Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Ultrasonic consolidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

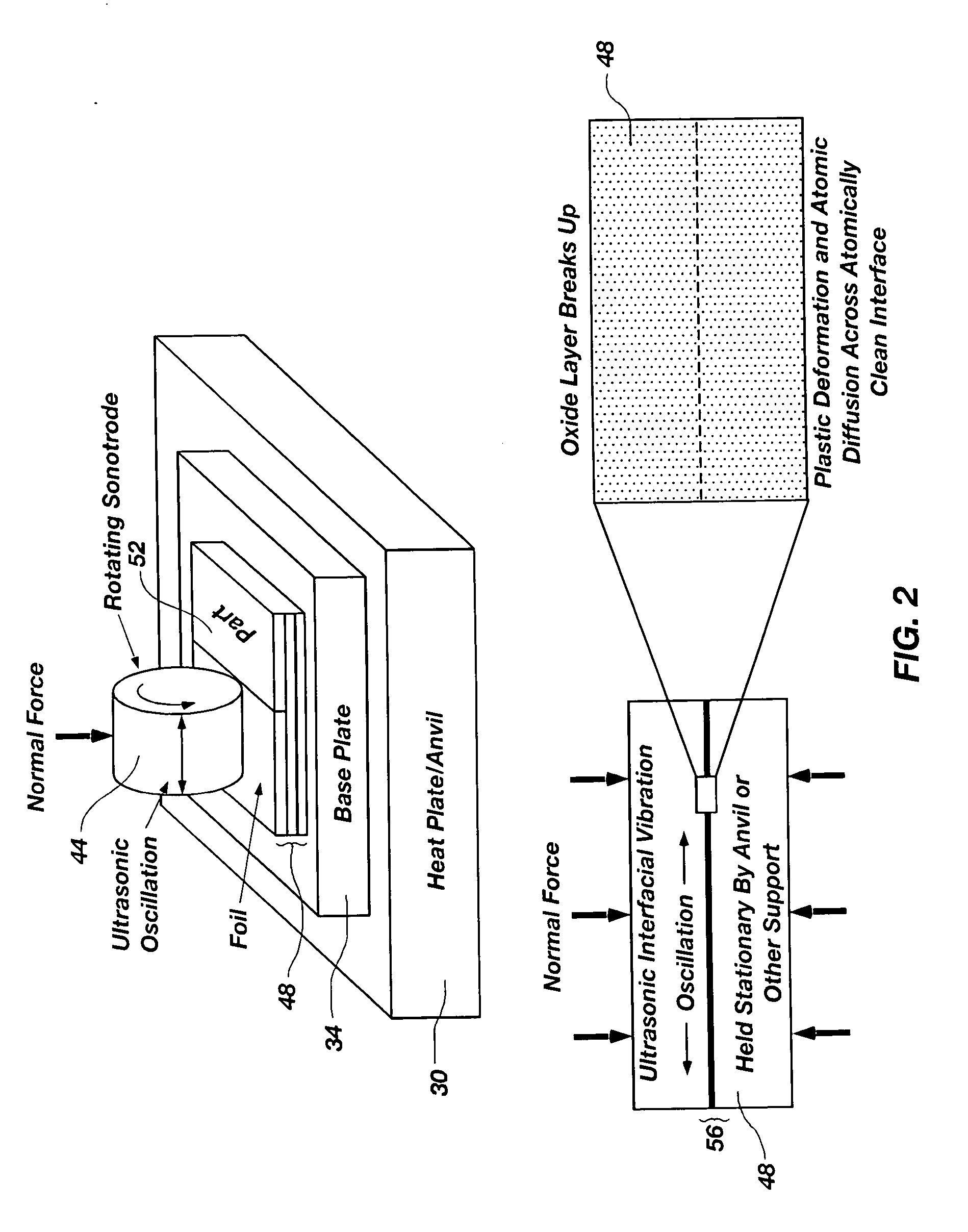

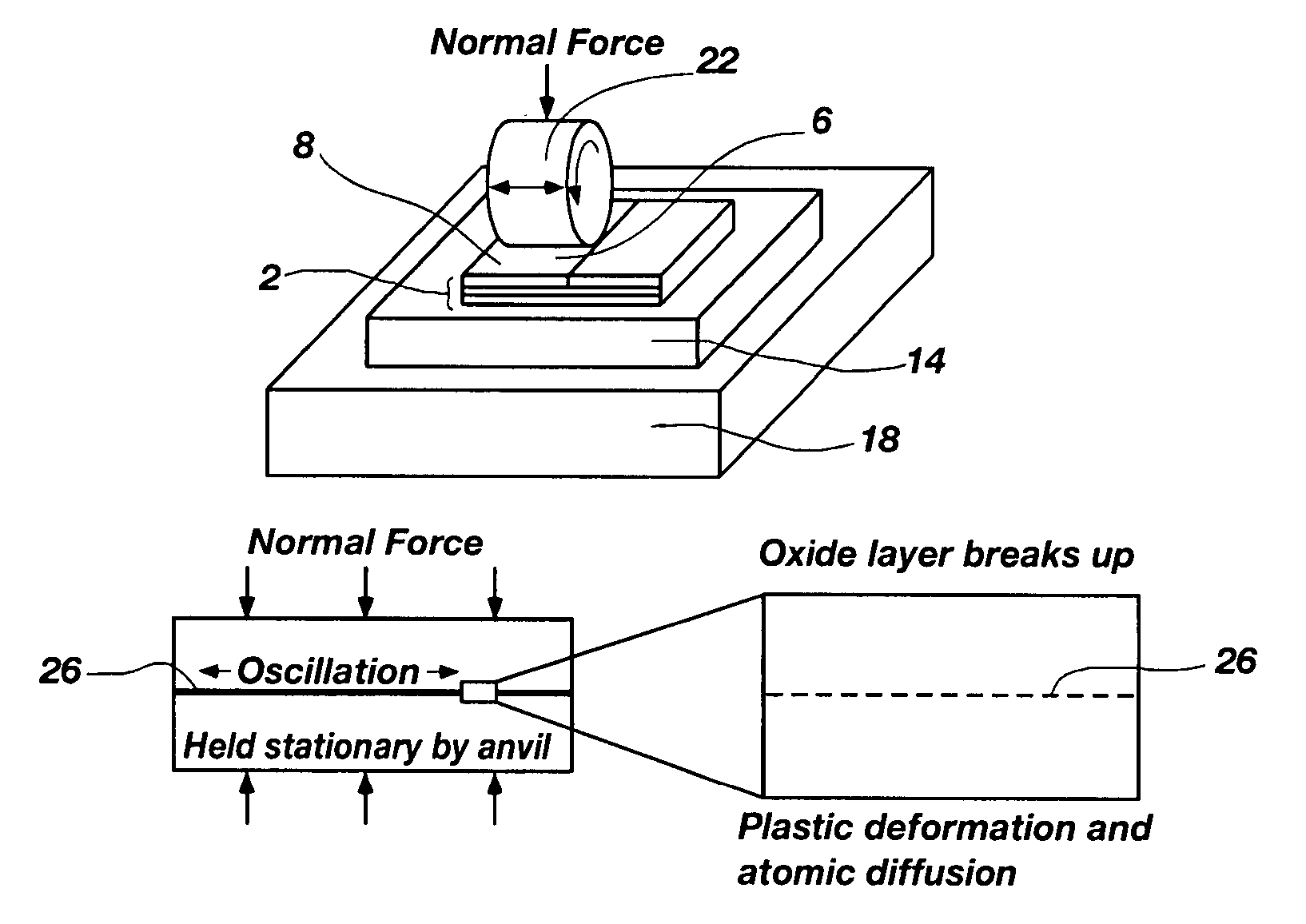

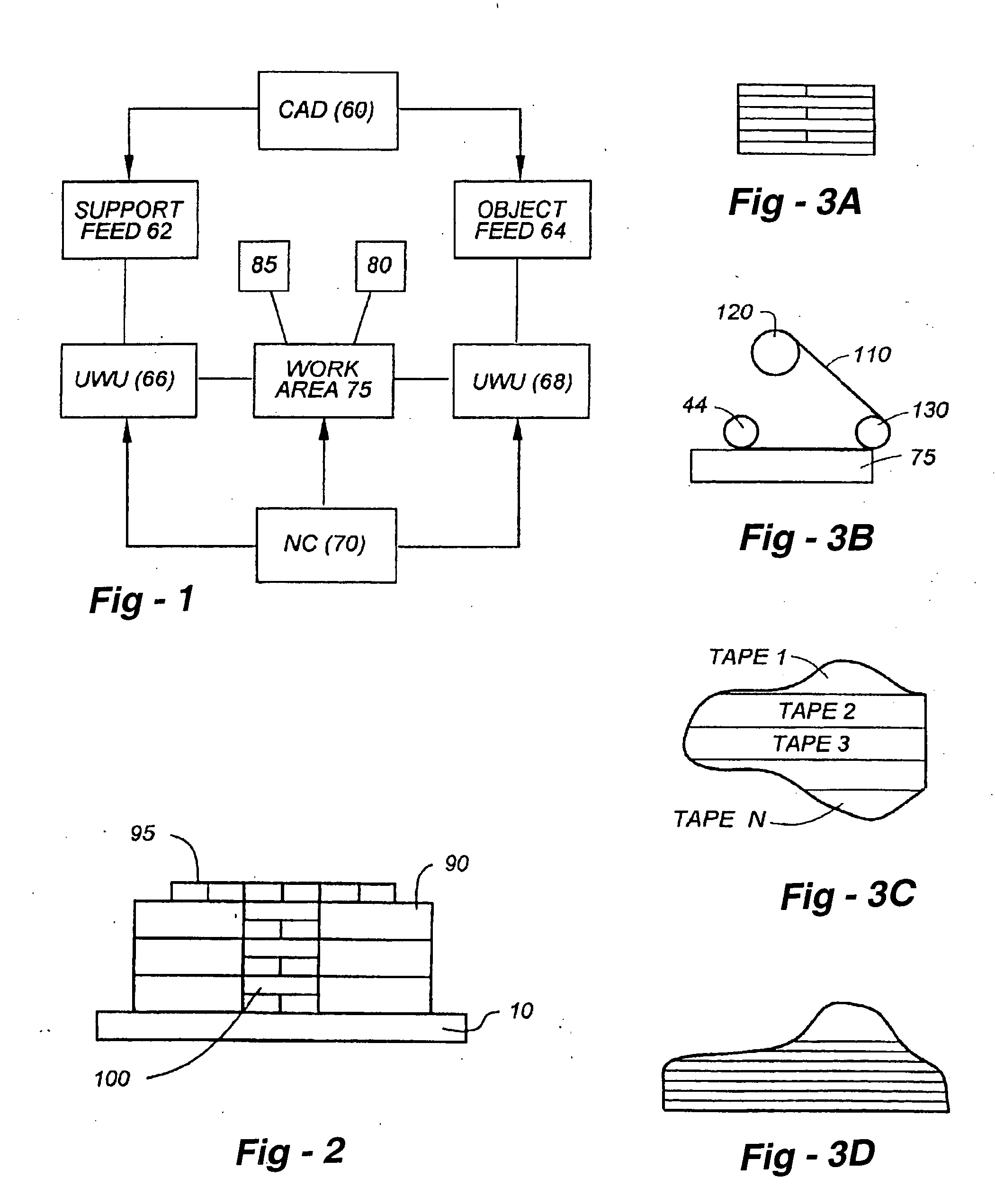

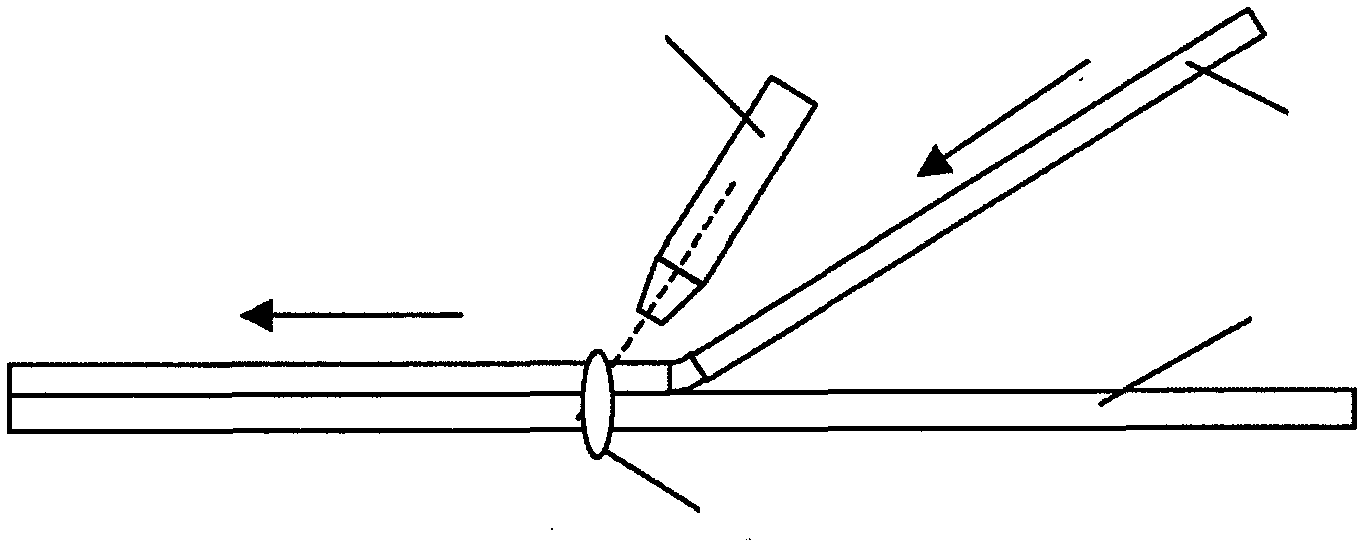

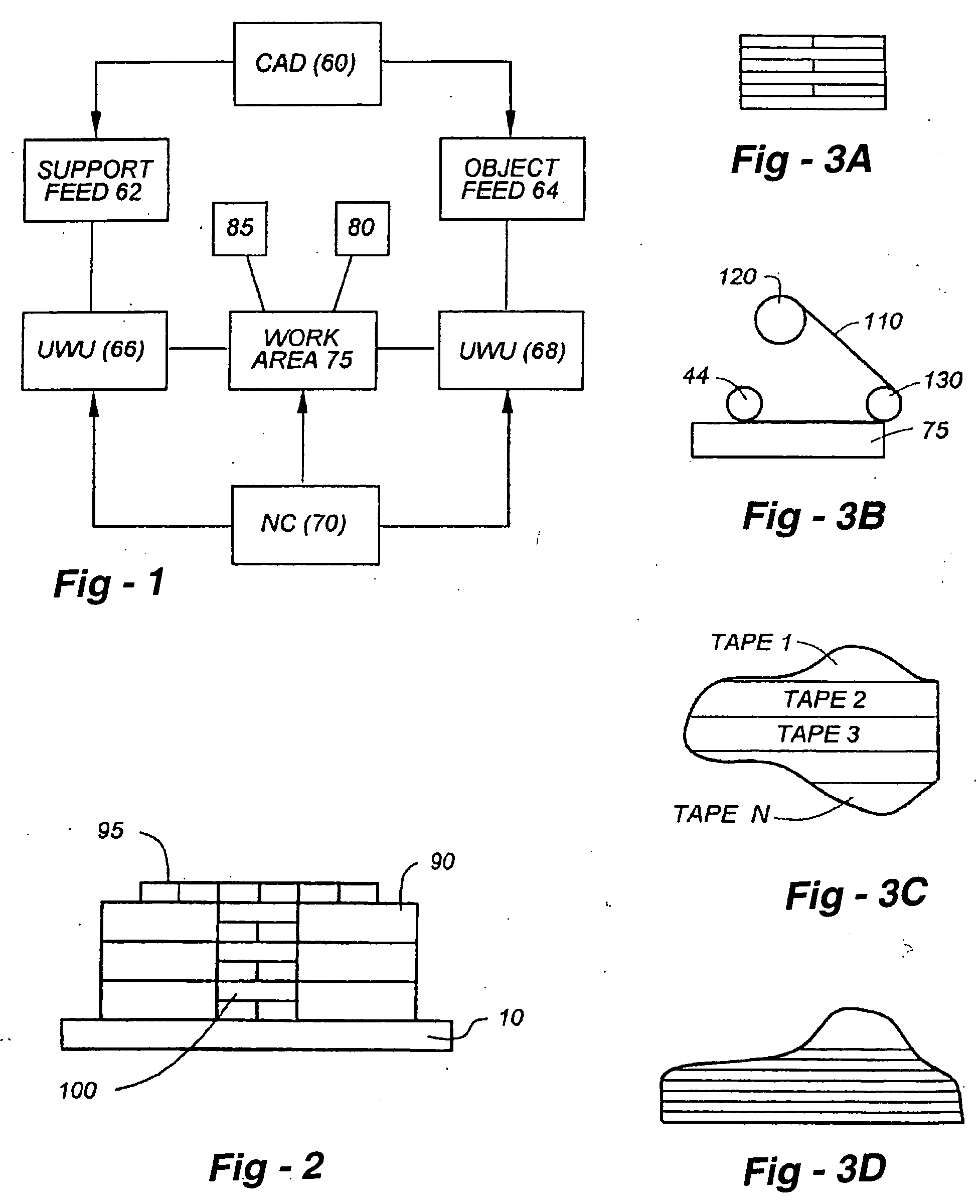

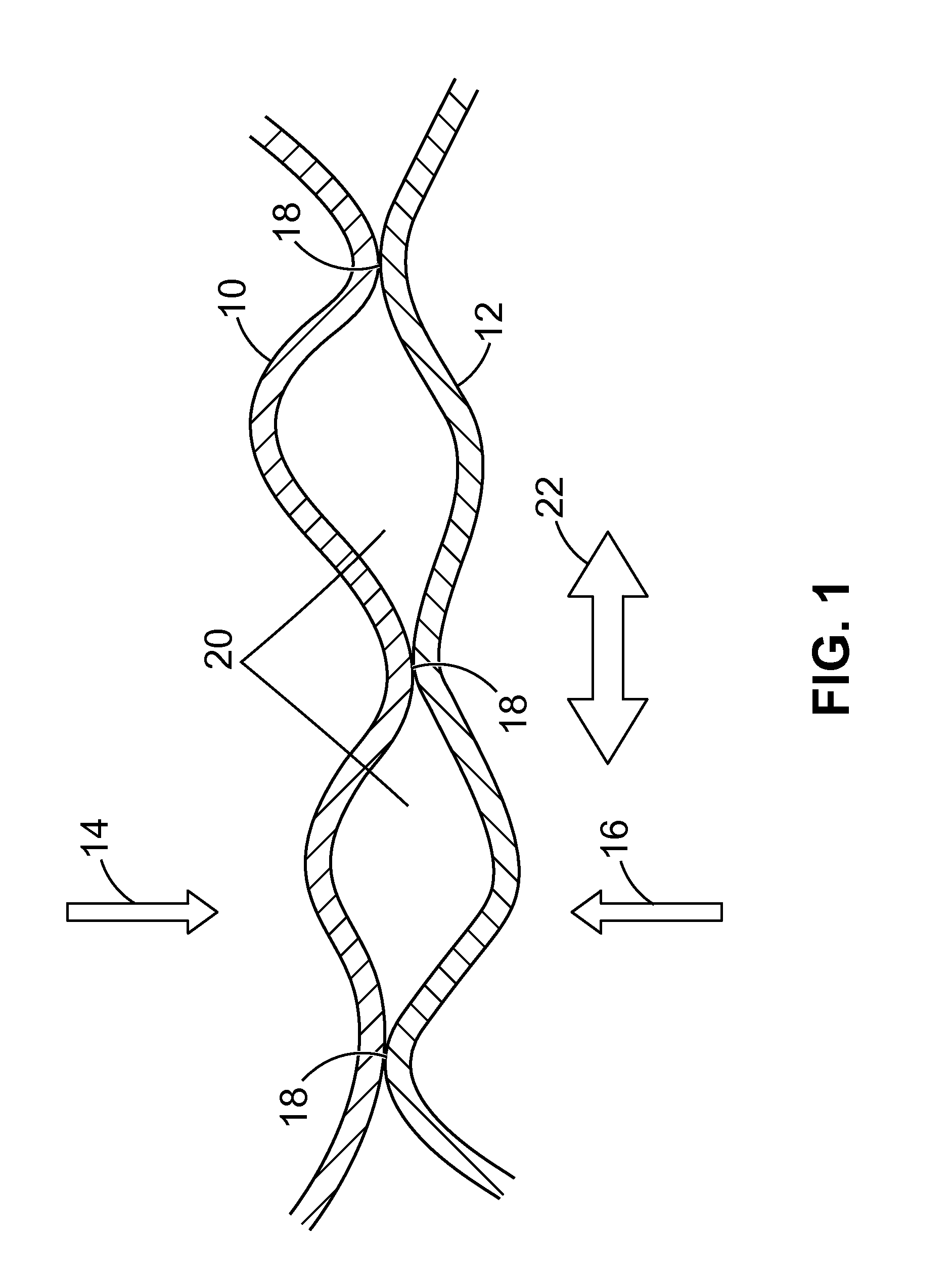

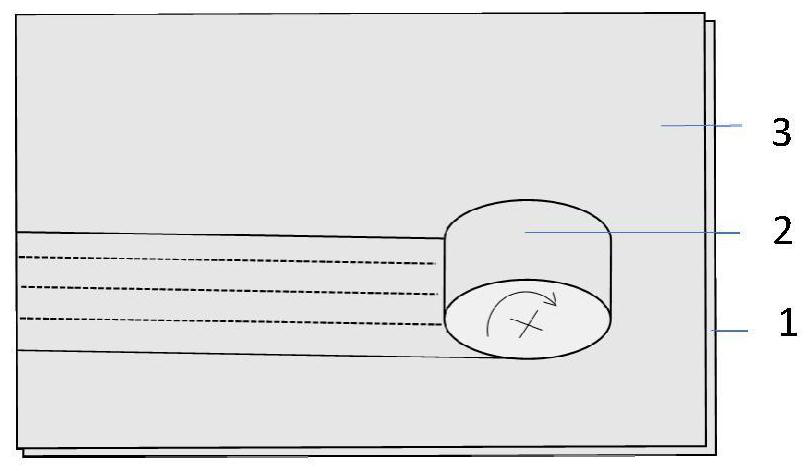

Ultrasonic Consolidation (UC) or Ultrasonic Additive Manufacturing (UAM) is a low temperature additive manufacturing or 3D printing technique for metals. The process works by scrubbing metal foils together with ultrasonic vibrations under pressure in a continuous fashion, i.e., sheet lamination classification in additive manufacturing. Melting is not the formation mechanism. Instead, metals are joined in the solid-state via disruption of surface oxide films between the metals, i.e. ultrasonic metal welding mechanisms. CNC contour milling is used interchangeably with the additive stage of the process to introduce internal features and add detail to the metal part. UAM has the ability to join multiple metal types together, i.e., dissimilar metal joining, with no or minimal intermettalic formation and allows the embedment of temperature sensitive materials at relatively low temperature—typically less than 50% of the metal matrix melting temperature.

