder mass, control the speed of the ball mill to 150-400rpm, and the ball milling time to 60-120h;

[0028] Step 2, mix powder

[0029] TiB ball-milled in step 1 2 The particles are mixed with Ag powder with an average particle size of 50-100 μm and a purity of not less than 99.99% in a mixer, TiB 2 The particles account for 0.1-10% of the total mass, the sum of the mass percentages of the two components is 100%, and the mixing time is 1-5h;

[0030...

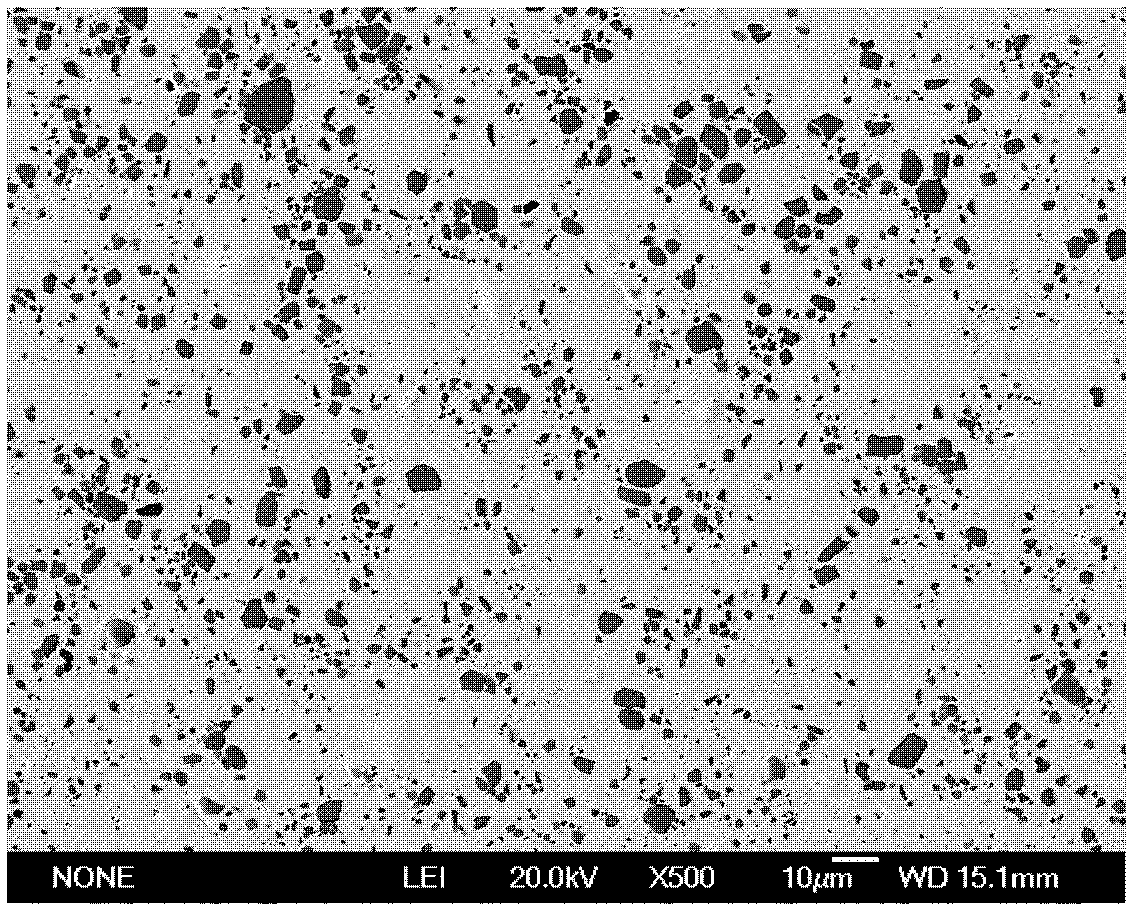

Embodiment 1

[0035] TiB with an average particle size of 1-10 μm and a purity of not less than 99.9% 2 The particles are ball milled in a high-energy ball mill, the balls are agate balls, the ball-to-material ratio is 60:1, and anhydrous ethanol is added as a process control agent in the ball mill, and the addition amount is TiB 2 2% of the total mass of the powder, the speed of the ball mill is controlled to 200rpm, and the ball milling time is 60h; the ball-milled TiB 2 The particles are mixed with Ag powder with an average particle size of 50-100 μm and a purity of not less than 99.99% in a mixer, TiB 2 The particles account for 4% of the total mass, the sum of the mass percentages of the two components is 100%, and the powder mixing time is 4h; the mixed powder is cold-pressed at a pressure of 350MPa, and the holding time is 30s; the compact is controlled by the mold The diameter is 30mm, and the height of the compact is 25mm; the compact is placed in a high-temperature vacuum sinteri...

