Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122results about How to "Reduced wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

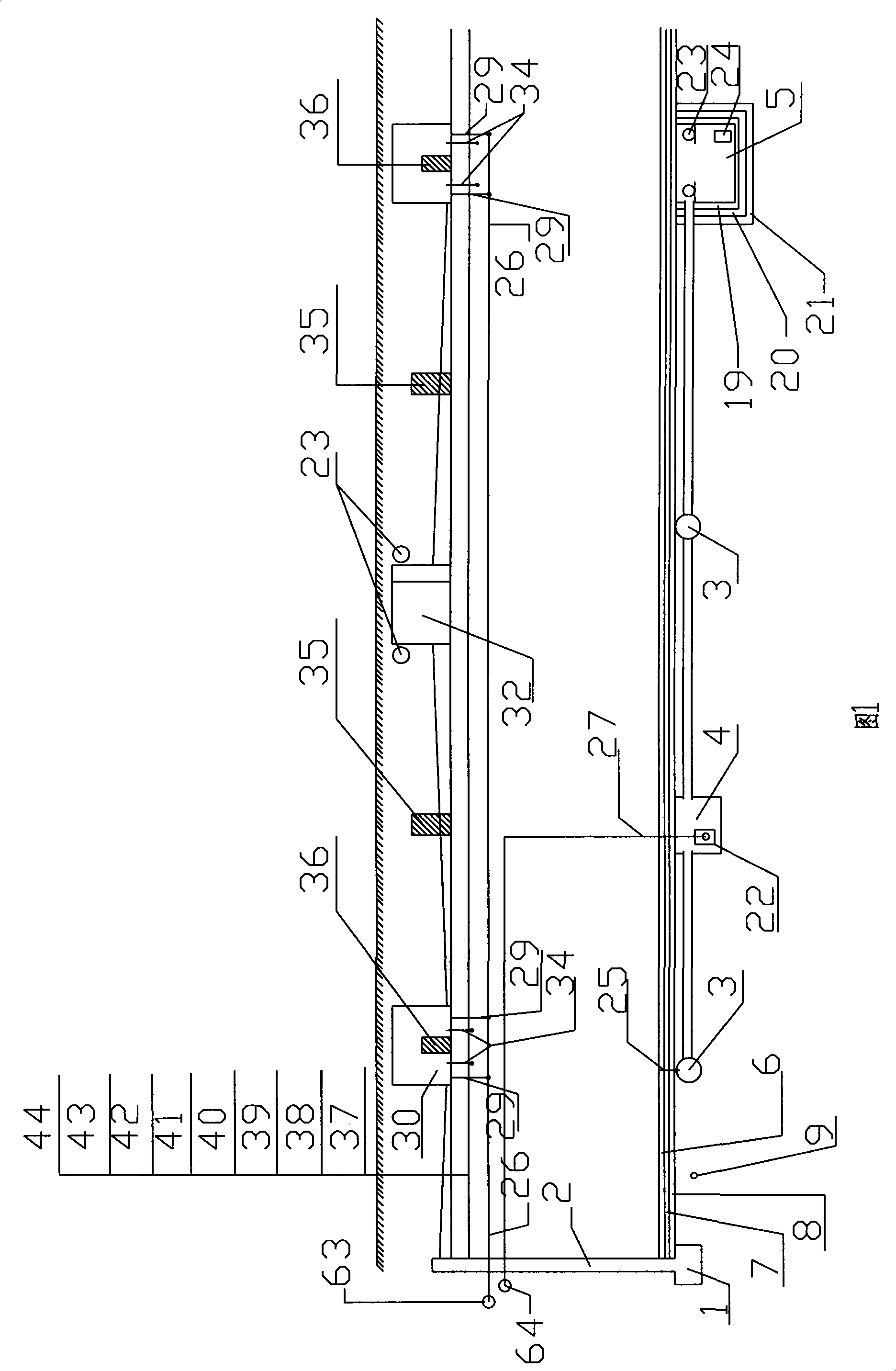

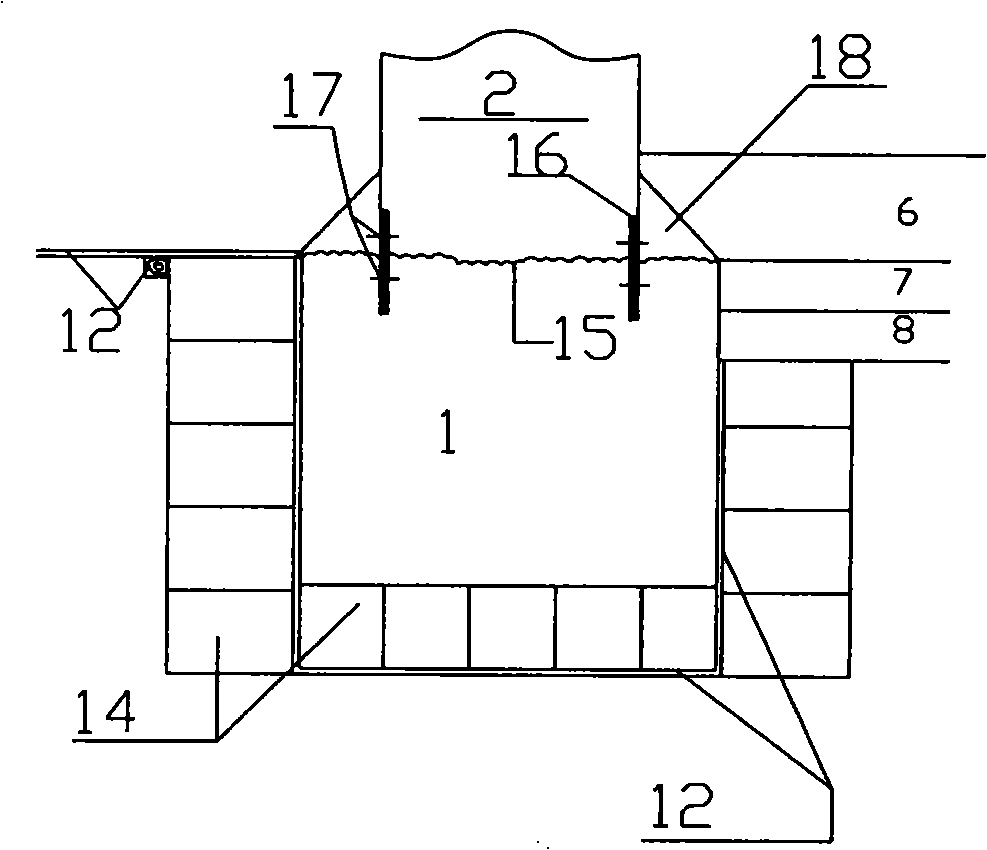

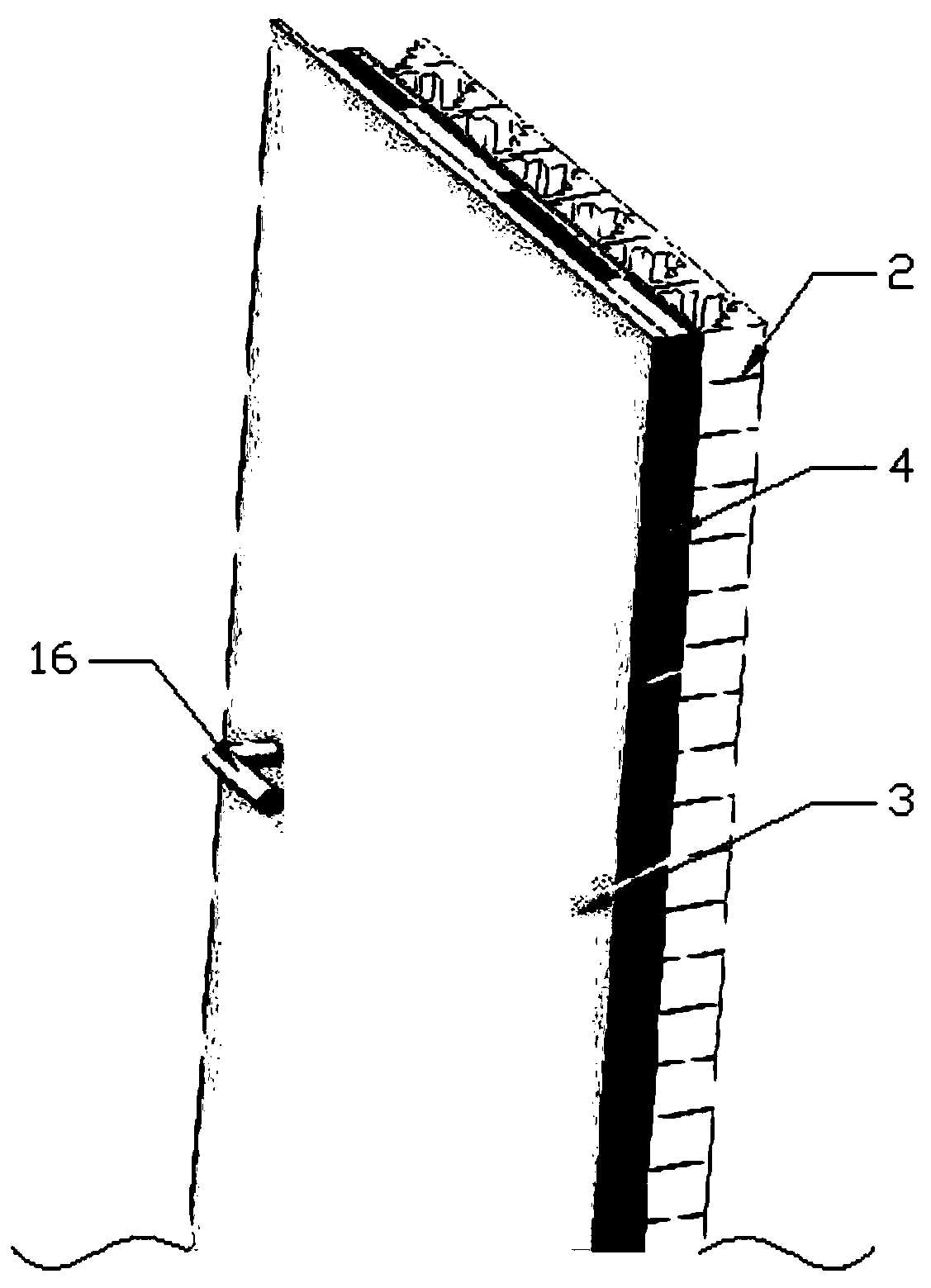

Method and system for basement engineering water proof and water drain

InactiveCN101298782AFree from buoyancyFrom erosionArtificial islandsProtective foundationBasementLine tubing

A basement engineering waterproof and drainage method is provided. The wall footing of the outside wall in basement engineering is embedded in watertight or micro-watertight soil rock layer or cement soil layer. The wall footing intercepts water by a thin-part structure. The cushion of the basement engineering soleplate and the falling layer of the top board are composed of combined water-proof layers. The late poured band, the movement joint and the horizontal construction joint at the lower part of the outside wall are treated by a water-proof structure combined with waterproofing measures. The basement engineering is provided with a drainage system. The groundwater and surface water at the soleplate are drained into city drainage pipelines via a soleplate part of the drainage system. The rainwater of overburden layer bottom of the top board is then drained into city drainage pipelines via the indoor part of the drainage system. The invention is designed by adopting a one-body method of arranging the basement engineering waterproofing, drainage and anti-floating as well as underground engineering space enclosing structure and pipelines, thereby shortening the construction period, reducing the engineering cost, increasing the durability and reliability of underground building space enclosing structure and waterproof layer as well as pipelines.