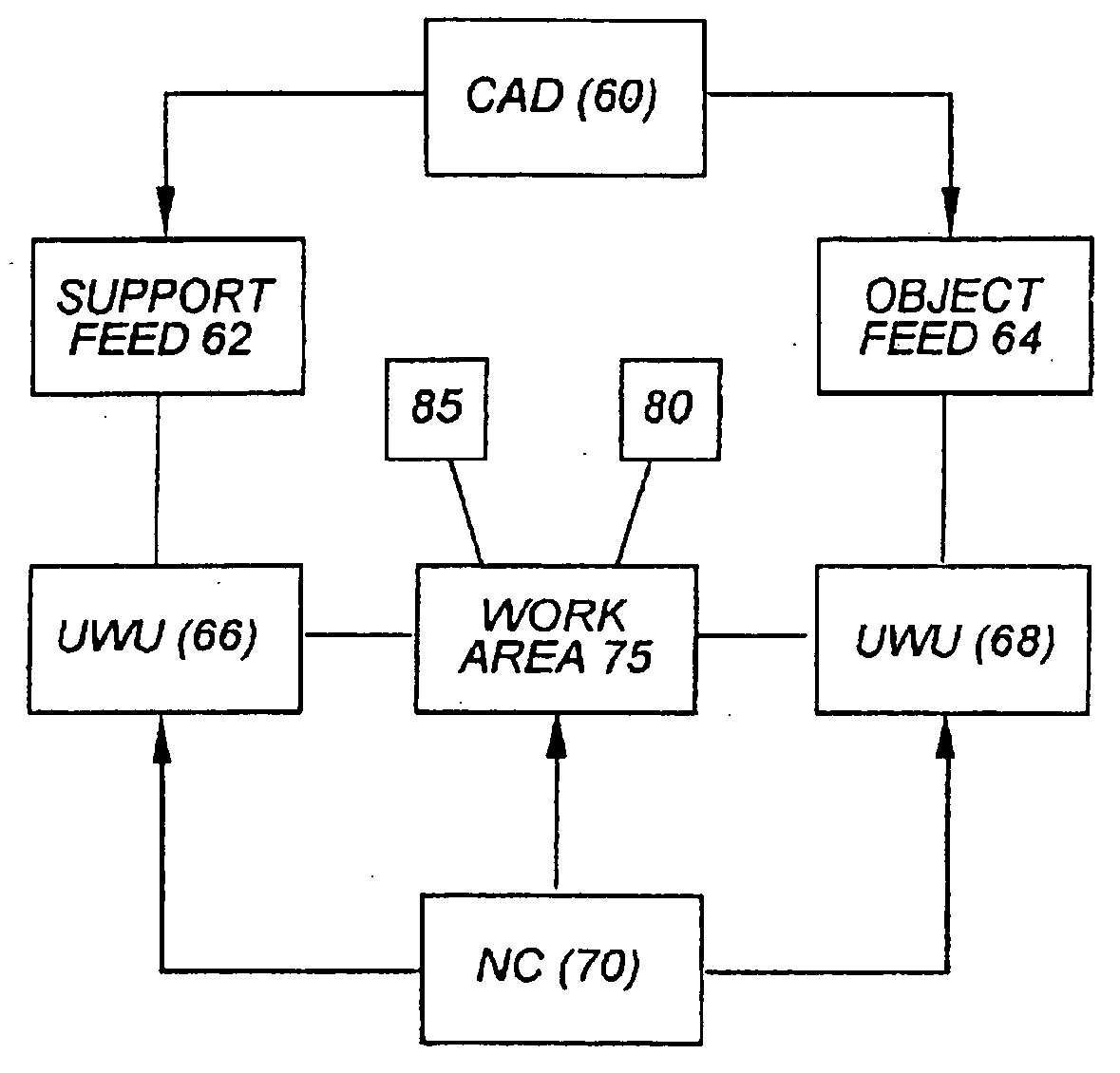

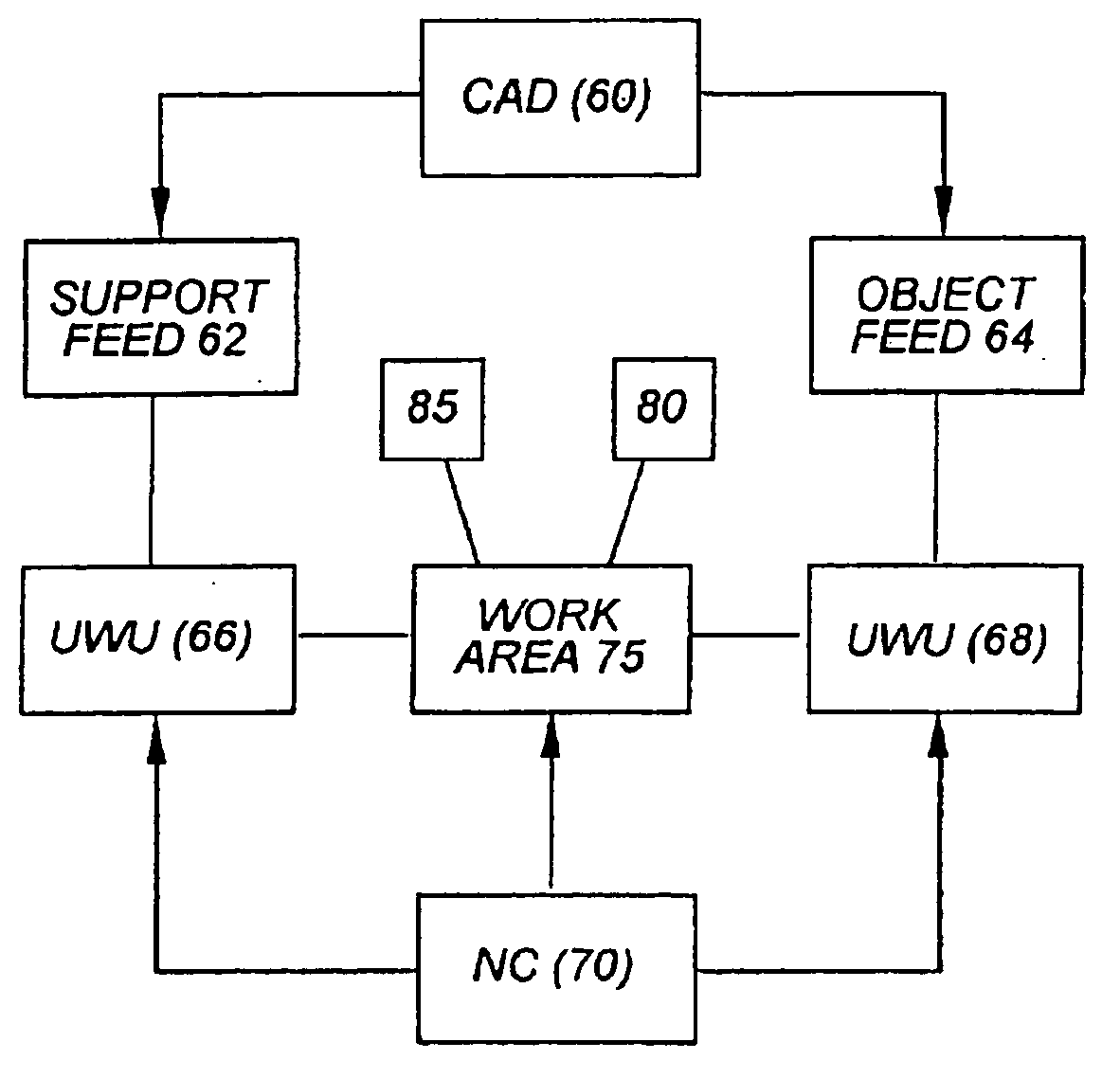

Method for creating highly integrated satellite systems

InactiveUS20070040702A1Low costEasy to produceDetection of traffic movementArtificial satellitesSonificationContinuous use

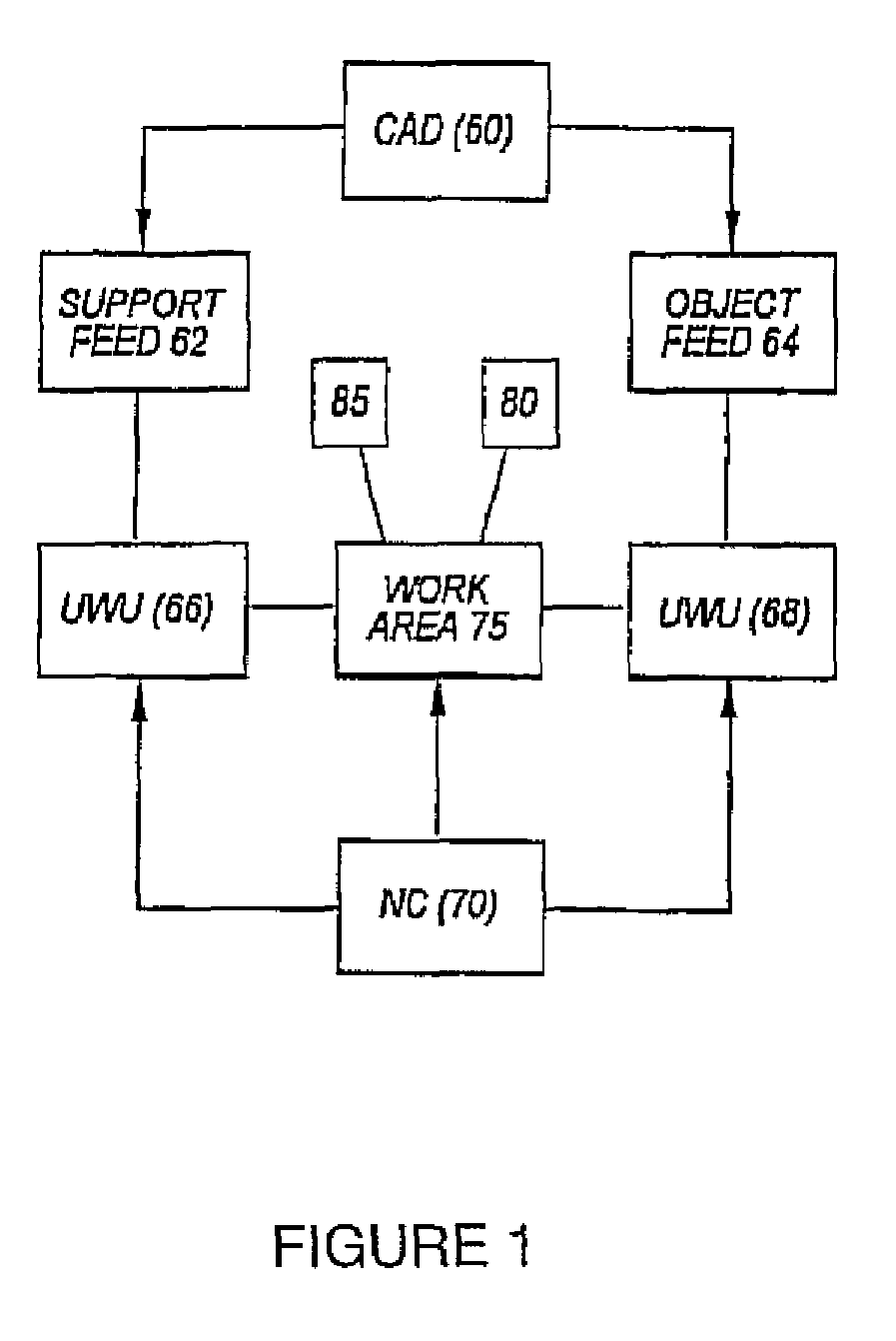

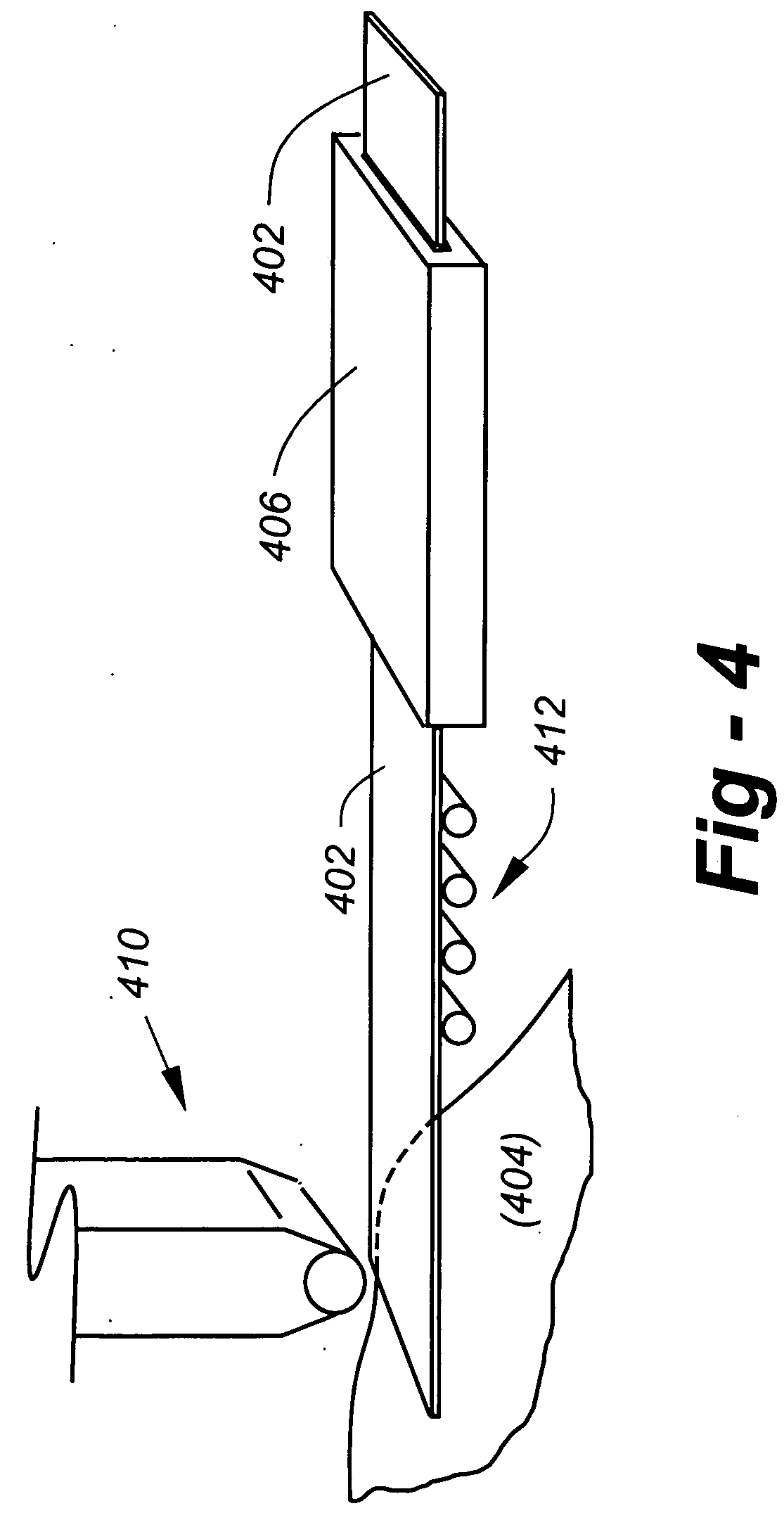

A method for manufacturing or creating highly integrated satellite systems intended for use within or to construct one or more satellite variants. The integrated satellite systems comprise embedded or encapsulated components, circuitry, and / or networks. Although other methodologies may be employed, an ultrasonic consolidation process is adapted to fabricate integrated satellite systems having a material matrix wherein one or more satellite components and / or material trace elements may be encapsulated. A direct write process may be used simultaneously or in succession with the ultrasonic consolidation process to deposit material traces onto one or more surfaces of the satellite components, thereby providing functional mesoscopic devices or systems.

Owner:UTAH STATE UNIVERSITY

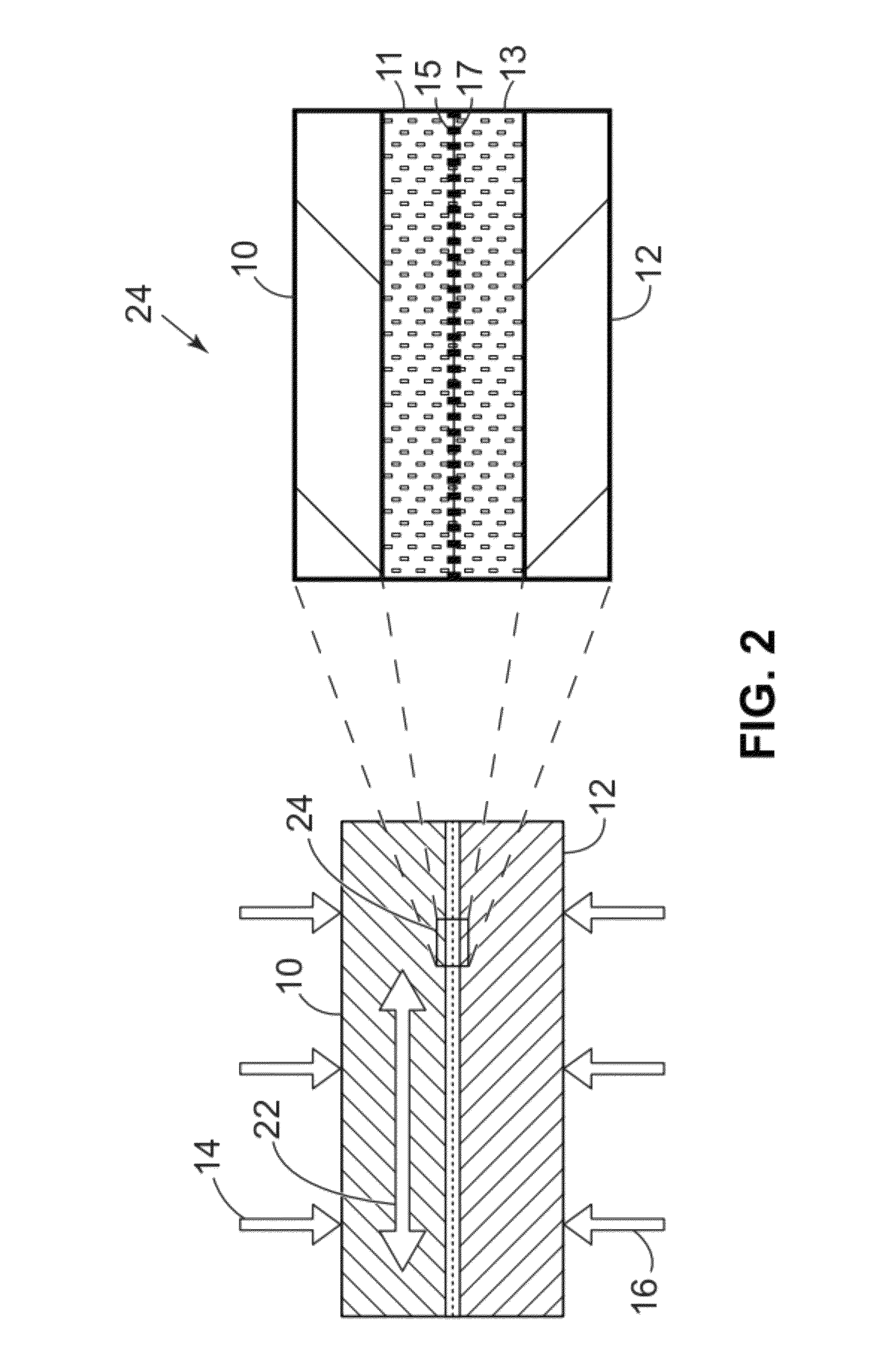

Surface roughness reduction for improving bonding in ultrasonic consolidation rapid manufacturing

InactiveUS20070295440A1Efficient manufacturingReduce contact surfaceAdditive manufacturing apparatusLaminationMetallurgySurface roughness

A method for enhancing the bonding and linear weld density along the interface of material layers deposited in accordance with an ultrasonic consolidation manufacturing process, the method comprising: initiating an ultrasonic consolidation manufacturing process; depositing a first material layer having a contact surface; reducing surface roughness of the contact surface to prepare the contact surface to receive a subsequent material layer, the step of reducing facilitating an increased percentage and quality of material contact between the first and subsequent material layers; and bonding a subsequent material layer to the contact surface of the first material layer, as prepared.

