Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Heat treatment deformation is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel for nitrocarburizing and nitrocarburized parts

InactiveUS20110186182A1Deeper effective case hardeningHeat treatment deformation is smallSolid state diffusion coatingMetal layered productsCase hardeningMaterials science

Owner:NIPPON STEEL CORP

Heat treatment process for die steel

The invention discloses a heat treatment process for die steel. The heat treatment process for the die steel is characterized in that the heat treatment process comprises the following steps that 1, preheating treatment is conducted, specifically, isothermal spheroidizing annealing needs to be conducted immediately after the die steel is forged, the heating temperature is 840 DEG C-860 DEG C, and heat preservation lasts for 2-4 h; then the die steel is cooled to 720 DEG C-740 DEG C, and the constant temperature lasts for 4-6 h; the die steel is subjected to furnace cooling till to be 500 DEG C or blow, taken out of a furnace and subjected to air cooling; and 2, quenching and tempering are conducted, specifically, the quenching temperature is 1100 DEG C-1150 DEG C, and oil cooling is conducted; the tempering temperature is 530 DEG C-540 DEG C, tempering is conducted for two to three times, heat preservation lasts for 1.0-2.0 h each time, and the hardness of the die steel is 57-63 HRC. According to the heat treatment process for the die steel, the hardness and the abrasion resistance of the die steel can be improved.