Owner:朱邃科 +2

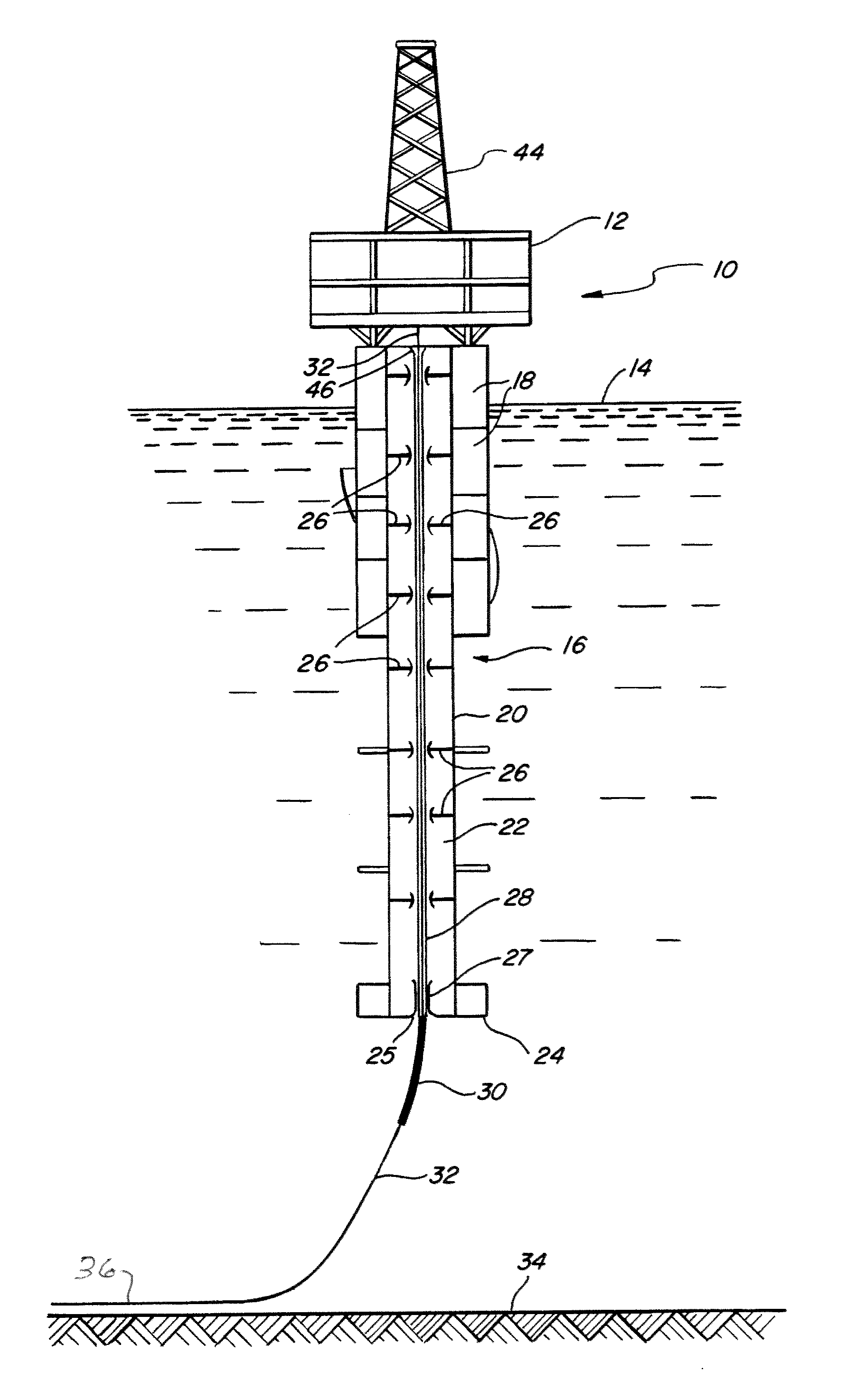

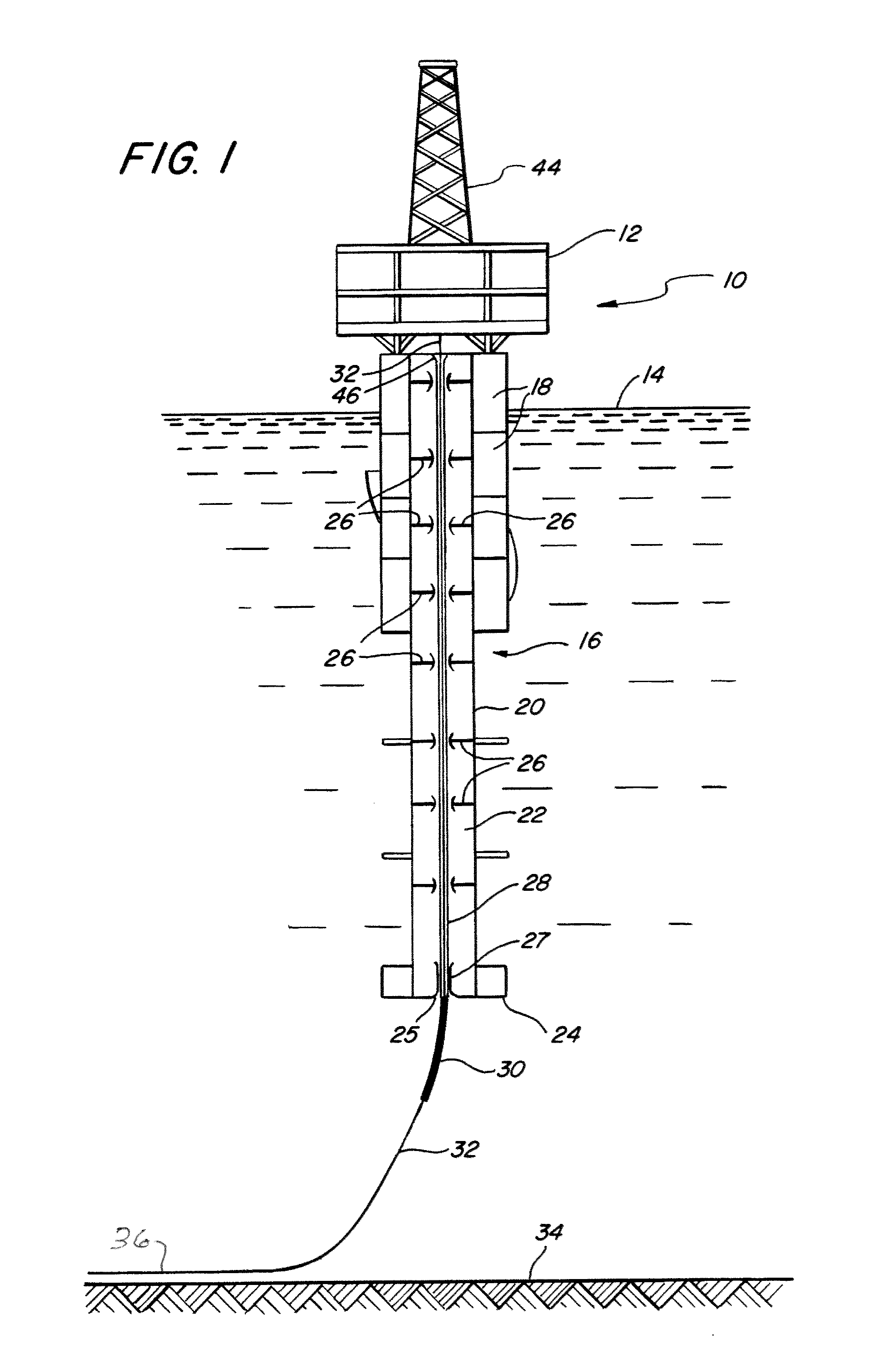

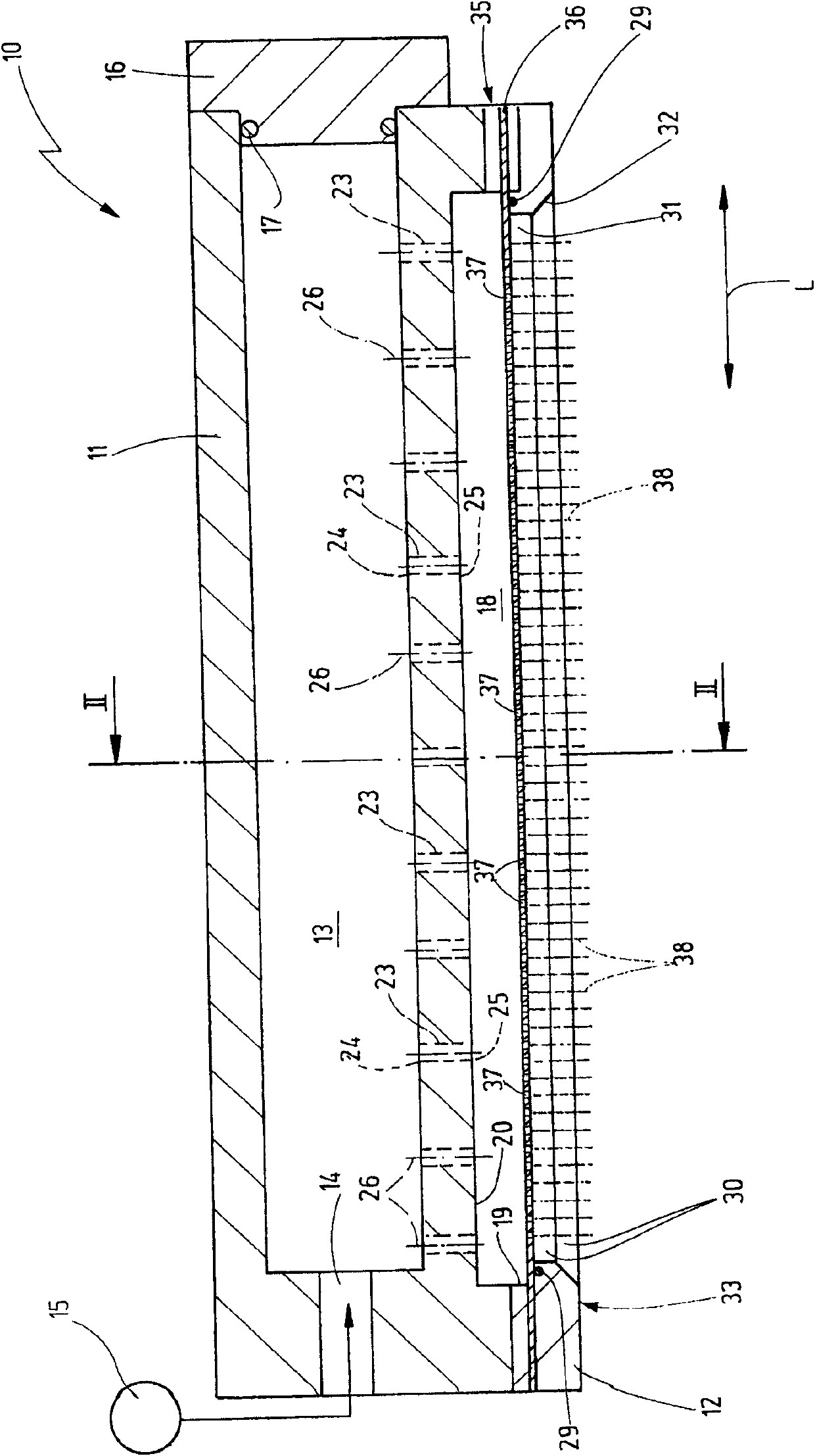

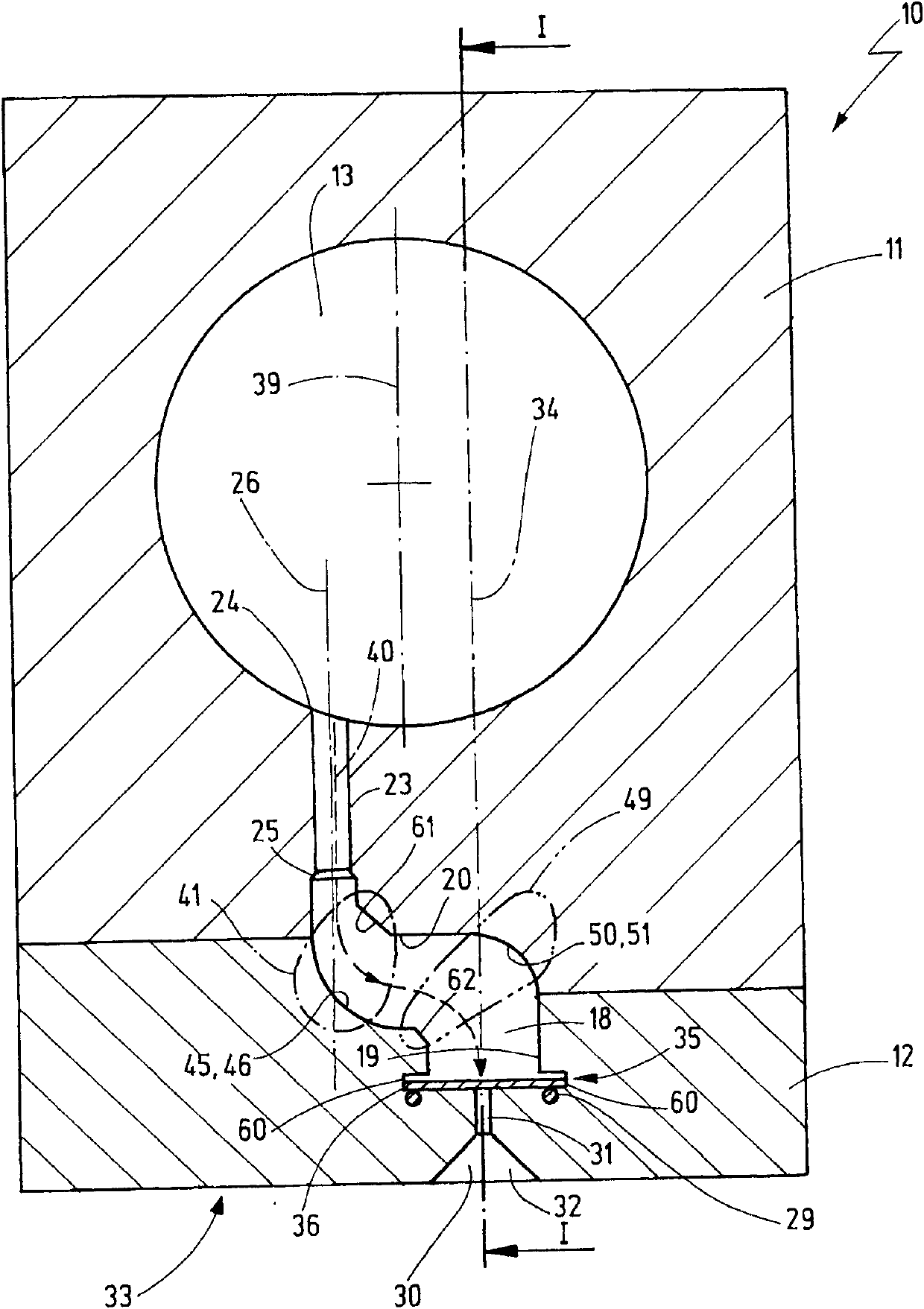

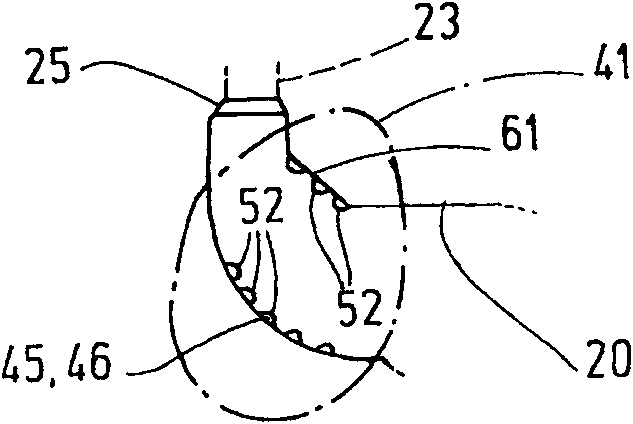

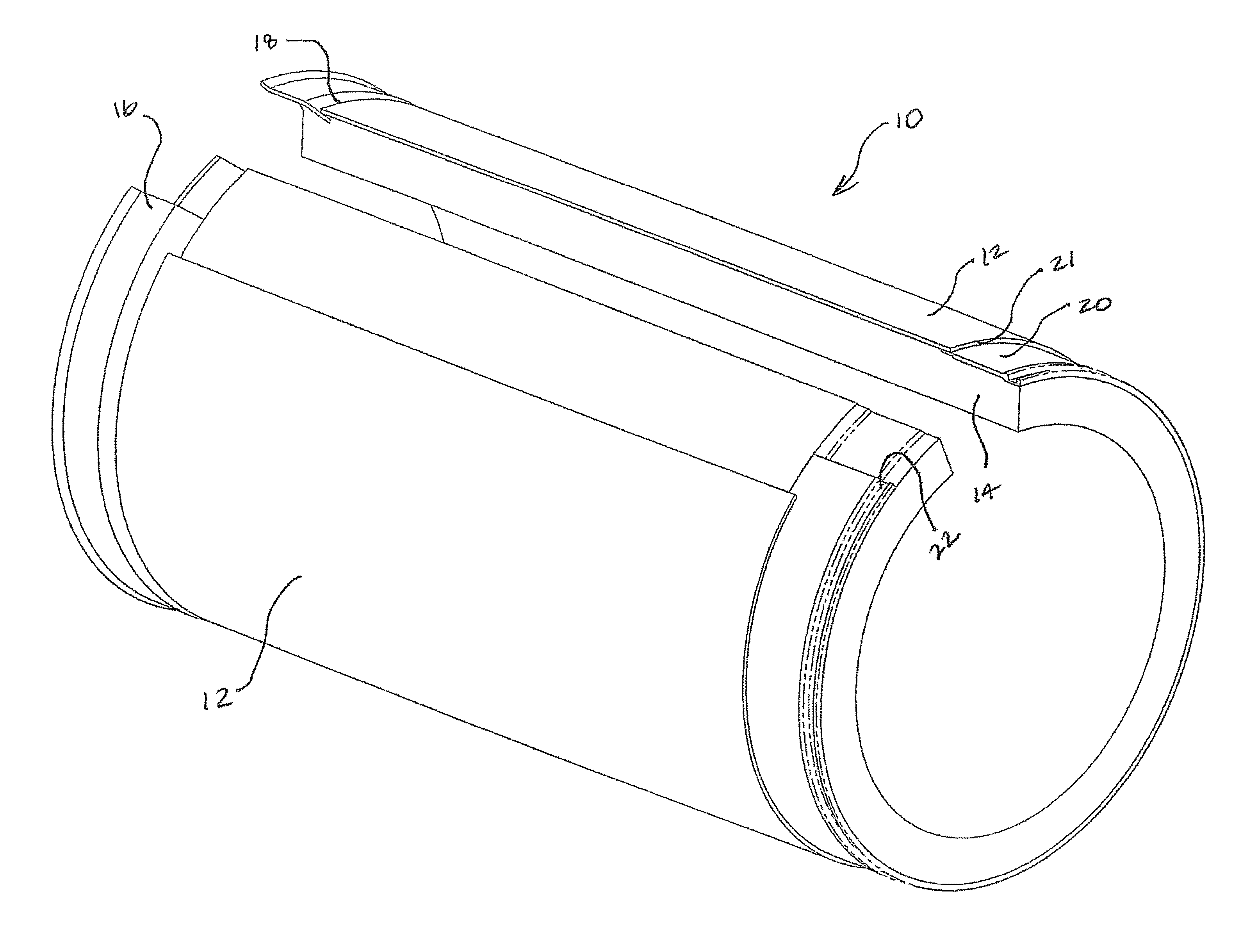

Control of flexible riser curvature at the keel of a floating structure

ActiveUS20080044233A1Reduction in pipe wall thicknessReduce outside diameterPipe laying and repairDrilling rodsGradual transitionEngineering

A bend-limiting conduit controls the curvature of a catenary riser extending from the seafloor as it enters the centerwell of a spar-type offshore platform through the keel of the platform. The conduit has a bore dimensioned to receive the riser, and it extends from an upper end constrained within the keel to a lower end disposed below the keel. The conduit has increasing flexibility and weight per unit length from the upper end to the lower end, which results in a lateral load being applied to the riser as it passes through the conduit, thereby causing a gentle and gradual transition in the riser from a curved configuration at the lower end of the conduit, to a straight configuration as it emerges from the upper end of the conduit.

Owner:TECH FRANCE SA

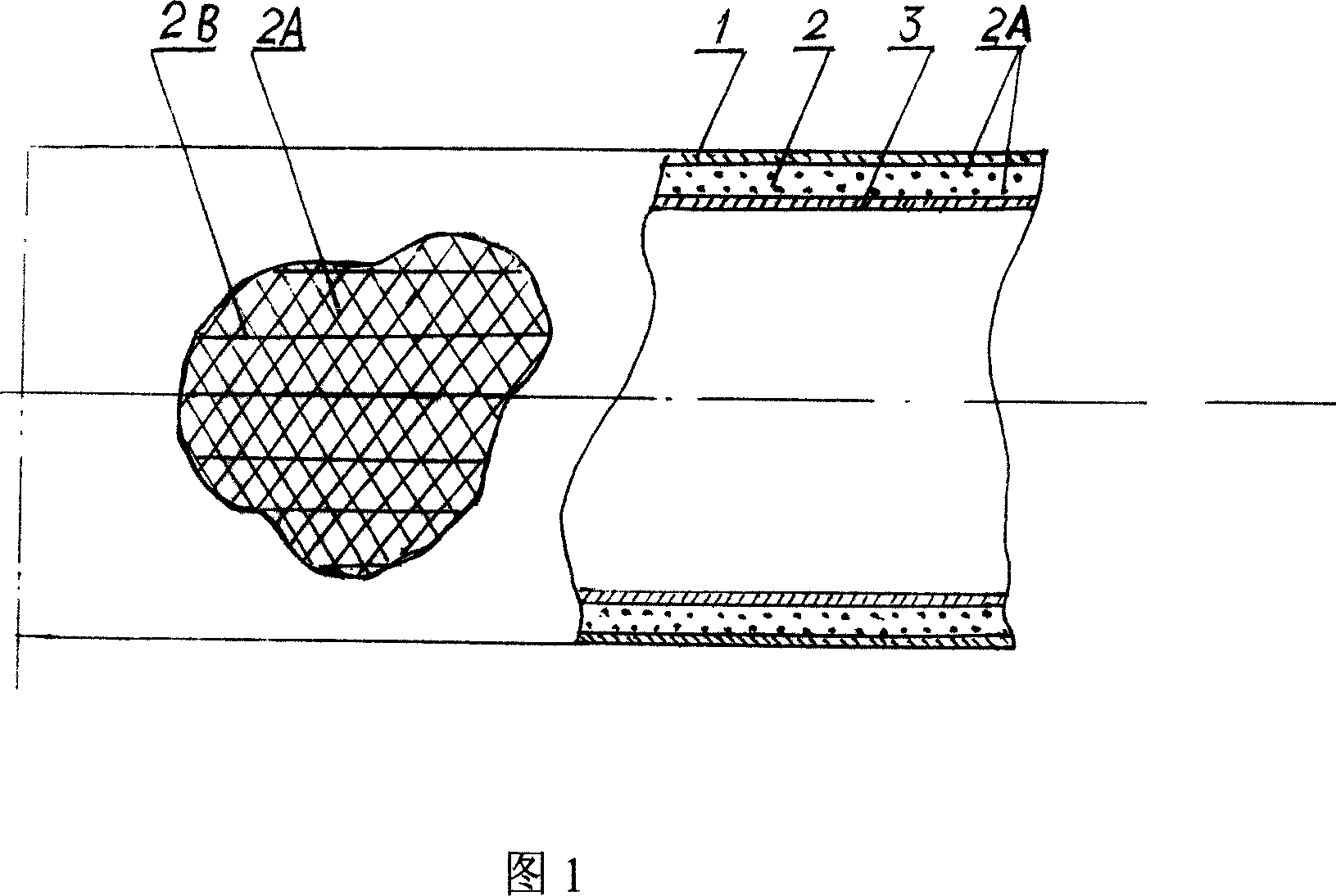

Antistatic flame-proof light high-intensity resin steel mesh composite tube and production technique

ActiveCN101012901AImprove corrosion resistanceImprove aging performanceNon-macromolecular adhesive additivesRigid pipesFiberAntistatic agent

The invention relates to an anti-static fireproof light high-strength resin steel network composite tube and relative production. The tube comprises three layers as the liner layer with anti-leakage or abrasion-resistant function, a strength layer coiled by strength fiber and added steel base material, and a surface layer coiled with dense fiber at the face. The invention is characterized in that: 1, the composite adhesive solidifier of liner layer (1) is added with 5-10 deals of glass scales and / or 5-15 deals of graphite scales; 2, each 100 deals of resin of composite adhesive solidifier is added with 0.5-5 deals of antioxidant; 3, each 100 deals of resin of composite adhesive solidifier is added with 2-10 deals of short tangent fiber to form slurry composite adhesive solidifier coiled with the mesh steel wire to form the strength layer.

Owner:TANGSHAN JIAJI COMPOSITE PIPE CORP

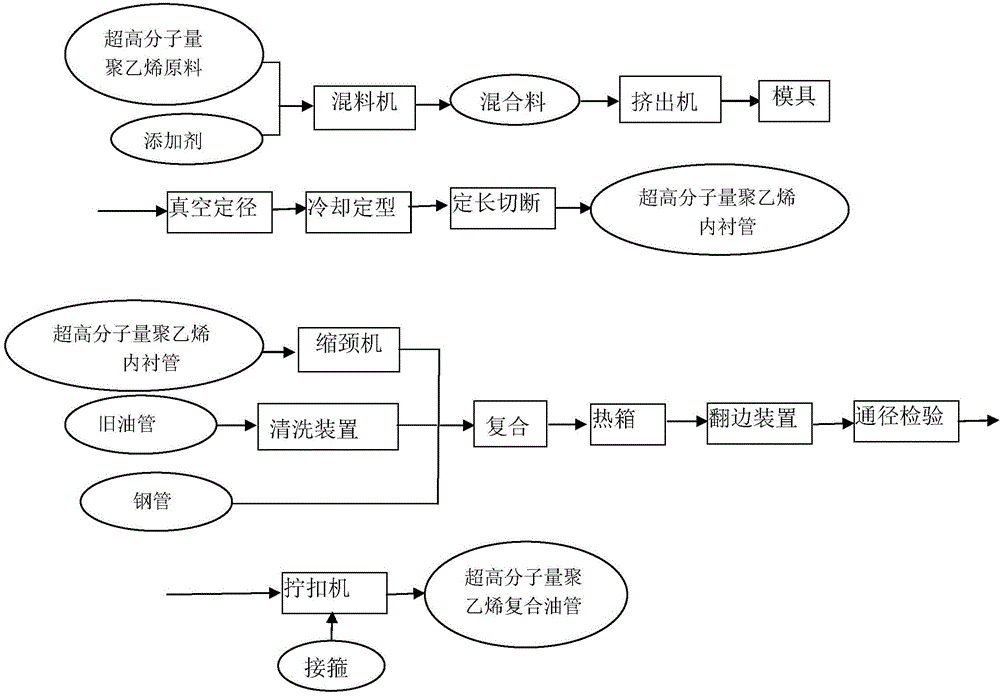

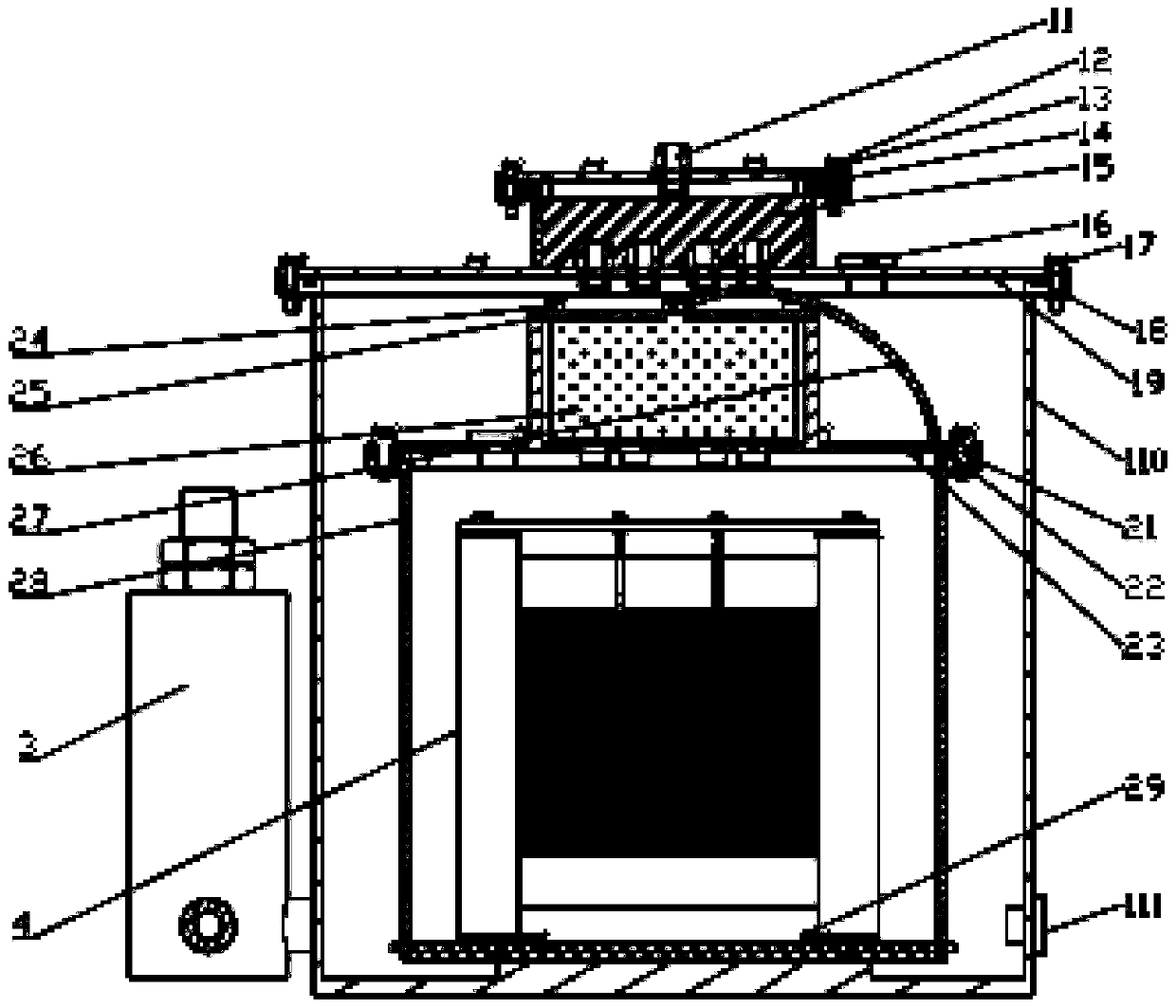

Production method and production system of ultrahigh molecular weight polyethylene compound oil pipe

ActiveCN103600503AImprove liquidityReduced wall thicknessTubular articlesTemperature resistanceWear resistance

The invention discloses a production method and a production system of an ultrahigh molecular weight polyethylene compound oil pipe. The method utilizes the memory property of the ultrahigh molecular weight polyethylene material and a special composite technology: conducting hole shrinkage treatment on an ultrahigh molecular weight polyethylene lining pipe with outer diameter larger than the inner diameter of a steel pipe, sheathing in the steel pipe, heating to restore inner diameter of the ultrahigh molecular weight polyethylene lining pipe, and forming the lining pipe with the steel pipe into an integral structure to reach a compactness and firmness without layering and stripping. By introducing additives, the invention greatly improves liquidity of the ultrahigh molecular weight polyethylene in order to produce the inner lining pipe with small wall thickness and reduce cost. The ultrahigh molecular weight polyethylene compound oil pipe provided by the invention comprehensively reserves specific superior performances of good memory property, high impact resistance, good temperature resistance, wear resistance, corrosion resistance, wax precipitation and fouling resistance of ultrahigh molecular weight polyethylene pipe. The invention also discloses a production system supporting the production method.

Owner:王庆昭

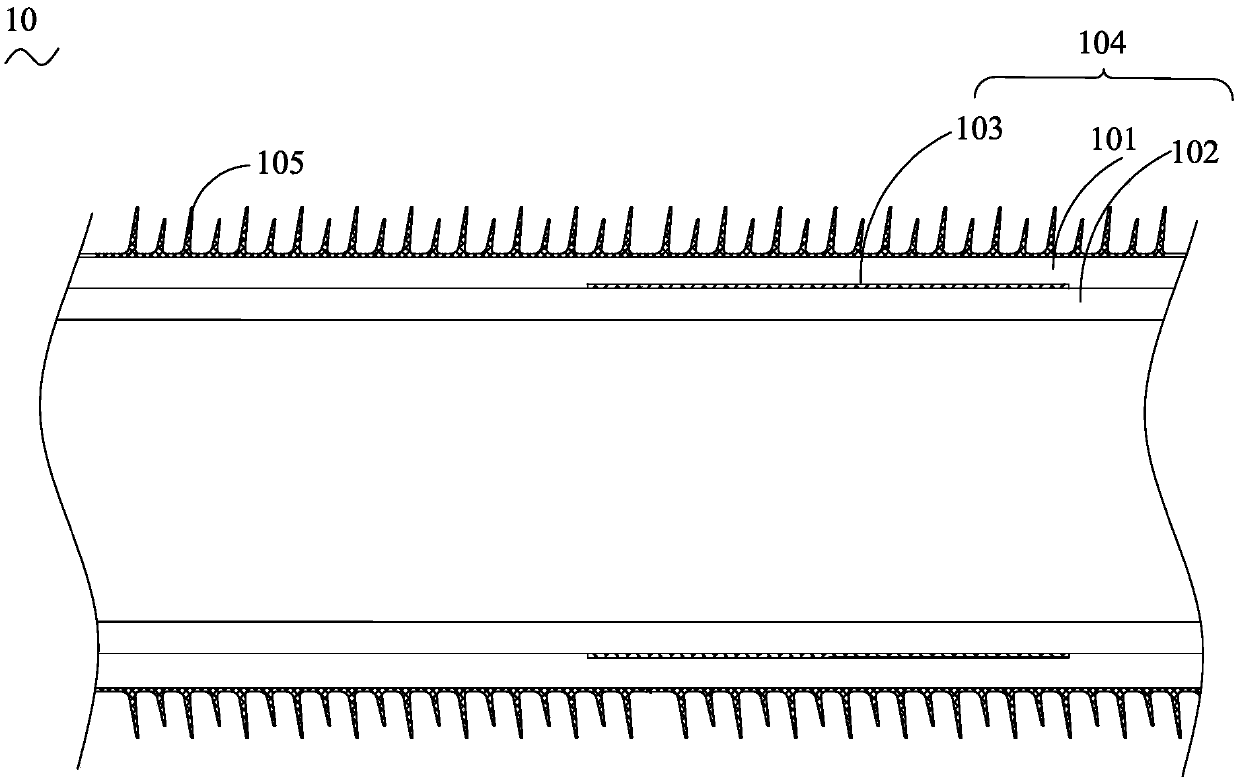

Injector for textile processing machine

InactiveCN102021752AReduced wall thicknessAvoid quality problemsSpray nozzlesNeedling machinesSpray nozzleTextile processing

The invention relates to an injector for a textile processing machine, particularly to an injector for a textile processing machine for making napping textile materials. An inflow chamber is arranged in an injector main body for acquiring a pressing medium from the inflow chamber, wherein the inflow chamber is connected to the fluid in a pressure distribution chamber through a plurality of connecting pipes; a cylindrical opening arranged in the injector main body represents a connecting channel; the channels are arranged in one or two rows so as to shift away from a longitudinal central plane of the inflow chamber; the pressure distribution chamber adjoined with the connecting pipe comprises a first wall section for forming a first declination surface; the declination surface is at least diagonally or transversely extended relative to a longitudinal axis of the connecting pipes in a plurality of sections; the medium flowed from the connecting pipe declines through the first declination surface; a water injected flow is formed through a nozzle opening; and the water injected flow is injected by an outflow opening through the injector.

Owner:GROZ BECKERT KG

Epoxy sizing composition for filament winding

InactiveUS20060036003A1Good dispersionWet tensile strength performanceThin material handlingEpoxy resin coatingsEpoxySilanes

A sizing composition containing an epoxy film former, a silane package that includes an aminosilane coupling agent and an epoxy silane coupling agent, a cationic lubricant, a non-ionic lubricant, an antistatic agent, and at least one acid is provided. The epoxy resin emulsion includes a low molecular weight liquid epoxy resin and one or more surfactants. The epoxy resin preferably has an epoxy equivalent weight of from about 185 to about 192. The sizing composition may optionally contain polyurethane or epoxy / polyurethane film former. The sizing composition may be used to size glass fibers used in filament winding applications to form reinforced composite articles with improved mechanical properties, wet tensile properties, improved resistance to cracking, and improved processing characteristics. The sizing composition also provides improved processing parameters such as low fuzz and reduced drag.