Owner:UTAH STATE UNIVERSITY

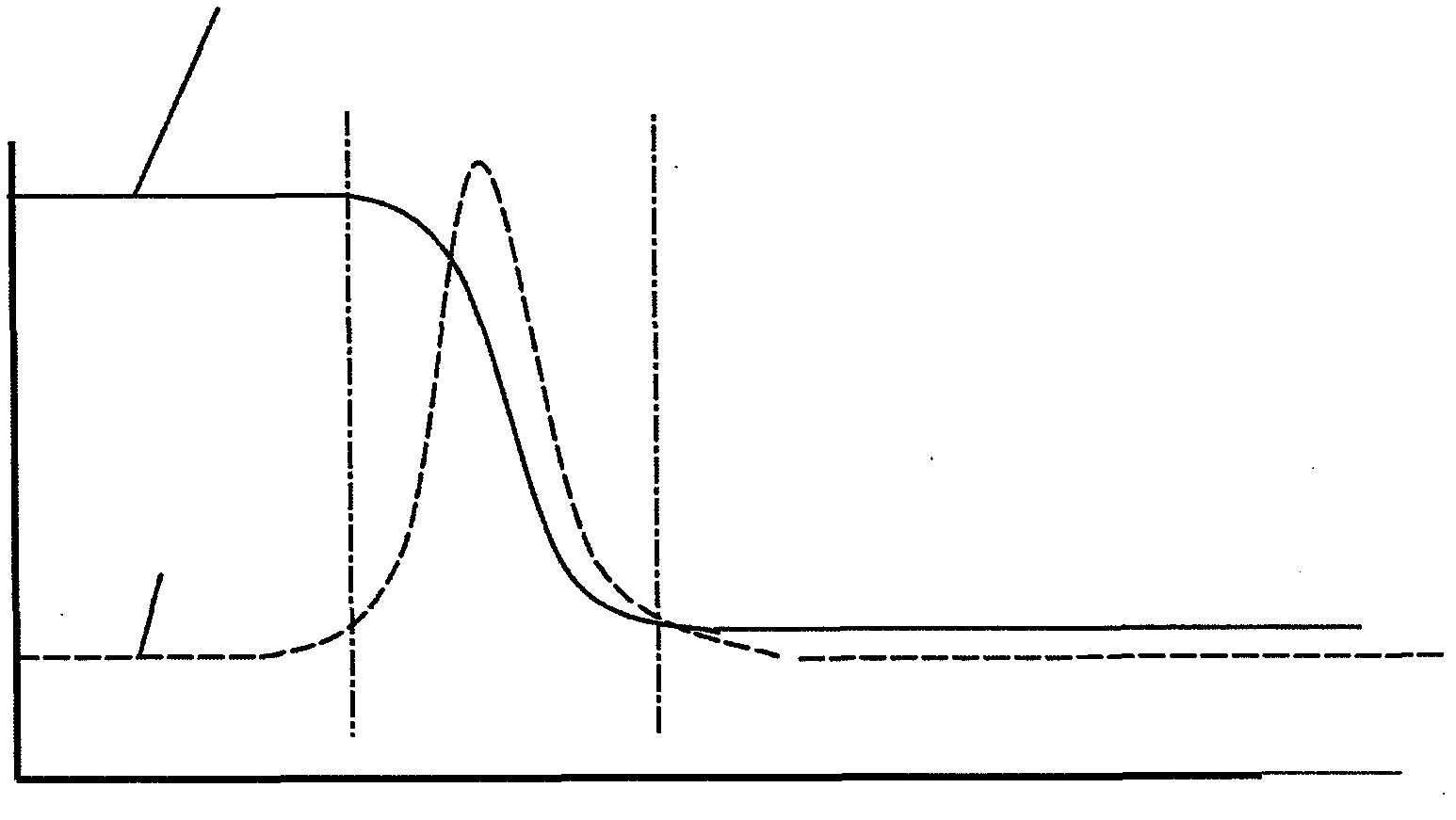

Closed-loop control of power used in ultrasonic consolidation

Disclosed is method of enhancing bond quality in an ultrasonic consolidation process using a sonotrode having a power output level. The preferred embodiment includes the steps of inputting a plurality of process parameters associated with a localized geometry over which the ultrasonic consolidation is occurring, and varying the relationship between these parameters to control the power output level to optimize bond quality between layers of material as they are consolidated. The process parameters, alone or in combination, may include the speed of the consolidation; the amplitude of the ultrasonic energy; applied force; and / or temperature.

Owner:SOLIDICA

Method and apparatus for fabricating a fibre reinforced thermoplastic composite structure

InactiveCN102076475ALayered product treatmentLaminationThermoplastic compositesUltrasonic consolidation

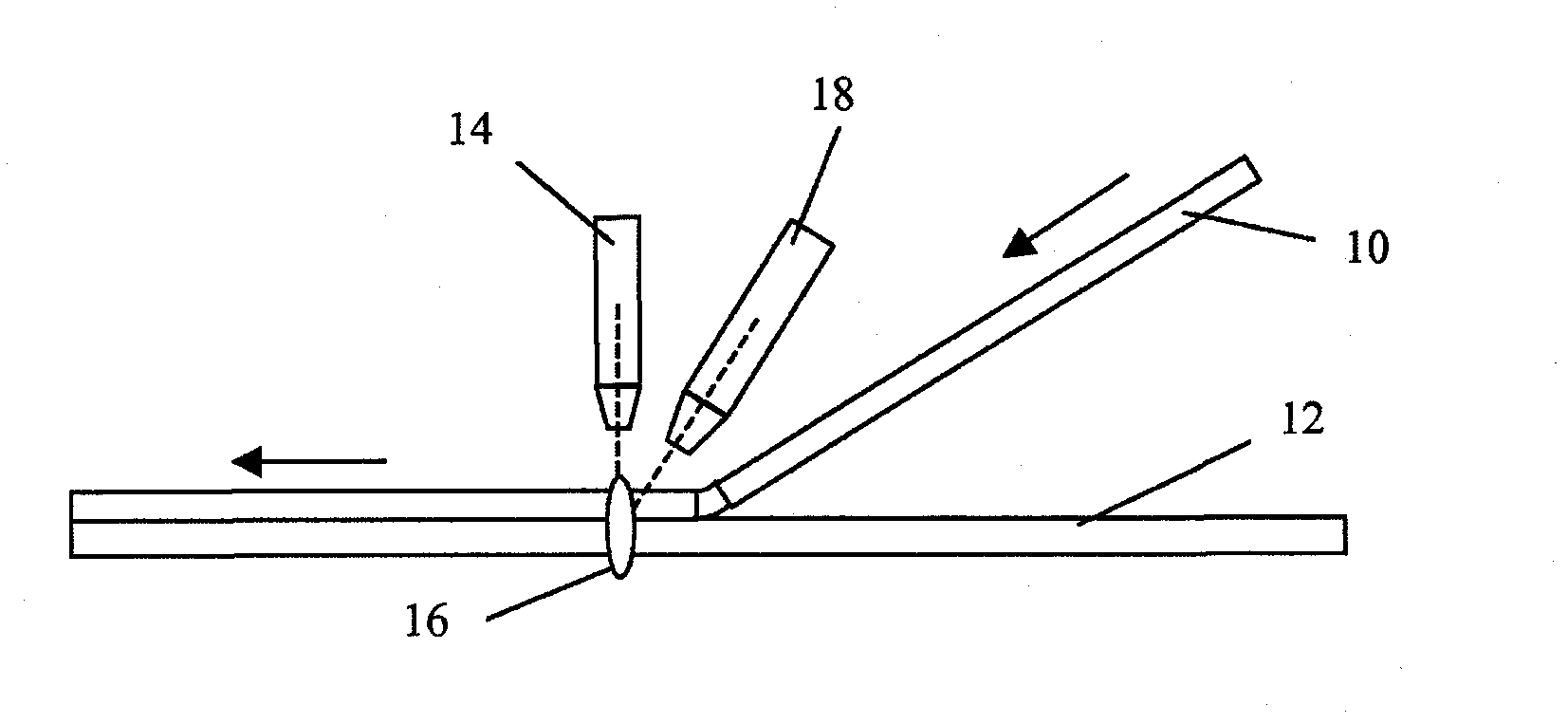

The invention provides a method of fabricating a fibre reinforced thermoplastic composite structure comprising: placing a first layer of fibre reinforced thermoplastic material on top of a second layer of fibre reinforced thermoplastic material; providing a local heating source and locally heating a portion of at least the upper layer of thermoplastic composite material; and providing an ultrasonic transducer and locally introducing ultrasonic energywaves to the heated portion of the thermoplastic material such that ultrasonic consolidation of the fibre reinforced thermoplastic occurs.

Owner:AIRBUS OPERATIONS LTD

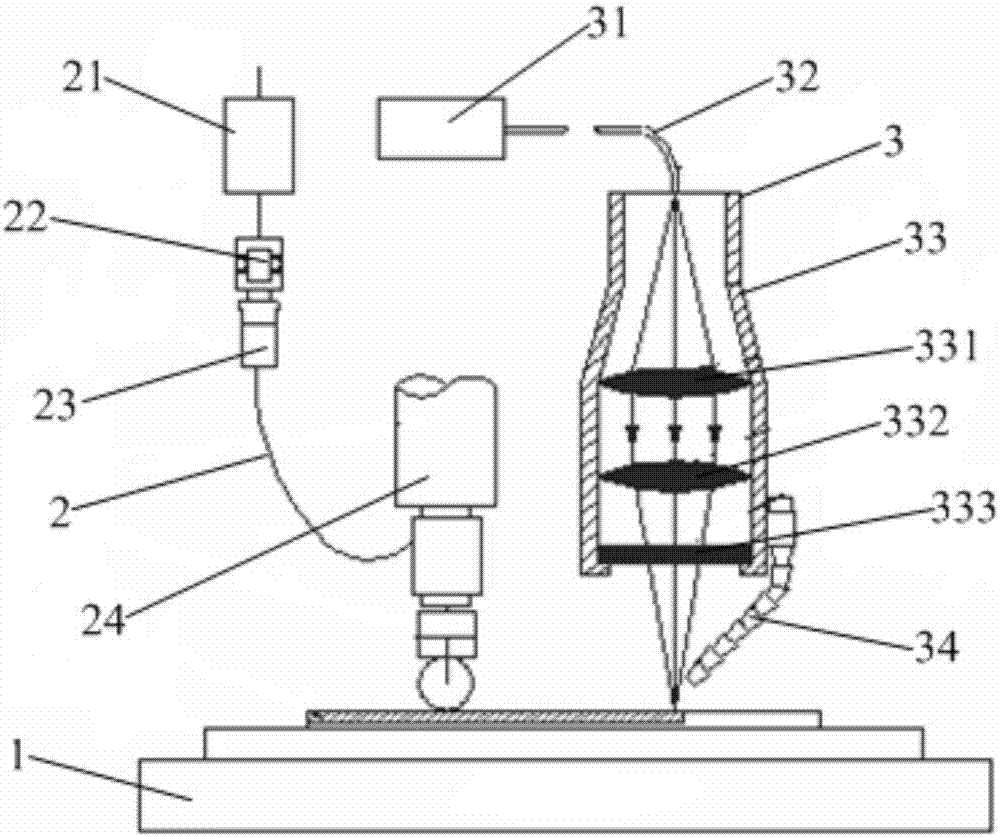

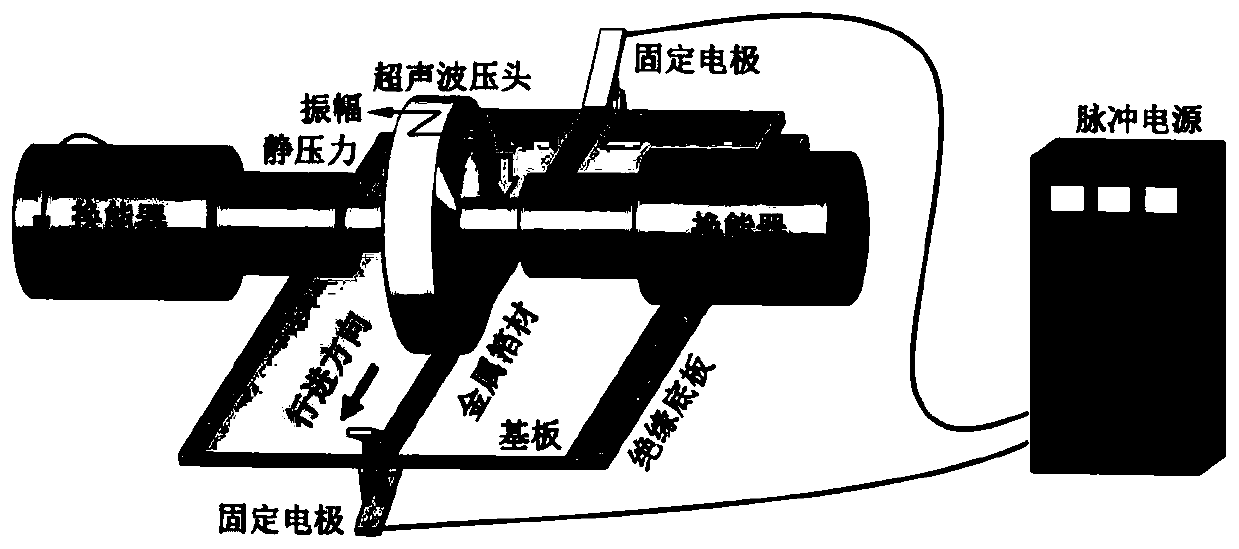

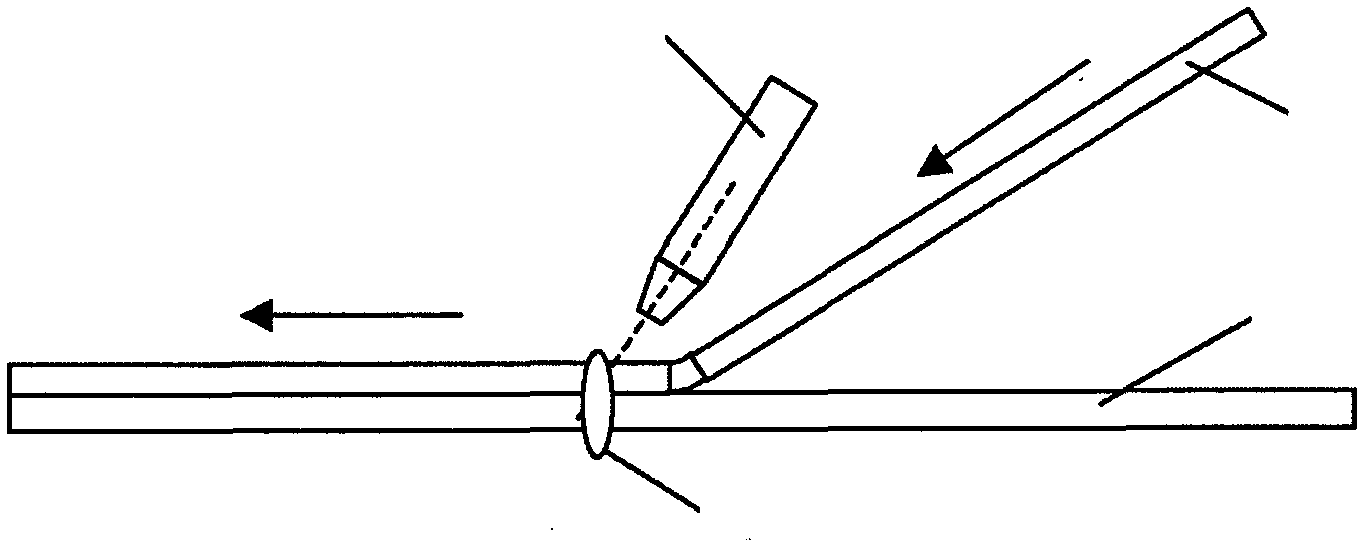

Heterogeneous metal laser-ultrasonic compound welding method and device

ActiveCN107984085ANarrow phase change rangeInhibition of mass productionLaser beam welding apparatusUltrasonic weldingLap joint

The invention provides a heterogeneous metal laser-ultrasonic compound welding method and device. The two advanced technologies of laser welding and ultrasonic consolidation are combined, that is, heterogeneous materials to be welded are connected in an overlap mode to form a lap joint, the position to be welded is welded in a laser welding mode, and the connecting purpose is realized. Under the condition that the temperature of the joint to be welded is below 10-30% of the melting point of an upper layer base material, ultrasonic welding is conducted, and efficient connection of the joint isrealized. According to the heterogeneous metal laser-ultrasonic compound welding method and device, the problem that a brittle joint is formed during welding of heterogeneous materials through a traditional welding method is solved, the problem that only a high energy beam welding method is adopted, though massive formation of intermetallic compound can be partially restrained, the strength of thejoint is still not high is also solved, and the problem difficult to solve that ultrasonic consolidation is only adaptive to low-melting-point thin plate welding is solved.

