High-nickel eutectic high-entropy alloy powder for additive manufacturing and preparation method of high-nickel eutectic high-entropy alloy powder

A high-entropy alloy and additive manufacturing technology, which is applied in the coating process and coating of metal materials, can solve the problems of low plasticity and high-temperature strength, reduce surface oxidation, uniform and stable melting point, and reduce microscopic The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

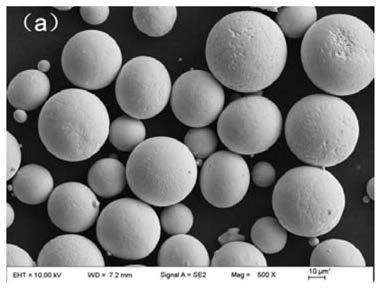

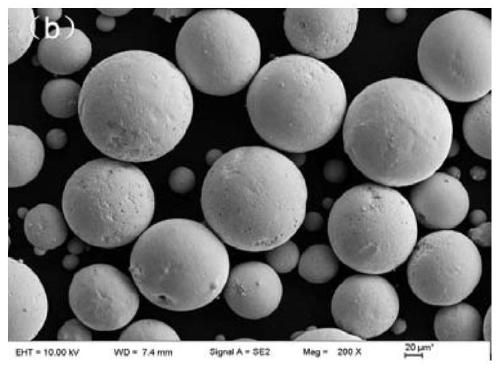

[0025] Taking the preparation of Al0.5CrFeCoNi2.1Si0.02B0.03 high nickel eutectic high entropy alloy powder as an example, the process flow is as follows figure 1 The specific operation process is as follows:

[0026] The weight of the metal element or intermediate alloy of each alloy element will be calculated according to the molar ratio of Al0.5CrFeCoNi2.1Si0.02B0.03 high-nickel eutectic high-entropy alloy, wherein the weight of aluminum is calculated according to the molar ratio of 0.51, and the weight of silicon and boron is calculated according to 0.021 Calculate the weight with the molar ratio of 0.032; put the weighed metal element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com