Owner:OCV INTELLECTUAL CAPITAL LLC

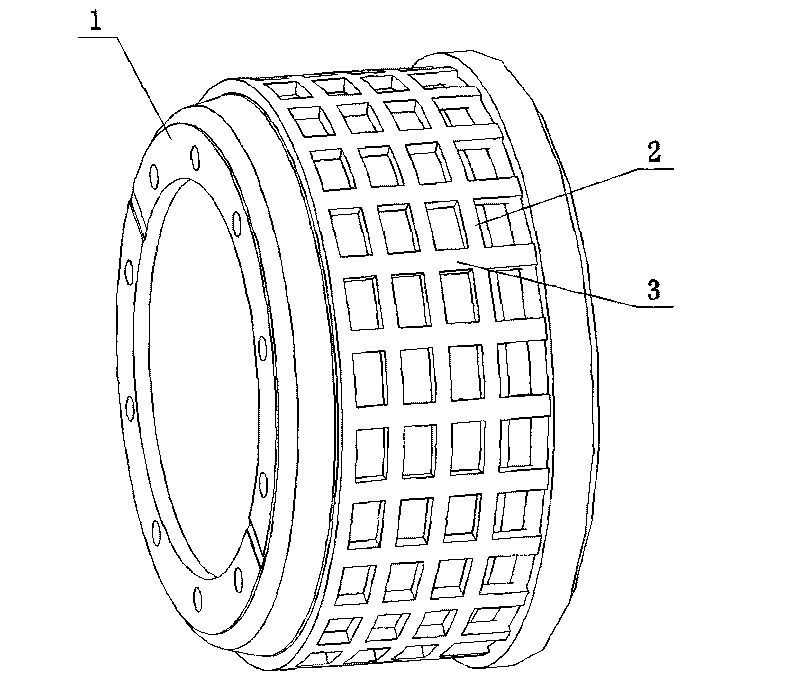

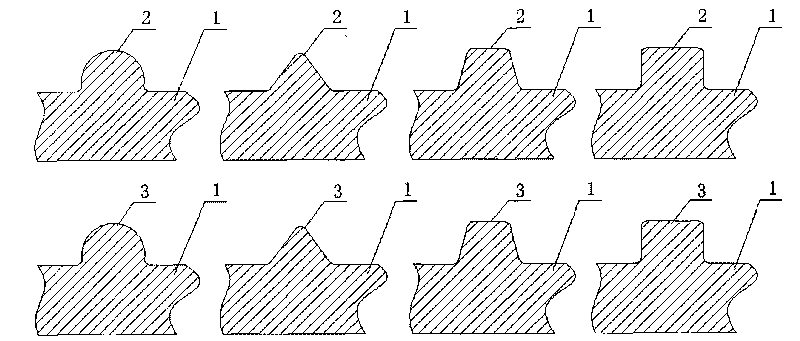

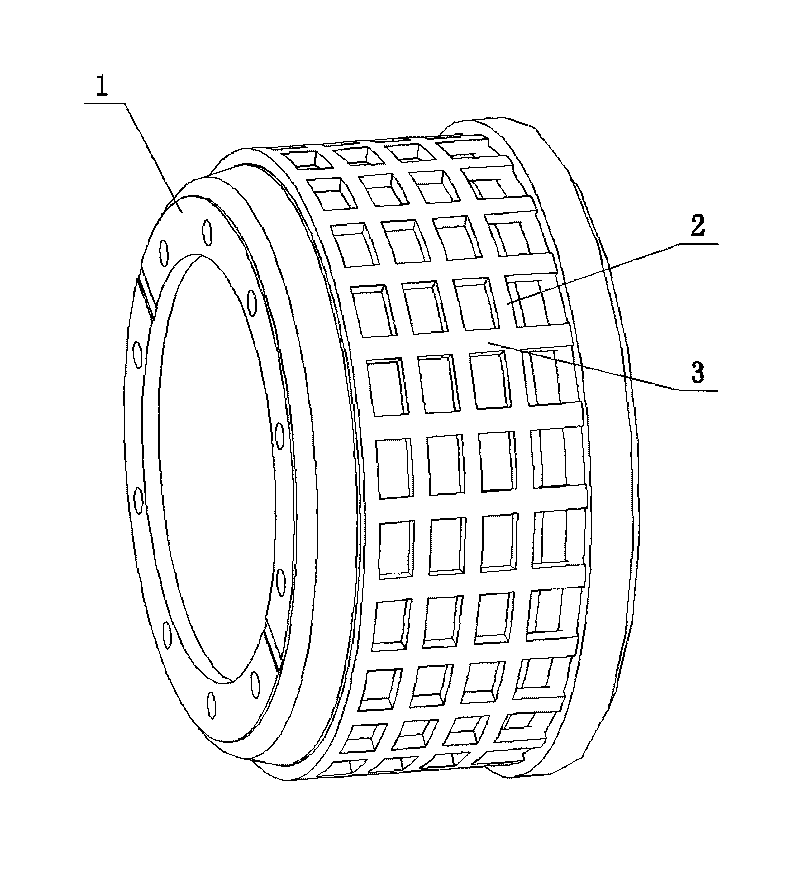

Automobile brake drum with latticed stiffeners

ActiveCN101713444AIncreased Strength and RigidityIncrease cooling areaBraking drumsDistortionAutomotive engineering

The invention discloses an automobile brake drum with latticed stiffeners, which comprises a brake drum body. The latticed stiffeners are arranged on the outer circumference surface of the brake drum body, and comprise a plurality of ring-shaped stiffeners which are perpendicular to the axes of the brake drum body and a plurality of strip stiffeners which are parallel with the axes of the brake drum body. The latticed stiffeners can obviously improve the strength of the brake drum, increase the stiffness, reduce the probabilities of the cracking and distortion of the brake drum caused by the effects of heat and brake force, maintain the good joint between a brake shoe and the brake drum, and simultaneously increase the heat radiating area of the brake drum, thereby effectively reducing the temperature of the brake drum, reducing the affect of the heat to steel rings and tyres, increasing the service lives of the brake drum, friction disks and the tyres, effectively preventing the accidents caused by the chap of the brake drum and tyre burst, and improving the driving security.

Owner:PENGLAI WANSHOU MACHINERY

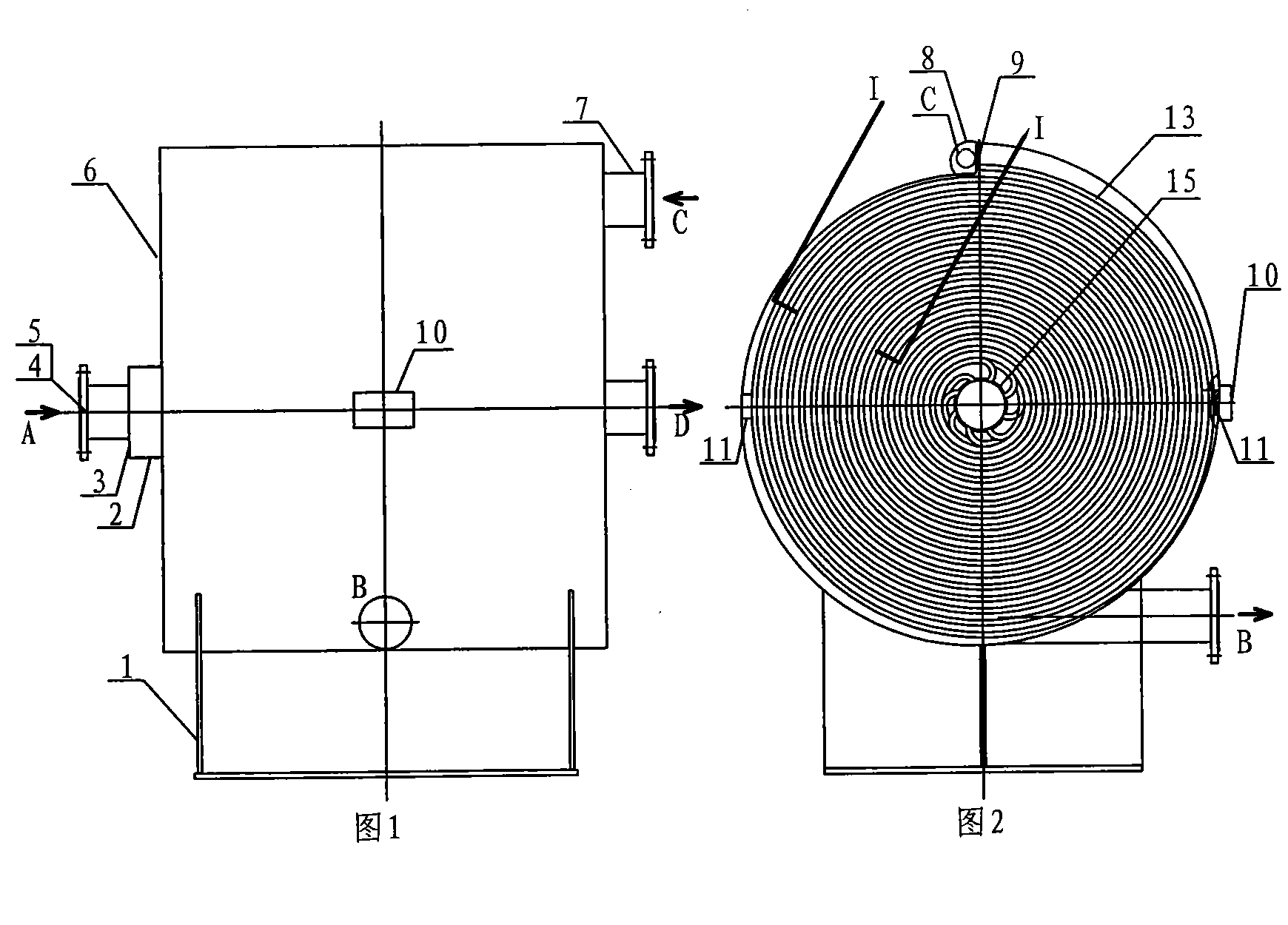

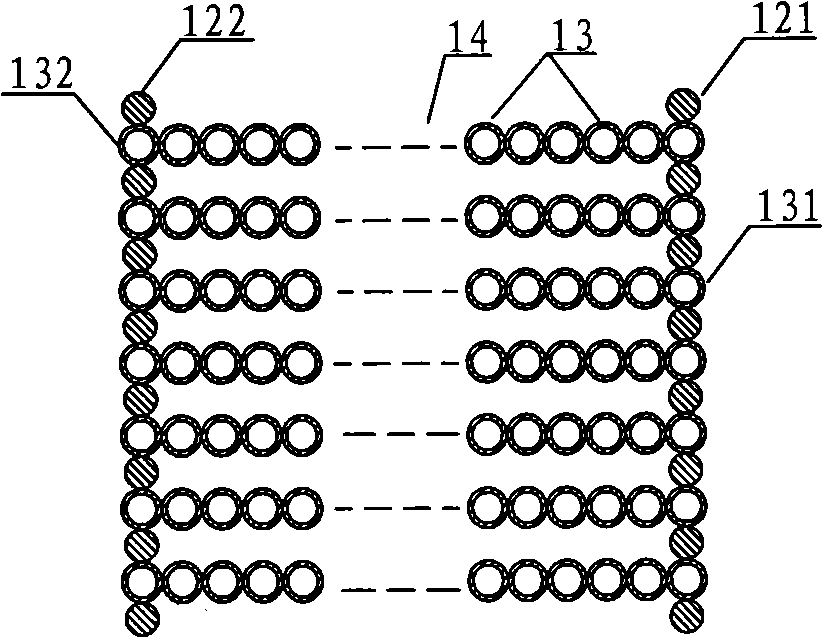

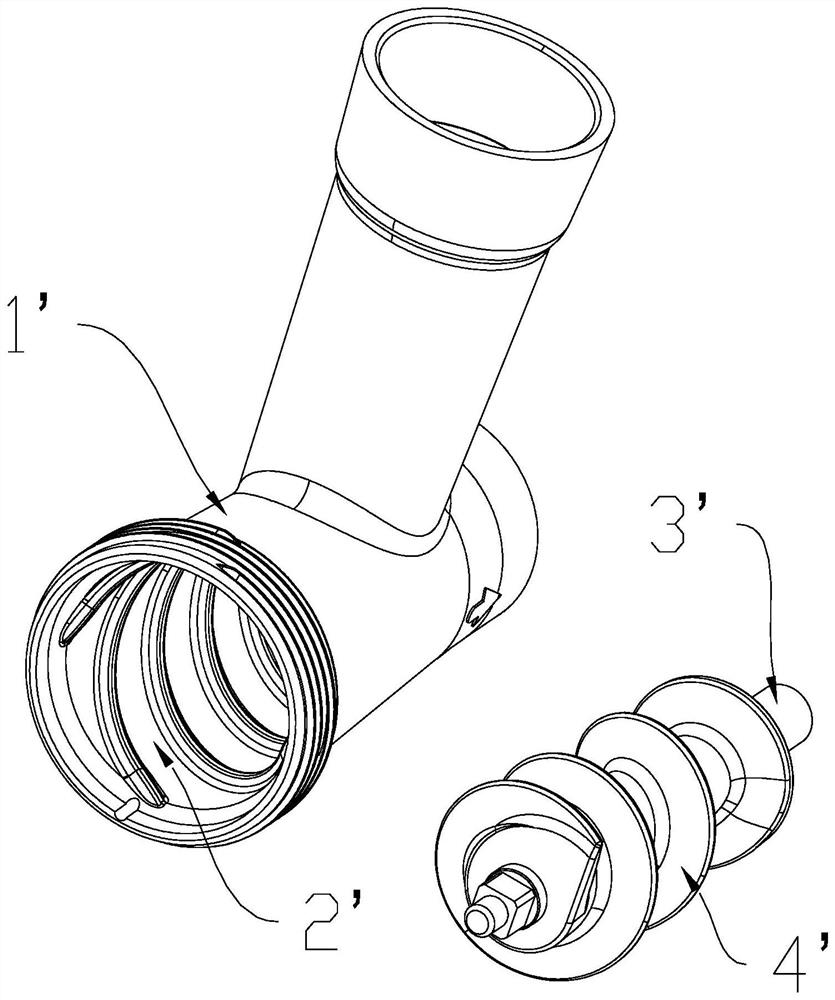

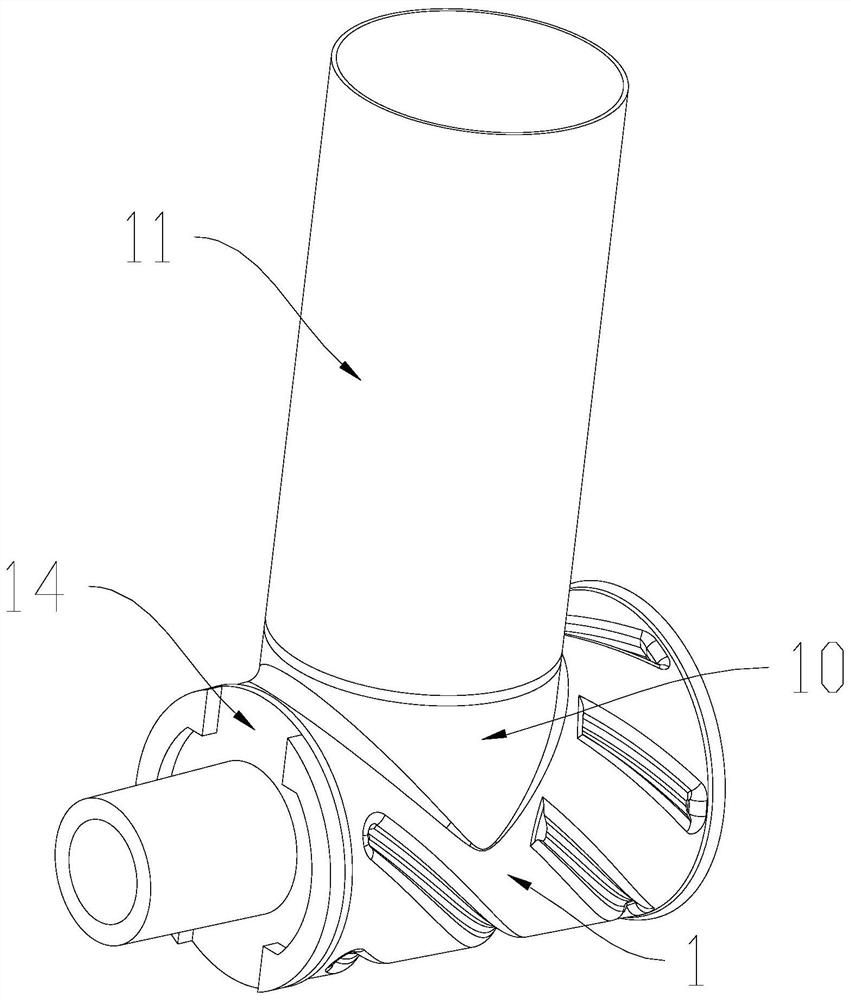

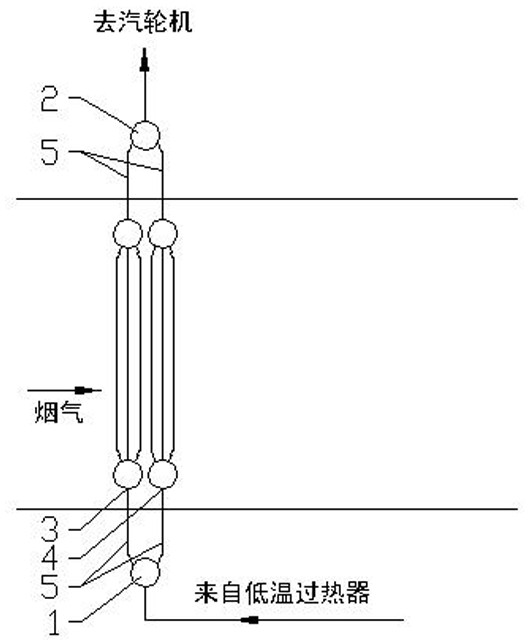

Spiral coil heat exchange device

ActiveCN101782339AImprove utilizationReduce heat transfer areaChemical industryStationary tubular conduit assembliesChemical industryCooling tower

The invention discloses a spiral coil heat exchange device, which comprises a barrel with a medium inlet, a medium outlet and a central tube. A plurality of spiral coils are arranged in parallel without clearance in the barrel and are in a spiral involute shape by taking the central tube as the axis. A spiral involute out-tube channel is formed between an outer wall of a spiral coil group and an inner wall of the barrel. A spiral involute in-tube channel is composed of the spiral coil group and the central tube; and two media perform reverse-flow heat exchange in the two independent spiral involute channels respectively. The spiral coil heat exchange device has the advantages of greatly increasing the heat exchange area, improving the heat exchange efficiency and energy utilization degree, reducing the thickness of the tube wall on the premise of not increasing the length of the pipeline, along with compact structure, small volume and light weight, high bearing capacity, good sealing effect and no streaming phenomenon. The spiral coil heat exchange device is applied to energy, petroleum, chemical industry, daily life and other fields, can be used as the heat exchange device for boilers, water heaters, cooling towers and other devices, and can be singly used for performing heat exchange between two fluids of gas and gas, liquid and liquid, and gas and liquid at different temperatures.

Owner:石家庄市石换换热环保有限公司

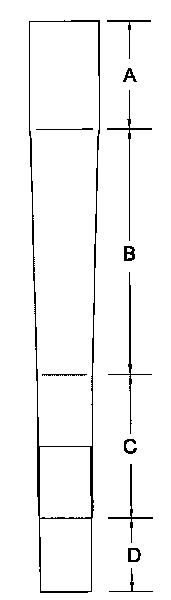

Method for manufacturing conical riser of direction column of motorcycle by adopting cold extrusion process

The invention relates to a method for manufacturing a conical riser of a direction column of a motorcycle by adopting a cold extrusion process, which comprises the steps of: firstly, performing surface decontamination derusting treatment on a straight steep pipe blank; then cold-extruding the straight steep pipe blank into a conical riser blank; and finally performing end surface chamfering, fine turning of surface bearing positions and thread rolling treatment of thread sections on the conical riser blank to obtain a finished product of the conical riser. The cold extrusion working procedure comprises the steps of: placing the straight steep pipe blank into a cold extrusion mold cavity, then starting a press to ensure that a male mold end on the press aligns with the end surface of the straight steep pipe blank, and only slowly imposing an axial pressure on the straight steep pipe blank to make the straight steep pipe blank extruded and molded into the conical riser blank in the cold extrusion mold cavity, wherein the male mold end is provided with a positioning boss matched with an inner hole of the straight steep pipe blank. The method has the advantages of needing low cost for raw materials, greatly improving the strength of a large end of the produced conical riser, and having no cracks on the large end during the production, thereby improving the qualification rate of products.

Owner:周安

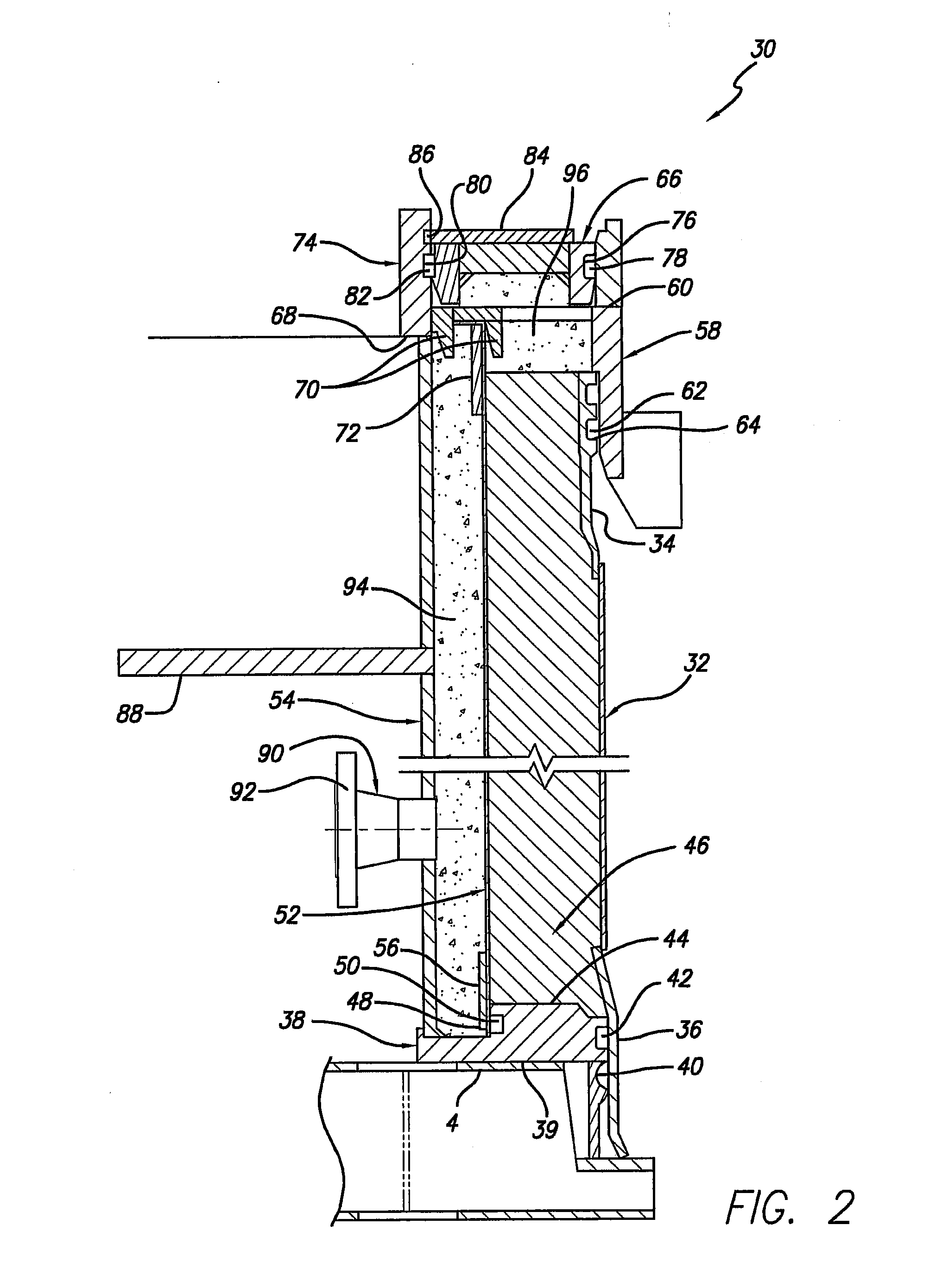

Pressure cast concrete or mortar lined steel pipes and methods of making the same

ActiveUS8069880B2Reduce the overall diameterSave raw materialsHeat exhanger conduitsLaminationMetallurgyMetal

Pressure cast lined steel pipes comprise an annular concrete or mortar liner along an inside diameter, and a metal shell surrounding the liner, wherein the liner is in direct contact with the metal shell. The wall thickness of the liner can be from 10 to 50 times the thickness of the metal shell. The pipe may be coated with a dielectric material. A mold assembly used to form the pipe includes an annular concrete or mortar composition chamber formed between the metal shell and an inner mold member. Pressurized water is used in the mold assembly to pressurize the concrete or mortar composition and exert a desired pressure force onto the metal shell while the composition cures in the mold. Once a desired degree of cure is achieved, the pressure is removed causing the metal shell to exert a desired compression force onto the cured liner.

