Method for preparing silver-tin oxide electrical contact material by virtue of sol-gel technique

A technology of electric contact material and gel technology, which is applied in the field of preparing silver-tin oxide electric contact materials, can solve the problems of high powder temperature, limited application range of electric contact materials, and difficulty in controlling the size of tin oxide, etc., and achieves Improved anti-welding and arc erosion resistance, easy subsequent processing, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

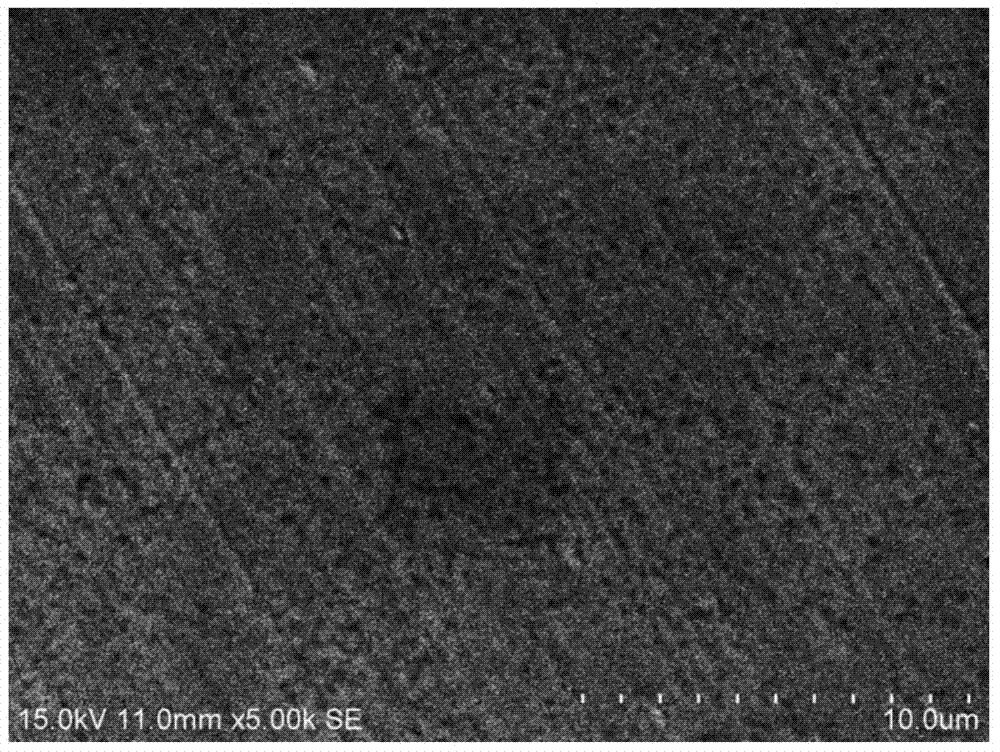

Image

Examples

Embodiment 1

[0035] This embodiment is to prepare a silver-tin oxide electrical contact material with a mass percentage of 88% silver and 12% tin oxide, and proceed according to the following steps:

[0036] (1) Raw material configuration

[0037] In this embodiment, silver nitrate and tin oxide powder with an average particle size of 20nm are used as raw materials, calculated according to the mass percentage of silver and tin oxide in the electrical contact material, and 2.4g of tin oxide powder and 27.7g of silver nitrate are weighed for future use;

[0038] (2) the silver nitrate raw material that takes by weighing is added in deionized water, is mixed with the silver nitrate aqueous solution of 0.1mol / L;

[0039] (3) Weigh 6.1 g of glycine according to the silver nitrate and glycine molar ratio of 2:1, add it to the silver nitrate aqueous solution in step (2), stir until completely dissolved, and obtain a clear and transparent solution;

[0040] (4) Add the tin oxide raw material that...

Embodiment 2

[0048] This embodiment is to prepare a silver-tin oxide electrical contact material with a mass percentage of 90% silver and 10% tin oxide, and proceed according to the following steps:

[0049] (1) Raw material configuration

[0050] In this embodiment, silver nitrate and tin oxide powder with an average particle size of 200 nm are used as raw materials, calculated according to the mass percentage of silver and tin oxide in the electrical contact material, and 2.0 g of tin oxide powder and 28.3 g of silver nitrate are weighed for future use;

[0051] (2) the silver nitrate raw material that takes by weighing is added in deionized water, is mixed with the silver nitrate aqueous solution of 0.5mol / L;

[0052] (3) Weigh 12.5 g of glycine according to the silver nitrate and glycine molar ratio of 1:1, add it to the silver nitrate aqueous solution in step (2), stir until completely dissolved, and obtain a clear and transparent solution;

[0053] (4) Add the tin oxide raw material t...

Embodiment 3

[0061] This embodiment is to prepare a silver-tin oxide electrical contact material with a mass percentage of 94% silver and 6% tin oxide, and proceed according to the following steps:

[0062] (1) Raw material configuration

[0063] In this embodiment, silver nitrate and tin oxide powder with an average particle size of 5 μm are used as raw materials, calculated according to the mass percentage of silver and tin oxide in the electrical contact material, and 12.0 g of tin oxide powder and 296.1 g of silver nitrate are weighed for future use;

[0064] (2) the silver nitrate raw material that takes by weighing is added in deionized water, is mixed with the silver nitrate aqueous solution of 1mol / L;

[0065] (3) Weigh 523.3 g of glycine according to the silver nitrate and glycine molar ratio of 1:4, add it to the silver nitrate aqueous solution in step (2), stir until completely dissolved, and obtain a clear and transparent solution;

[0066] (4) Add the tin oxide raw material t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com