Method and device for evaluating metal mechanical properties by ultrasonic cavitation

An ultrasonic transducer, metal technology, applied in measuring devices, using a single impact force to test the strength of materials, scientific instruments, etc. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

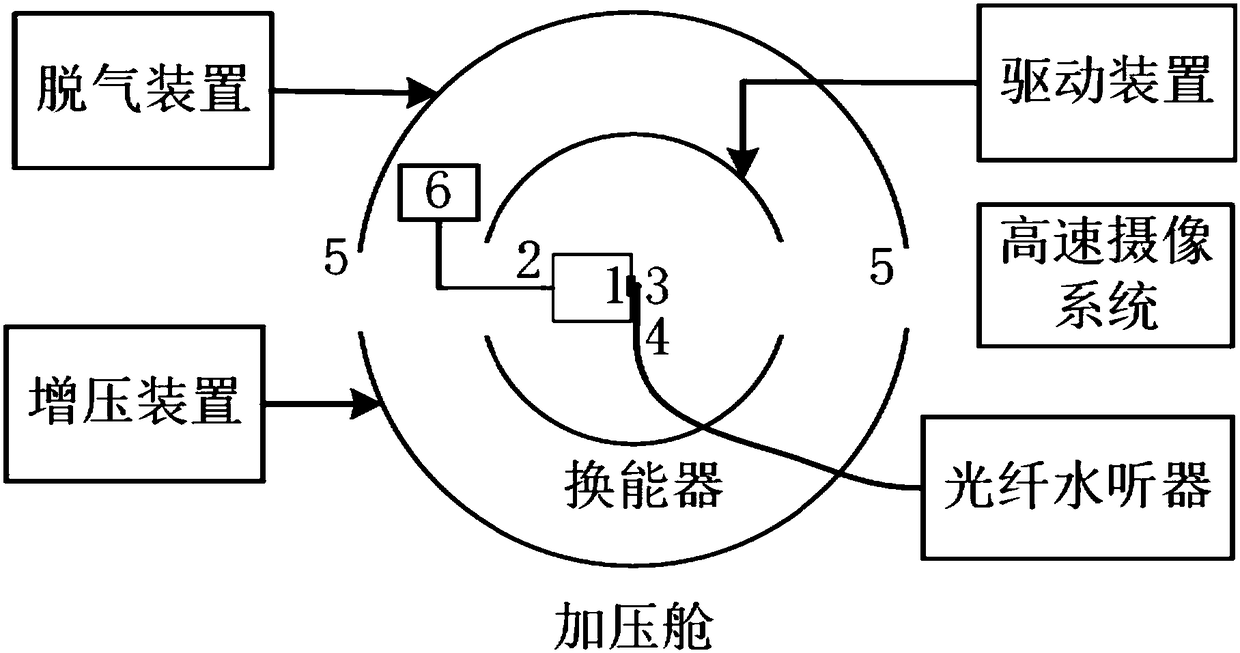

[0047] The operation steps of this embodiment are as follows:

[0048] 1) Prepare degassed water, inject water into the pressurized cabin and remove air bubbles on the inner surface of the ultrasonic transducer;

[0049] 2) Cut copper and nickel into Ф10mm×1mm thin slice samples (the sample is a cylinder with a diameter of 10mm and a thickness of 1mm) by EDM technology, and firstly use 3000-mesh sandpaper to hand-grind the criss-cross to the naked eye Recognizable smoothness, and then surface polishing in the corresponding electrolyte of copper and aluminum;

[0050] 3) Fix the polished copper sheet and nickel sheet on the tooling, expose the end of the optical fiber and stick it parallel to the surface of the sample, then put the tooling horizontally into the ultrasonic transducer, close the pressurized chamber, and fill it with water;