Owner:NWPC LLC

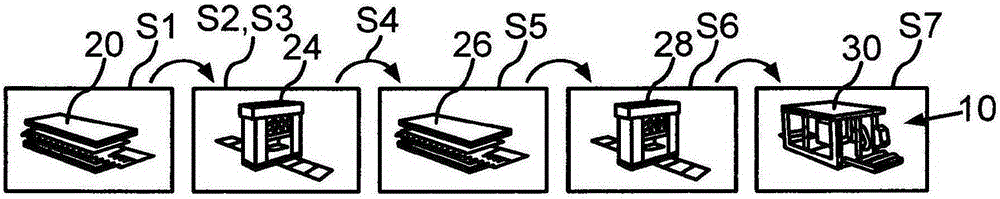

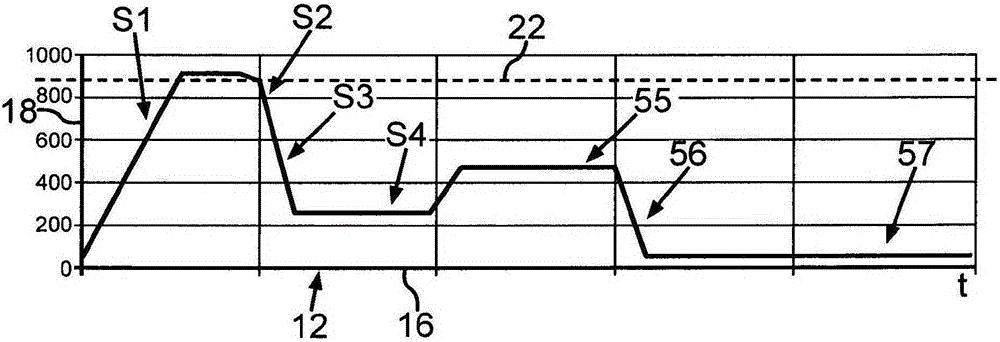

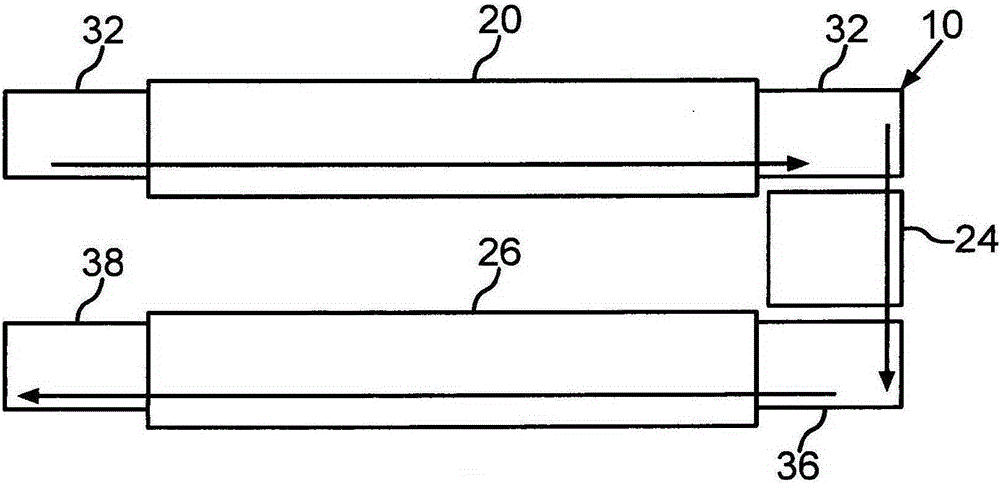

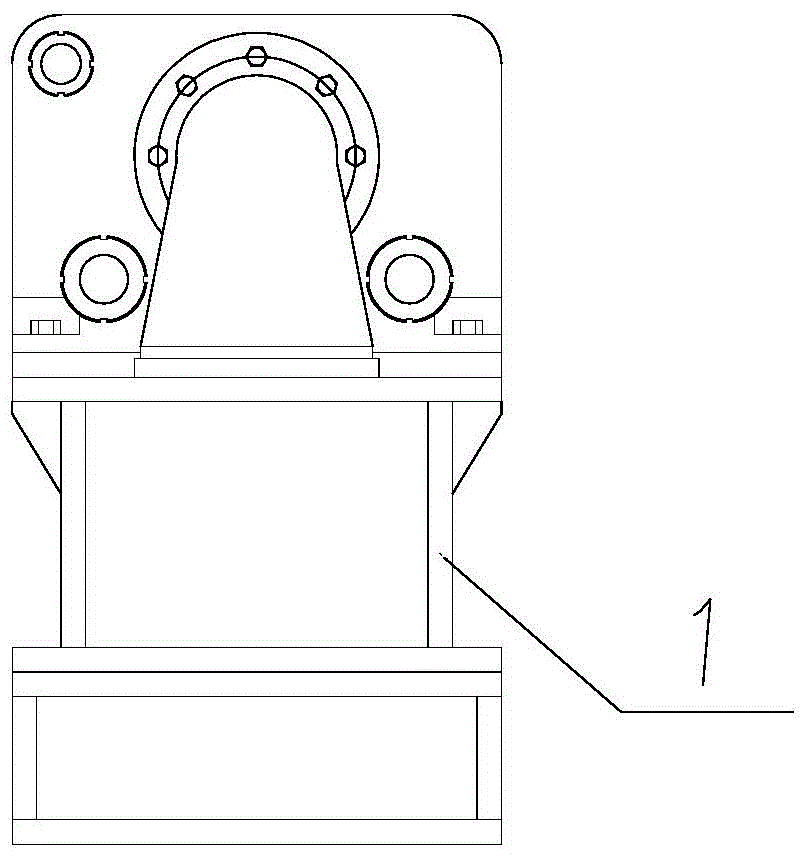

Process and installation for producing a press-hardened sheet steel component

InactiveCN105358718ATime-saving or cheap to manufactureImprove energy absorptionFurnace typesHeat treatment furnacesSheet steelTempering

The invention relates to a process and an installation for producing a press-hardened sheet steel component, comprising the steps of: a) heating (step S1) a component blank, formed from a hot-workable steel sheet, at least to the austenitizing temperature of the steel material by means of a heating device (20), b) hot working (step S2) the component blank by means of a forming tool (24), c) cooling (step S3) the component blank in the forming tool (24) to a temperature above the material-specific martensite finish temperature, preferably to a temperature of at least 200 DEG C, d) transferring (step S4) the component blank from the forming tool (24) to a heating device (26), e) tempering (step S5) the component blank while stabilizing the austenite by means of the heating device (26), wherein the component blank is transferred directly from the forming tool (24) to the heating device (26) (step S4) while avoiding cooling of the component blank to less than the material-specific martensite finish temperature, preferably less than 200 DEG C.

Owner:DAIMLER AG

Tube forming machine

InactiveCN105710233ASimple structureEasy to operateMetal-working feeding devicesStripping-off devicesTube drawingStart button

The invention discloses a pipe forming machine. A linear slide rail is arranged on the base, a sliding piece and an oil cylinder for driving the sliding piece are respectively arranged at both ends of the slide rail, and a pipe clamping device is installed on the first sliding piece. A male mold base is installed on the second sliding part, a male mold mandrel is installed on the male mold base, a female mold base is arranged between the two ends of the slide rail, a female mold is installed on the female mold base, the structure is simple, The operation is convenient, and the processes of squeezing, expanding and pumping can be completed at one time, and the processing of the thickness of the pipe wall can be completed, which reduces the labor intensity of the staff and improves the production efficiency. The pipe forming machine also includes a drawstring electronic ruler, a servo control system, a PLC control system and a human-computer interaction panel, which can realize precise positioning of the pipe and precise processing of the wall thickness. It is convenient and fast to compile and modify programs and data through the human-computer interaction panel; the PLC control system and hydraulic servo control system realize the automation of pipe processing, and only need to press the start button to automatically complete the working cycle.

Owner:中山市阿洛奇美第体育用品有限公司

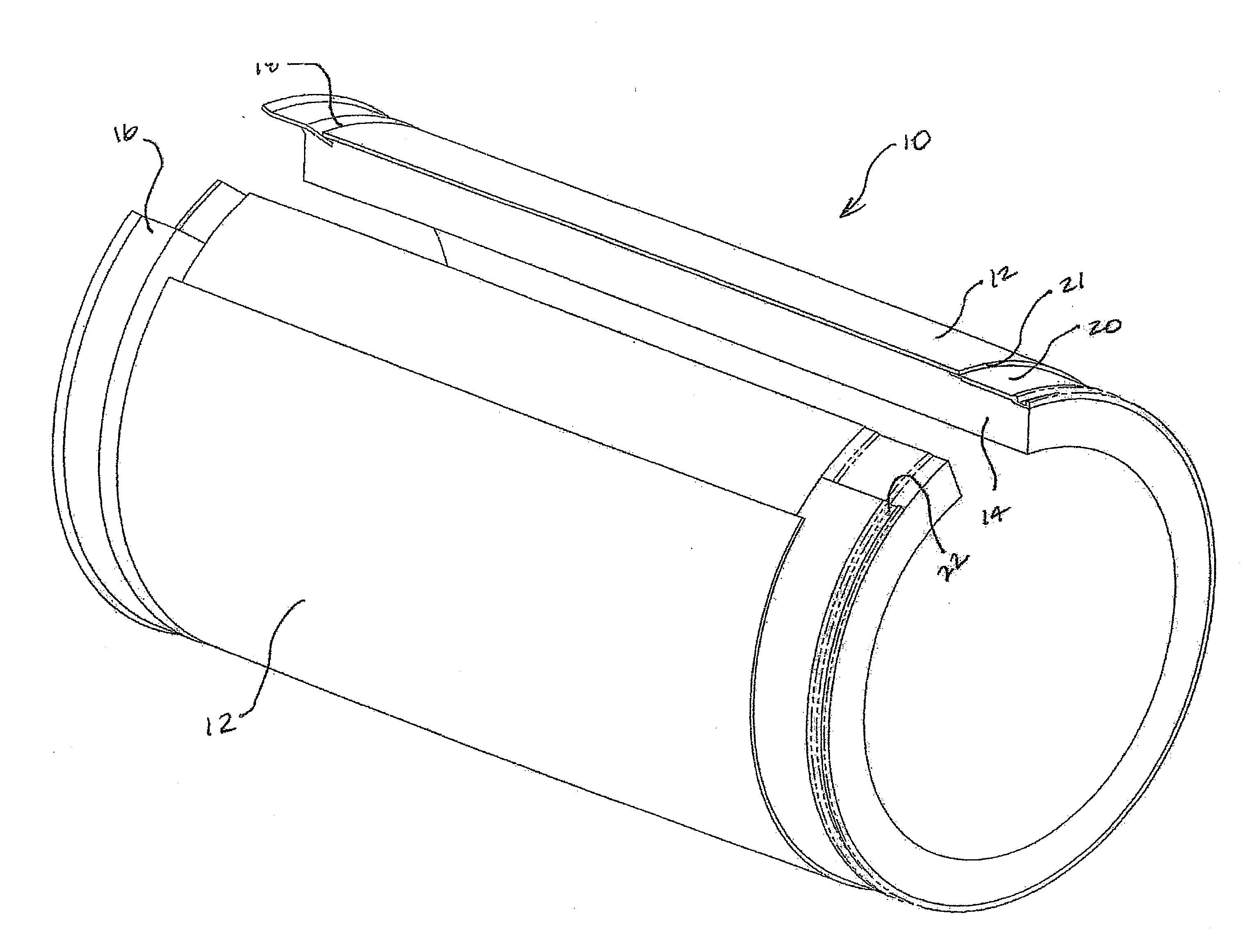

Pressure cast concrete or mortar lined steel pipes and methods of making the same

ActiveUS20120152396A1Reduce the overall diameterSave raw materialsMetal rolling stand detailsHeat exhanger conduitsSteel tubeMetal

Pressure cast lined steel pipes comprise an annular concrete or mortar liner along an inside diameter, and a metal shell surrounding the liner, wherein the liner is in direct contact with the metal shell. The wall thickness of the liner can be from 10 to 50 times the thickness of the metal shell. The pipe may be coated with a dielectric material. A mold assembly used to form the pipe includes an annular concrete or mortar composition chamber formed between the metal shell and an inner mold member. Pressurized water is used in the mold assembly to pressurize the concrete or mortar composition and exert a desired pressure force onto the metal shell while the composition cures in the mold. Once a desired degree of cure is achieved, the pressure is removed causing the metal shell to exert a desired compression force onto the cured liner.

