Spiral coil heat exchange device

A spiral coil and tubular heat exchange technology, applied in the field of heat exchange devices, can solve the problems of high strength requirements of heat exchange plates, limited pressure bearing capacity, and affecting heat exchange efficiency, etc., and achieve compact structure and pressure bearing capacity High, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

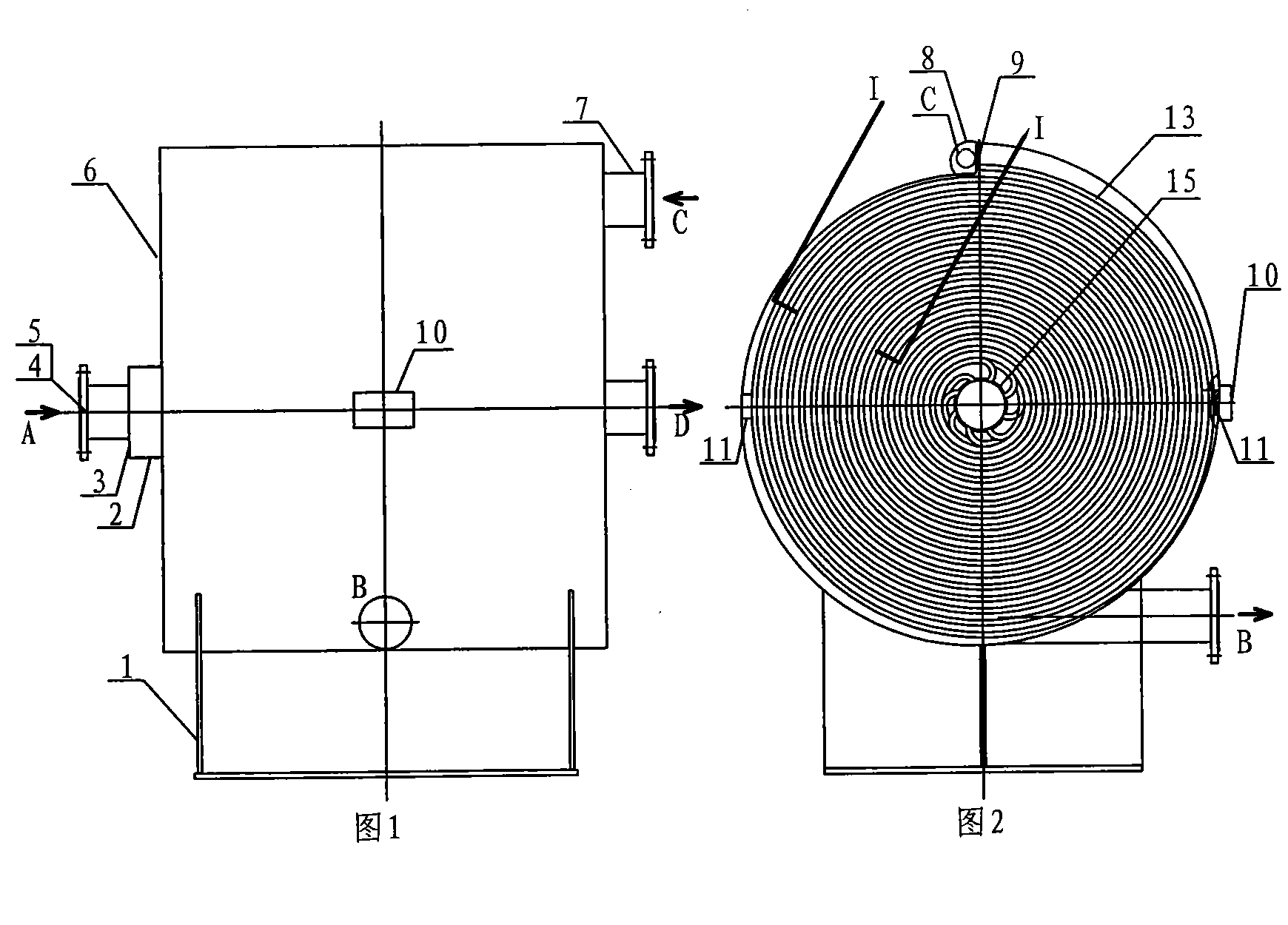

[0033] figure 1 -- Figure 5 Shown is a horizontal spiral coil heat exchanger, metallic.

