Silver-based contact material with high fusion welding resistance and preparation method of silver-based contact material

A contact material and welding-resistant technology, which is applied in the field of low-voltage contact materials, can solve the problems of poor welding resistance and achieve the effects of improving poor welding resistance, arc erosion resistance and material transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

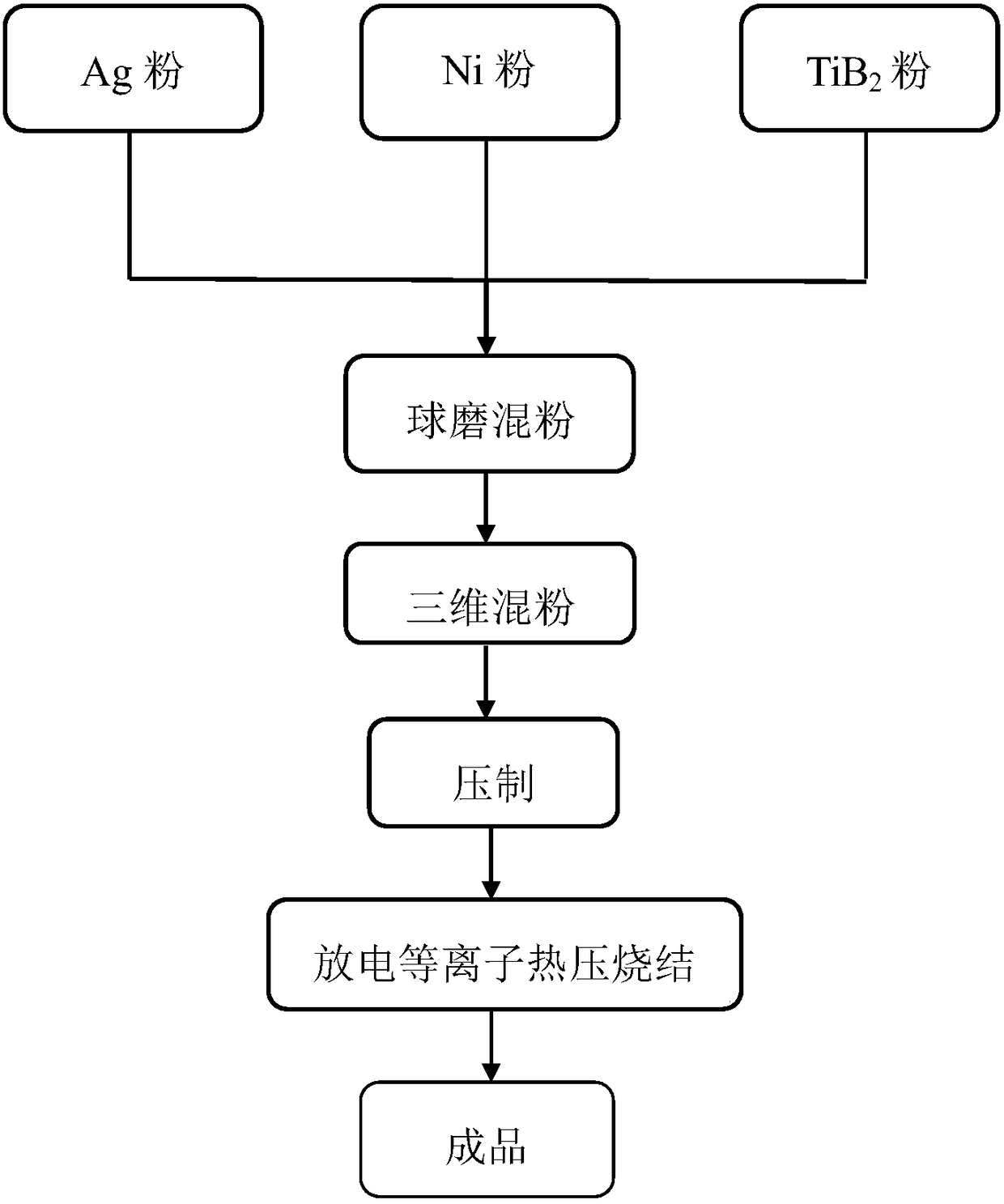

[0023] A kind of preparation method specific process of the silver-based contact material with high anti-welding performance is as follows figure 1 As shown, the specific operation steps are as follows:

[0024] Step 1, weighing the following materials according to the mass percentage: 2% to 15% of Ni powder with a purity of not less than 99.9% and a particle size of 50nm, and TiB with a purity of not less than 99.9% and a particle size of 50nm 2 2% to 8% Ag powder and 77% to 96% Ag powder with a purity of not less than 99.9% and a particle size of 72 μm, the sum of the mass percentages of the above components is 100%;

[0025] Step 2, the weighed Ag powder, Ni powder and TiB 2 Put the powder into a ball mill, add absolute ethanol and polyvinylpyrrolidone to pre-mix the powder, the speed of the ball mill is 250-350r / min, and mix the powder for 4-8 hours to obtain the pre-mixed powder;

[0026] Step 3, put the pre-mixed powder into the three-dimensional powder mixer for re-mi...

Embodiment 1

[0033] Step 1, weigh the following materials according to the mass percentage: 2% Ni powder with a purity of not less than 99.9% and a particle size of 50nm, TiB with a purity of not less than 99.9% and a particle size of 50nm 2 2% Ag powder with a purity of not less than 99.9%, 96% of Ag powder with a particle size of 72 μm, and the sum of the mass percentages of the above components is 100%;

[0034] Step 2, the weighed Ag powder, Ni powder and TiB 2 Put the powder into a ball mill, and add absolute ethanol and polyvinylpyrrolidone to pre-mix the powder. 2 0.5% and 0.5% of the total mass of the powder, the speed of the ball mill is 250r / min, and the powder is mixed for 4 hours to obtain the premixed powder;

[0035] Step 3, put the pre-mixed powder into the three-dimensional powder mixer for re-mixing, the vibration frequency is 30Hz, and the mixing time is 2h, to obtain the mixed powder;

[0036] Step 4, put the mixed powder after re-mixing in step 3 into a mold for press...

Embodiment 2

[0039] Step 1, weigh the following materials according to mass percentage: 15% of Ni powder with a purity of not less than 99.9% and a particle size of 50nm, TiB with a purity of not less than 99.9% and a particle size of 50nm 2 8% Ag powder with a purity of not less than 99.9%, 77% of Ag powder with a particle size of 72 μm, and the sum of the mass percentages of the above components is 100%;

[0040] Step 2, the weighed Ag powder, Ni powder and TiB 2 Put the powder into a ball mill, and add absolute ethanol and polyvinylpyrrolidone to pre-mix the powder.2 1.2% and 2.0% of the total mass of the powder, the speed of the ball mill is 350r / min, and the powder is mixed for 8 hours to obtain the premixed powder;

[0041] Step 3, put the pre-mixed powder into the three-dimensional powder mixer for re-mixing, the vibration frequency is 40Hz, and the mixing time is 6h to obtain the mixed powder;

[0042] Step 4, put the mixed powder after re-mixing in step 3 into a mold for pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com