Owner:重庆基石机械有限公司

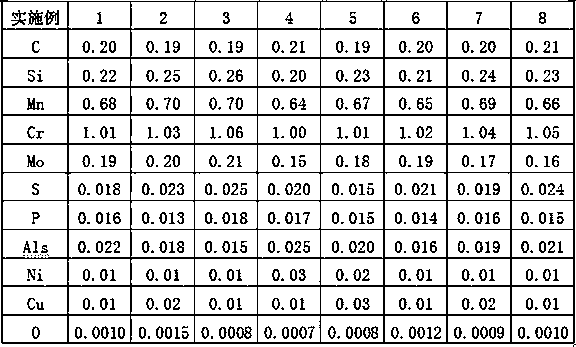

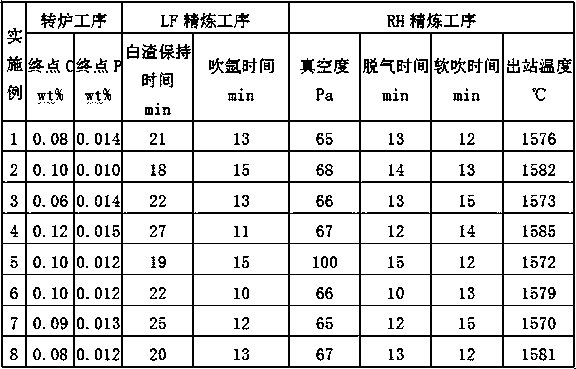

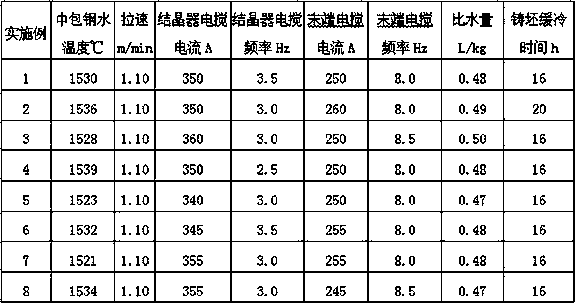

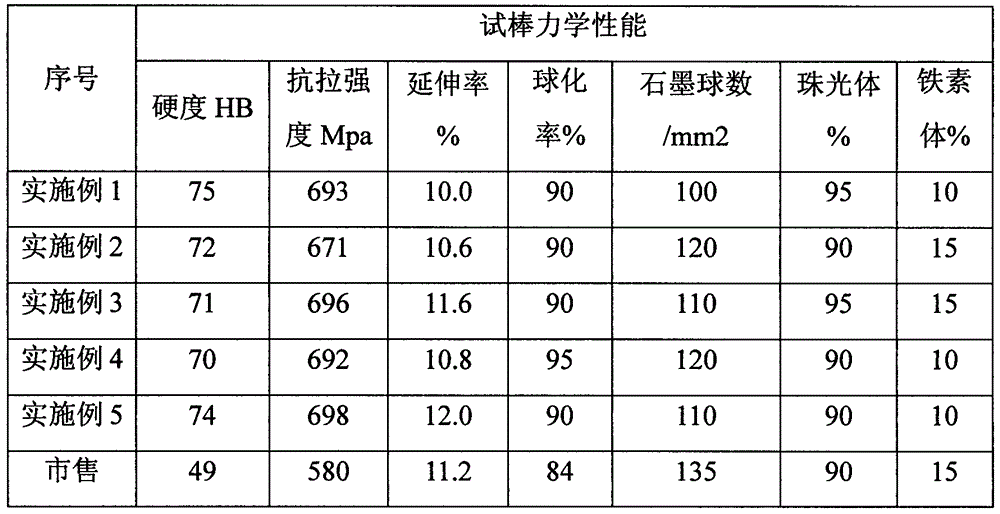

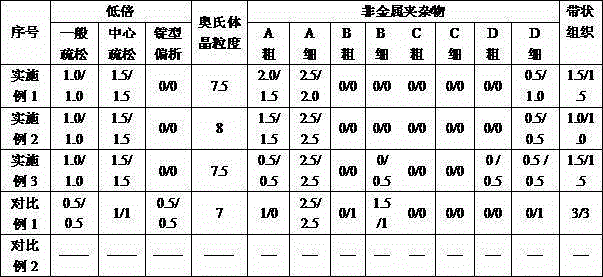

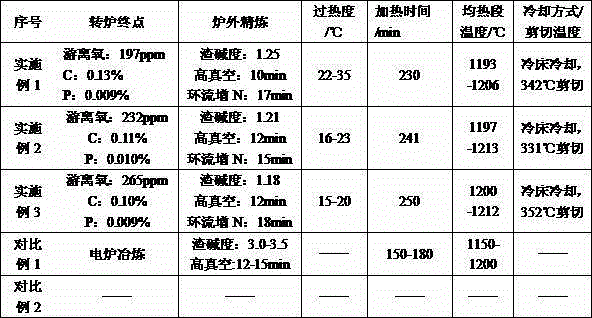

Gear steel 20CrMoSH and technology for improving hardenability stability thereof

The invention discloses gear steel 20CrMoSH and a technology for improving the hardenability stability thereof. The technology comprises the procedures of converter smelting, LF refining, RH refining,continuous casting, heating and rolling. The gear steel is prepared from the chemical components, by weight, 0.19%-0.21% of C, 0.20%-0.26% of Si, 0.64%-0.70% of Mn, 1.00%-1.06% of Cr, 0.15%-0.21% ofMo, 0.015%-0.025% of S, smaller than or equal to 0.018% of P, 0.015%-0.025% of Als, smaller than or equal to 0.03% of Ni, smaller than or equal to 0.03% of Cu, smaller than or equal to 0.0015% of O and the balance Fe and unavoidable impurities. According to the gear steel 20CrMoSH which is produced through the method and has the diameter phi ranging from 28 mm to 50 mm, the hardenability J1.5 ranges from 40 HRC to 45 HRC, the hardenability J5 ranges from 37 HRC to 42 HRC, the hardenability J9 ranges from 28 HRC to 33 HRC, and the maximum discrete value of the hardenability of the steel in thesame furnace is not larger than 3 HRC. The heat-treatment deformation of a gear can be significantly reduced by means of high-stability hardenability, and therefore the meshing precision of the gear is improved. The method is low in cost and high in production efficiency, and the product has the advantages that the hardenability is stable, the gear heat-treatment deformation is small, and the machined gear is high in meshing precision and low in service life.

Owner:HANDAN IRON & STEEL GROUP +1

Cold work die steel and preparation method thereof

The invention provides cold work die steel. The cold work die steel comprises C, Si, Mn, Cr, Mo, W, V, P, S, Cu, Mg, Ti, Sr, Zr, B, Zn, Re, Sn, Pb, Be, Sc, Li, Ni, La, Al and the balance iron, wherein the sum of the mass percentages of the components is 100%. The nodular cast iron comprises multiple kinds of nonmetal, metal and transition metal elements. Because the elements are added and cooperate with one another, the oxidation resistance, the corrosion resistance, the abrasion resistance, the compression resistance and the shock resistance of a compressor cylinder block of an air conditioner are improved, and the service life of the compressor cylinder block of the air conditioner under severe working conditions is prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Automobile rear-bridge spiral conic gear of manganese-copper alloy autenite-bainite nodular iron and its preparing method

InactiveCN1936368AGuaranteed hardenabilityGuaranteed nodularityPortable liftingFurnace typesRoughcastCupola furnace

This invention relates to a MnCu alloy ADI car rear axle screw bevel gear and its preparation method, which takes ordinary pig iron as the raw material of said gear, applies a duplex method of cupola and electric cooker, takes rear earth, Mg and silicon iron alloy as the nodulizer to be processed then to slag and eliminate slag, gestates and casts the gear roughcast in two times, then finishes it after mechanical process, isothermal quenching and temper, in which, the composed weight percentage of said gear is: C 3.4-3.8%, Si 2.4-2.9%, Mn 0.4-1.0%, Cu 0.5-1.2%, P less than 0.06%, S less than 0.02% and the rest is iron.