Owner:NANCHANG UNIV

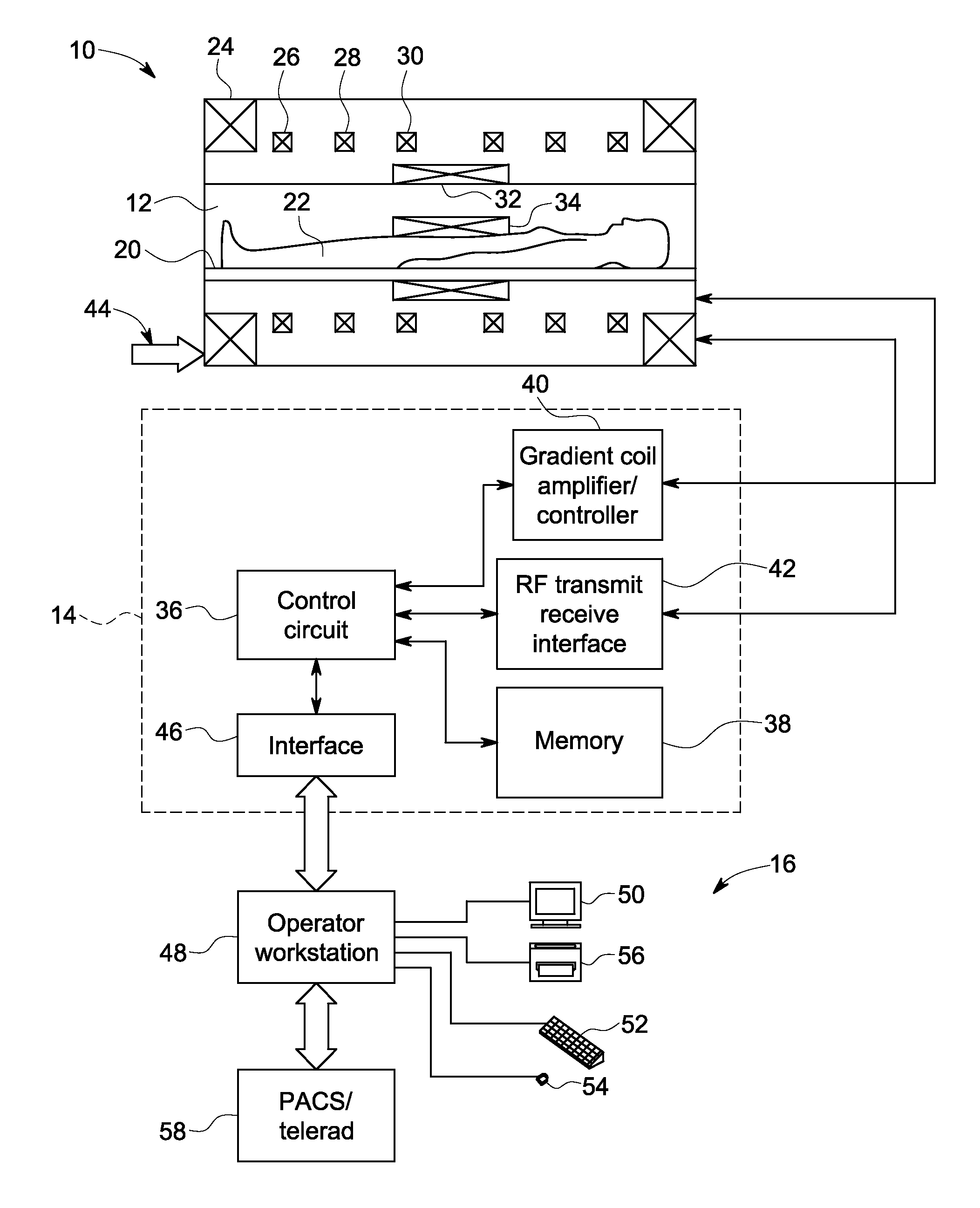

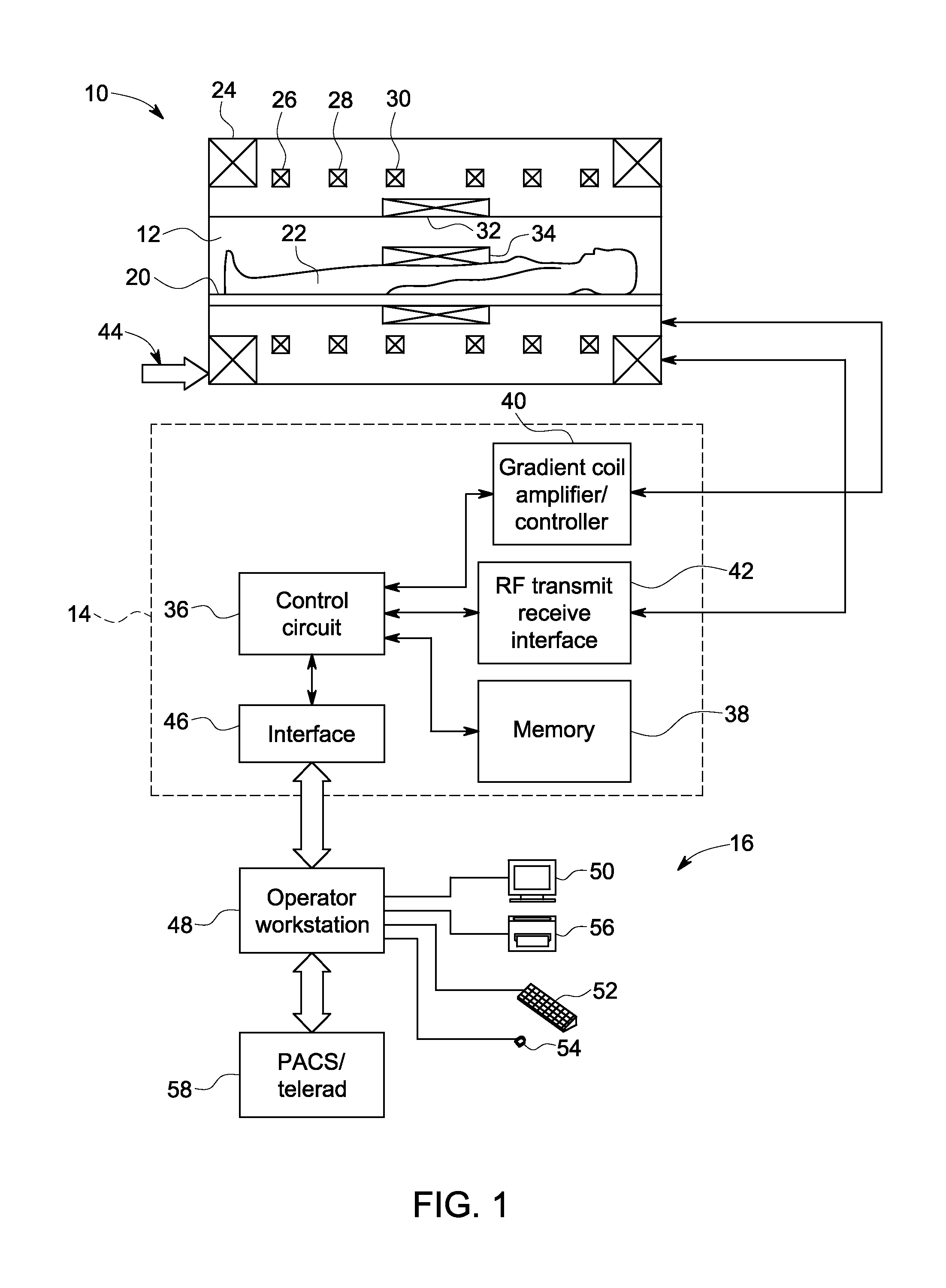

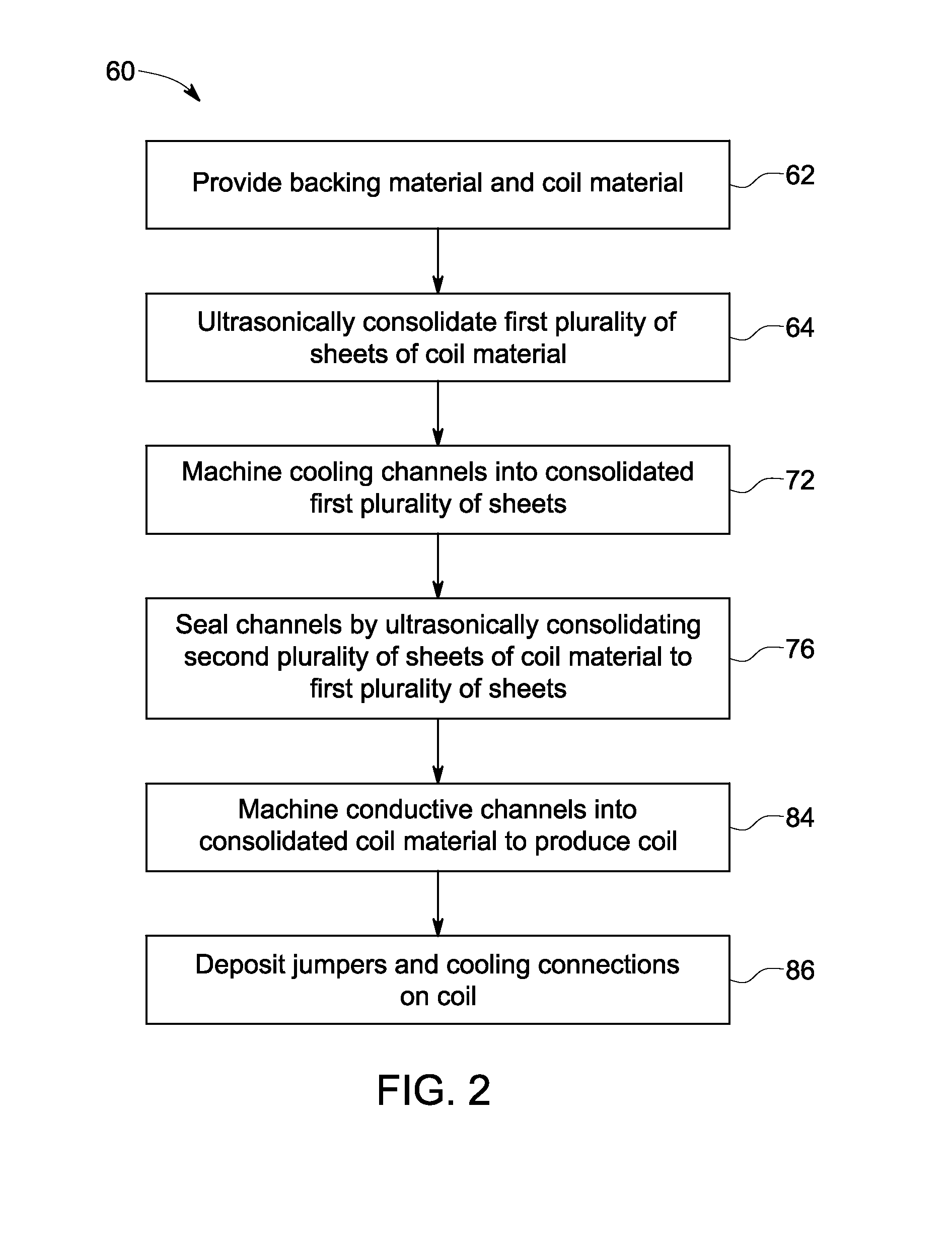

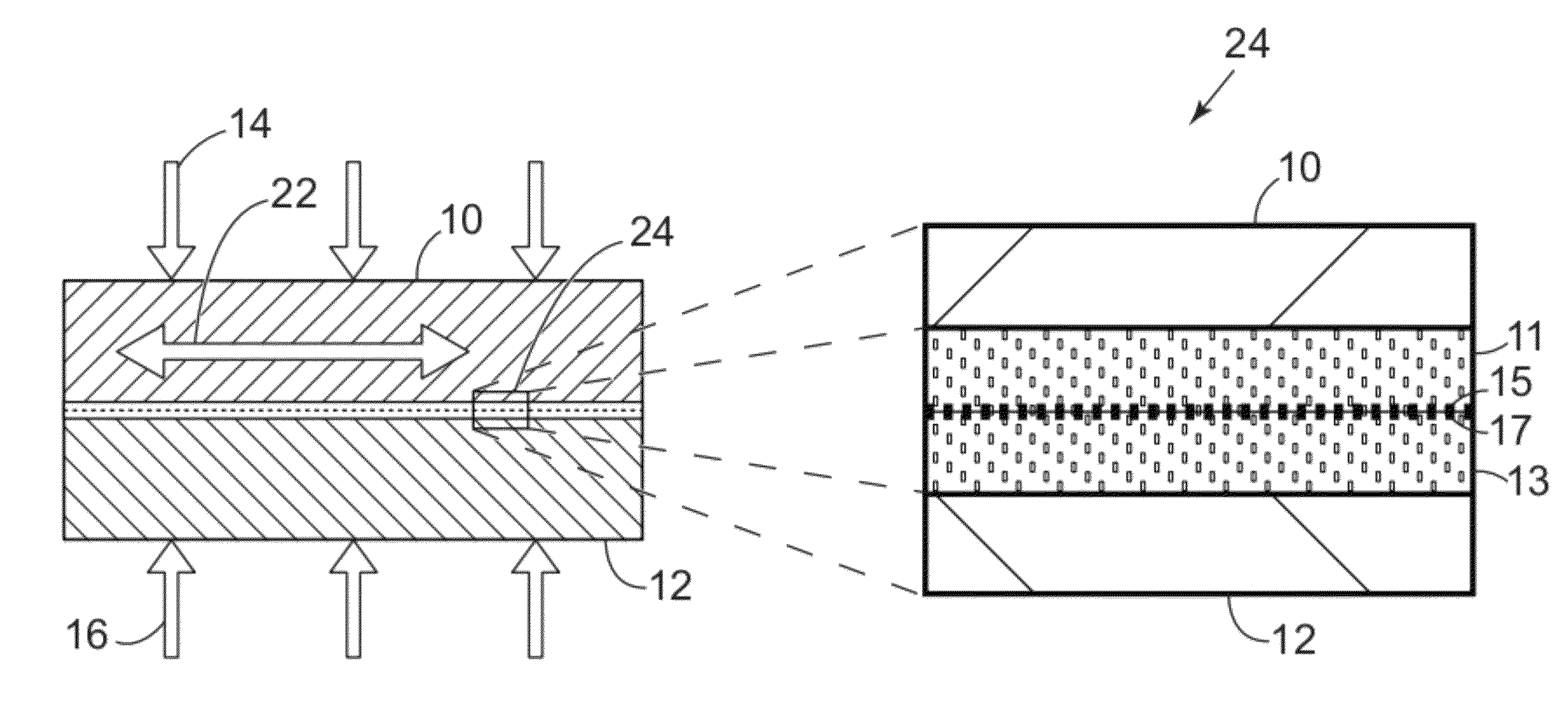

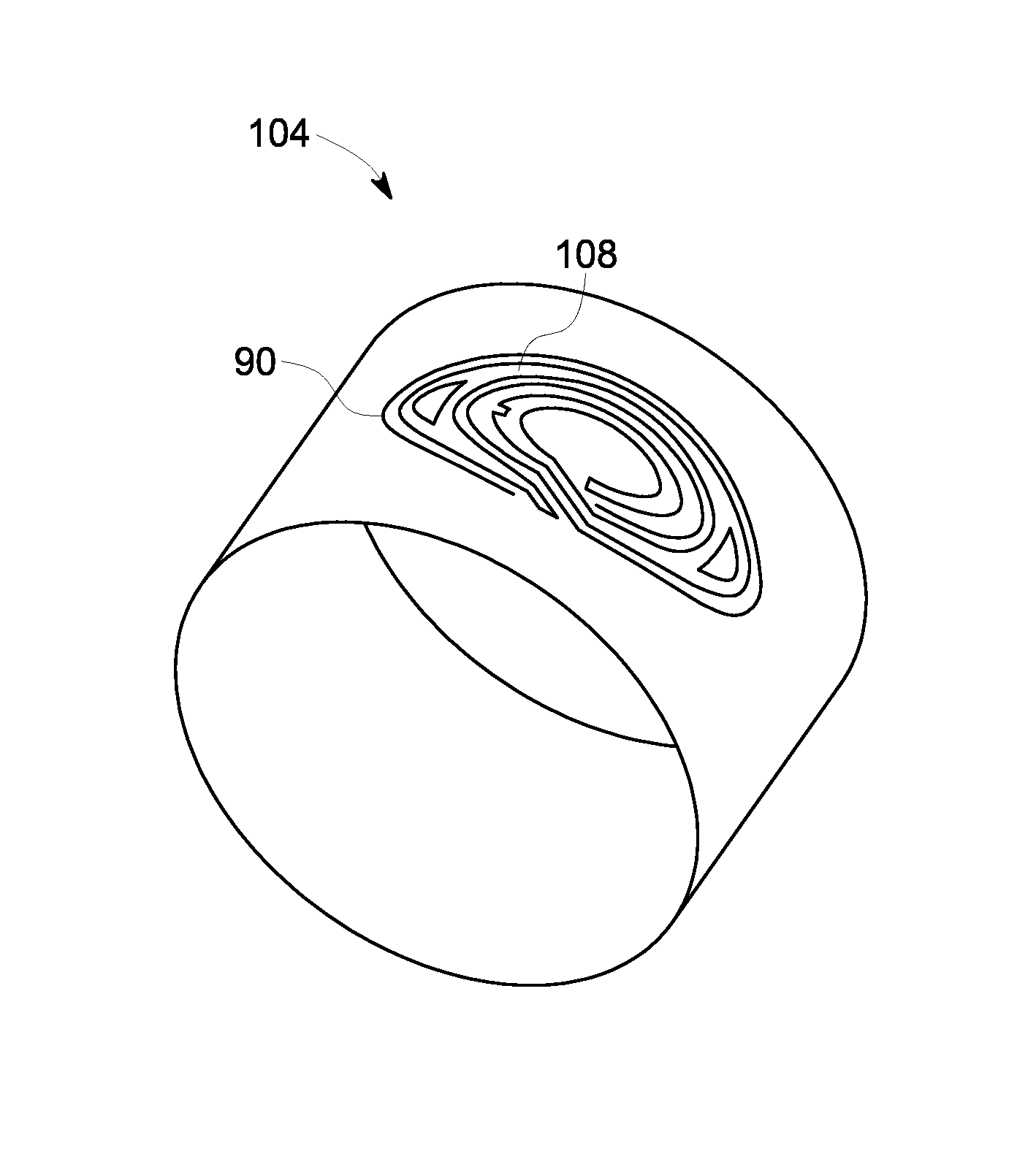

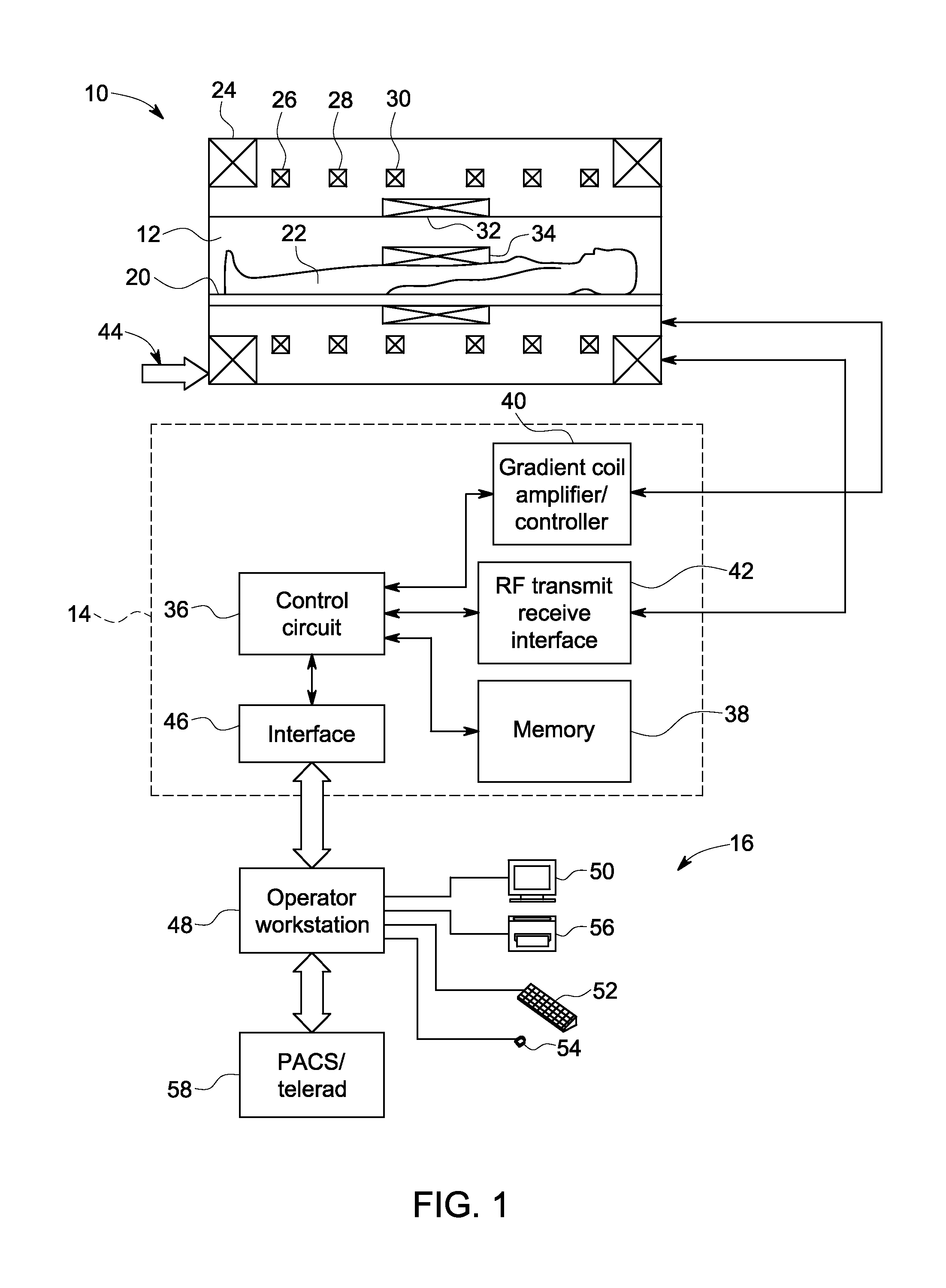

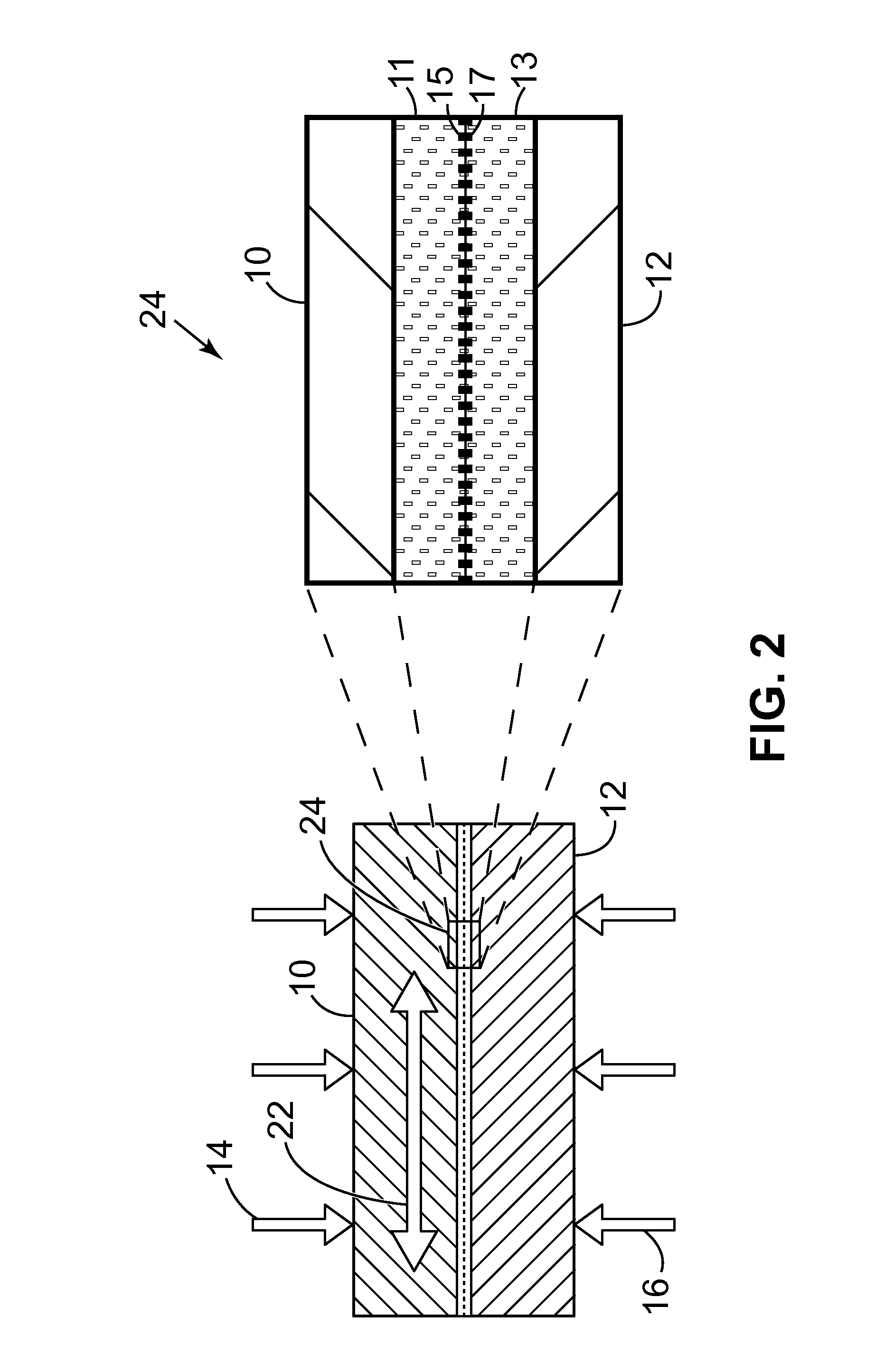

System and method for manufacturing magnetic resonance imaging coils using ultrasonic consolidation

ActiveUS20140184372A1Transformers/inductances coolingMagnetic measurementsConductive materialsEngineering

The embodiments disclosed herein relate generally to magnetic resonance imaging systems and, more specifically, to the manufacturing of a gradient coil assembly for magnetic resonance imaging (MRI) systems. For example, in one embodiment, a method includes ultrasonically consolidating a plurality of sheets of a conductive material to form a consolidated structure and machining one or more conductive channels into the consolidated structure to form an inductor.

Owner:GENERAL ELECTRIC CO

Orthopaedic implants fabricated from amorphous or partially amorphous calcium-based metal alloys

InactiveUS20070166349A1Additive manufacturing apparatusBone implantArticular surfacesBase metal alloy

Orthopaedic implants are formed using processes whereby a metal alloy is cooled at a rate rapid enough that an amorphous or partially amorphous structure is retained. In the preferred embodiment, the metal alloy is a calcium-based metal alloy. The fabrication process may include die-casting or additive manufacturing process of the type wherein material increments are consolidated in accordance with the description without melting the material in bulk. Such processes include ultrasonic consolidation, electrical resistance consolidation, and frictional consolidation. The material increments are provided in the form of sheets, elongated tapes, filaments, dots or droplets. A preferred method includes a casting process to produce an initial form having an outer surface followed by an additive manufacturing process used to build up at least a portion of the outer surface. For example, the portion may include an intramedullary stem, bone-ingrowth surface, or articulating surface.

Owner:SOLLDICA

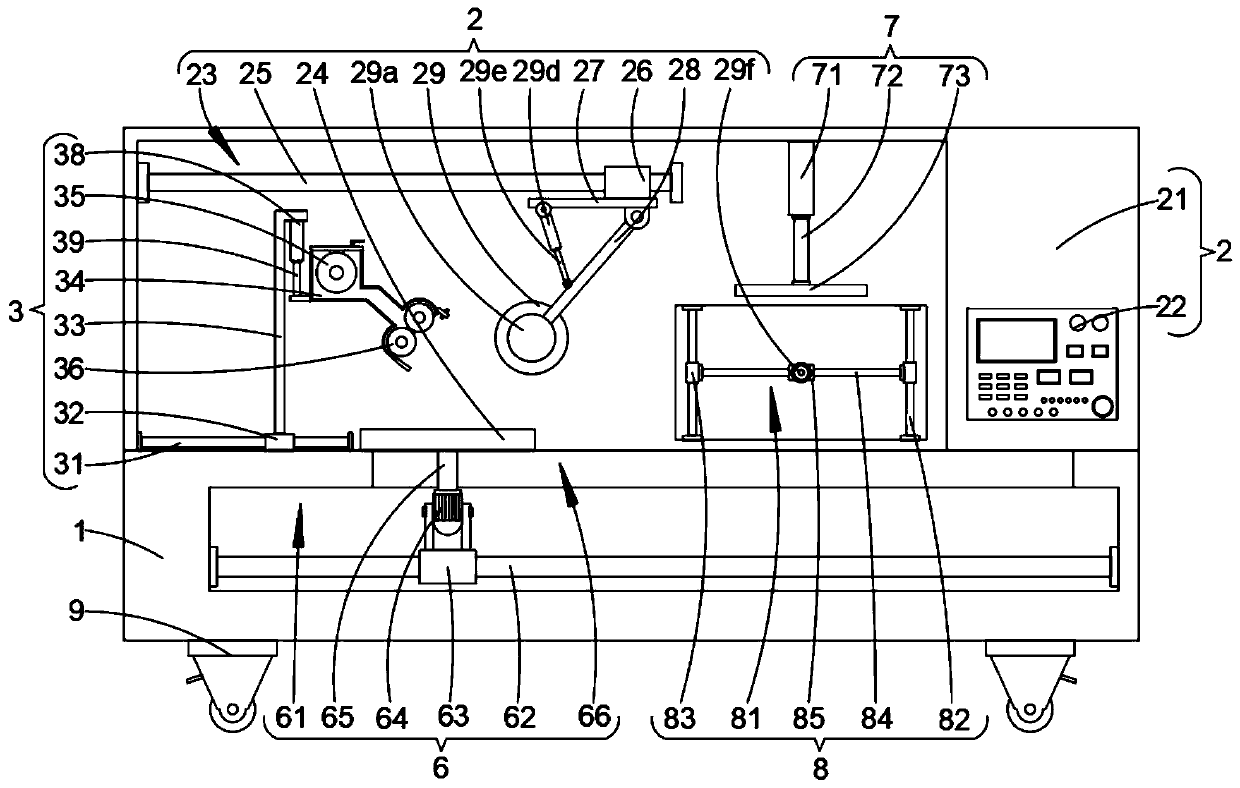

Ultrasonic solidification-friction stir composite added material manufacturing device and application method

ActiveCN110587166APromote interdiffusionImprove mechanical propertiesAdditive manufacturing apparatusWelding apparatusNumerical controlMetal foil