[0034] The heat exchange device includes a cylinder 6 with a primary medium inlet A and an outlet B, a secondary medium inlet C and an outlet D, such as figure 1 shown. refer to figure 2 , The cylinder body 6 is provided with a central pipe 15 which is a spiral coiled pipe 13 whose axis is spirally involute. The spiral coiled pipe 13 communicates with the central pipe at one end of the axis.

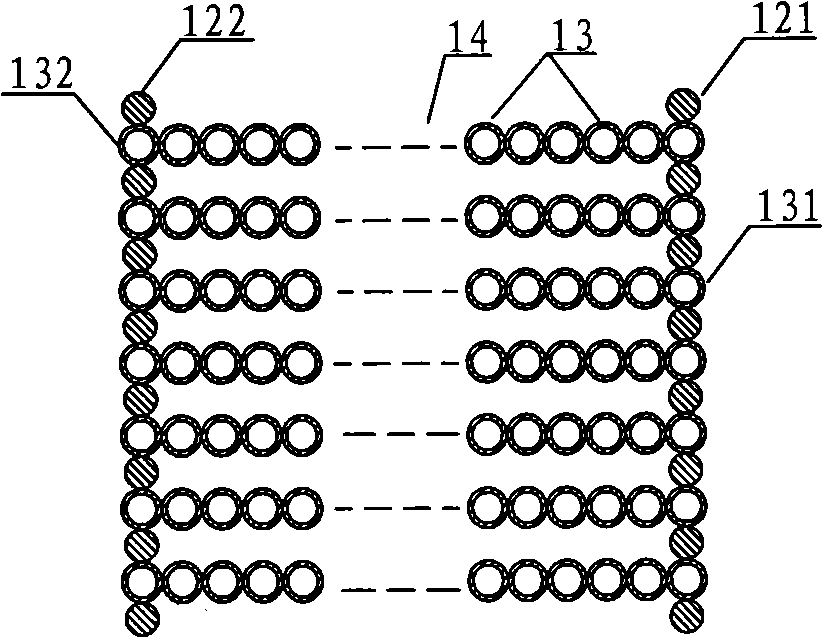

[0035] refer to image 3 , there are many spiral coils 13, and they are arranged side by side without gaps to form a spiral coil group 14, and the spiral coils 13 are mutually staggered on the central tube 15 on the outer wall (refer to figure 2 , Figure 4 , Figure 5 ). Adjacent helical coils 13 are welded and fixed at corresponding helical coils of their helical involutes.

[0036] The two outer end spiral coils 131, 132 located at the edge of the spiral coil group 14 are fixedly weld...

Embodiment 2

[0041] Figure 6 -- Figure 8 Shown is a vertical spiral coil heat exchanger, metal.

[0042] The heat exchange device includes a cylinder body 6 with primary inlet A and outlet B, secondary medium inlet C and outlet D, such as Figure 6 shown. refer to Figure 7 , Figure 8 , The cylindrical body 6 is provided with a central tube 15 and a spiral coil 13 with the central tube 15 as the axis in a spiral involute shape, and the spiral coil 13 communicates with the central tube at one end of the axis.

[0043] refer to Figure 7 , Figure 8 , There are many spiral coil tubes 13, they are arranged side by side without gaps to form a spiral coil tube group 14, and the spiral coil tubes 13 are connected to the central tube 6 on the central partition plate 16 provided in the central tube 15 in a staggered manner. Adjacent helical coils 13 are welded and fixed at corresponding helical coils of their helical involutes.

[0044]The two outer end spiral coils 131, 132 located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com