Owner:NWPC LLC

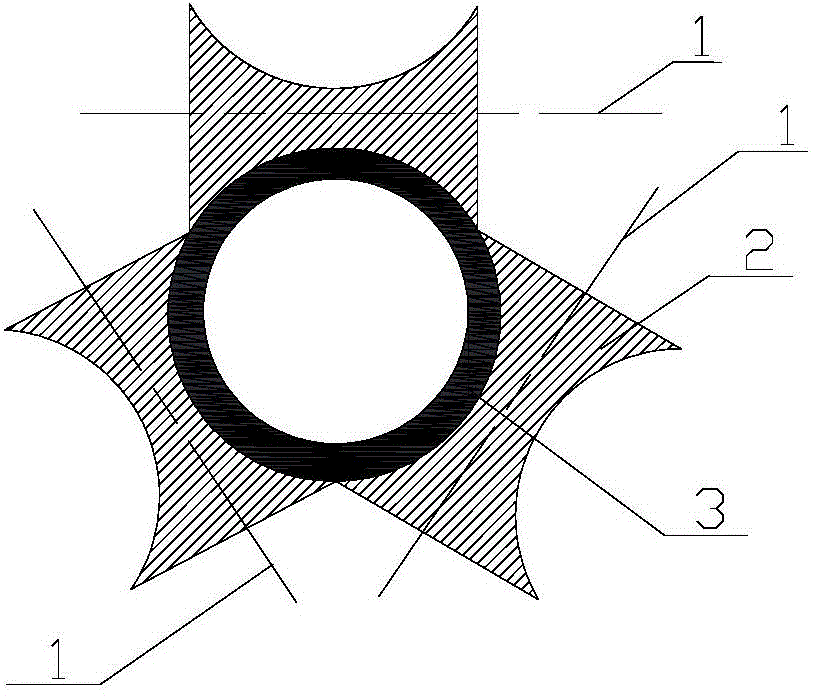

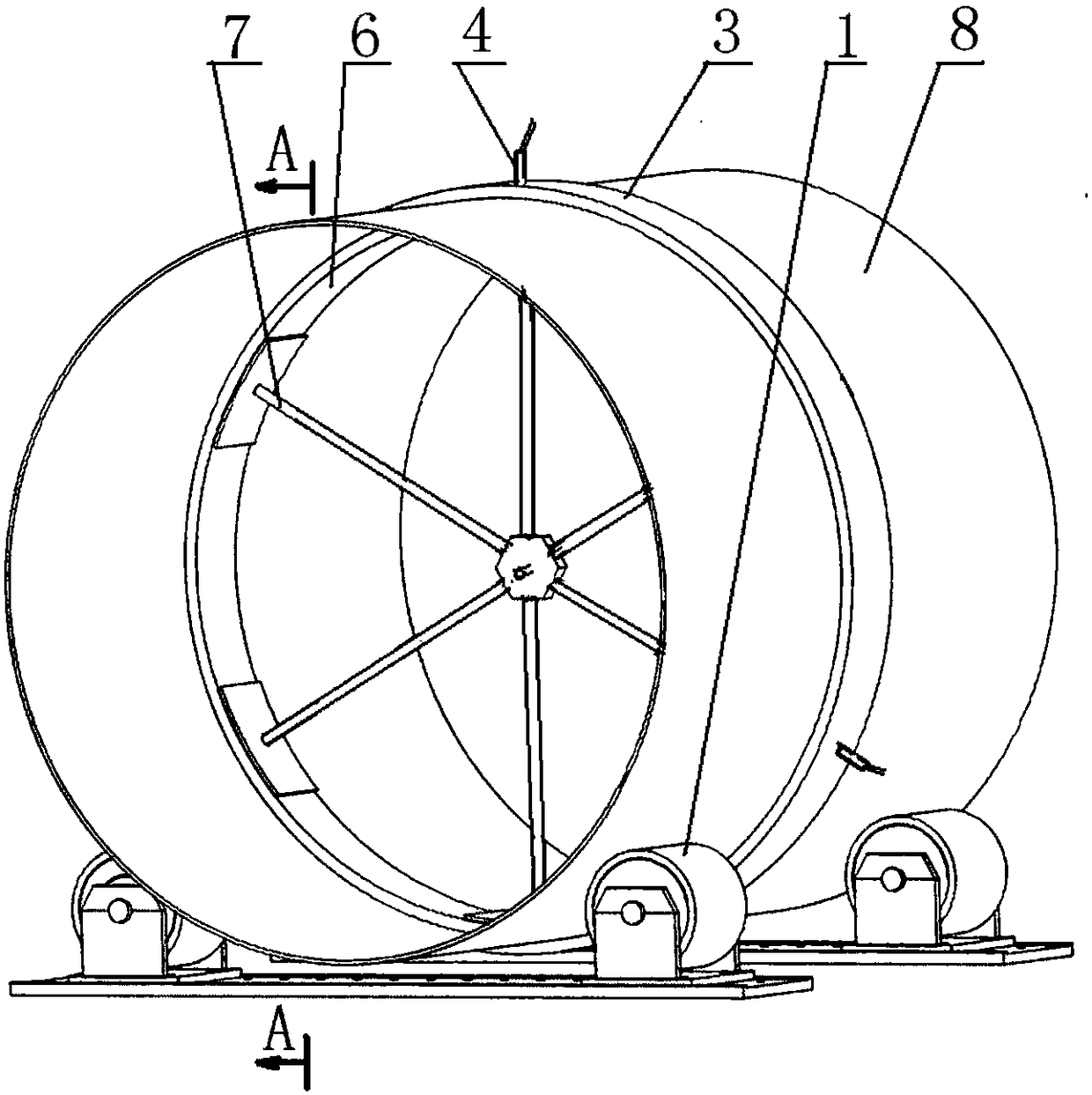

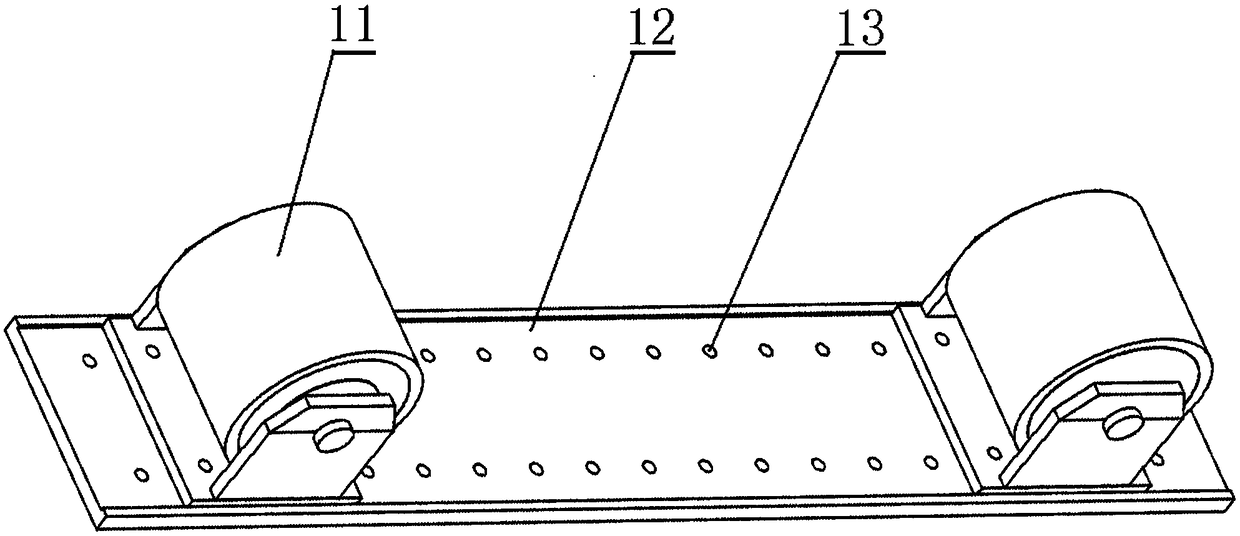

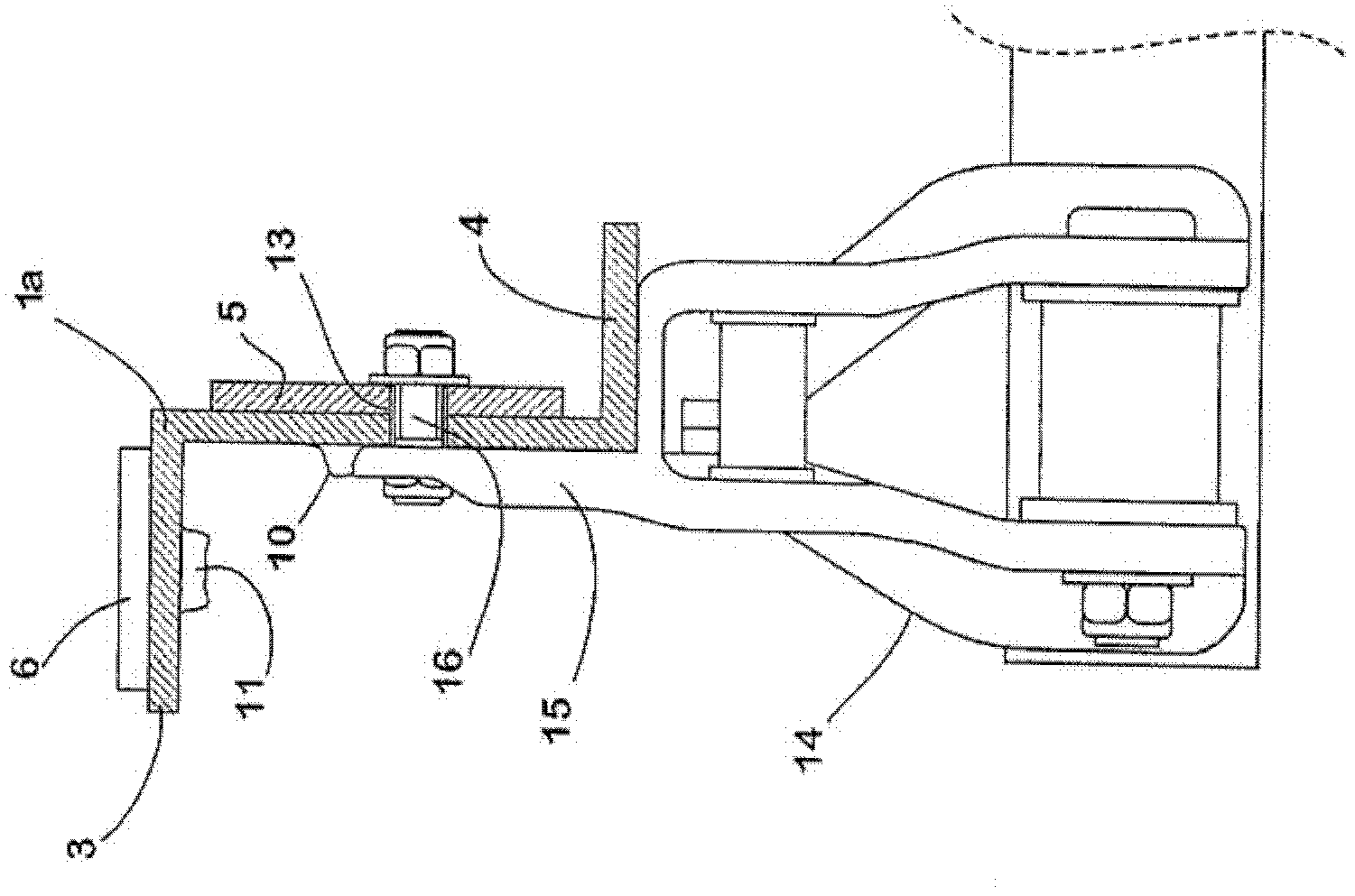

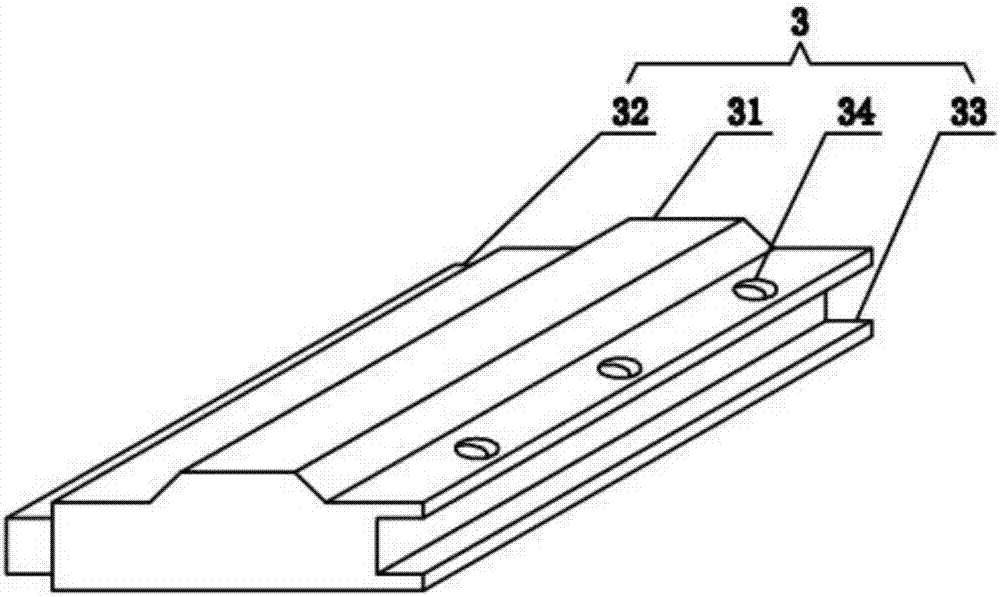

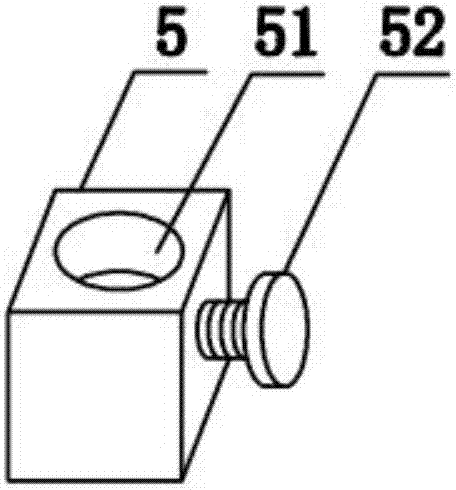

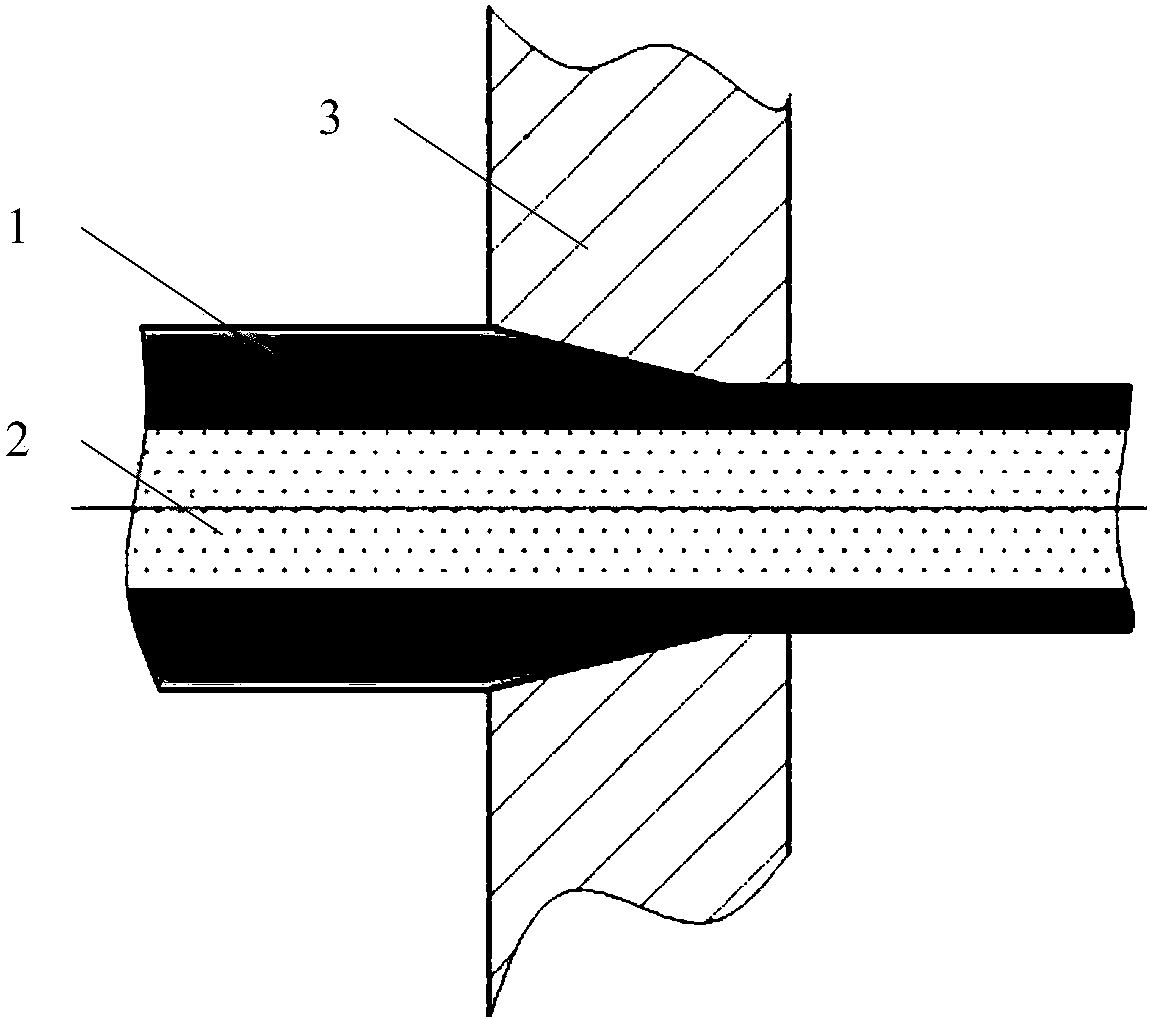

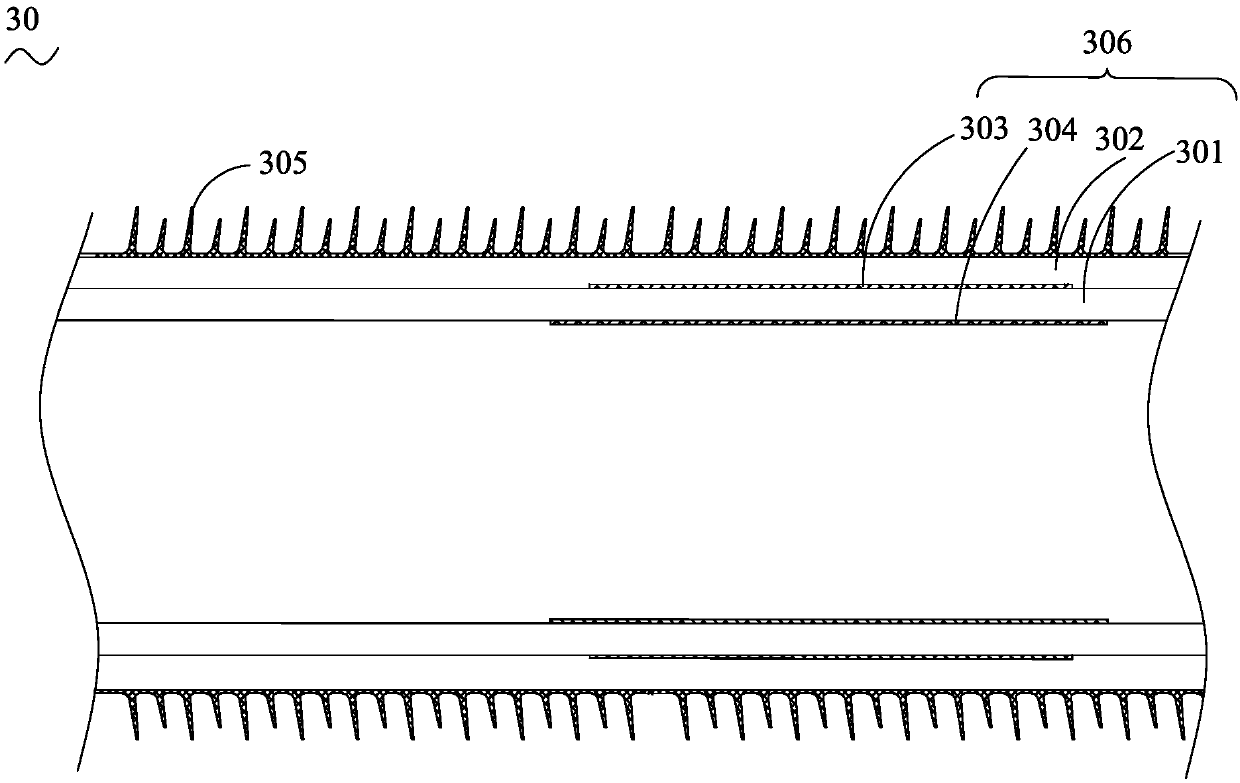

Large-pipe-diameter thin-wall pipe post-welded heat treatment device and using method thereof

PendingCN108517398AImprove insulation effectHeat dissipation is slowFurnace typesHeat treatment process controlTemperature controlEngineering

The invention discloses a large-pipe-diameter thin-wall pipe post-welded heat treatment device and a using method thereof, and belongs to the technical field of welding heat treatment. The device comprises steel pipe supporting seats (1), electric heating elements (2), insulating layers (3) on the electric heating elements (2), thermocouples (4), a binding material (5), an inner pipe wall heat preservation layer (6) and a supporting frame (7), wherein the electric heating elements (2) are basically equally and uniformly arranged along the outer circumference of a steel pipe (8), and each of the electric heating elements (2) and the corresponding thermocouple (4) are respectively connected with the corresponding heat treatment temperature control instrument. During use, the electric heatingelements (2) of the device is electrified and heated, so that an annular weld joint (9) of the steel pipe (8) and the nearby area are heated to the heat treatment temperature, cooling is carried outafter heat preservation, and then the post-welded heat treatment of the steel pipe is completed. By the adoption of the large-pipe-diameter thin-wall pipe post-welded heat treatment device and the using method thereof, a better welding heat treatment and heat preservation effect can be obtained, the heating temperature is controlled accurately, the heating temperature fluctuation is small, the heat treatment deformation can be reduced, and the performance uniformity after heat treatment can be improved.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

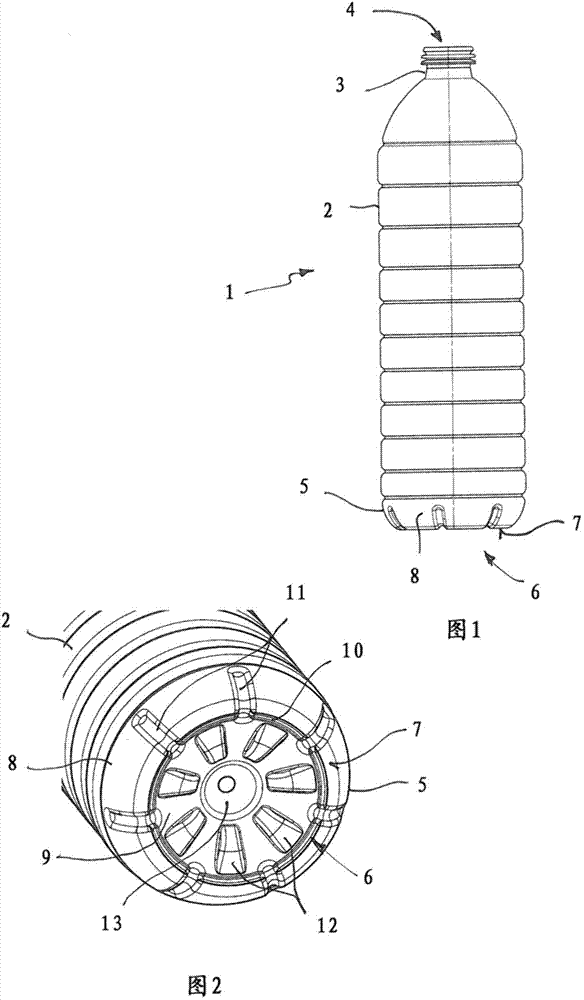

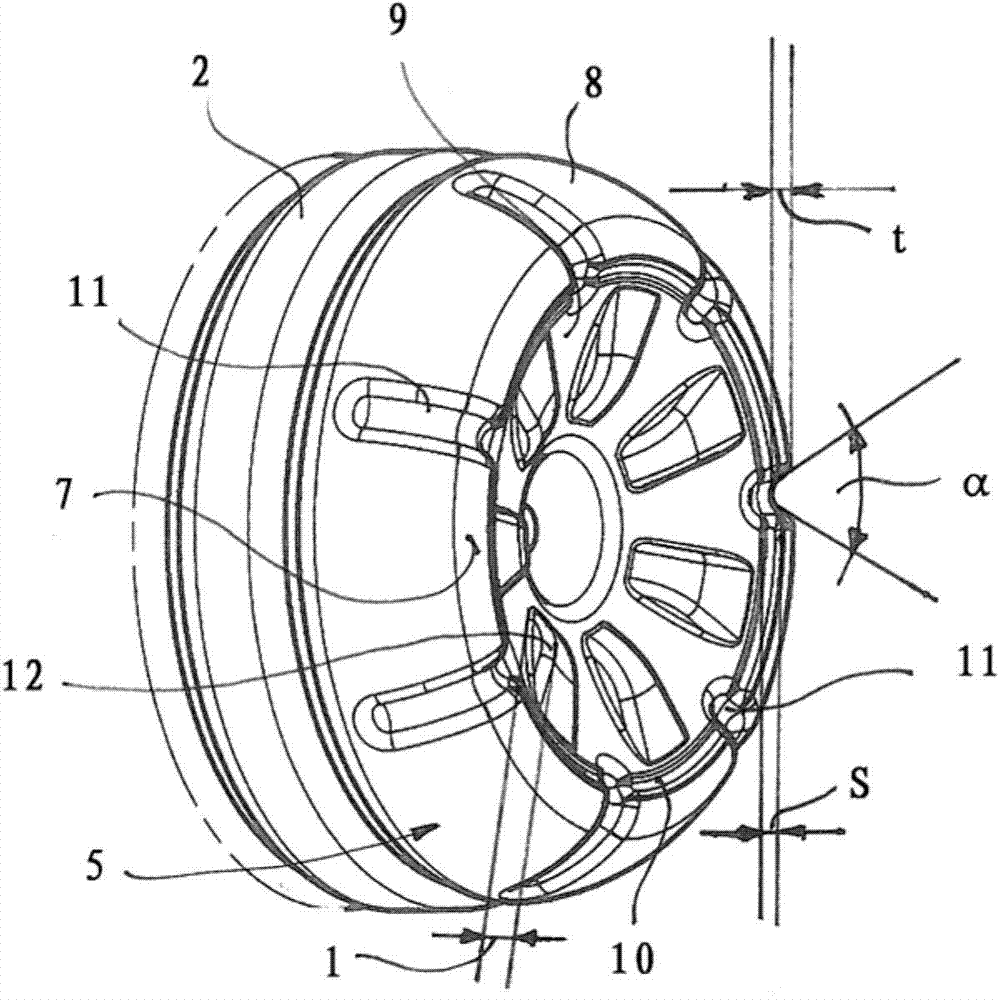

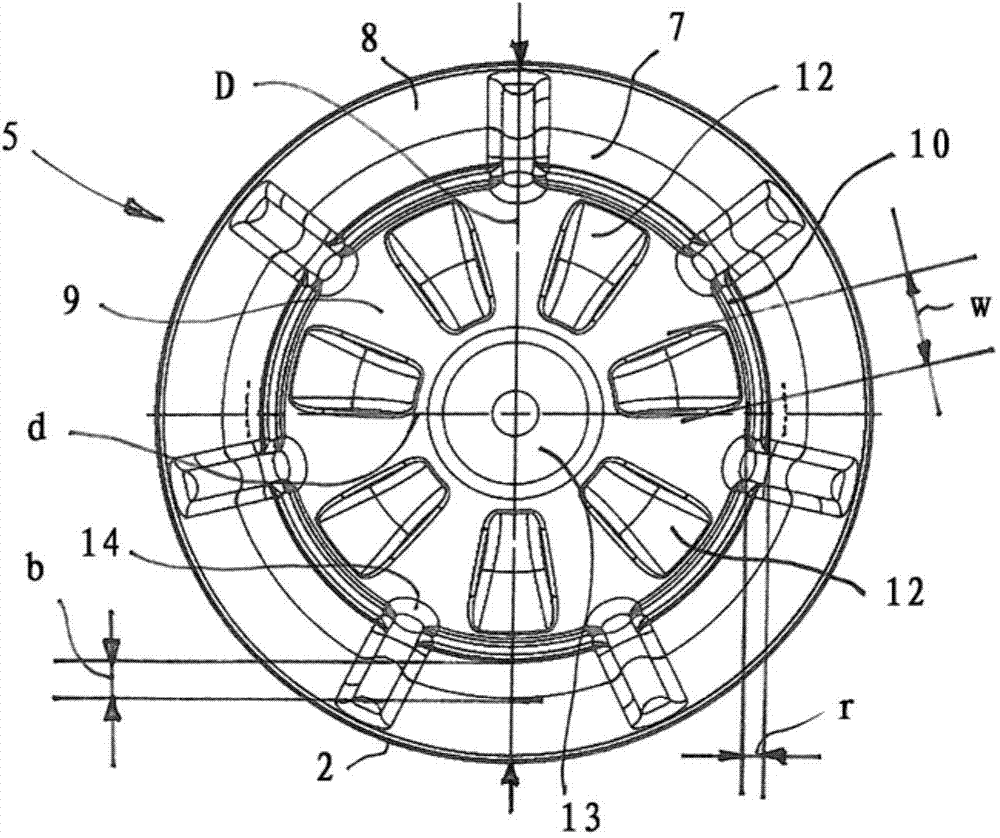

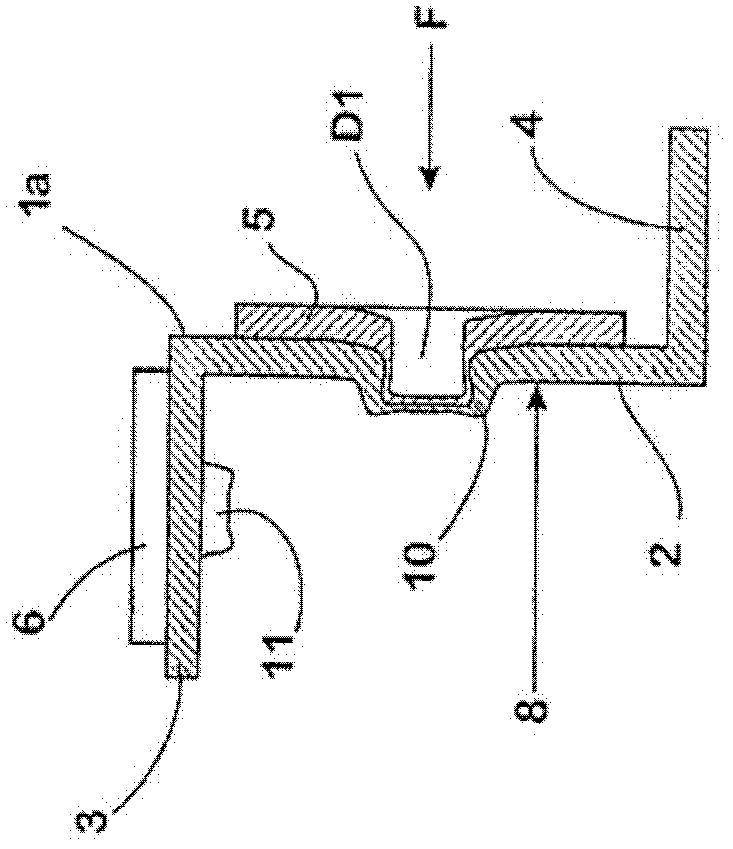

Plastic container

The invention relates to a plastic container, in particular for storing liquid products under slight positive pressure, which container has a container body (2) which extends along a longitudinal axis. The one longitudinal end of the container body (2) is adjoined by a container neck (3), which is equipped with at least one pouring opening (4). The other longitudinal end of the container body (2) is adjoined by a bottom section (5) which has a container bottom (6) and an edge region (8) which is drawn up laterally and which merges into the container body (2). The container bottom (6) has a concave section (9) which is curved in the direction of a container interior bounded by the container body, and the circumference of which section is connected via an axially protruding stepped transition region (10) to a standing surface (7), which opens into the edge region (8) that is drawn up laterally. The standing surface (7) and at least one sub region of the stepped transition region (10) are interrupted by a first number of grooves (11). Formed in the concave section (9) is a second number of panel-like projections (12), which extend substantially between the stepped transition region (10) and the longitudinal axis and end in front of the stepped transition region (10).