The invention provides an ultrasonic solidification-friction stir composite added material manufacturing device and an application method. The ultrasonic solidification-friction stir composite added material manufacturing device comprises a shell, a machining mechanism, a metal foil conveying mechanism, a driving mechanism, a cutting mechanism, a movable steering mechanism, an extrusion mechanism,an adjusting mechanism and locking universal wheels; the machining mechanism is fixedly connected into the shell; and the machining mechanism comprises a numerical control machining center, a controlpanel, a machining cavity, a substrate, a first electric slide rod, a first electric slide sleeve, a mounting plate, a connecting plate, a machining head, a transducer, an amplitude change rod, an insulation sleeve, a first cylinder, a first piston rod and a friction stir head. The ultrasonic solidification-friction stir composite added material manufacturing device can prepare high-performance metal samples; the mechanical performances of the samples are higher than forgings by 20-50%; and the device is low in size limiting, can machine large-size complex-structured parts, can from more thantwo metal materials according to working conditions and typical performance requirements of parts, and realizes preparation of heterogeneous / gradient function materials.

Owner:ZHEJIANG OCEAN UNIV

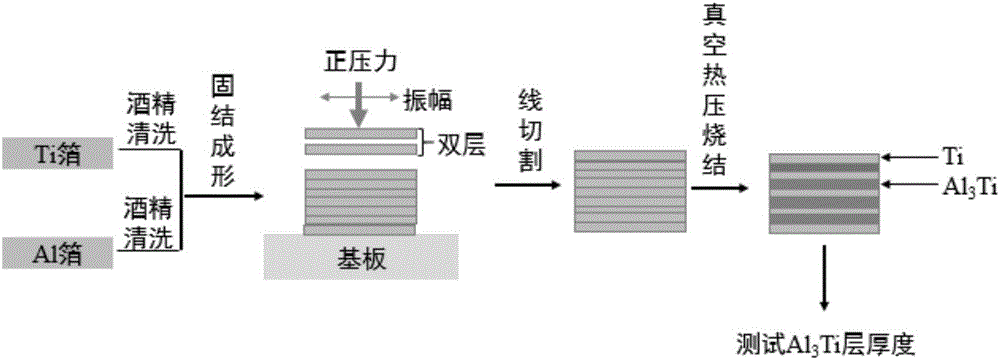

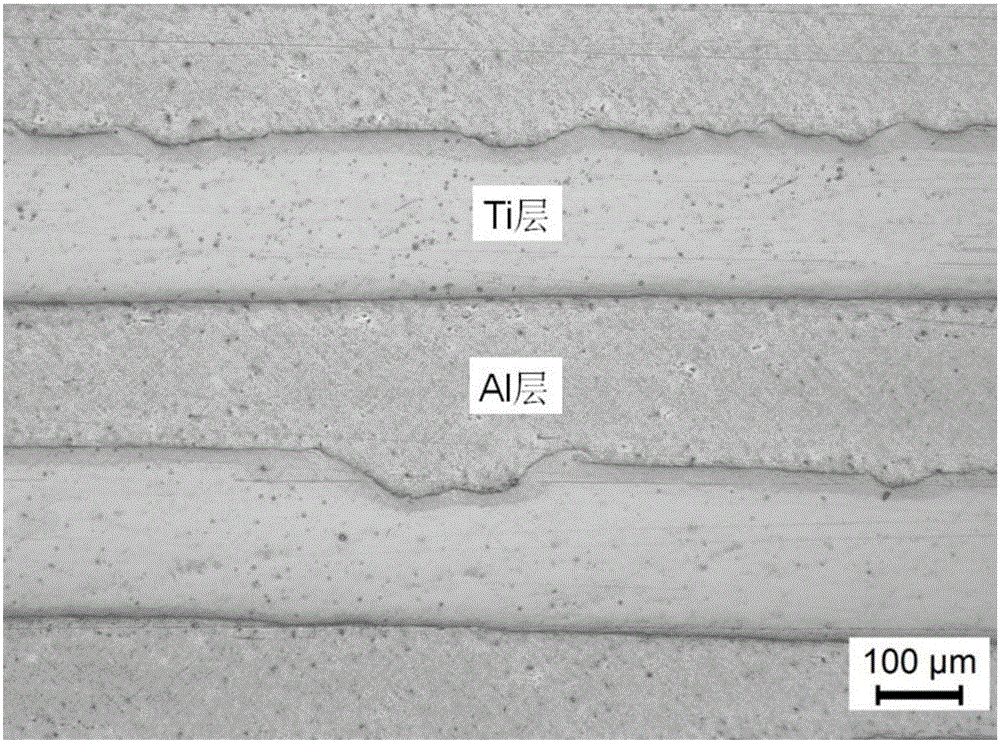

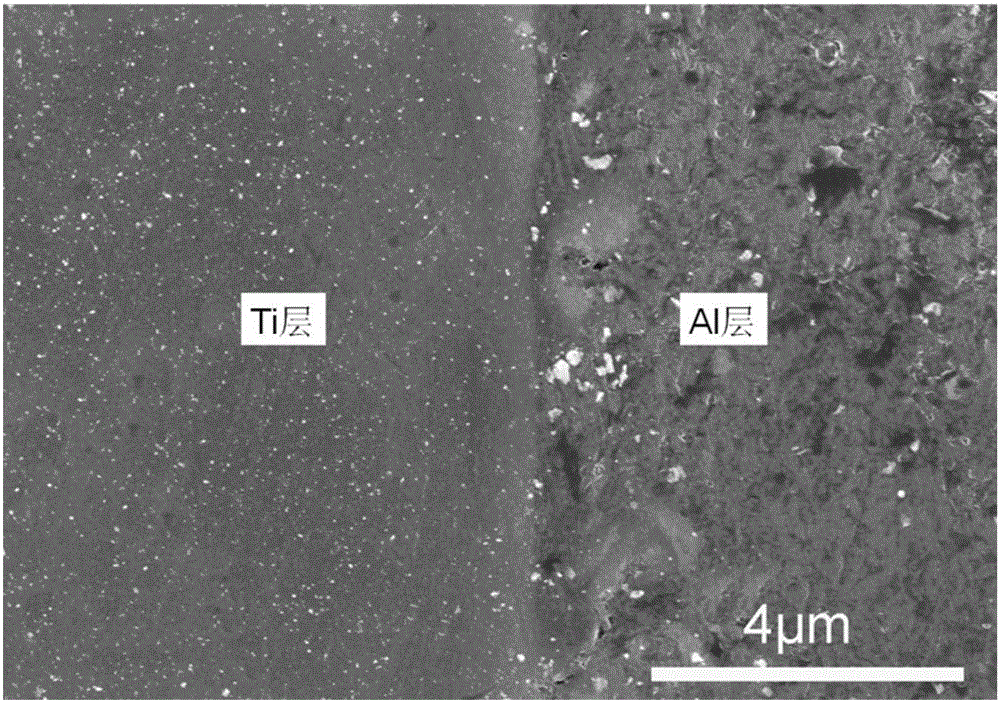

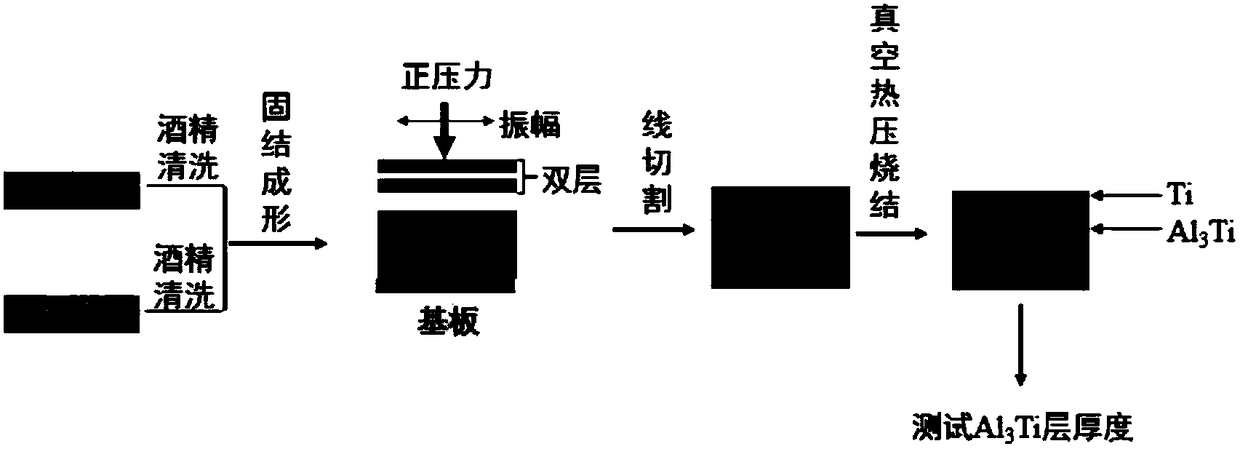

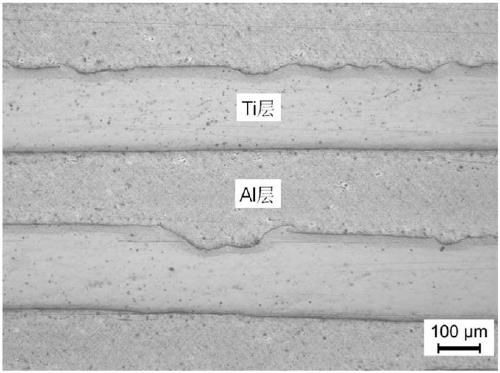

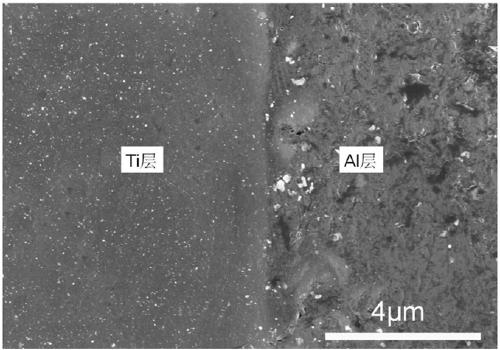

Rapid preparation method of composite material Ti/Al3Ti based on ultrasonic consolidation forming as supplementary means

ActiveCN106476358ASimple pretreatment processShort preparation cycleLayered product treatmentLaminationAlcoholMetal foil

The invention provides a rapid preparation method of a composite material Ti / Al3Ti based on ultrasonic consolidation forming as supplementary means. The method comprises putting a cut Al band and a cut Ti band in an ultrasonic cleaner, washing the bands through alcohol for 15-20min, alternately and orderly stacking the Al band and the Ti band in an order of Al band-Ti band, preparing a Ti / Al prefabricated band through an ultrasonic consolidation fast formation device, separating the Ti / Al prefabricated band obtained by the ultrasonic consolidation forming from a base plate, putting the Ti / Al prefabricated band in a vacuum hot press furnace and carrying out hot press sintering to obtain the layered composite material Ti / Al3Ti. The rapid preparation method solves the problem that the traditional metal foil metallurgy technology for preparing the layered composite material Ti / Al3Ti has a slow reaction rate and a long preparation period, and provides a novel technological approach for further industrialization of the composite material Ti / Al3Ti.

