Method for in-situ enhancement of high-temperature oxidation resistance of Cu-Cr-Zr alloy

A high-temperature oxidation resistance, copper-chromium-zirconium technology, which is applied in the field of in-situ enhancement of high-temperature oxidation resistance of copper-chromium-zirconium alloys, can solve the problems of no high-temperature oxidation resistance and high-temperature oxidation, and achieve the effect of optimizing high-temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings.

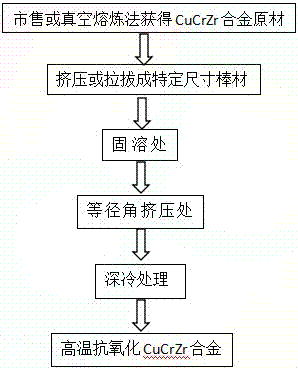

[0028] Such as figure 1 As shown, an in-situ method for enhancing the high-temperature oxidation resistance of a copper-chromium-zirconium alloy includes:

[0029] The copper-chromium-zirconium alloy after solid solution is subjected to equal channel angular extrusion treatment, and a large number of dislocation defects are formed in the alloy material, and these defects are used as nucleation points for the precipitation of the second phase particles during the subsequent cryogenic treatment. Facilitate the dispersion distribution of precipitated phases;

[0030] During the cryogenic treatment, the thermodynamic conditions of the precipitation process are adjusted to make the dislocation defect as the nucleation point to reduce the nucleation activation energy;

[0031] During the cryogenic treatment, the kinetic conditions of the precipitation process are adjusted to control the increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com