Owner:ALPLA WERKE ALWIN LEHNER

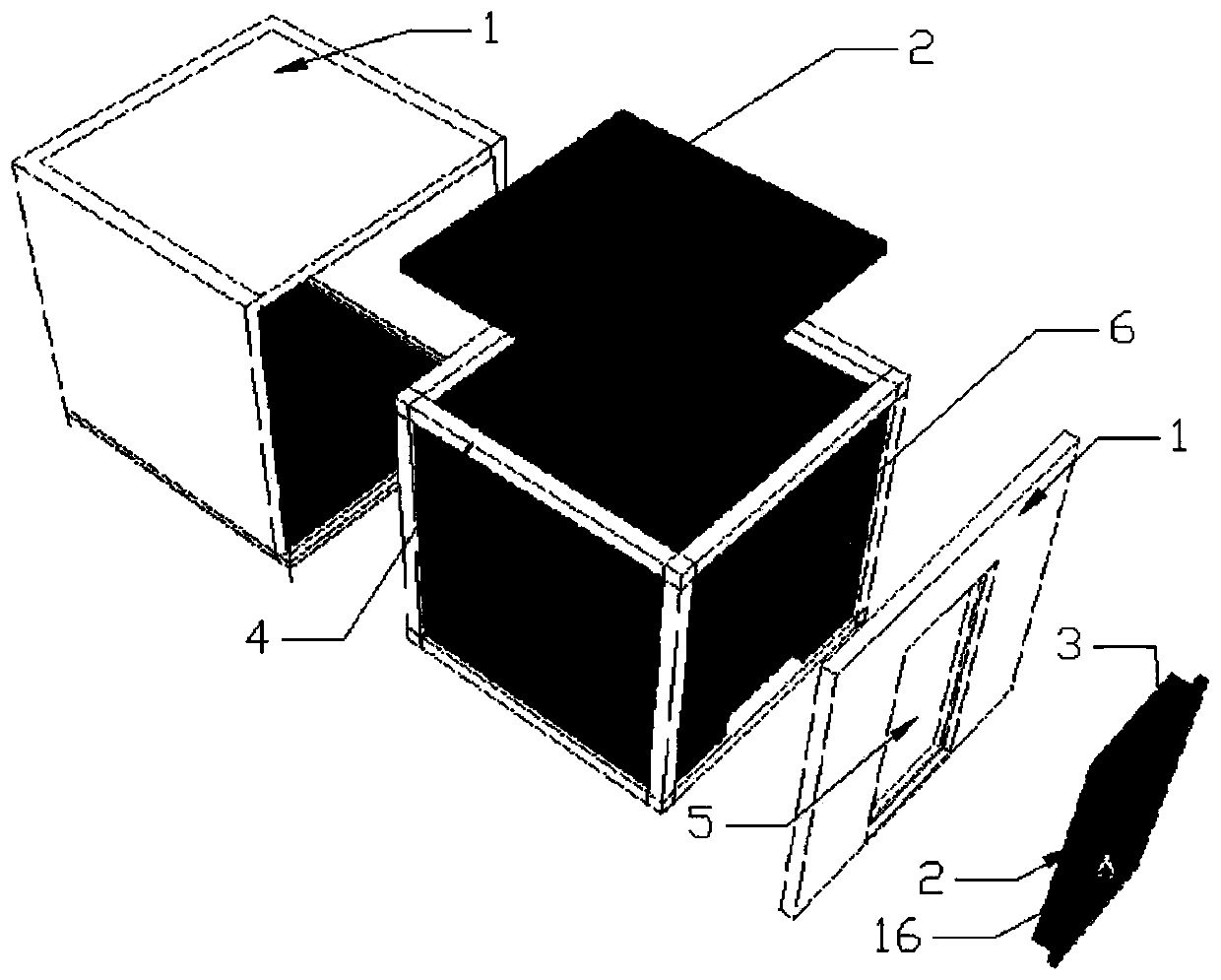

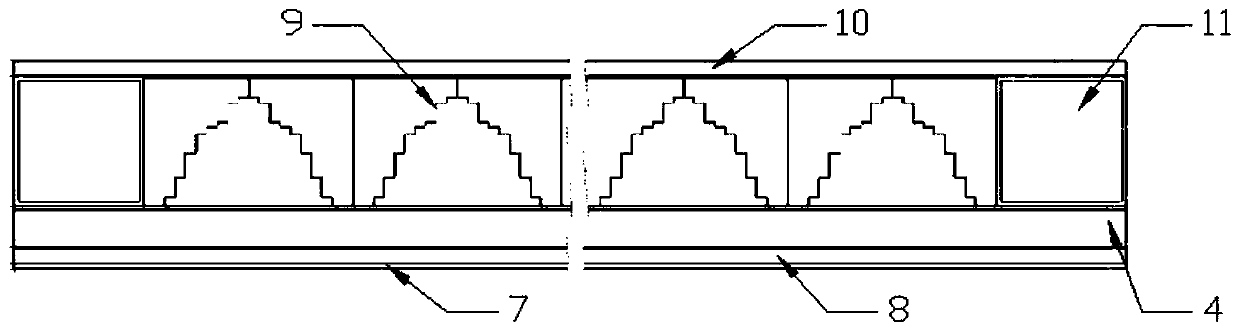

Superstructure mute chamber

PendingCN110905242AGood sound absorptionLow toxicitySpecial buildingSound proofingFixed frameEngineering

The invention provides a superstructure mute chamber, and relates to the field of sound absorption and insulation materials. The superstructure mute chamber comprises an outer wall body, an inner wallbody and a door plate, wherein the outer wall body and the inner wall body are both in a hollow cuboid shape; the inner side wall of the outer wall body is connected with the outer side wall of the inner wall body through a fixing frame; a first through hole and a second through hole are formed in the side walls of one ends of the outer wall body and the inner wall body correspondingly; the sidewalls of one ends of the first through hole and the second through hole are hinged to the side wall of one end of the door plate; the outer wall body comprises an outer decoration layer; a sound insulation layer is arranged on the inner side wall of the outer decoration layer; the inner wall body comprises a sound absorption superstructure material layer; the sound absorption superstructure material layer comprises a plurality of unit bodies; each unit body is composed of a wavelength tube and a Helmholtz resonance cavity; and the outer side wall of one end of the sound absorption superstructure material layer is connected with the fixing frame, and the outer side wall of the other end of the sound absorption superstructure material layer is connected with a surface micro-perforated plate.The superstructure mute chamber is good in sound absorption and insulation effect, capable of reducing toxicity, small in occupied space and long in service life.

Owner:南京光声超构材料研究院有限公司

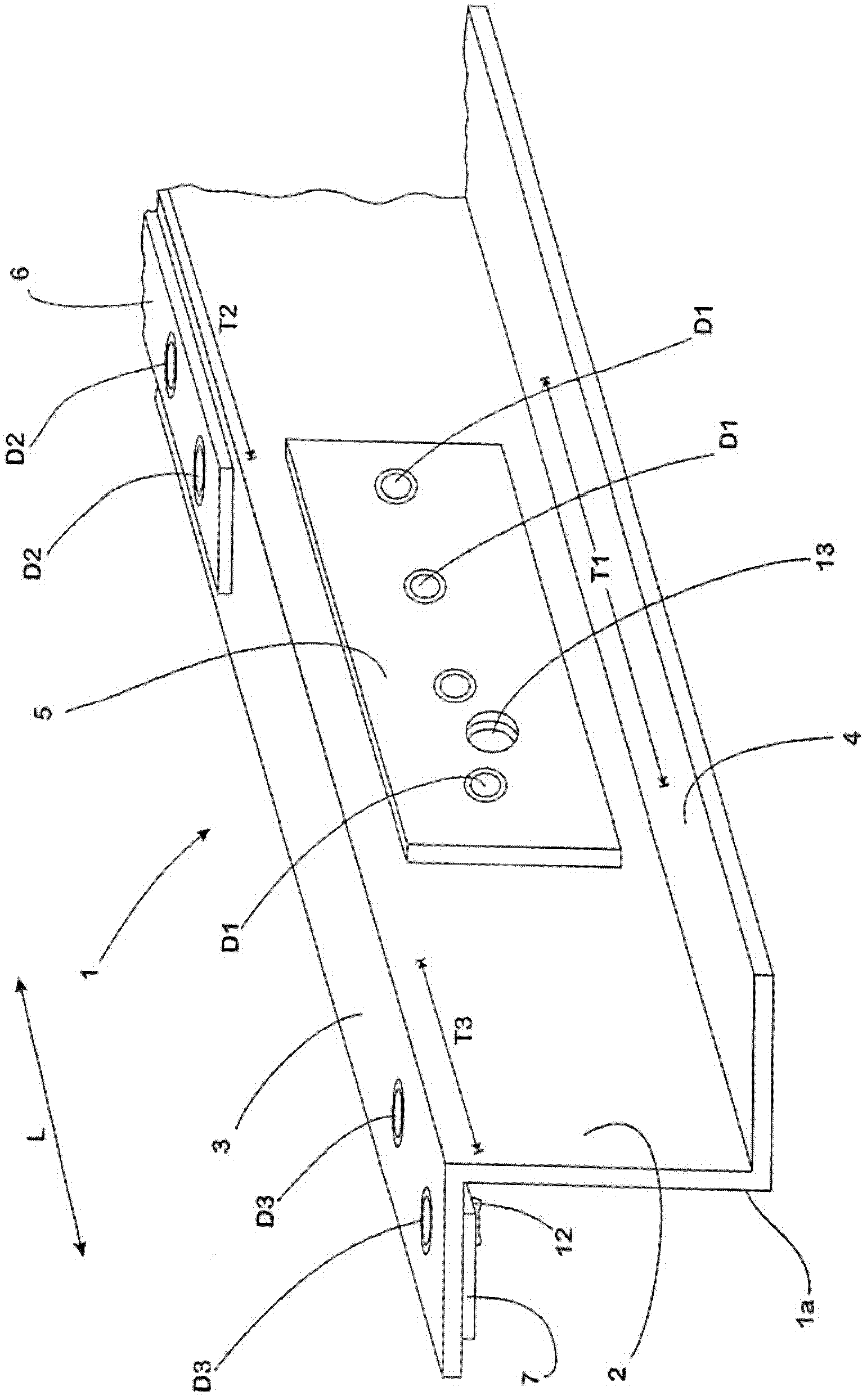

Utility vehicle chassis and method for manufacturing a profile longitudinal beam for a utility vehicle chassis of said type

InactiveCN103608245AImprove fatigue strengthAvoid time costUnderstructuresEngineeringCommercial vehicle

The present invention relates to a profiled beam for a vehicle chassis, wherein a reinforcement plate (5, 6, 7) bears against at least one part (T1 - T3) of the profiled beam (1, 20), which reinforcement plate is connected fixedly and non-detachably to the associated part (T1 - T3) of the profiled beam (1, 20). The profiled beam (1, 20) according to the invention for a vehicle chassis, and a utility vehicle chassis constructed using a profiled beam of said type, can be produced inexpensively and have optimal usage characteristics while being of minimal weight. This is achieved in that the connection between the reinforcement plate (5, 6, 7, 22) and the associated part (T1, T2, T3) of the profiled beam (1, 20) is produced by means of at least one clinched connection (D1 - D4).

Owner:SCHMITZ CARGOBULL

Steel structure simple house capable of being rapidly dismounted and mounted

InactiveCN106988426AFactory highImprove completenessBuilding constructionsBrickArchitectural engineering

The invention discloses a steel structure simple house that can be quickly disassembled and assembled in the technical field of steel structures, which includes a frame, a support rod is installed on the top of the frame, a sliding block is sleeved on the support rod, and the left and right sides of the sliding block The side is movably connected with a bracket, the left side of the bracket is movably connected with the first roof, the right side is movably connected with the second roof, the first roof and the second roof are connected by hinges, and the first roof and the second roof are movably connected. The bottom of the second roof is connected with a support column, and the bottom end of the support column is fixed to the top of the frame. The light steel structure fittings of the present invention have a high degree of industrialization and mechanization, a high degree of commercialization, and a fast on-site construction speed without affecting It is conducive to civilized construction to nearby residents. Compared with traditional brick-concrete structure houses, the wall thickness is smaller, which can increase the effective use area, and the light steel structure houses are light in weight and have good shock absorption performance.

Owner:华新顿现代钢结构制造有限公司

Metal thin-wall pipe preparation method, metal thin-wall pipe fitting and cardiovascular stent

InactiveCN107671506AImprove smoothnessReduced wall thicknessStentsProsthesisCardiovascular stentSurface smoothness

The invention provides a metal thin-wall pipe preparation method, a metal thin-wall pipe fitting and a cardiovascular stent. The metal thin-wall pipe preparation method comprises the following steps:a blind hole is drilled in the end surface of a metal rod to be drawn to obtain a drawn blank; an empty drawing process is adopted to perform the reducing treatment on the drawn blank to obtain a primary-drawn blank; a mold core is inserted in the blind hole of the primary-drawn blank; and the primary-drawn blank is fixed in a drawing mold for at least once of cold drawing treatment to obtain a metal thin-wall pipe. The metal thin-wall pipe fitting is prepared by adopting the metal thin-wall pipe preparation method; and the cardiovascular stent is prepared by adopting the metal thin-wall pipefitting. The prepared metal thin-wall pipe is lower in pipe wall thickness; and the strength of the metal thin-wall pipe fitting and the pipe wall surface smoothness are higher to meet the use requirements of the cardiovascular stent.

Owner:房文斌

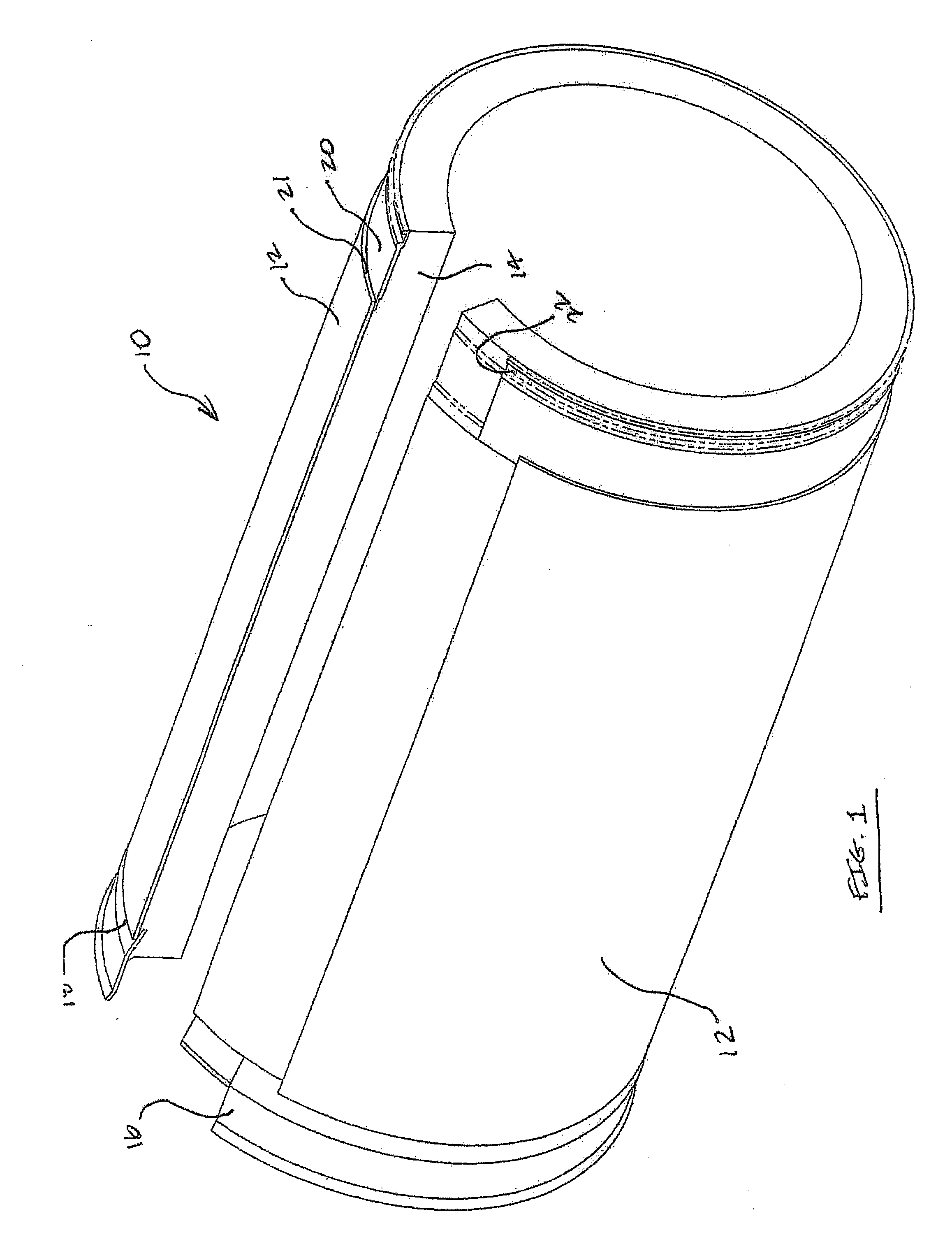

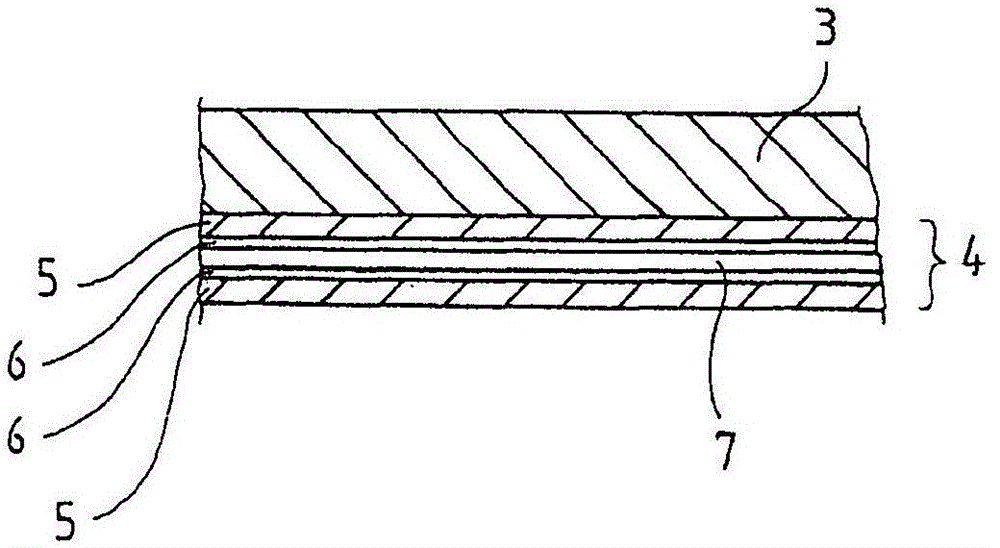

Multi-layer tube of improved physical properties

InactiveCN1832851AGood dimensional stabilityAvoids the need to add unwanted solvent-based adhesivesPaper/cardboard wound articlesSynthetic resin layered productsEngineeringPolypropylene

A pipe having a pipe wall of multilayer structure, wherein said multilayer structure comprises one or more sublayers, each said sublayer consisting of a woven polymeric network interposed between one or more outer layers, the Said outer layer is a material selected from the group consisting of paper, polypropylene and polyethylene, wherein said tube is formed by adhering said sub-layers to each other while simultaneously winding said sub-layers onto a mandrel.

Owner:EZYTUBE

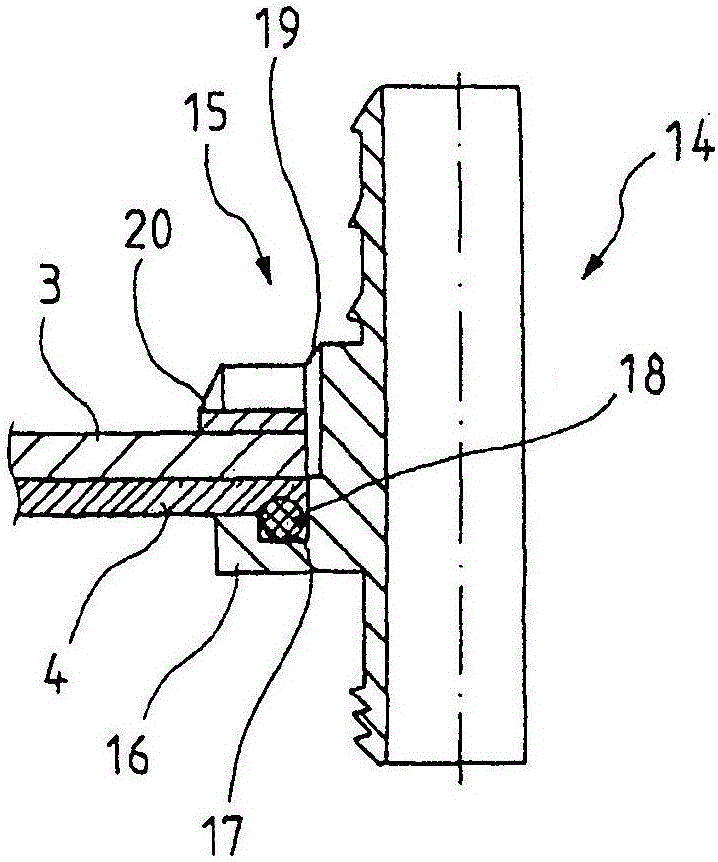

Method for manufacturing a fuel tank and fuel tank

InactiveCN105050845AReduced wall thicknessReduce weightUnderstructuresDomestic articlesWork in processFibrous composites

Method for manufacturing a fuel tank on the basis of thermoplastic material, comprising the following steps: • producing semifinished products (3) in sheet form from a fibre composite material with a matrix of thermoplastic material, • laminating the semifinished products (3) with a laminate (4) that comprises at least one barrier layer (7) for hydrocarbons, • heat-treating the laminated semifinished products (3+4) until the thermoplastic material plasticizes, • thermoforming the plasticized semifinished products in a thermoforming mould to form shells (1, 2) and • joining the shells (1, 2) to form an essentially closed tank.