Owner:HARBIN ENG UNIV

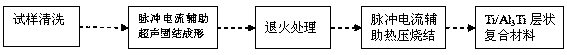

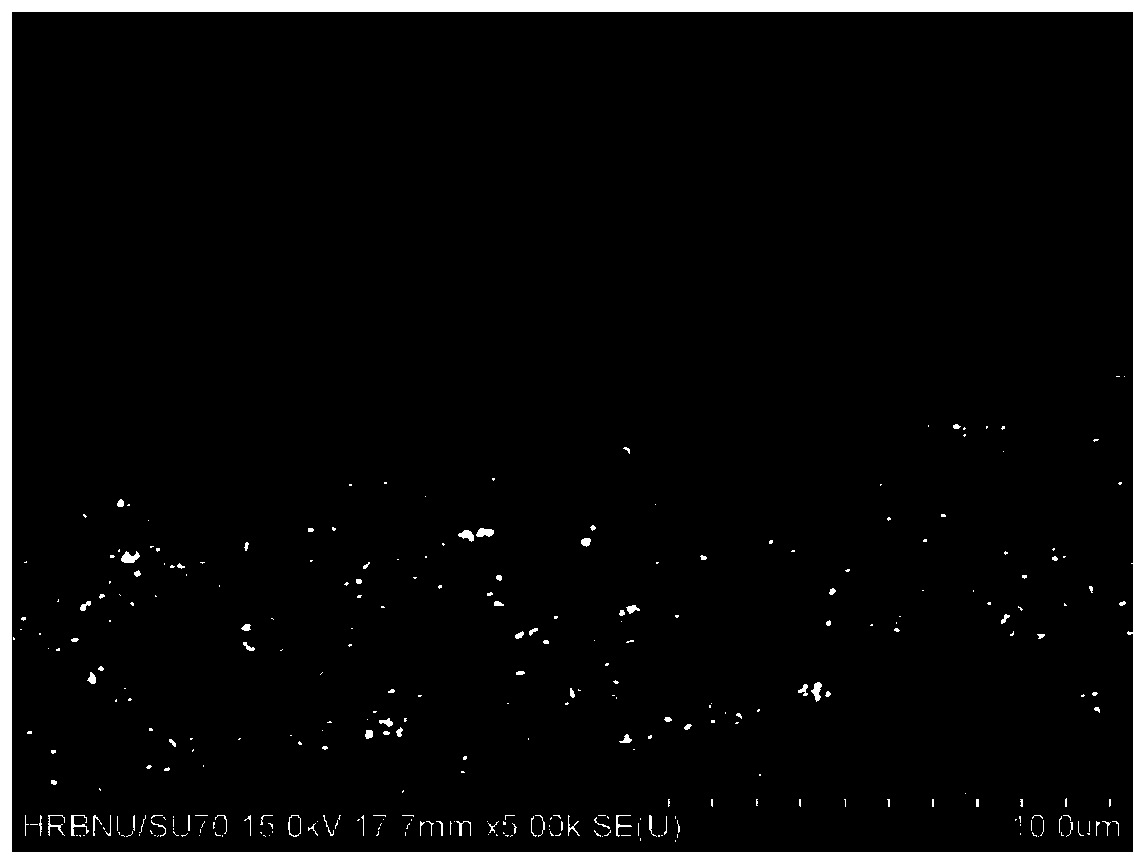

Preparation method of Ti/Al3Ti layered composite material

The invention provides a preparation method of a Ti / Al3Ti layered composite material. The preparation method is characterized by comprising the following steps that S1, a sample is cleaned; S2, pulsecurrent auxiliary ultrasonic consolidation forming is carried out; S3, annealing treatment is carried out; and S4, pulse current auxiliary hot-pressing sintering is carried out. According to the preparation method, the atomic diffusion in the ultrasonic consolidation process can be promoted, the Ti / Al interface bonding quality is improved, the follow-up in-situ reaction test is facilitated, Ti / Alcan be activated through the instantaneous high energy, the reaction efficiency is improved, the crack defect is overcome, and then the Ti / Al3Ti layered composite material with high density and good bonding quality is obtained.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Method for preparing metal layered composite material through high-energy pulse current assisted ultrasonic consolidation

InactiveCN111014934AImprove plastic deformation abilityFully consolidatedNon-electric welding apparatusMetal foilPulse electric field

The invention provides a method for preparing a metal layered composite material through high-energy pulse current assisted ultrasonic consolidation, and the method comprises the following steps: preparing one or more metal foils, cleaning oil stains on the surface, and drying the cleaned foils for later use; connecting a pulse current power supply with ultrasonic consolidation equipment to ensurethat a strip / substrate between the positive electrode and the negative electrode of the pulse current is a unique path; by adopting a synchronous coupling mode, applying a pulsed electric field withcurrent density and frequency in the ultrasonic consolidation process, and finishing single-pass metal foil consolidation; and after the step 3 is completed, repeating the process of the step 3 as required to realize layer-by-layer accumulation and solidification of the metal foils, and finally, preparing the metal layered composite materials with different thicknesses / layers and obtaining the metal layered composite material prepared by high-energy pulse current assisted ultrasonic solidification. The electroplastic effect of the pulse current utilized by the method is essentially different from that of a traditional method for improving the plasticity of the material through the heat effect, and the plastic deformation capacity of the material can be instantaneously improved under the condition of extremely small temperature rise.

Owner:HARBIN ENG UNIV

Depositing heat-treated aluminum using ultrasonic consolidation

A system, method, and articles are disclosed with respect to depositing aluminum or alloys thereof, utilizing ultrasonic object consolidation. The method aspect of the invention comprises the steps of heat-treating an aluminum-based feedstock and ultrasonically consolidating the feedstock to a substrate to produce a part or a repair of a part, as might be required in an aerospace or aircraft structure. The feedstock may be solution heat-treated. This would include situations wherein the feedstock is solution heat treated off-line and maintained under controlled temperature conditions to prevent precipitation of solutes prior to the ultrasonic consolidation. Alternatively, the feedstock may be heat-treated on-line by passing it through a temperature- and / or atmosphere-controlled chamber prior to ultrasonic consolidation. The feedstock may be supported to minimize slumping due to creep. The feedstock may be T4, or may be aged, to T6, for example. The feedstock may be allowed to age naturally at room temperature, or a heat source may be used to artificially age the consolidated feedstock. The substrate may be aged or unaged. The source of the aluminum-based feedstock is in the form of tapes, sheets, wires, or droplets.

Owner:SOLIDICA

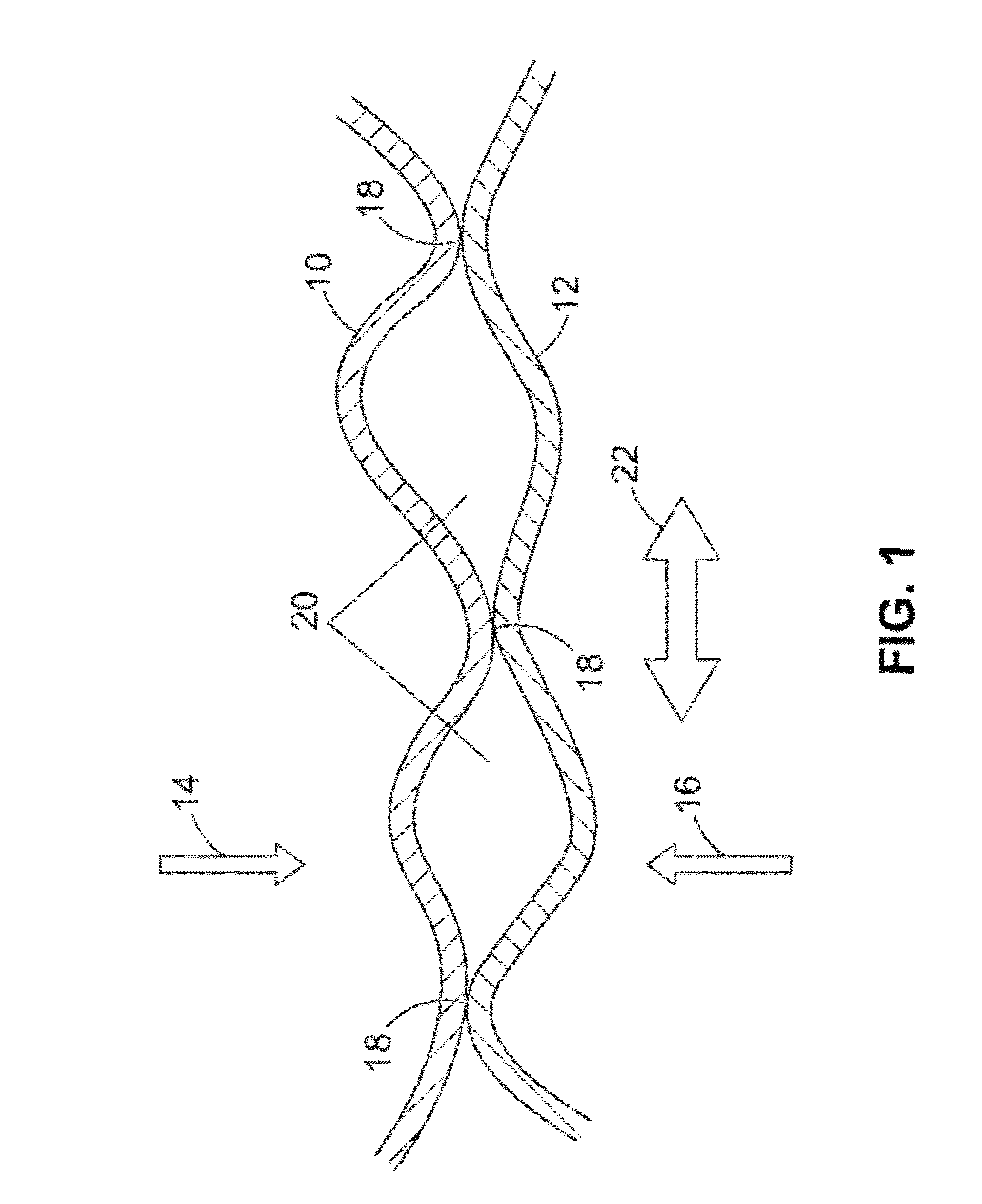

Composite biaxially textured substrates using ultrasonic consolidation

InactiveUS8210420B1Welding/cutting auxillary devicesAuxillary welding devicesAlloyUltimate tensile strength

A method of forming a composite sheet includes the steps of: providing a first sheet having a surface and including a metal or alloy, the first sheet having a given strength characteristic; providing a second sheet having a surface and a strength characteristic that is superior to the given strength characteristic of the first sheet; disposing the first sheet and the second sheet in an aligned opposing position with at least a portion of the surface of the first sheet touching the surface of the first sheet to form a contact area; and bonding the first sheet to the second sheet at least in part by applying an oscillating ultrasonic force to at least one of the first sheet and the second sheet to form a composite sheet, the first sheet having a cube texture characterized by a φ-scan having a FWHM of no more than 15° in all directions.

Owner:UT BATTELLE LLC

System and method for manufacturing magnetic resonance imaging coils using ultrasonic consolidation

ActiveUS9355774B2Transformers/inductances coolingMagnetic measurementsEngineeringConductive materials

Owner:GENERAL ELECTRIC CO

Gel ultrasonic concussion forming method for metal parts

InactiveCN103350229AEliminate Bubble ProblemsReduce defectsHigh concentration(Hydroxyethyl)methacrylate

The invention discloses a gel ultrasonic concussion forming method for metal parts and belongs to the field of metal part preparation in powder metallurgy production process. The method includes the steps that metal powder is suspended in premixed liquid of hydroxyethyl methylacrylate and methylbenzene to obtain high-concentration suspension slurry, and the slurry is poured into a mould to be subject to ultrasonic concussion, wherein the premixed liquid has a certain concentration, and an initiating agent is dissolved in the premixed liquid; curing time is controlled through adjusting the adding quantity of a catalyst in the slurry so that a curing reaction can be completed in the concussion process after a certain time; the viscosity of the slurry is controlled through adding the appropriate amount of macromolecular plasticizer, wherein the problems of uneven density and composition segregation caused by concussion are solved. The method can overcome the defects that a common gel-casting formed product is high in porosity and low in strength, improve solid content of the common gel-casting formed product greatly and prepare high-density and high-strength metal products, and is especially suitable for preparing the metal parts which are difficult to machine, such as cemented carbide and high-melting-point alloy.

Owner:UNIV OF SCI & TECH BEIJING

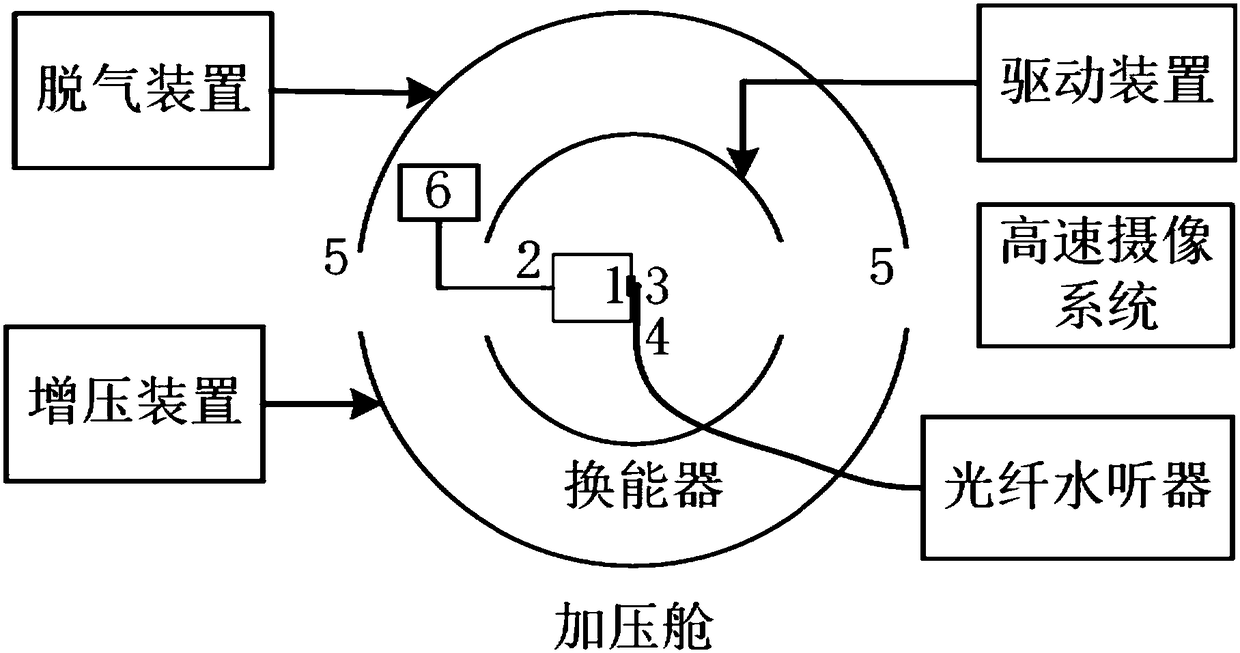

Method and device for evaluating metal mechanical properties by ultrasonic cavitation

ActiveCN108225948AMechanical Properties ScienceImprove mechanical propertiesWeather/light/corrosion resistanceMaterial strength using single impulsive forceUltrasonic cavitationTransducer

The invention provides a method and device for evaluating metal mechanical properties by ultrasonic cavitation. The method comprises the following steps of (1) preparing de-aerated water; injecting water into a pressurization cabin, and removing bubbles of the inner surface of an ultrasonic transducer; (2) cutting metal to be detected into slice samples; (3) fixing the metal slice samples in the ultrasonic transducer; parallelly sticking optical fiber on the metal sample surface; fully injecting water; (4) starting a driving device of the transducer; connecting a high-speed image pick-up system; (5) determining the focus position and the optimal work frequency of the ultrasonic transducer; regulating the position of the sample so that the focus is positioned on the surface; (6) shooting the metal cavitation erosion process through high-speed image pickup; (7) observing the metal surface damage appearance, and evaluating the mechanical property by combining the metal physical property.The metal mechanical property is evaluated from the metal surface topography angle by an acoustic cavitation method; the advantages of science and convenience are realized; important theoretical and application values are realized for studying the metal mechanical constitutive relationship.

Owner:CHONGQING MEDICAL UNIVERSITY

Composite biaxially textured substrates using ultrasonic consolidation

InactiveUS8424745B1Welding/cutting auxillary devicesAuxillary welding devicesAlloyRe crystallization

A method of forming a composite sheet includes disposing an untextured metal or alloy first sheet in contact with a second sheet in an aligned opposing position; bonding the first sheet to the second sheet by applying an oscillating ultrasonic force to at least one of the first sheet and the second sheet to form an untextured intermediate composite sheet; and annealing the untextured intermediate composite sheet at a temperature lower than a primary re-crystallization temperature of the second sheet and higher than a primary re-crystallization temperature of the first sheet to convert the untextured first sheet into a cube textured sheet, wherein the cube texture is characterized by a φ-scan having a FWHM of no more than 15° in all directions, the second sheet remaining untextured, to form a composite sheet.

