Method for preparing silver-based electrical contact material with fibrous structure

An electric contact material, fibrous technology, applied in the field of preparation of fibrous structure silver-based electrical contact materials, can solve the problem of difficulty in obtaining fibrous structure silver-based materials, difficulties in large-scale production, poor plasticity and ductility, and equal reinforcement question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

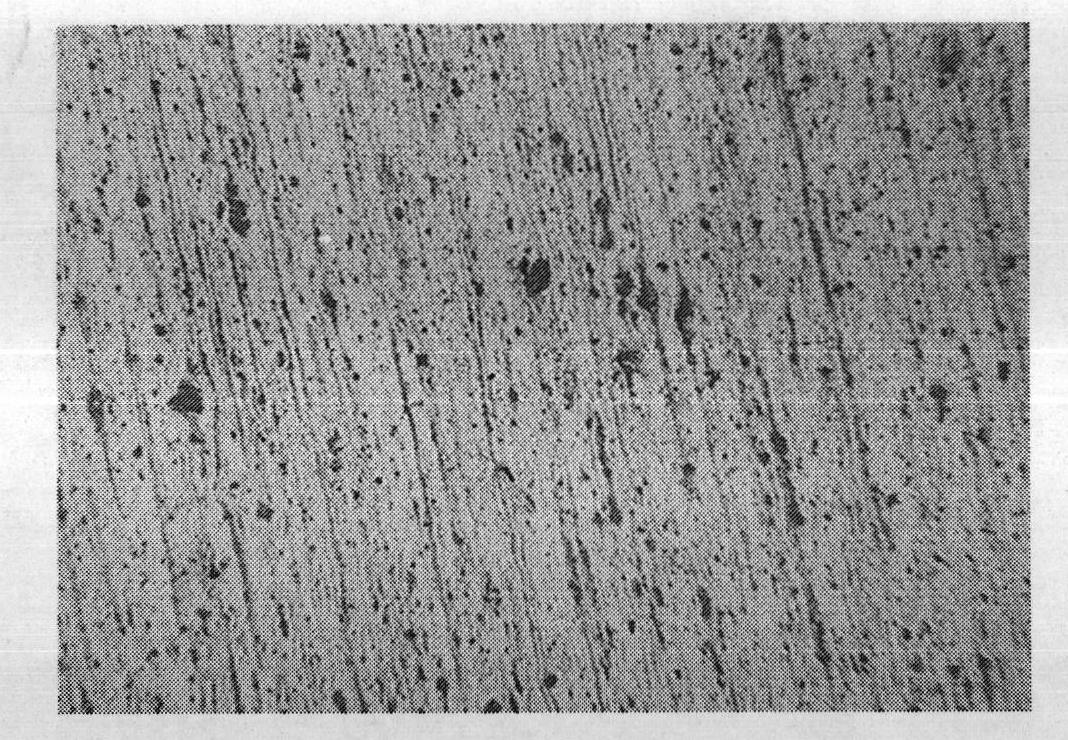

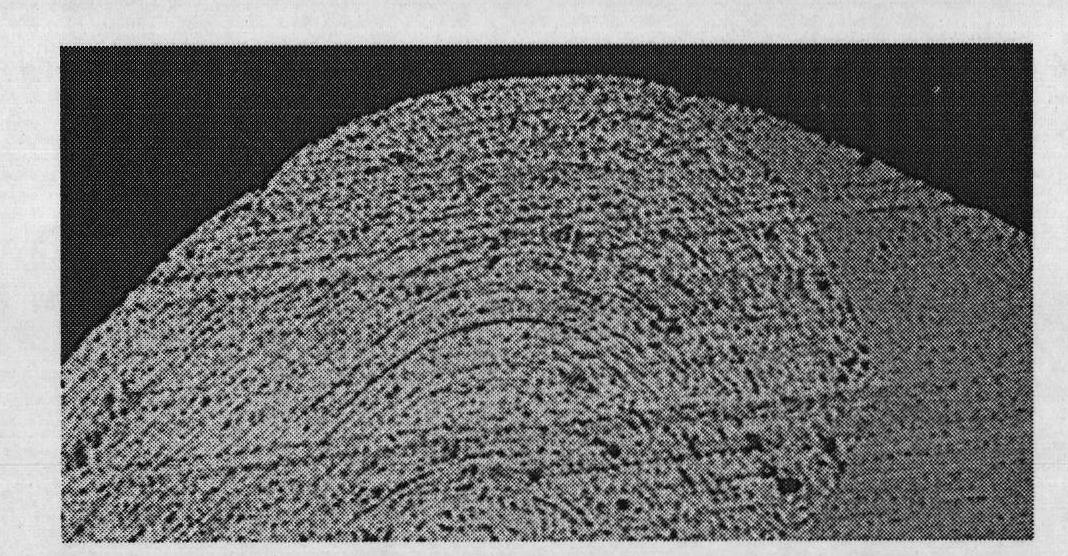

[0034] combine figure 1 and figure 2 , to prepare AgSnO 2 (12) Contact material as an example

[0035] The first step is to obtain matrix Ag powder with a particle size of 200 mesh. The silver is subjected to three-stage atomization treatment, and the atomized silver powder is passed through a 200-mesh sieve.