Owner:KAUTEX TEXTRON

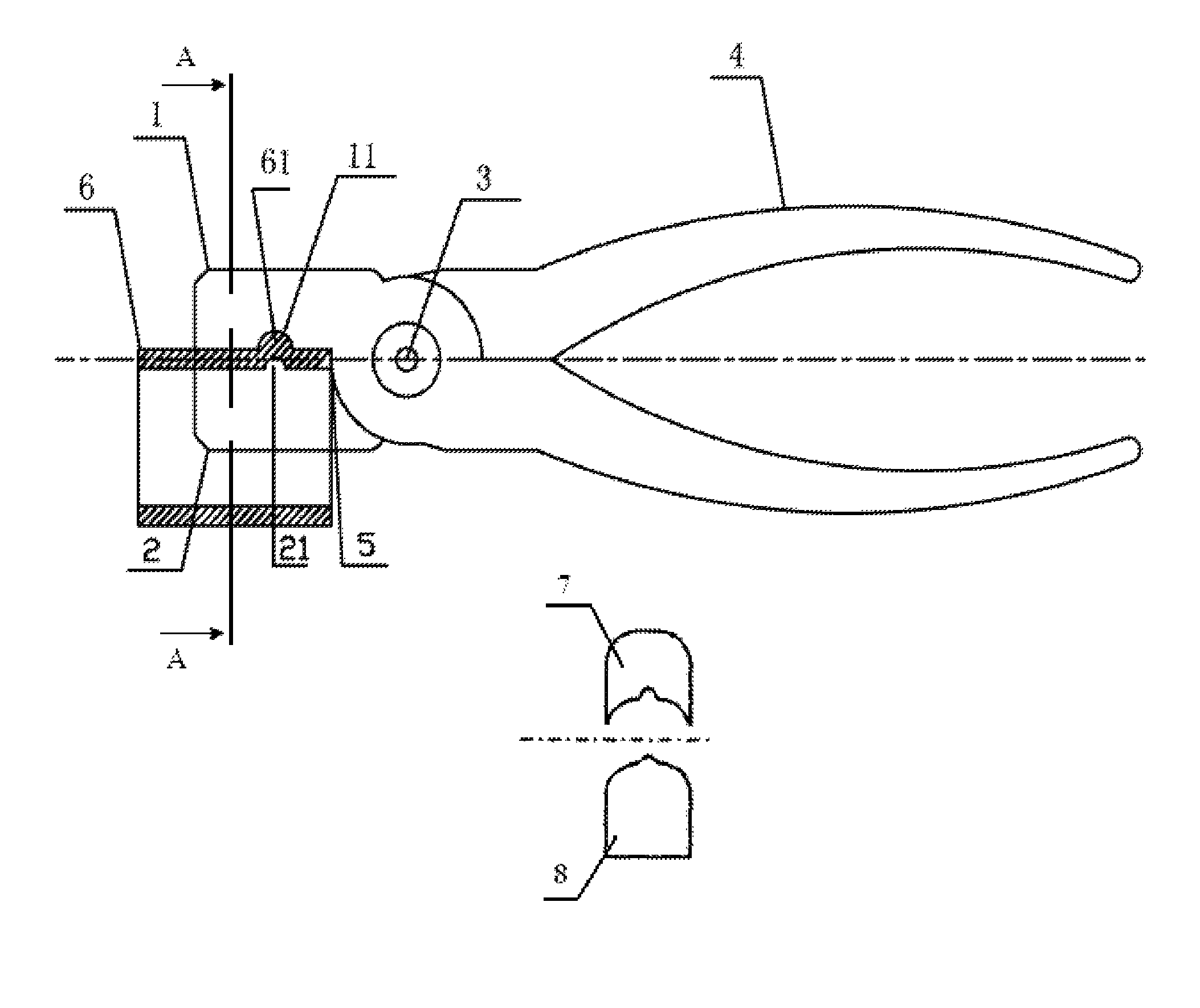

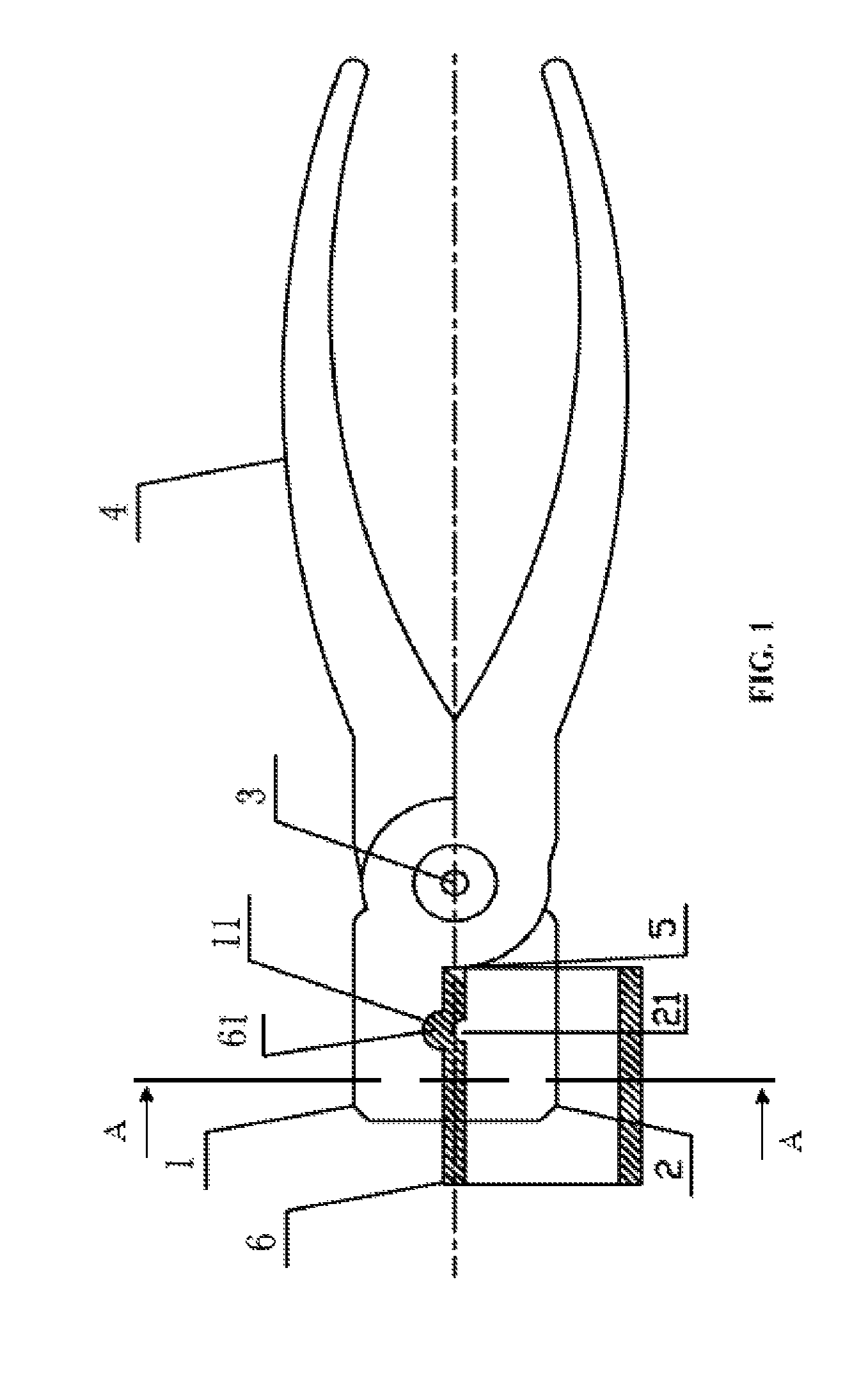

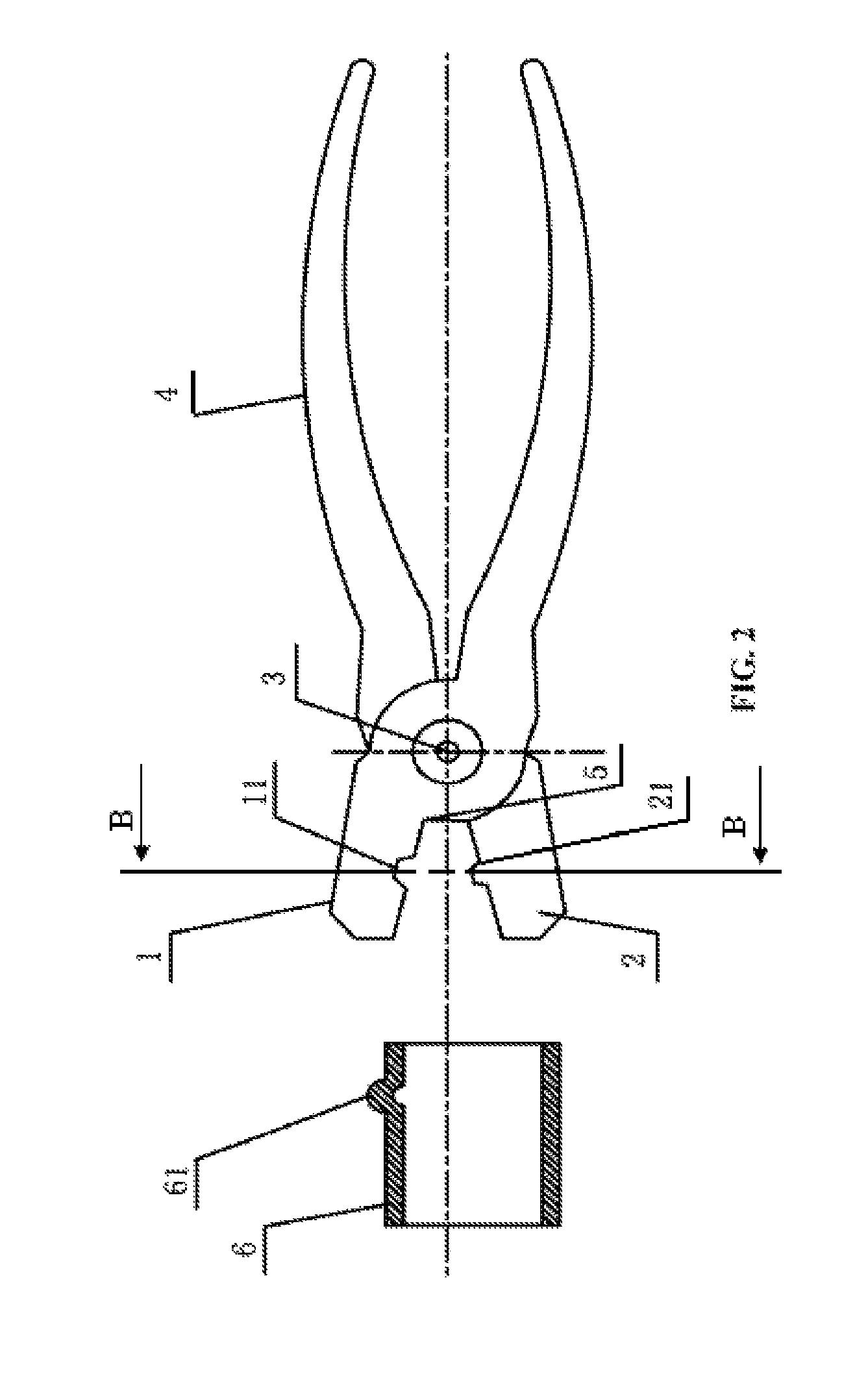

Pliers

InactiveUS8776571B2Reduce weightCheap and portable and convenient for operationShaping toolsExtrusion diesCross connectionEngineering

Owner:PANG HAOHUI +1

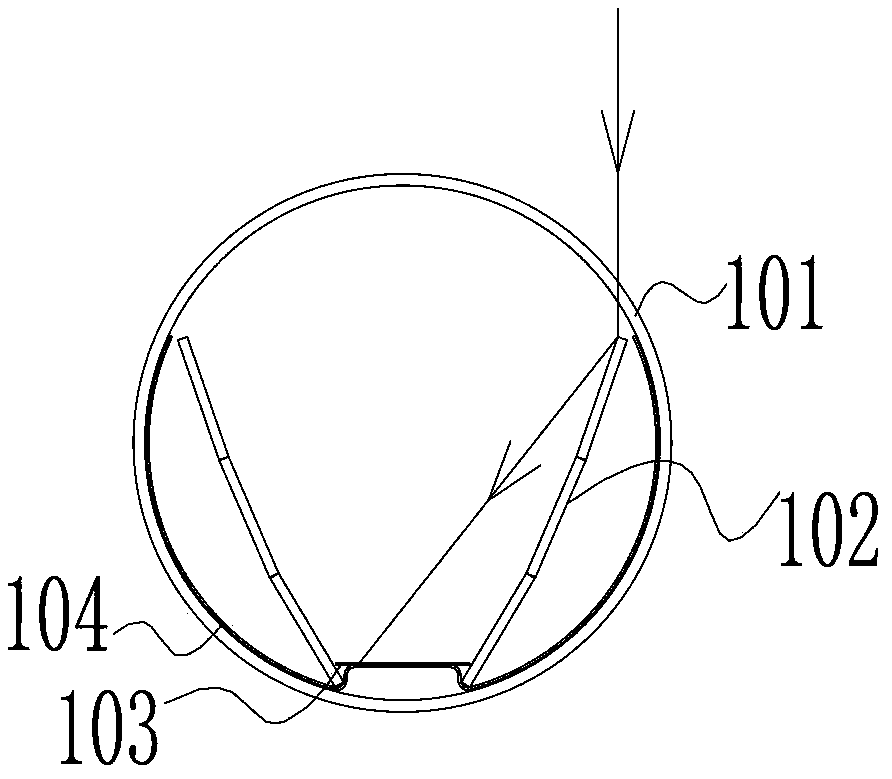

Tubular tracking concentrating photovoltaic module

InactiveCN103456824AEfficient concentrating power generationReduced wall thicknessPhotovoltaic supportsBatteries circuit arrangementsWeather resistanceEngineering

The invention provides a tubular tracking concentrating photovoltaic module. The tubular tracking concentrating photovoltaic module comprises a concentrating system, a photovoltaic battery pack and a heat sink in good heat-conducting contact with the photovoltaic battery pack. The tubular tracking concentrating photovoltaic module is characterized in that the tubular tracking concentrating photovoltaic module is provided with a glass tube shell with the two ends closed, the concentrating photovoltaic battery pack applies tracking with the illuminated face toward the sunlight, and then efficient concentrating power generation can be performed. The tubular tracking concentrating photovoltaic module has the advantages of being low in cost, excellent in sealing performance, good in weather resistance, high in mechanical strength, strong in self-supporting force and long in service life.

Owner:刘庆云

Antistatic flame-proof light high-intensity resin steel mesh composite tube and production technique

ActiveCN100436910CImprove corrosion resistanceImprove aging performanceNon-macromolecular adhesive additivesRigid pipesFiberAntistatic agent

The invention relates to an anti-static fireproof light high-strength resin steel network composite tube and relative production. The tube comprises three layers as the liner layer with anti-leakage or abrasion-resistant function, a strength layer coiled by strength fiber and added steel base material, and a surface layer coiled with dense fiber at the face. The invention is characterized in that: 1, the composite adhesive solidifier of liner layer (1) is added with 5-10 deals of glass scales and / or 5-15 deals of graphite scales; 2, each 100 deals of resin of composite adhesive solidifier is added with 0.5-5 deals of antioxidant; 3, each 100 deals of resin of composite adhesive solidifier is added with 2-10 deals of short tangent fiber to form slurry composite adhesive solidifier coiled with the mesh steel wire to form the strength layer.

Owner:TANGSHAN JIAJI COMPOSITE PIPE CORP

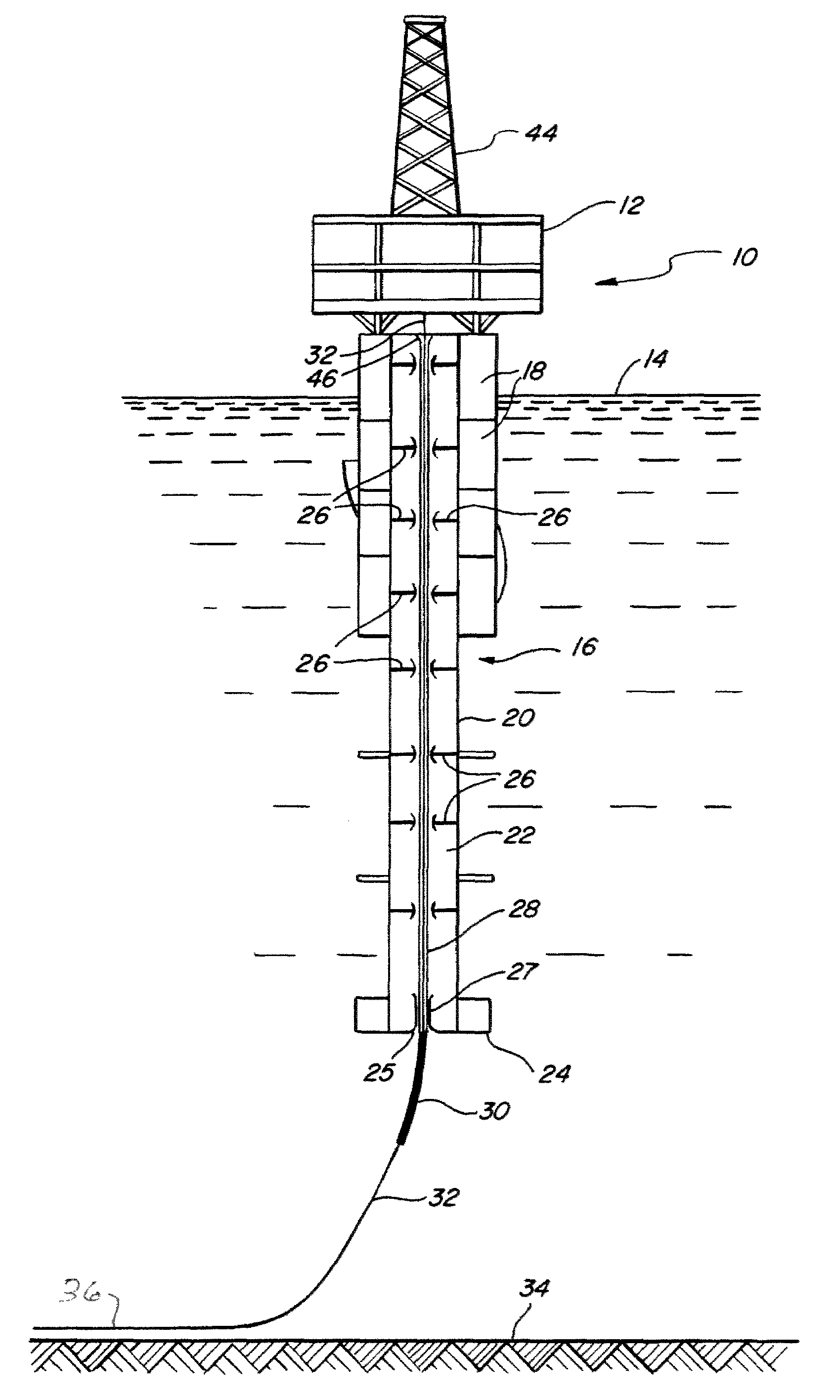

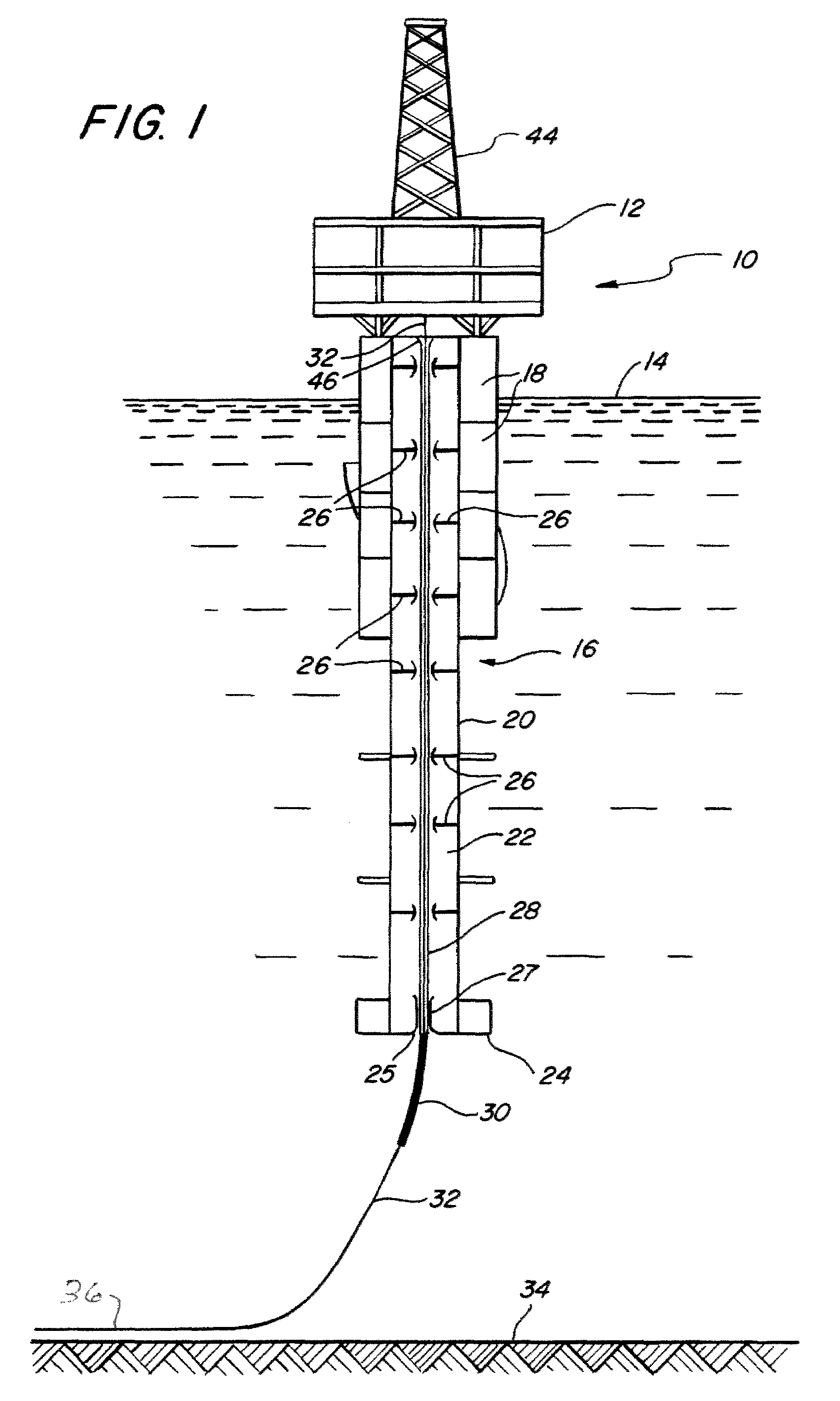

Control of flexible riser curvature at the keel of a floating structure

ActiveUS7556452B2Increasing flexibility and complianceIncrease in weight per unit lengthPipe laying and repairDrilling rodsKeelEngineering

A bend-limiting conduit controls the curvature of a catenary riser extending from the seafloor as it enters the centerwell of a spar-type offshore platform through the keel of the platform. The conduit has a bore dimensioned to receive the riser, and it extends from an upper end constrained within the keel to a lower end disposed below the keel. The conduit has increasing flexibility and weight per unit length from the upper end to the lower end, which results in a lateral load being applied to the riser as it passes through the conduit, thereby causing a gentle and gradual transition in the riser from a curved configuration at the lower end of the conduit, to a straight configuration as it emerges from the upper end of the conduit.