Owner:UT BATTELLE LLC

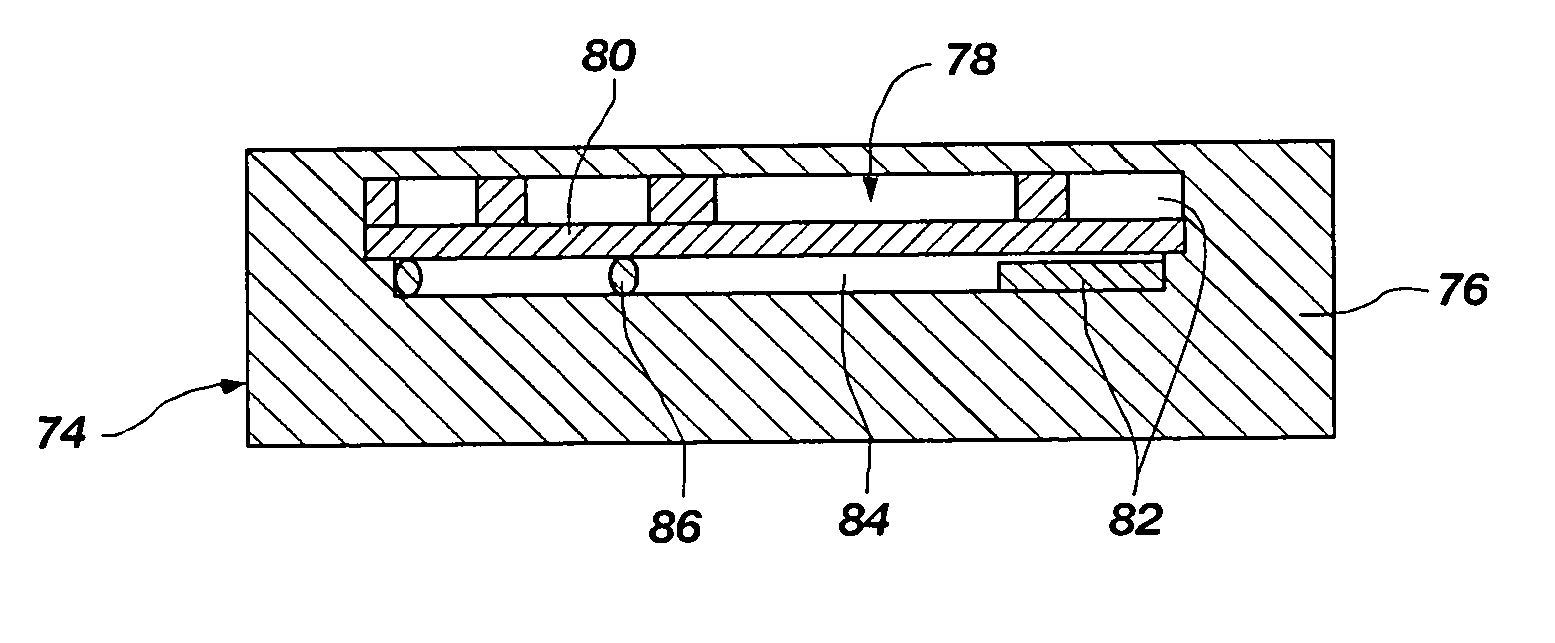

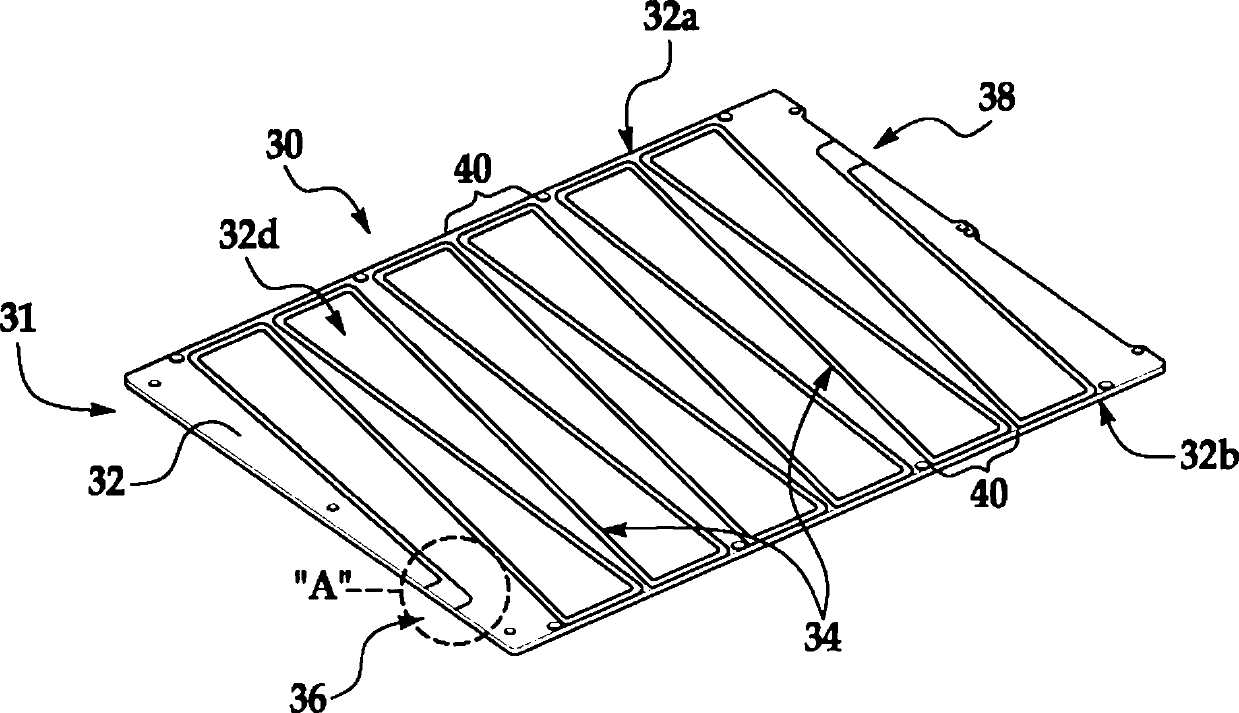

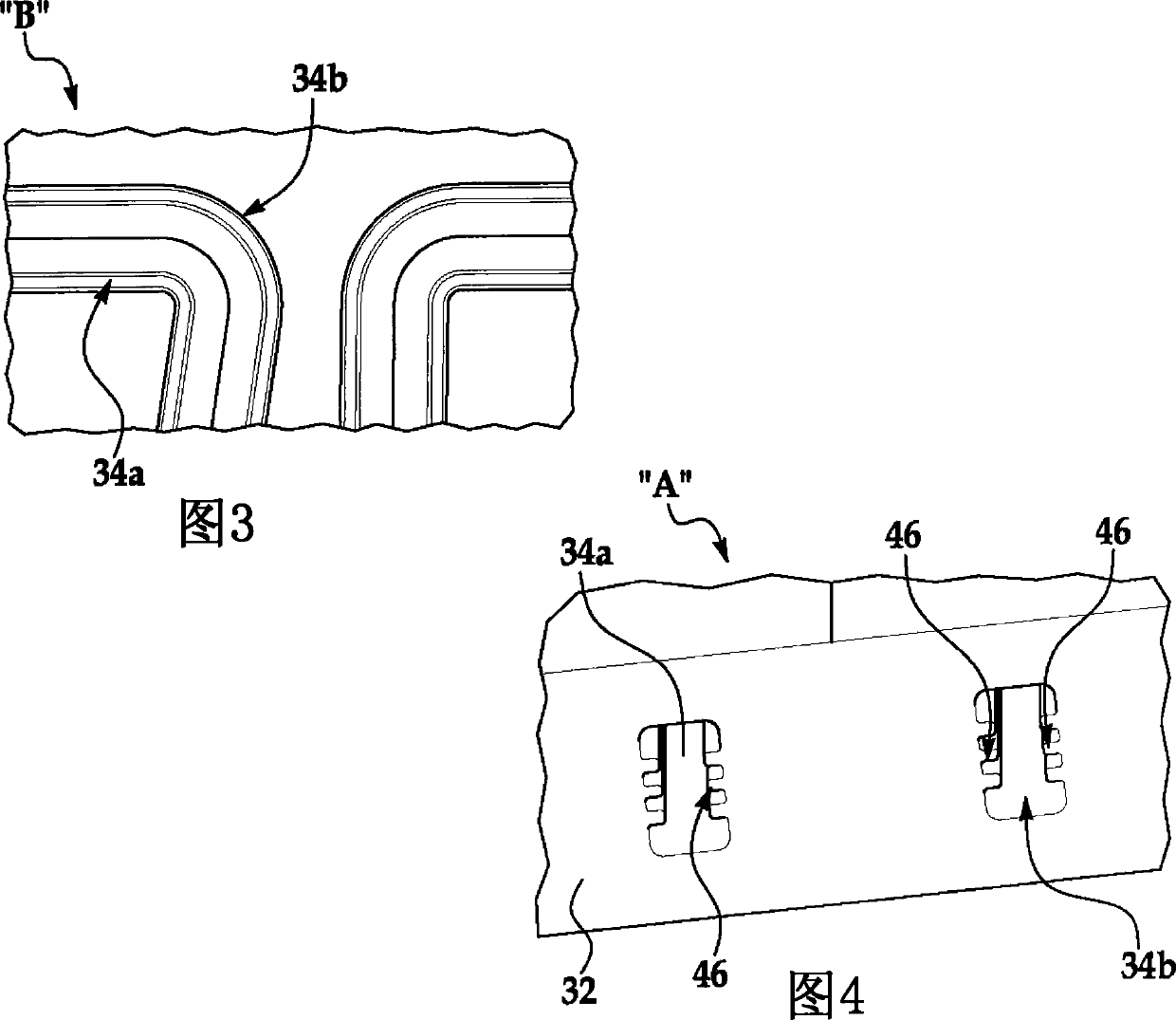

Thermal management device and method for making the same

ActiveCN101594768BImprove reliabilityImprove heat transfer performanceLayered product treatmentSemiconductor/solid-state device detailsThermal energyEngineering

A thermal management device suitable for use as an electronic chassis includes a monolithic, monocoque body having integrally formed channels for carrying thermal energy away from a heat source, such as electronic components. The device may be fabricated using additive / subtractive manufacturing processes such as ultrasonic consolidation.

Owner:THE BOEING CO

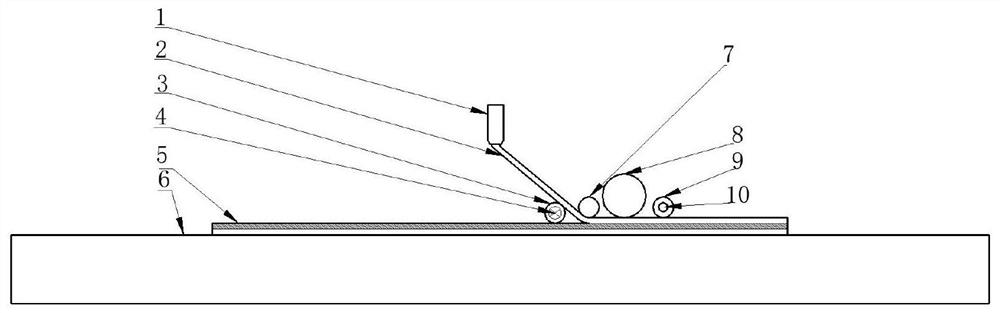

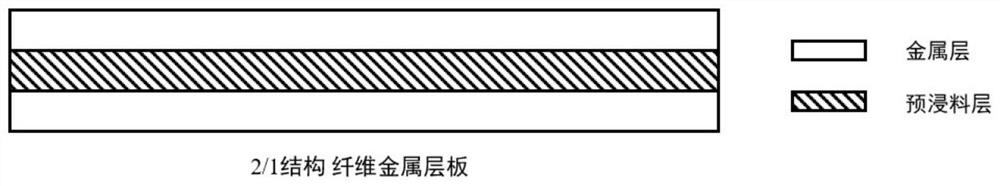

Fiber metal laminate composite material and preparation method thereof

ActiveCN112848555AReduce porositySimple structureAnodisationLamination ancillary operationsUltrasonic assistedFiber metal laminate

The invention discloses a fiber metal laminate composite material and a preparation method thereof, and belongs to the field of preparation and forming of advanced composite materials. The method comprises the steps that metal sheets are taken, and the surfaces of the metal sheets are sequentially subjected to degreasing treatment, acid pickling, anodic oxidation treatment and primer spraying; the metal sheets and fiber resin layers are alternately laid on a working platform through ultrasonic-assisted rolling equipment, ultrasonic treatment and rolling are carried out layer by layer in the laying process, and a formed fiber metal laminate is cooled after laying is completed; and after the formed fiber metal laminate is cooled to the room temperature, the working platform is opened, and the prepared fiber metal laminate composite material is taken out. According to the invention, original ultrasonic-assisted rolling equipment is adopted for conducting ultrasonic treatment on the fiber metal laminate through ultrasonic vibration, the ultrasonic consolidation additive manufacturing method does not need an autoclave procedure, the preparation time is shortened, and the preparation efficiency is improved.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

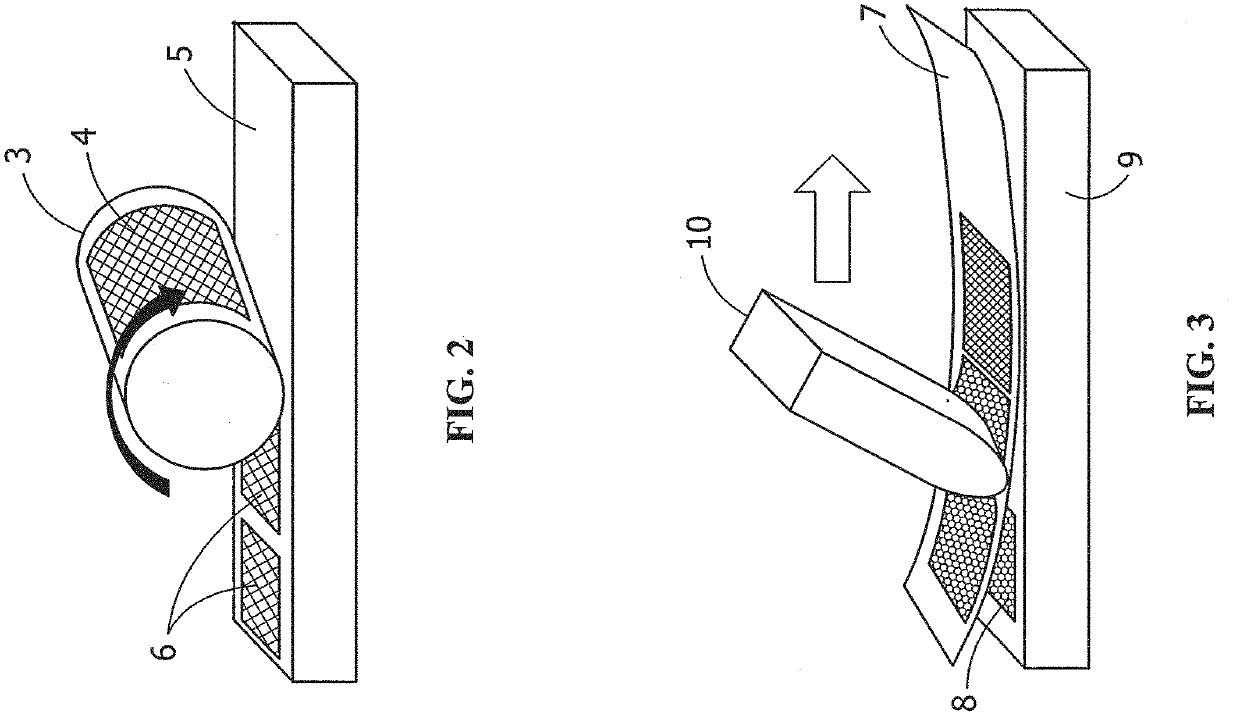

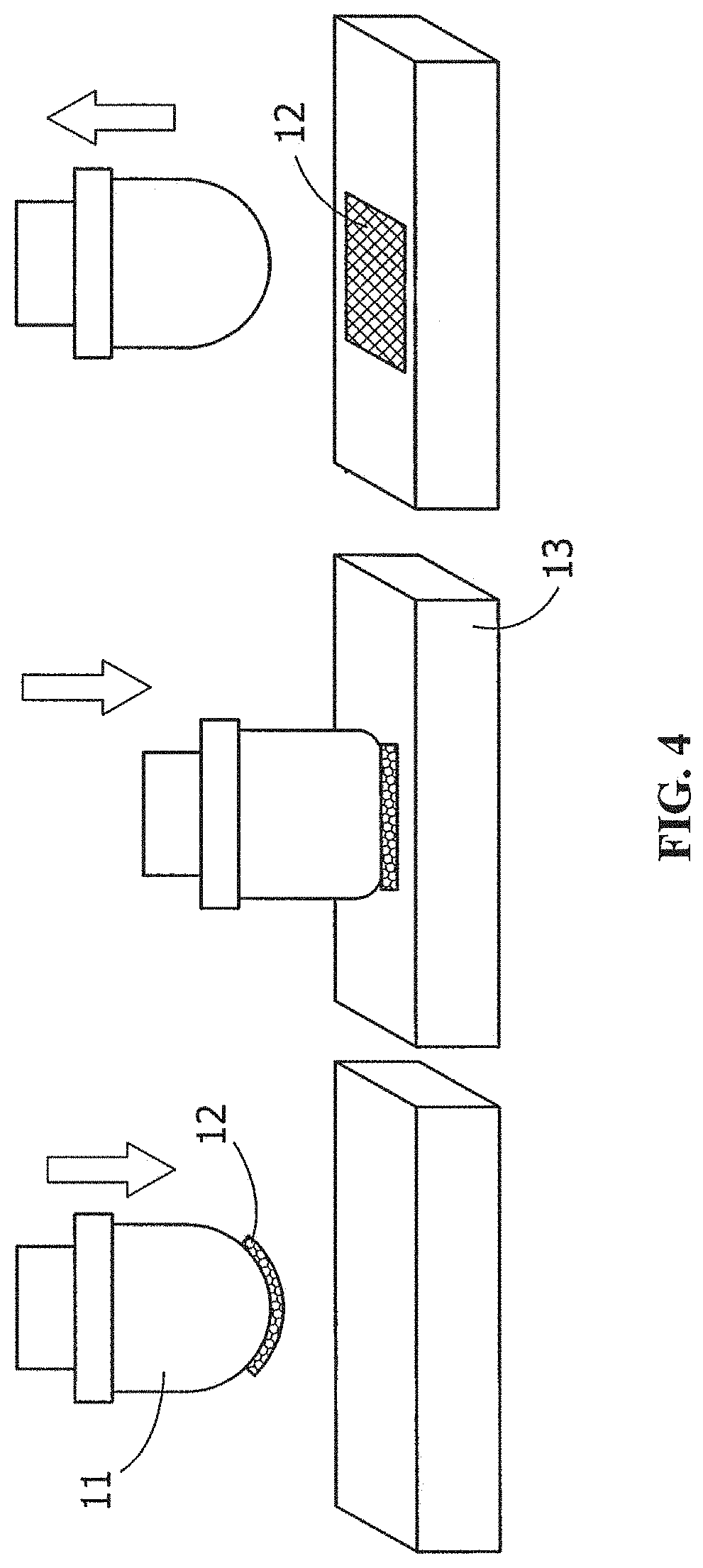

Ultrasonic consolidation of particulates in ink for functional coatings

A process for ultrasonically consolidating particulates in an ink onto a substrate at ambient temperatures in less than 5 seconds to form a completely dense, well adhered functional coatings is disclosed. The coating can be used for electronic components. The process is applicable to various substrates such as metals, plastics and ceramics.

Owner:TE CONNECTIVITY GERMANY GMBH +1

Method of additively manufacturing metal composite board with built-in circuit

ActiveCN107745549AImprove mechanical propertiesImprove forming efficiencyMetal layered productsMetal foilConductive materials

The invention discloses a method of additively manufacturing metal composite board with a built-in circuit and belongs to the field of additively manufacturing. A technical problem is solved by providing such method, by which a circuit is directly wrote to the metal composite board, so that the circuit and the metal composite board are manufactured at the same time to form the integrated metal composite board with the built-in circuit via the additively manufacturing. In one technical scheme for solving the problem, the method includes the steps of: pre-cutting preset circuit paths in a metalfoil material; performing ultrasonic consolidation shaping to the metal foil material; and successively filling the circuit paths with an insulation material, a conductive material and an insulation material, and integrating the circuit with the metal composite board. The method can be widely applied to the field of additively manufacturing.

Owner:ZHONGBEI UNIV

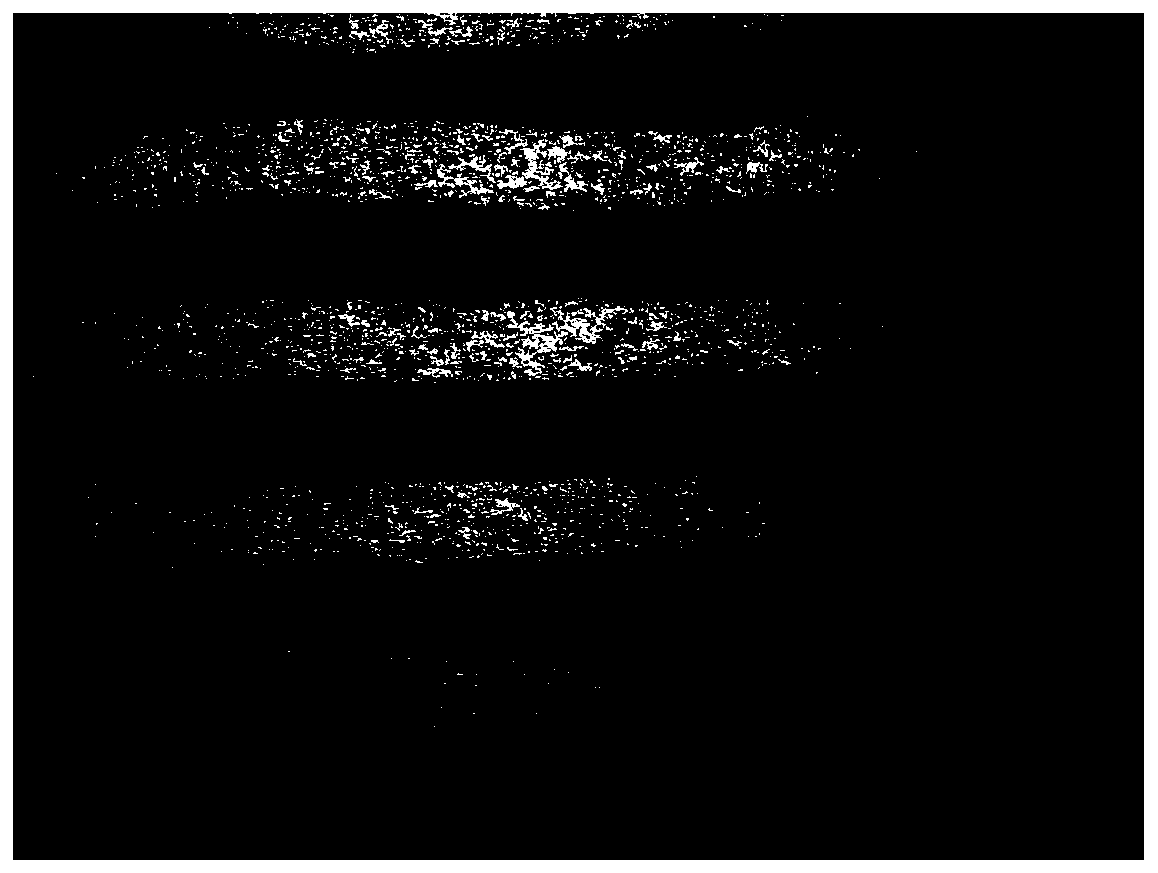

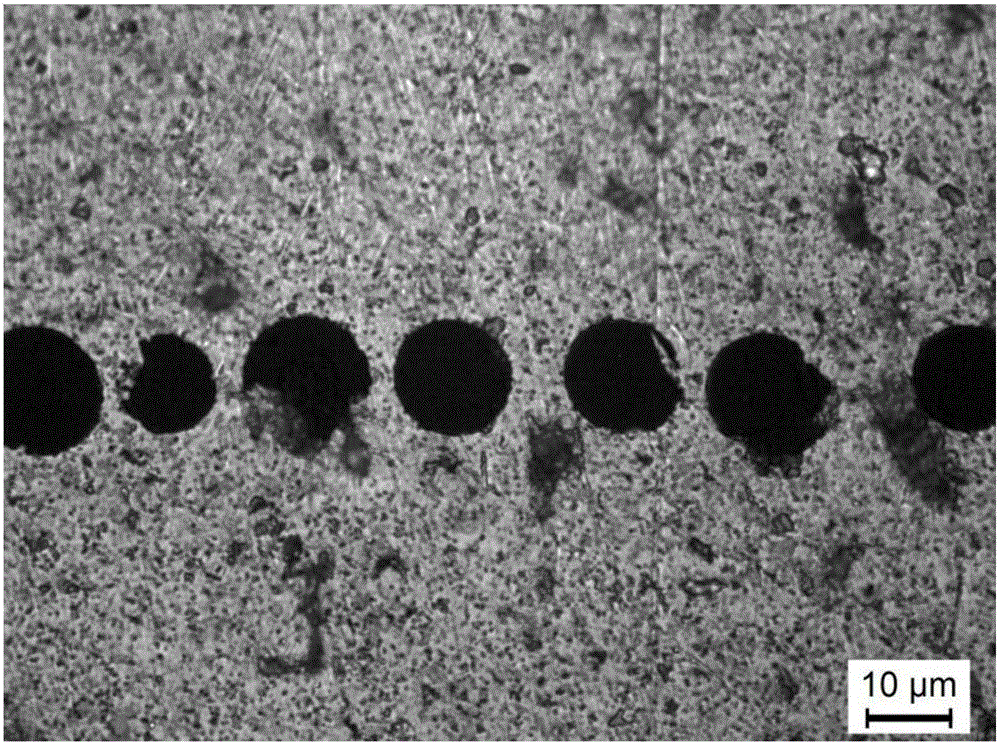

Ultrasonic consolidation rapid manufacturing method for continuous ceramic fiber uniform-distribution aluminum strip

ActiveCN105220086ASolving Dispersion ProblemsSolve for uniformityFibre dispersionRapid manufacturing

The invention relates to an ultrasonic consolidation rapid manufacturing method for a continuous ceramic fiber uniform-distribution aluminum strip. According to the pretreatment technological parameters of SiC ceramic fibers and Al2O3 ceramic fibers, the holding temperature ranges from 600 DEDG C to 700 DEG C, and the holding time is 1.5 h and 0.5 h. According to the manufacturing technological parameters of the pretreated bundle ceramic fiber uniform-distribution aluminum strip, at normal temperature, the added load ranges from 125 kgf to 150 kgf, the amplitude ranges from 20 microns to 40 microns, and the speed ranges from 30 mm / s to 50 mm / s. Bundle fibers in the manufactured fiber uniform-distribution aluminum strip are scattered and distributed uniformly, and are well bonded with the aluminum strip, the interface bonding situation is good, aluminum strips are bonded closely and have no obvious interface, and the rapid forming manufacturing method can be used for manufacturing the ceramic fiber uniform-distribution aluminum strip.

