Preparation method of shape-controllable ordered layer porous chromium carbide skeleton carbon material for supercapacitor

A supercapacitor, chromium carbide technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, hybrid capacitor electrodes, etc., can solve the problem of irregular morphology, single carbide skeleton carbon microporous structure, etc. problems, to achieve the effect of being beneficial to storage, promoting rapid transmission, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve 3.48g SDBS in 15mL deionized water, add 60mL to a concentration of 2mol L -1 hydrochloric acid, stir well at 35°C, then add 0.2mL·s -1 Add 10mL tetrakis(1-methylethyl)silicate and 1mL acetic acid to form a homogeneous solution at the speed of The obtained product was filtered, washed with deionized water, dried at 100° C., and finally calcined at 550° C. for 24 hours to obtain a white mesoporous silicon powder.

[0033] Dissolve 1 g of chromium acetylacetonate, 2 g of glucose and 0.15 g of citric acid in an ethanol solution, add 1.5 g of mesoporous silicon white powder, and place the mixture at 150° C. for 24 h to obtain a yellow or brown powder. Place the yellow or brown powder in an Ar atmosphere, react with HCl gas at 800°C for 5 hours, and then pass Ar gas at this temperature for 5 hours to obtain a gray powder. Soak the gray powder in hydrofluoric acid for more than 24 hours, wash with deionized water, filter with suction, and dry at 100°C to obtain chro...

Embodiment 2

[0035] Dissolve 58g of P123 in 435mL of deionized water, add 1725mL to a concentration of 2mol L -1 of hydrochloric acid, stirred evenly at 35°C, and then with 0.5mL·s -1 Add 133mL tetraethyl orthosilicate and 72.5mL acetic acid to form a homogeneous solution at the speed of Wash with deionized water, dry at 100°C, and finally calcined at 550°C for 24 hours to obtain white mesoporous silicon powder.

[0036] Dissolve 25g of chromium acetate, 25g of furfuryl alcohol and 3g of p-toluenesulfonic acid in an ethanol solution, add 40g of mesoporous silicon white powder, and place the mixture at 80°C for 12h to obtain a yellow or brown powder. The yellow or brown powder was placed in an Ar atmosphere, and at 700 ° C with Cl 2 The gas was reacted for 3 hours, and then held at this temperature for 1.5 hours with Ar gas to obtain a gray powder. Soak the gray powder in hydrofluoric acid for more than 24 hours, wash with deionized water, filter with suction, and dry at 100°C to obtain ...

Embodiment 3

[0038] Dissolve 0.58g P123 in 9mL deionized water, add 6mL to a concentration of 5mol L -1 hydrochloric acid, stirred evenly at 35°C, and then with 1mL·s -1 Add 1.4mL tetraethyl orthosilicate at a high speed, add 0.45mL acetic acid to form a homogeneous solution, stir the mixed solution at 40°C for 24h, then stir in a polytetrafluoroethylene container at 100°C for 36h, filter the obtained product, Wash with deionized water, dry at 100°C, and finally calcined at 550°C for 24 hours to obtain a white powder of mesoporous silicon.

[0039] Dissolve 1.45g of chromium acetate, 0.29g of furfuryl alcohol and 0.023g of p-toluenesulfonic acid in ethanol solution, add 2.9g of mesoporous silicon white powder, and place the mixture at 80°C for 12h to obtain a yellow or brown powder. The yellow or brown powder was placed in an Ar atmosphere, and at 900°C with Cl 2 The gas was reacted for 3 hours, and then kept at this temperature for 3 hours, and then kept for 2 hours in an argon-hydrogen...

PUM

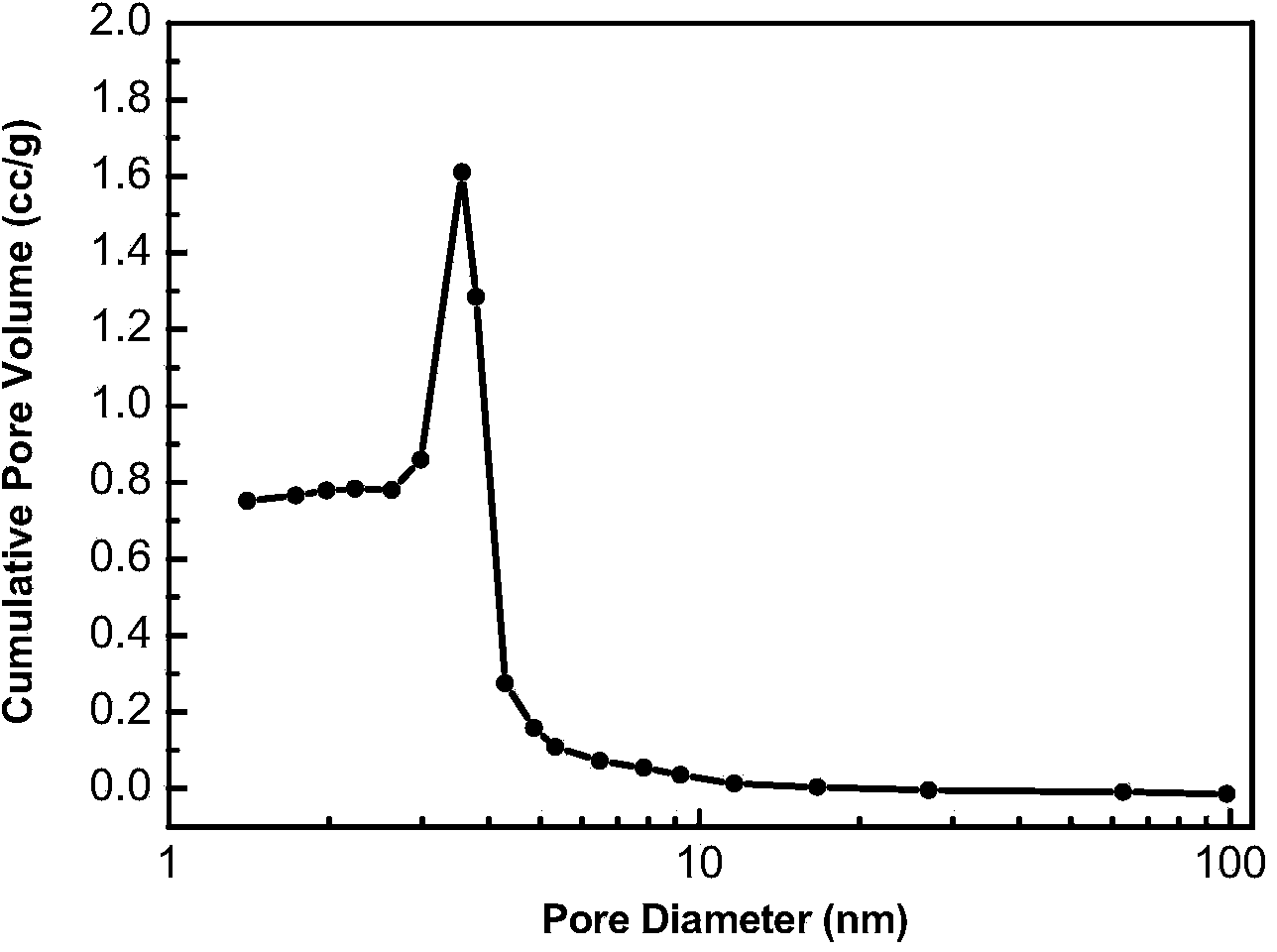

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com