Owner:TECH FRANCE SA

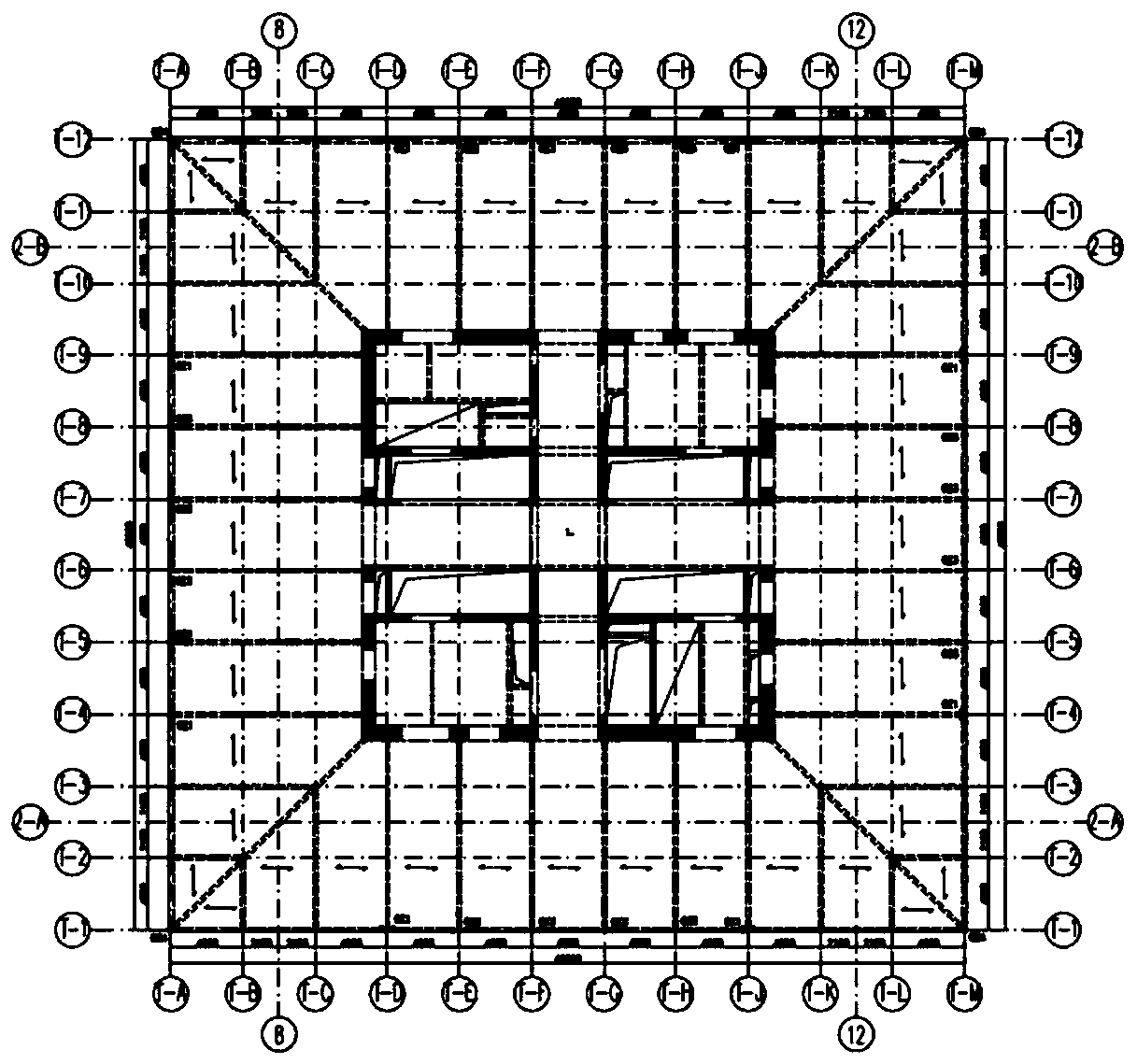

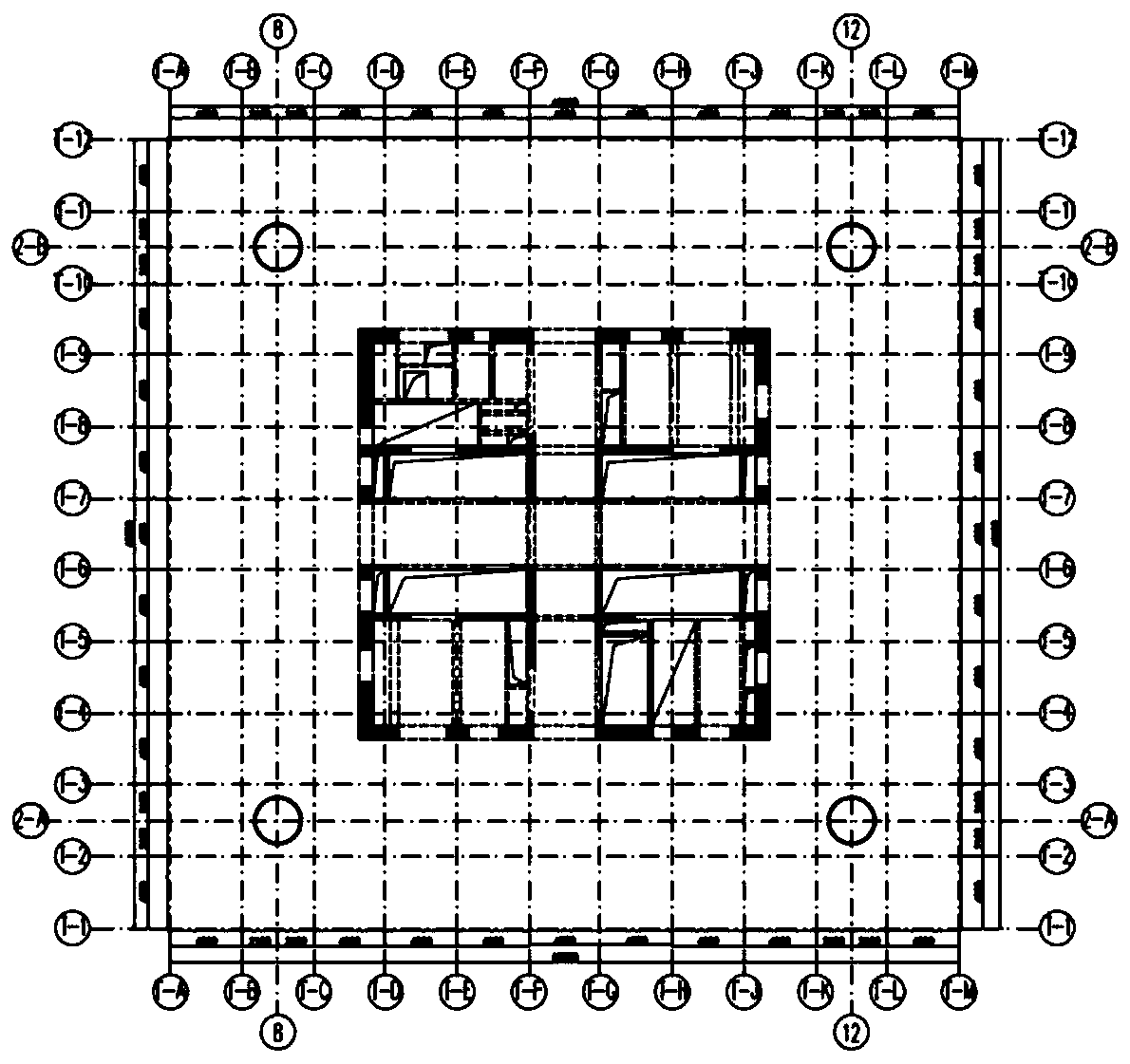

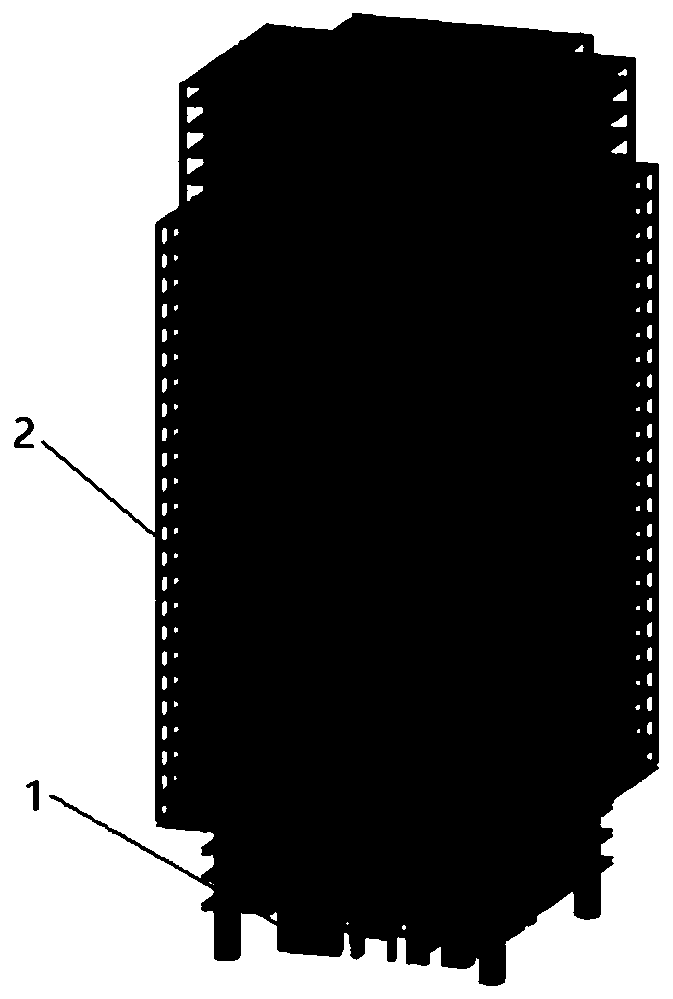

Core tube structure system with transfer layer

PendingCN109853741AMeet the requirements of transparencyIncrease the vertical force transmission pathExtraordinary structuresViscous dampingReinforced concrete

The invention relates to a core tube structure system with a transfer layer. The core tube structure system with the transfer layer comprises a core tube and an outer frame, the outer frame is arranged on the periphery of the core tube, the outer frame is an outer frame with a transfer structure, and a connected frame body and an umbrella shape transfer layer are included. The core tube structuresystem is a high-rise structure system with a shelter layer. In the shelter layer, a prestressed cable-stayed cable is connected between the outer frame and the core tube. Compared with the prior art,the core tube structure system with the transfer layer meets the requirements of a building form and meanwhile, increases the vertical force transmission path of the structure; the vertical load of the outer frame is transferred to the core tube in batches through the cable, the load of an outer frame column and a lower part transfer structure is reduced, and the structural redundancy is increased; and meanwhile, a viscous damping wall is arranged in the core tube, the seismic force of the core tube of reinforced concrete of a lower part floor is reduced, and the thickness of the core tube wall and the amount of steel bars and steel bones are reduced.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

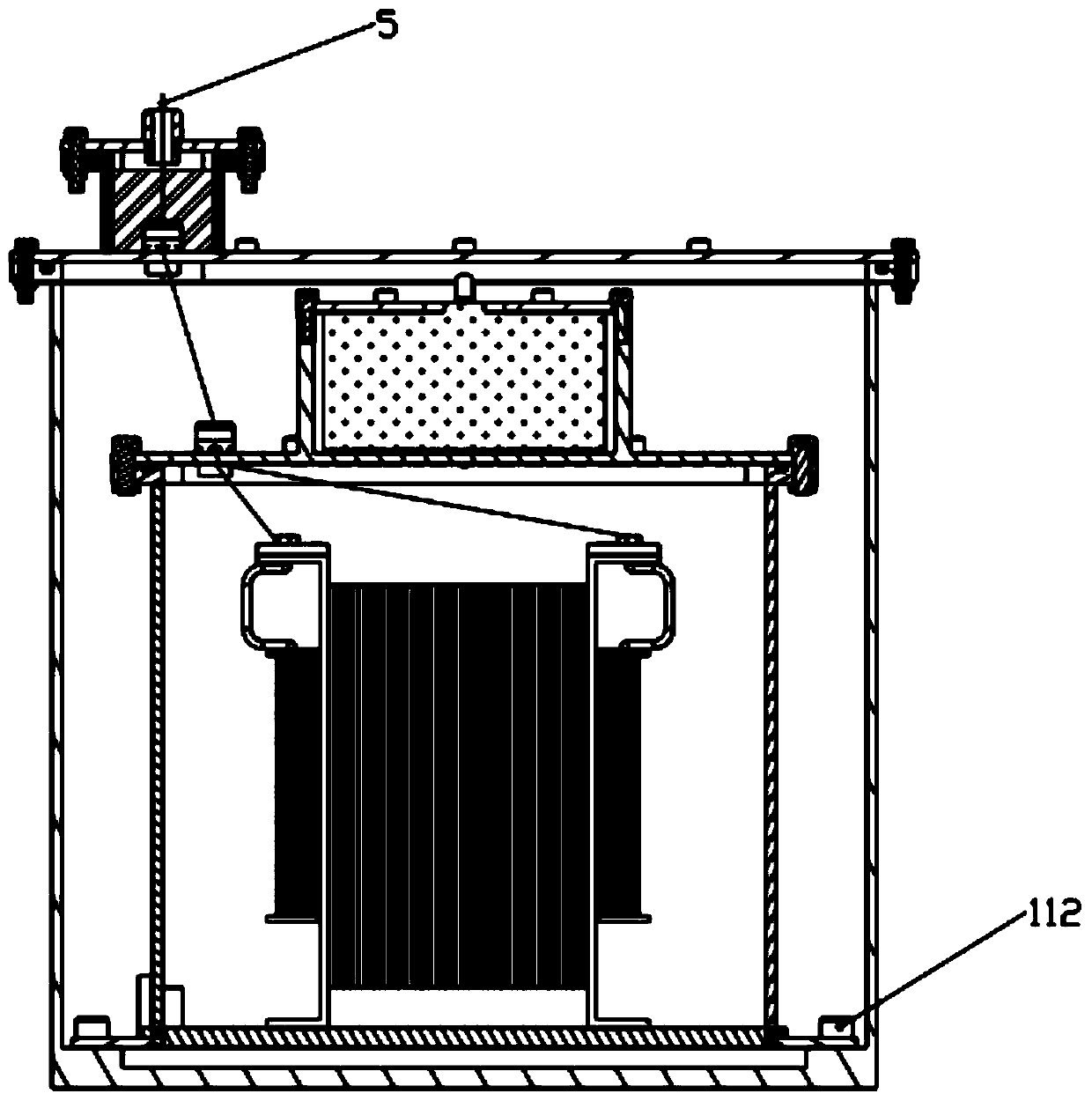

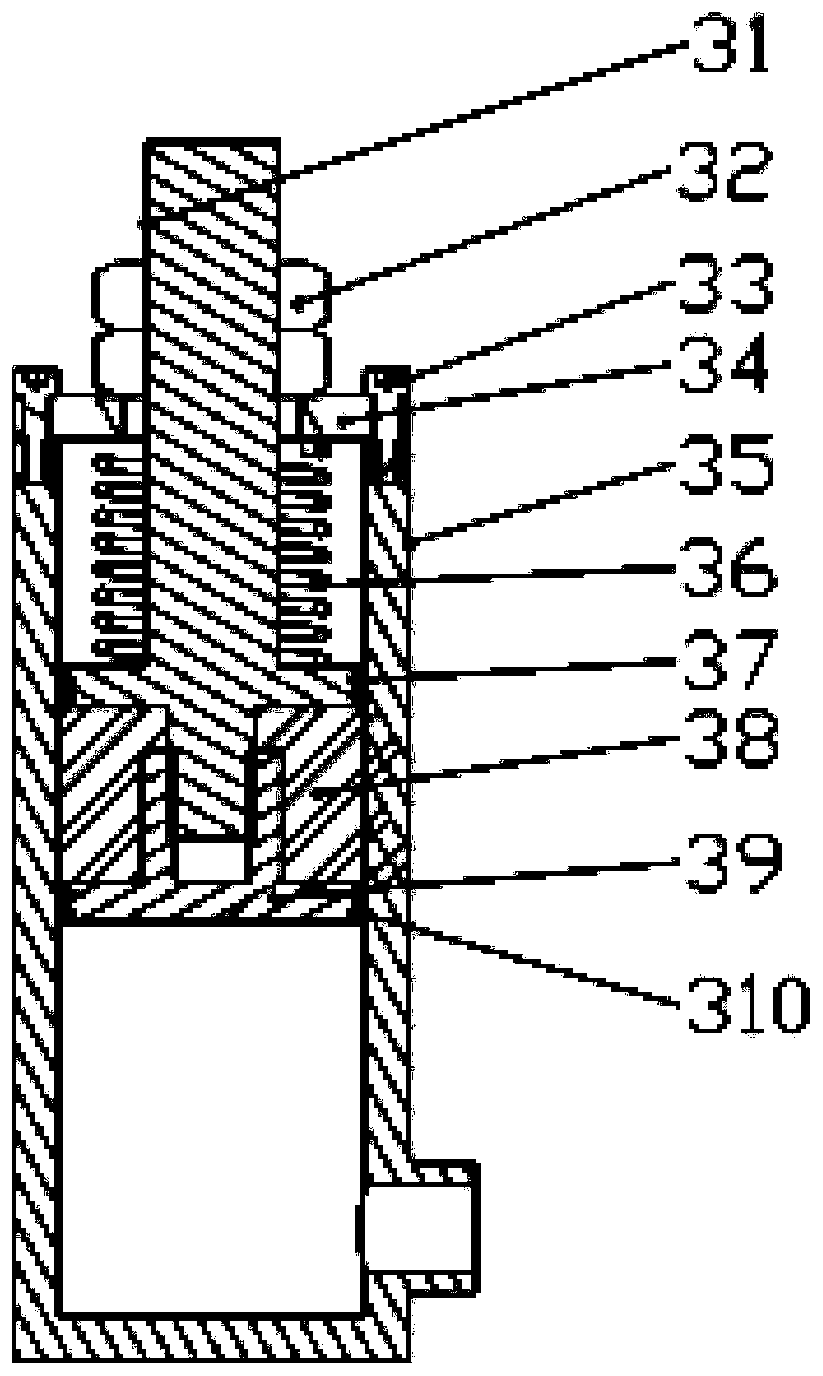

Double-level pressure compensation type underwater transformer

ActiveCN110379592AReduced wall thicknessAchieve lightweightTransformers/inductances casingsUnderwaterTransformer

The invention relates to a transformer applied to the deep sea environment and particularly relates to a double-level pressure compensation type underwater transformer having properties of light weight and high reliability. The transformer includes an outer casing, an inner casing, a pressure compensator, a transformer, a cable, an oil tank and a cable sealing cabin. The transformer is characterized in that the inner casing is mounted in the outer casing, the transformer is mounted in the inner casing, the oil tank is fixed on an upper cover of the inner casing, the cable sealing cabin is fixed to an upper cover of the outer casing, the cable penetrates through the upper cover of the outer casing and the upper cover of the inner casing through a watertight joint mounted on an upper cover of the cable sealing cabin and is then connected with the transformer, the upper cover of the outer casing is covered with an oil injection plug, the bottom of a side wall of the outer casing is provided with an oil drain plug and the pressure compensator, and the pressure compensator communicates with an inner chamber of the outer casing to achieve pressure compensation. The transformer is advantaged in that the transformer is compact in structure, is simple to assemble, is convenient to replace and maintain and has strong adaptability, stable operation and strong reliability in the severe environment.

Owner:JILIN UNIV

Production process of thin-wall boosting extruded tube and thin-wall boosting extruded tube

The invention discloses to a production process of a thin-wall boosting extruded tube and thin-wall boosting extruded tube, and belongs to the technical field of food processing equipment. The production process comprises the steps that after a high-quality pipe is selected and cut, a pipe blank with a boosting groove is formed in a bulging mode through a water swelling process, and then an annular pipe of an integrated structure used for welding a feeding pipe is drawn out; compared with a traditional metal casting process, a thin-wall boosting extrusion pipe manufactured through the production process has the advantages that the thickness of a pipe wall is greatly reduced, the thin-wall boosting extrusion pipe is light in weight, the energy consumption of the production process is low, the production cost is low, the process steps are simple, the production period is shortened, the production efficiency is improved, and the production cost is reduced, and continuous production can be realized.

Owner:杜亚玲

Composite insulator, manufacturing method thereof and composite sleeve

PendingCN109872848AExtended service lifeStrong electric field toleranceSupporting insulatorsInsulating bodiesComposite insulatorsSemiconductor materials

The invention discloses a composite insulator. The composite insulator comprises an insulation pipe and an umbrella skirt, wherein the umbrella skirt wraps the outer side of the insulation pipe, the insulation pipe comprises a first winding layer, a first semiconductor material layer and a second winding layer, the first winding layer deviates from the umbrella skirt, and the first semiconductor material layer is arranged between the first winding layer and the second winding layer and is arranged on a part of the cross section of an outer side of the first winding layer. The invention also discloses a manufacturing method of the composite insulator and a composite sleeve. By the mode, the semiconductor material layer is arranged in the insulation pipe, the interference of an electric field in the composite insulator can be reduced, the distribution of a local electric field is improved, the concentration of the electric field is reduced, the umbrella skirt is prevented from being electrically corroded by surface discharging, the shortening of the lifetime of the insulation pipe after long-term application is prevented, and the composite insulator can be applied to a strut insulator, the composite sleeve or other high-voltage power equipment.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

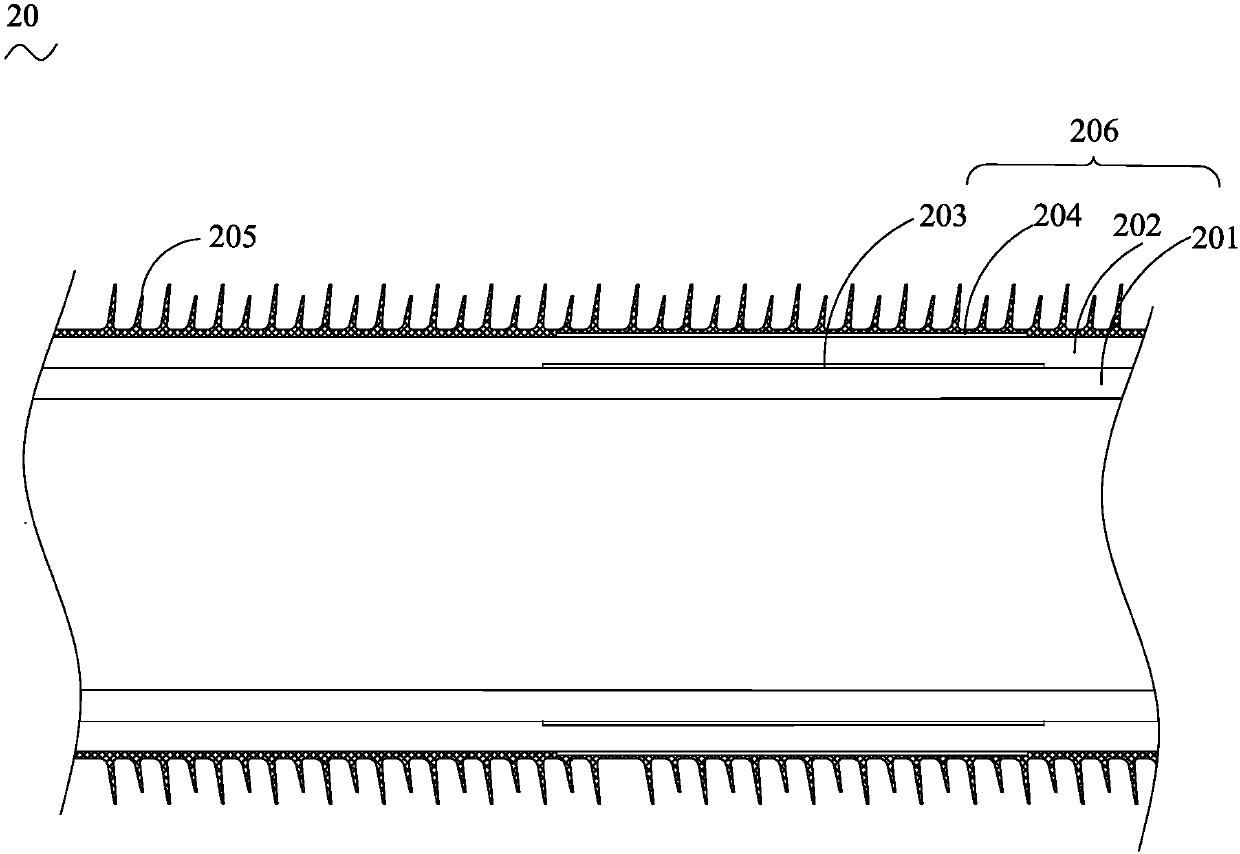

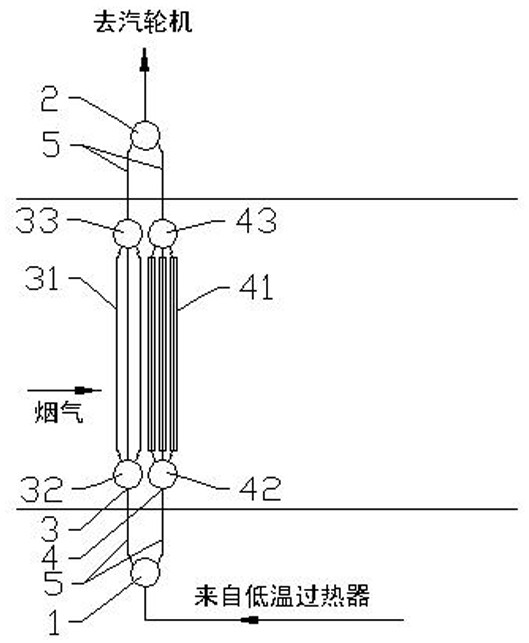

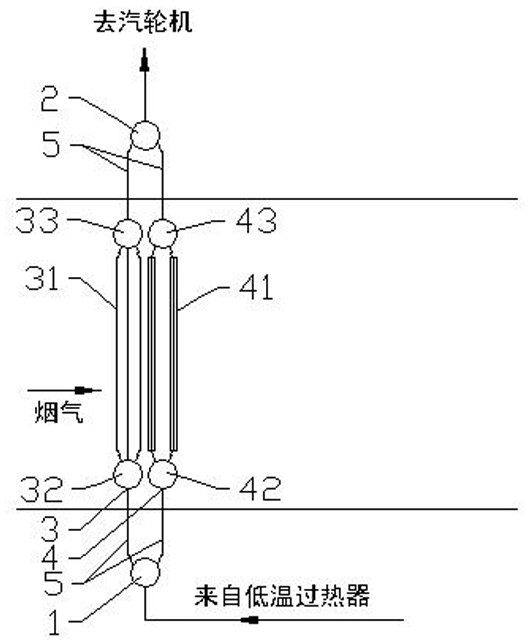

Multi-tube-bank superheater of waste heat boiler

PendingCN112097242ASimple structureReasonable layoutSteam superheatersPower stationProcess engineering

The invention relates to a multi-tube-bank superheater of a waste heat boiler and belongs to the technical field of power station boiler equipment. The multi-tube-bank superheater comprises a steam inlet header, a tube bank outlet header, a first tube panel and a second tube panel; the first tube panel and the second tube panel are arranged in parallel and connected with the steam inlet header andthe tube bank outlet header through connecting tubes correspondingly; a plurality of rows of first heating surfaces are arranged on the first tube panel; a plurality of rows of second heating surfaces are arranged on the second tube panel; the first heating surfaces adopt light tubes; the second heating surfaces adopt finned tubes; and the first tube panel is located on the front side of the second tube panel relative to the smoke flow direction. According to the multi-tube-bank superheater of the waste heat boiler, the technical problem that in the prior art, large temperature difference exists between the wall temperatures of the front rows of heating surfaces and the wall temperatures of the rear rows of heating surfaces is solved, the design difficulty of the heating surfaces is lowered, the risk that leakage and pipe explosion are prone to happening to welded junctions where the heating surfaces are connected with the headers is avoided, and unit operation safety is improved.

Owner:MHPS DONGFANG BOILER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com