Large-pipe-diameter thin-wall pipe post-welded heat treatment device and using method thereof

A post-weld heat treatment and thin-walled tube technology, which is applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of uneven heating temperature, large heat treatment deformation, and uneven performance, and achieve uniform heating temperature and heat treatment deformation. Small, improved performance uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

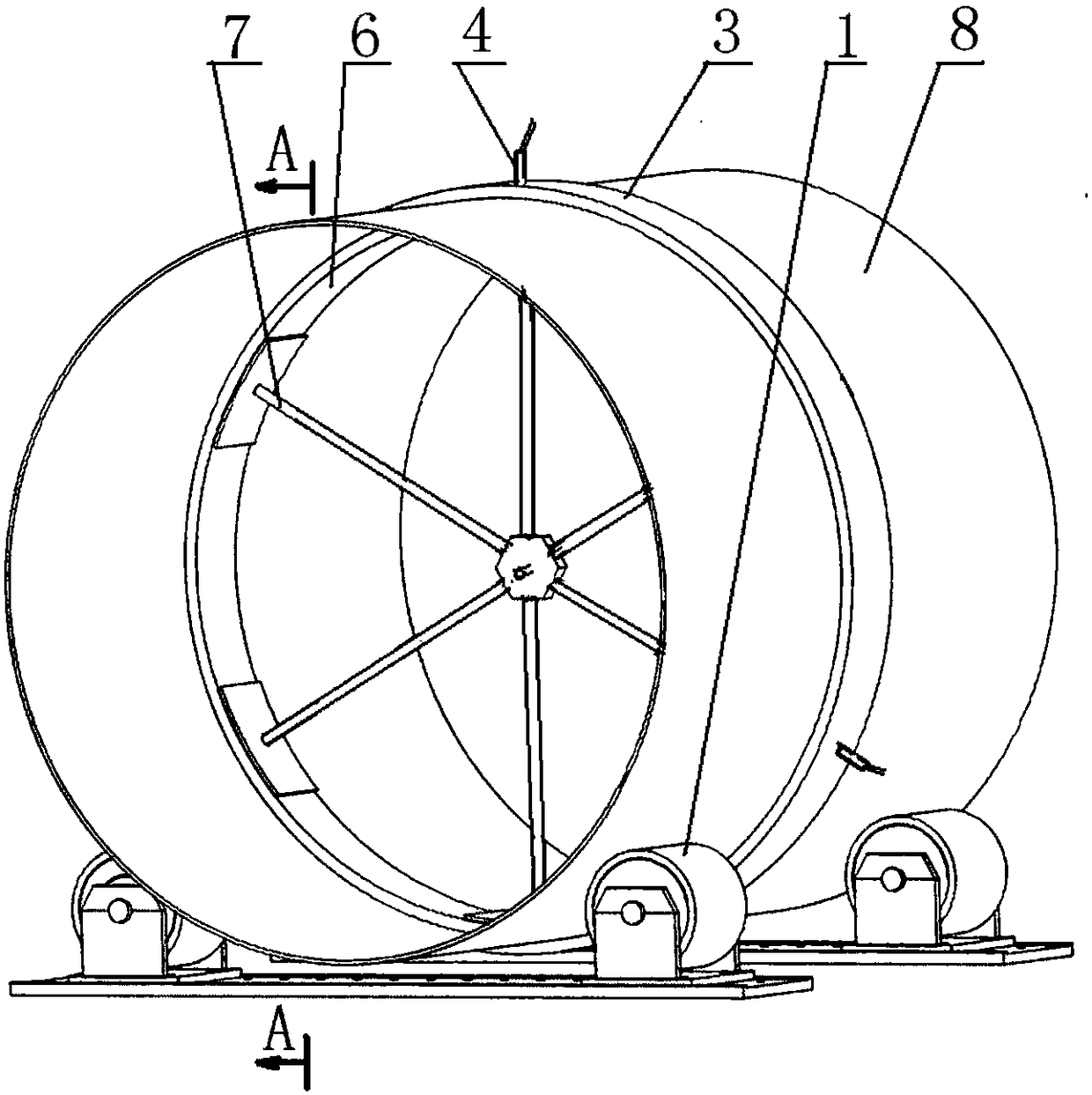

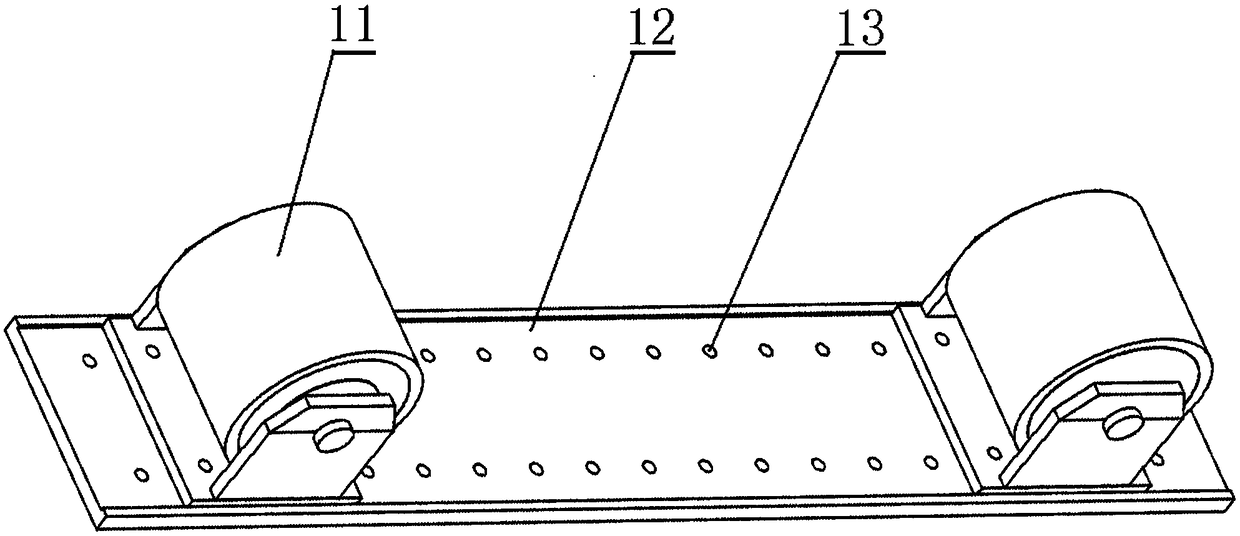

[0035] Concrete embodiment of the present invention is: as figure 1 , figure 2 , image 3 As shown, a post-weld heat treatment device for large-diameter thin-walled pipes includes a steel pipe support 1, a plurality of heating sheets 2 arranged close to the outer pipe wall, an asbestos insulation layer 3 covering the heating sheets 2, and is arranged on each An electric heating element 2 covers a temperature-measuring thermocouple 4 in contact with the outer wall of the steel pipe in the center of the coverage area, and a binding iron wire 5 for fixing the heating sheet 2 and the asbestos insulation layer 3 of the outer pipe wall, as well as the asbestos insulation layer arranged close to the inner pipe wall 6 and the support frame 7 used to fix the asbestos insulation layer 6 of the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com