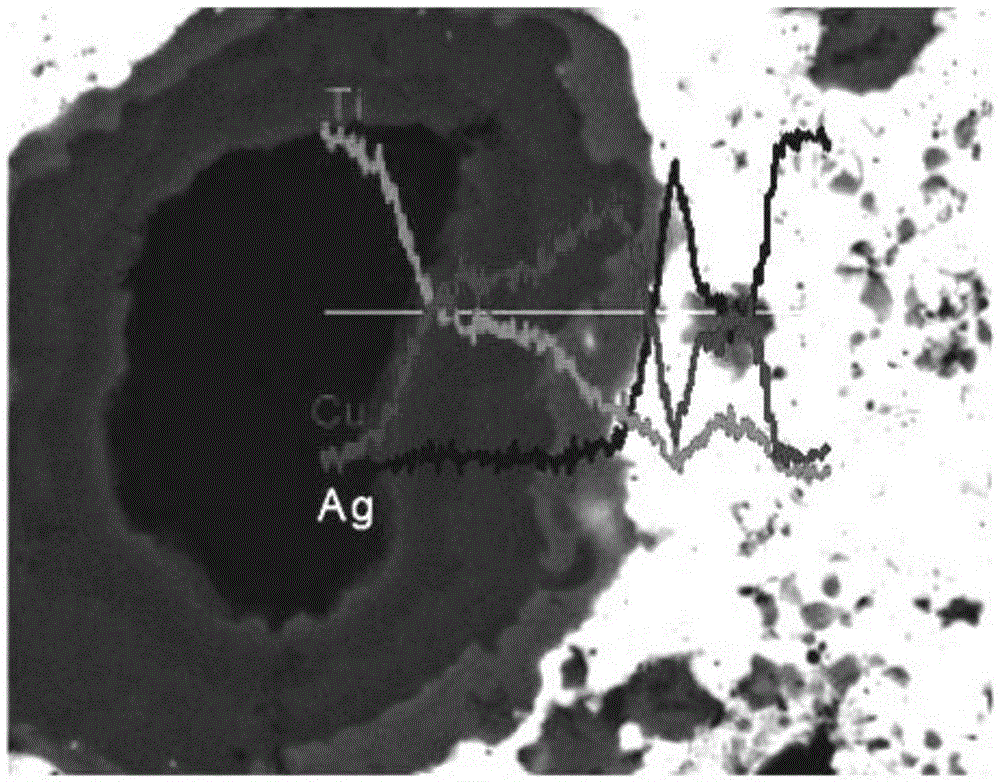

AgCuTi active brazing filler metal and preparation method thereof

A technology of active brazing material and ball-to-material ratio, which is applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as affecting the quality of alloy ingots, restricting application, high vacuum degree, etc. The equipment is easy to operate and the effect of improving the processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: This embodiment is used for AgCuTi active solder, which is made of 90-96% AgCu28 alloy powder, 2-5% electrolytic Cu powder and 1-7% Ti powder according to weight percentage.

[0028] The mass purity of electrolytic Cu powder and Ti powder in this embodiment is 99.9-99.99%

Embodiment 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that it is used for AgCuTi active solder, which is made of 93.5% AgCu28 alloy powder, 5% electrolytic Cu powder and 1.5% Ti powder according to the percentage. Others are the same as in Embodiment 1.

Embodiment 3

[0030] Embodiment 3: This embodiment is different from Embodiment 1 in that it is used for AgCuTi active solder, which is made of 92% AgCu28 alloy powder, 5% electrolytic Cu powder and 3% Ti powder according to the percentage. Others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com