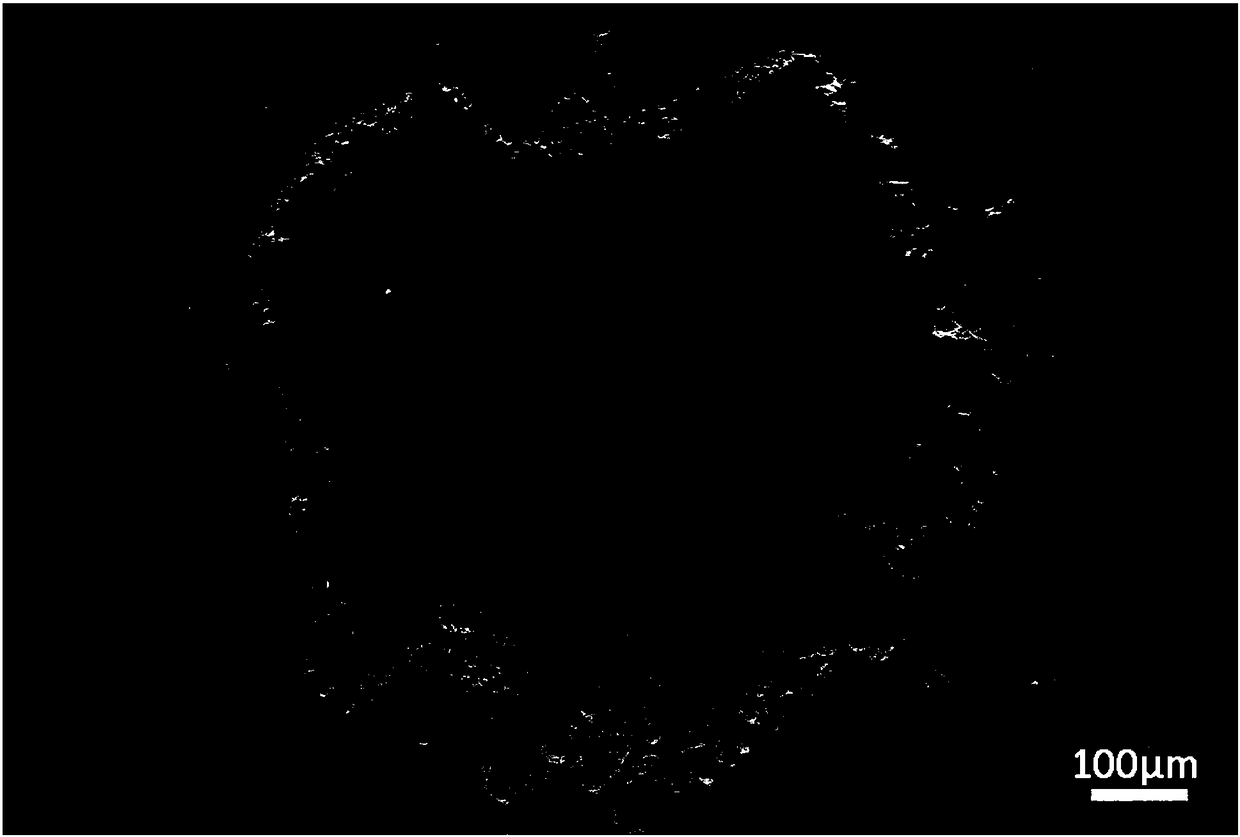

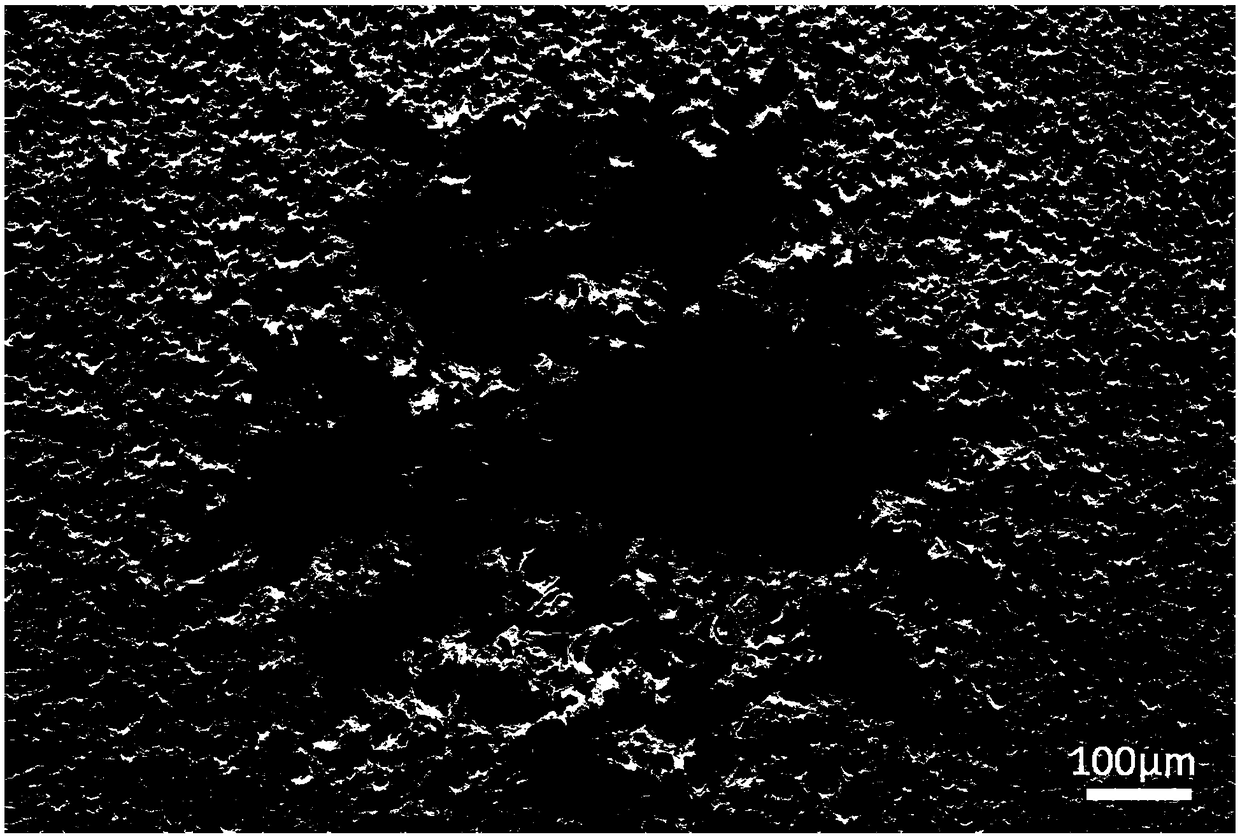

[0051]4) Start the driving device of the transducer, connect the high-speed camera system (the shooting frame rate is 3000fps, and the imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com