Owner:HARBIN ENG UNIV

Method and apparatus for fabricating fibre reinforced thermoplastic composite structure

An apparatus for fabricating a fibre reinforced thermoplastic composite structure is described. The apparatus comprises a localised heat source arranged to heat a portion of a stack of fibre reinforced thermoplastic material layers and an ultrasonic transducer arranged to locally introduce ultrasonic energy waves to the heated portion of the fibre reinforced thermoplastic material layers. The apparatus makes it possible to achieve ultrasonic consolidation of the layers occurs.

Owner:AIRBUS OPERATIONS LTD

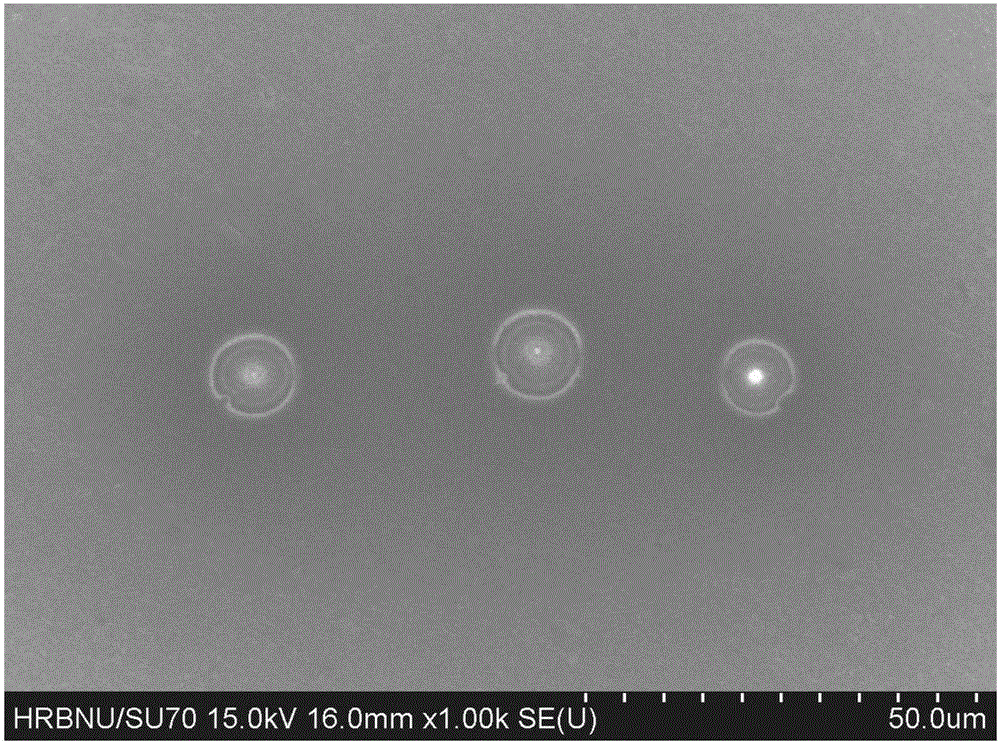

Ultrasonic consolidation forming method of zirconium-steel layered composite material

ActiveCN110216364BHigh yieldEasy to operateWelding/soldering/cutting articlesNon-electric welding apparatusSurface cleaningPhysical metallurgy

The invention discloses an ultrasonic consolidation forming method of a zirconium-steel layered composite material, which comprises the following steps: 1) performing surface cleaning treatment on the welding surface of the zirconium plate and the steel plate, 2) stacking the zirconium plate on top and the steel plate on the bottom to form a unit 3) Place the unit body on the ultrasonic consolidation forming workbench, preheat and raise the temperature, 4) Use ultrasonic consolidation forming equipment to weld according to a certain path until the zirconium steel composite forming. The invention belongs to low-temperature manufacturing, zirconium steel is combined by physical metallurgy, the diffusion layer is thin, the production cost is low, and the efficiency is high.

Owner:NANJING YOUTIAN METAL TECH

Rapid preparation method of composite material ti/al3ti based on ultrasonic consolidation forming

ActiveCN106476358BSignificant progressSimple pretreatment processLayered product treatmentLaminationAlcoholMetal foil

The invention provides a rapid preparation method of a composite material Ti / Al3Ti based on ultrasonic consolidation forming as supplementary means. The method comprises putting a cut Al band and a cut Ti band in an ultrasonic cleaner, washing the bands through alcohol for 15-20min, alternately and orderly stacking the Al band and the Ti band in an order of Al band-Ti band, preparing a Ti / Al prefabricated band through an ultrasonic consolidation fast formation device, separating the Ti / Al prefabricated band obtained by the ultrasonic consolidation forming from a base plate, putting the Ti / Al prefabricated band in a vacuum hot press furnace and carrying out hot press sintering to obtain the layered composite material Ti / Al3Ti. The rapid preparation method solves the problem that the traditional metal foil metallurgy technology for preparing the layered composite material Ti / Al3Ti has a slow reaction rate and a long preparation period, and provides a novel technological approach for further industrialization of the composite material Ti / Al3Ti.

Owner:HARBIN ENG UNIV

A method for additive manufacturing metal composite board with built-in circuit

ActiveCN107745549BImprove mechanical propertiesImprove forming efficiencyMetal layered productsMetal foilConductive materials

Owner:ZHONGBEI UNIV

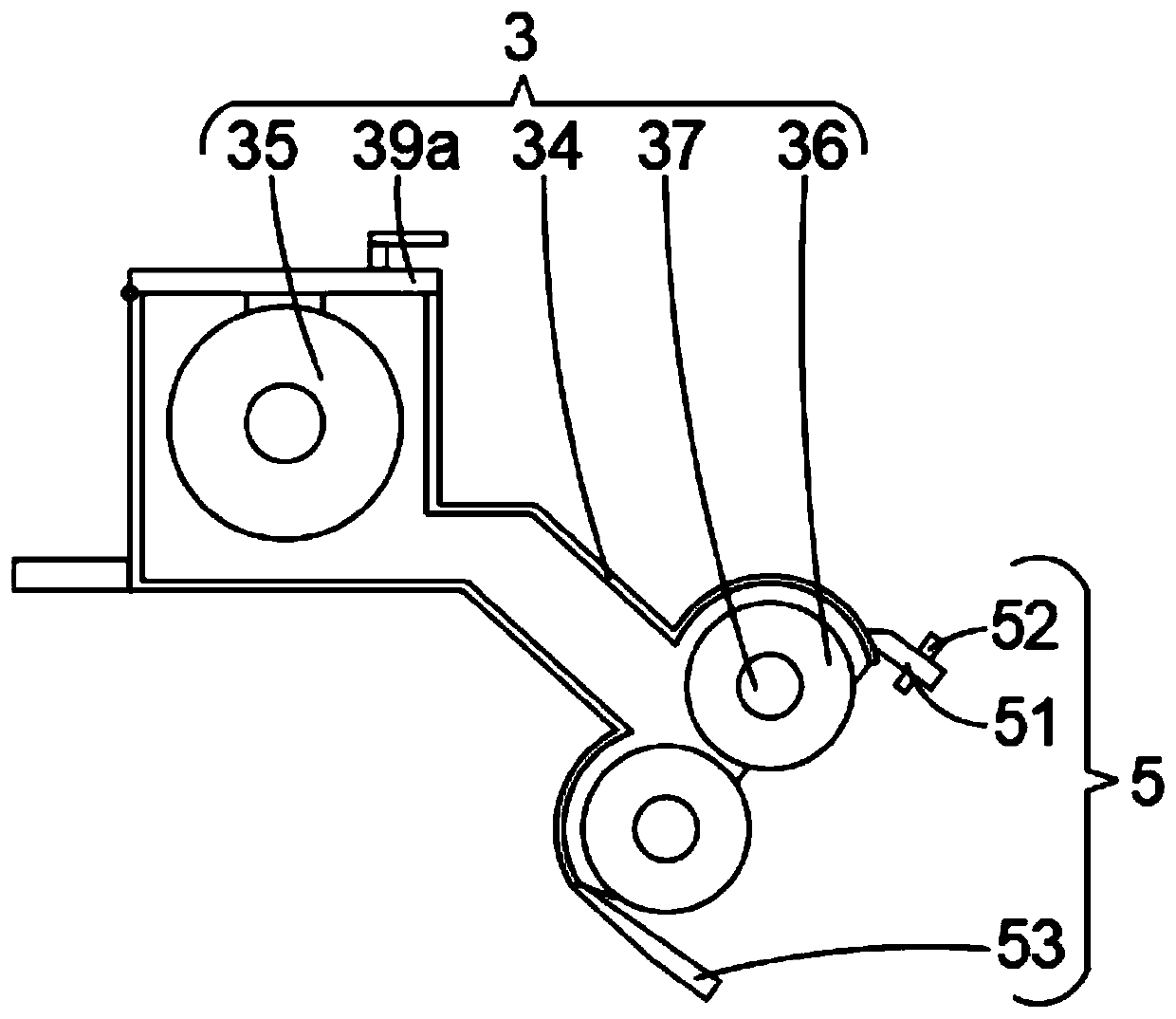

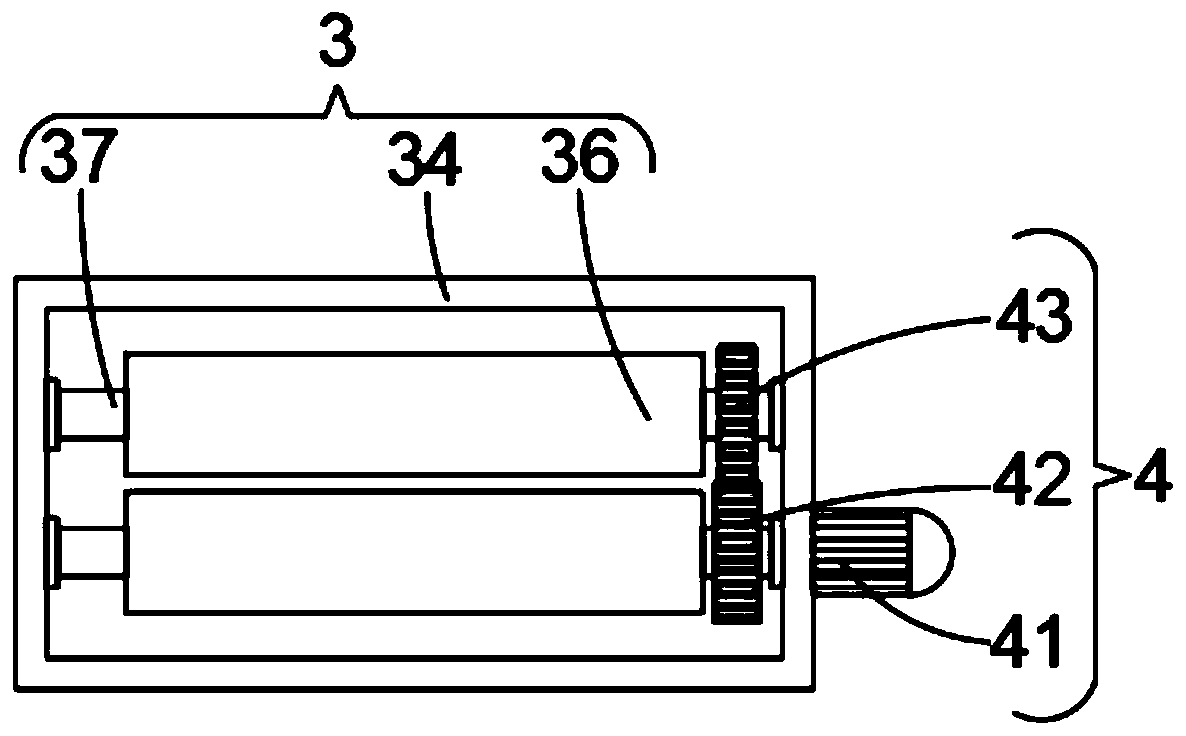

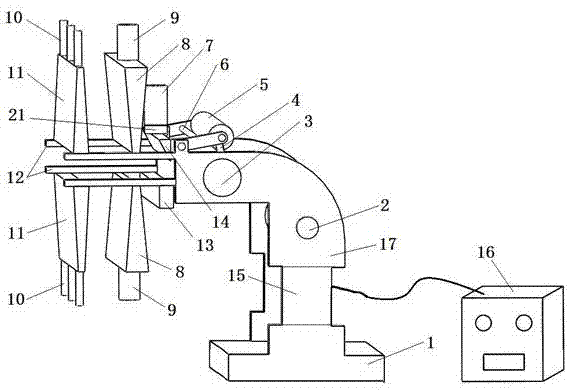

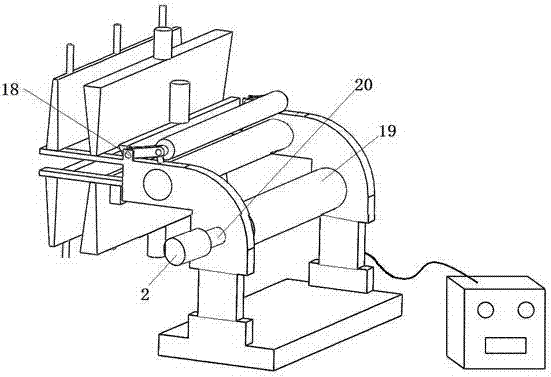

Strip conveying device used for ultrasonic consolidation additive manufacturing machine

PendingCN107381172ALower requirementLower supply costsCleaning using liquidsMetal working apparatusManufactured materialMechanical engineering

The invention discloses a strip conveying device used for an ultrasonic consolidation additive manufacturing machine, and belongs to the field of 3D printing additive manufacturing. In order to solve the technical problems, the strip conveying device used for the ultrasonic consolidation additive manufacturing machine can be used for straightening, cleaning and cutting raw materials. According to the technical scheme, the strip conveying device used for the ultrasonic consolidation additive manufacturing machine comprises a base, a machine frame and a strip conveying roller, and further comprises a first straightening roller, a second straightening roller, conveying rails and cutters, wherein the machine frame is arranged above the base, the strip conveying roller, the first straightening roller and the second straightening roller are arranged on the machine frame, the end of the machine frame is connected with the conveying rails, cleaning devices and drying devices are arranged on the upper and lower sides of the conveying rails, and the cutters are arranged on the conveying rails. The strip conveying device used for the ultrasonic consolidation additive manufacturing machine can be widely applied to the field of additive manufacturing.

Owner:ZHONGBEI UNIV

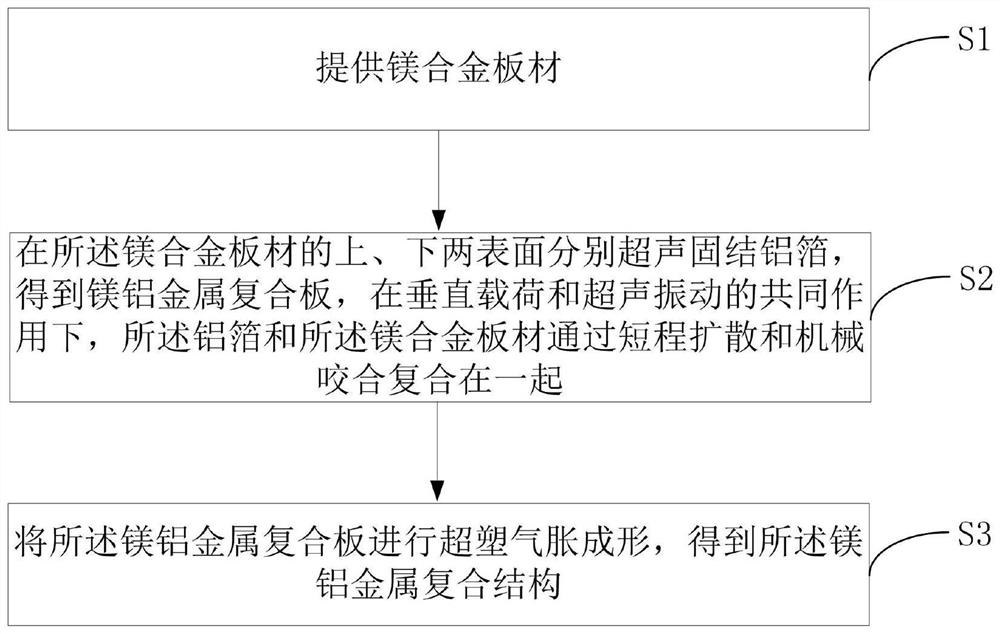

Manufacturing method of magnesium-aluminum metal composite structure

PendingCN114669651AImprove corrosion resistanceGood internal interface combinationMetal rolling arrangementsNon-electric welding apparatusReaction layerMg alloys

The invention relates to a manufacturing method of a magnesium-aluminum metal composite structure. The manufacturing method comprises the steps that S1, a magnesium alloy plate is provided; s2, aluminum foils are subjected to ultrasonic consolidation on the upper surface and the lower surface of the magnesium alloy plate correspondingly, a magnesium-aluminum metal composite plate is obtained, and under the combined action of vertical loads and ultrasonic vibration, the aluminum foils and the magnesium alloy plate are compounded together through short-distance diffusion and mechanical occlusion; and S3, the magnesium-aluminum metal composite plate is subjected to superplastic gas bulging forming, the magnesium-aluminum metal composite structure is obtained, an interface reaction layer is formed between the aluminum foil and the magnesium alloy plate, and metallurgical bonding is achieved. The aluminum foil has good corrosion resistance, so that the prepared magnesium-aluminum metal composite structure also has good corrosion resistance.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

A kind of gel ultrasonic vibration forming method of metal parts

InactiveCN103350229BEliminate Bubble ProblemsReduce defectsHigh concentration(Hydroxyethyl)methacrylate

The invention discloses a gel ultrasonic concussion forming method for metal parts and belongs to the field of metal part preparation in powder metallurgy production process. The method includes the steps that metal powder is suspended in premixed liquid of hydroxyethyl methylacrylate and methylbenzene to obtain high-concentration suspension slurry, and the slurry is poured into a mould to be subject to ultrasonic concussion, wherein the premixed liquid has a certain concentration, and an initiating agent is dissolved in the premixed liquid; curing time is controlled through adjusting the adding quantity of a catalyst in the slurry so that a curing reaction can be completed in the concussion process after a certain time; the viscosity of the slurry is controlled through adding the appropriate amount of macromolecular plasticizer, wherein the problems of uneven density and composition segregation caused by concussion are solved. The method can overcome the defects that a common gel-casting formed product is high in porosity and low in strength, improve solid content of the common gel-casting formed product greatly and prepare high-density and high-strength metal products, and is especially suitable for preparing the metal parts which are difficult to machine, such as cemented carbide and high-melting-point alloy.

Owner:UNIV OF SCI & TECH BEIJING

A packaging method for electronic components based on ultrasonic consolidation technology

ActiveCN107591337BReal-time monitoring of operationUniversalSemiconductor/solid-state device manufacturingHigh volume manufacturingMetal foil

The invention relates to an electronic component packaging method based on an ultrasonic consolidation technology, which belongs to the technical field of additive manufacturing. The technical problemto be solved is to provide a method of packging an electronic component using an ultrasonic consolidation technology. The technical scheme adopted to solve the technical problem is as follows: metalfoil is consolidated together layer by layer using an ultrasonic consolidation device, and when the height of the metal foil consolidated reaches the bottom of a groove, the current layer of metal foil is cut to form a hole according to the shape of an electronic component; then, the foil with a hole continues to be consolidated layer by layer to form a groove, the electronic component is installed in the groove, and molten resin is added to fix the electronic component; and finally, the metal foil continues to be consolidated layer by layer for sealing, in order to package the electronic component. The electronic component packaging method provided by the invention is simple and easy to implement, is of low cost, and can realize mass production. The electronic component packaging method can be widely used in the field of electronic component packaging.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com