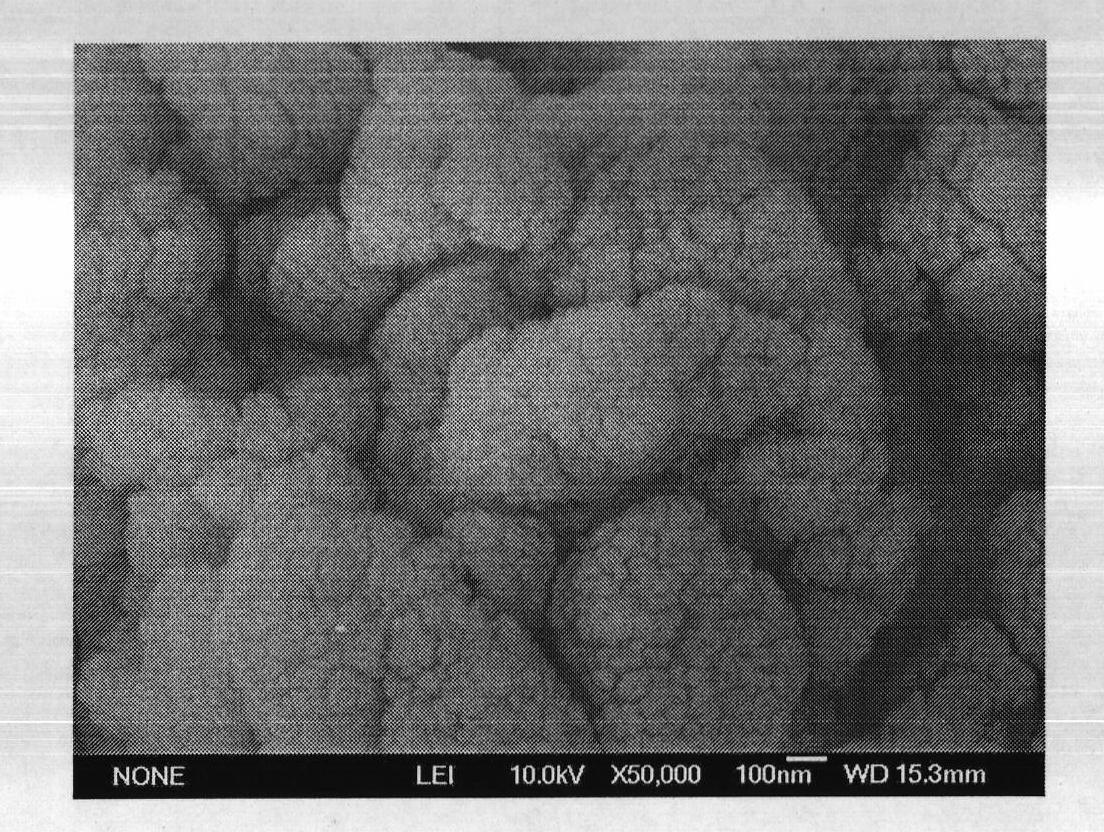

[0036] In the second step, the enhancement phase SnO 2 Powder (average particle size 80nm) 600g and Ag powder 400g obtained in the first step are uniformly mixed, then placed in a high-energy ball mill tank and carried out ball milling, ball milling speed 280 rev / min, ball milling time 10 hours, prepare the scanning electron micrograph of composite powder Such as figure 1 shown.

[0037] In the third step, pour 1Kg of the composite powder obtained in the second step and 4Kg of the silver powder obtained in the first step into a "V" type powder mixer for uniform powder mixing. When mixing powder, the rotating speed is 30 rpm, and the time is 4 hours.

[0038] Th...

Embodiment 2

[0044] Taking the preparation of AgCdO12 contact material as an example

[0045] In the first step, 600 g of CdO powder (average particle size of 1 μm) and 200 g of Ag powder with a particle size of 400 mesh are uniformly mixed, and then placed in a high-energy ball mill tank for ball milling at a ball milling speed of 240 rpm and a ball milling time of 10 hours.

[0046] In the second step, 800 g of the composite powder obtained in the first step and 4200 g of silver powder with a particle size of 400 mesh are poured into a "V" type powder mixing machine for uniform powder mixing. When mixing powder, the rotating speed is 25 rpm, and the time is 4 hours.

[0047] In the third step, put the powder obtained in the second step into a plastic cylinder with a diameter of 90 cm and a length of 150 cm, and perform cold isostatic pressing with a pressure of 300 MPa.

[0048] In the fourth step, the cold isostatic pressed green body obtained in the third step is sintered at a sinteri...

Embodiment 3

[0053] Taking the preparation of AgZnO(8) contact material as an example

[0054] In the first step, 400 g of the reinforcement phase ZnO powder (average particle size 100 nm) and 800 g of Ag powder with a particle size of 400 mesh are uniformly mixed, and then placed in a high-energy ball mill tank for ball milling, the ball milling speed is 240 rpm, and the ball milling time is 5 hours.

[0055] In the second step, 1200 g of the composite powder obtained in the first step and 3800 g of silver powder with a particle size of 600 mesh are poured into a "V" type powder mixing machine for uniform powder mixing. When mixing powder, the rotating speed is 30 rpm, and the time is 4 hours.

[0056] In the third step, put the powder obtained in the second step into a plastic cylinder with a diameter of 90 cm and a length of 150 cm, and perform cold isostatic pressing with a pressure of 100 MPa.

[0057] In the fourth step, the cold isostatic pressed green body obtained in the third st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com