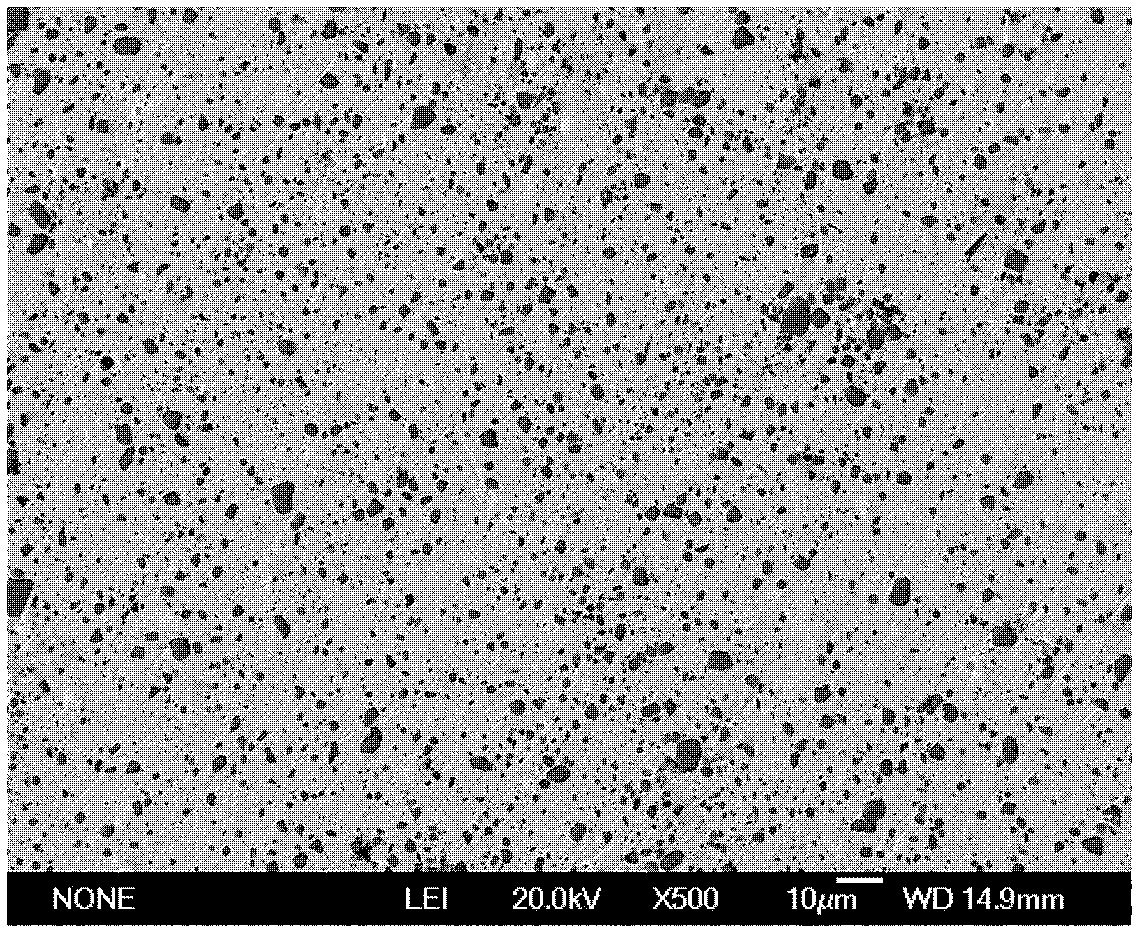

Embodiment 2

[0037] TiB with an average particle size of 1-10 μm and a purity of not less than 99.9% 2 The particles are ball milled in a high-energy ball mill, the balls are agate balls, the ball-to-material ratio is 20:1, and anhydrous ethanol is added as a process control agent in the ball mill, and the addition amount is TiB 2 4% of the total mass of the powder, the ball mill speed is controlled to be 150rpm, and the ball milling time is 100h; the ball-milled TiB 2 The particles are mixed with Ag powder with an average particle size of 50-100 μm and a purity of not less than 99.99% in a mixer, TiB 2 The particles account for 0.1% of the total mass, the sum of the mass percentages of the two components is 100%, and the mixing time is 1h; the mixed powder is cold-pressed at a pressure of 200MPa, and the holding time is 40s; the compact is controlled by the mold The diameter is 20mm, and the height of the compact is 30mm; the compact is placed in a high-temperature vacuum sintering furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com