Owner:WUHAN UNIV OF TECH +1

Nitrogen-added 20MnCr5 gear steel and production method thereof

The invention relates to nitrogen-added 20MnCr5 gear steel. The gear steel comprises, by weight, 0.18-0.21% of C, Si with the amount smaller than or equal to 0.12%, 1.25-1.35% of Mn, 1.16-1.24% of Cr, P with the amount smaller than or equal to 0.020%, 0.020-0.030% of S, 0.025-0.045% of Al and 0.0060-0.0100% of N. The gear steel further comprises, by weight, Ni with the amount smaller than or equal to 0.10%, Cu with the amount smaller than or equal to 0.10%, B with the amount smaller than or equal to 0.0003%, O with the amount smaller than or equal to 15*10-6, and the balance Fe and other trace residual elements. The gear steel has the advantages of being stable in performance, small in heat treatment deformation and good in surface quality, and achieving hardenability band narrowing.

Owner:SGIS SONGSHAN CO LTD

Axle gear box shifting locking mechanism

InactiveCN101016947AReduce manufacturing difficultyEasy to processGearing controlGearing detailsGear wheelLocking mechanism

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

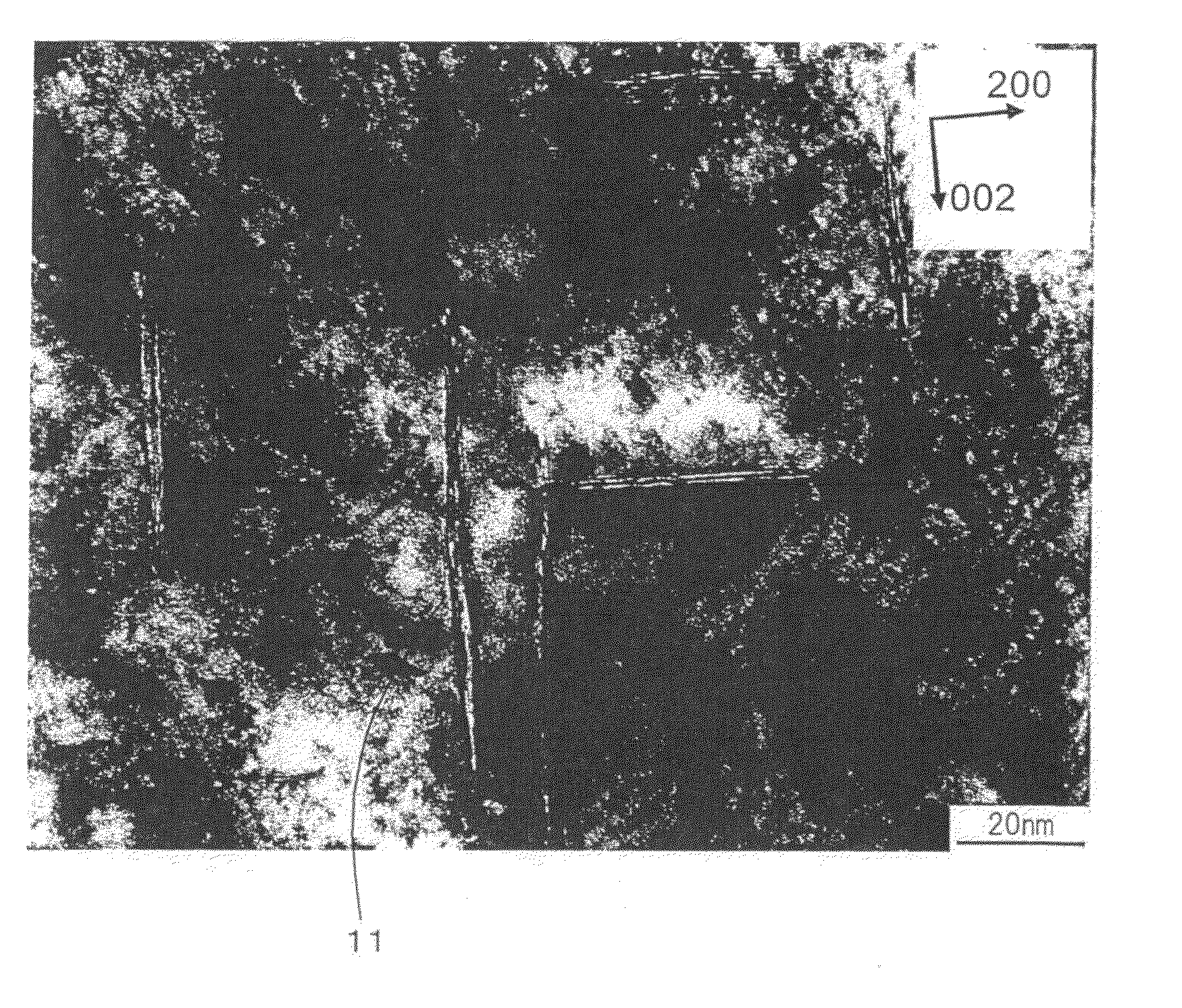

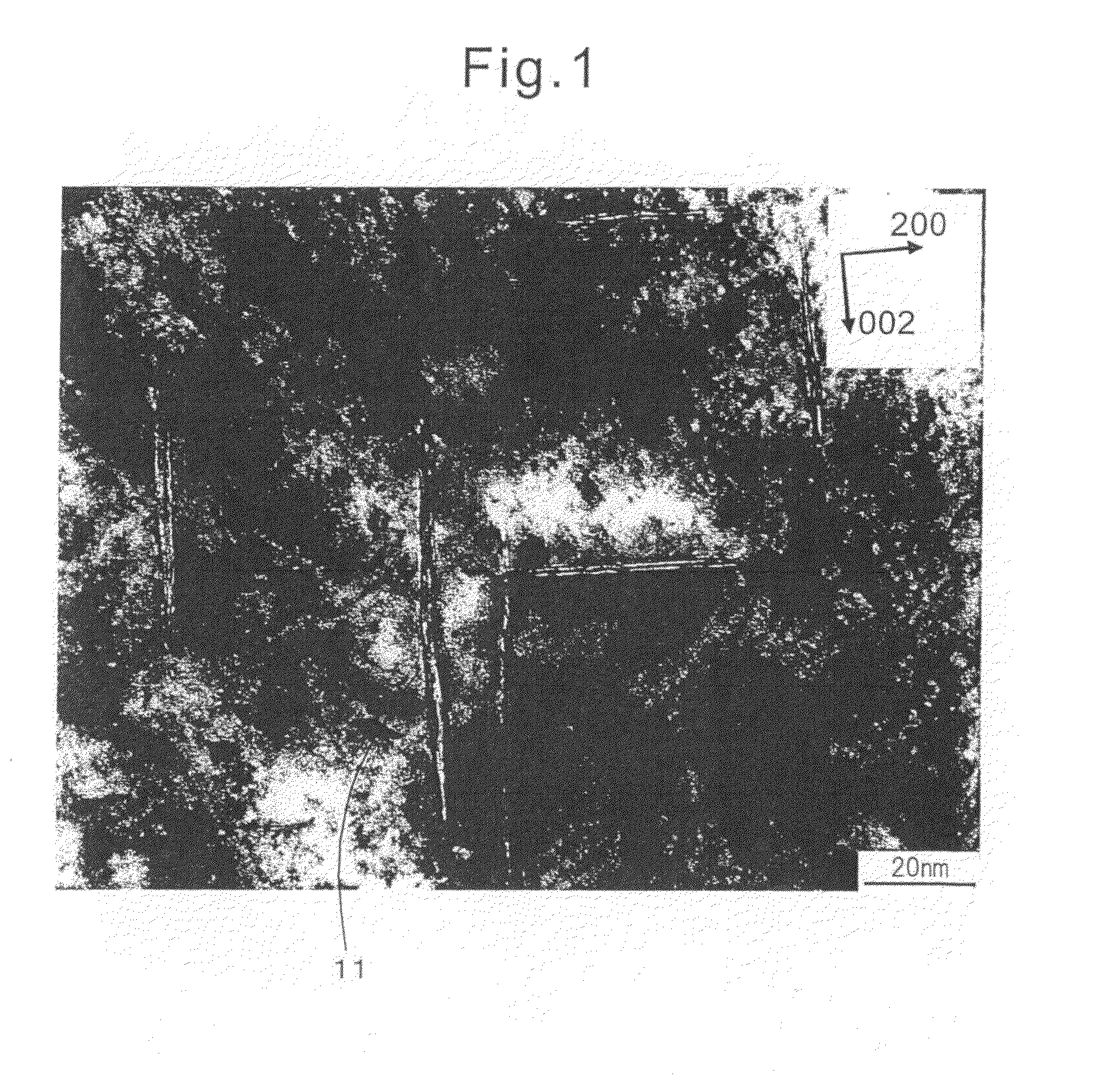

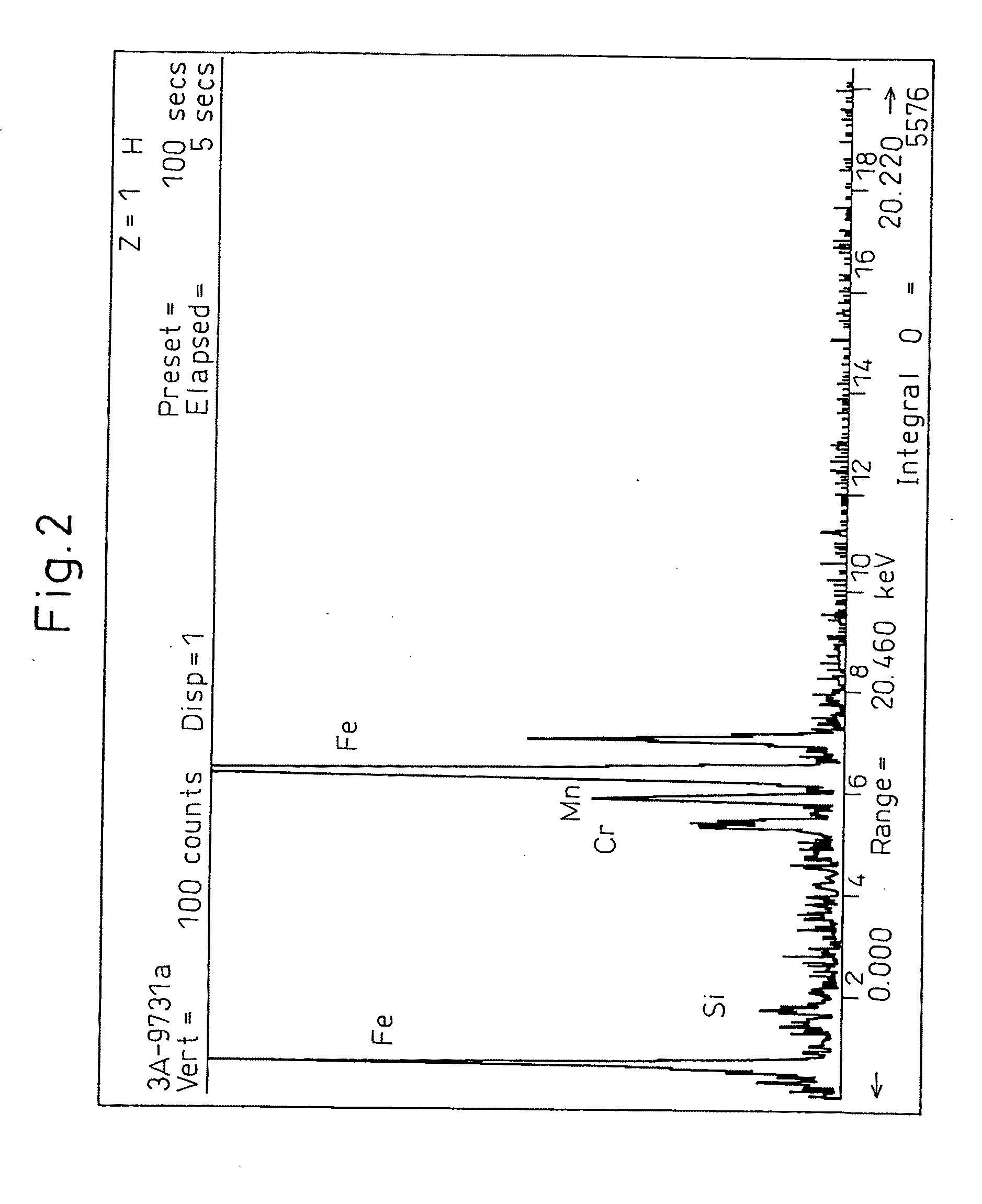

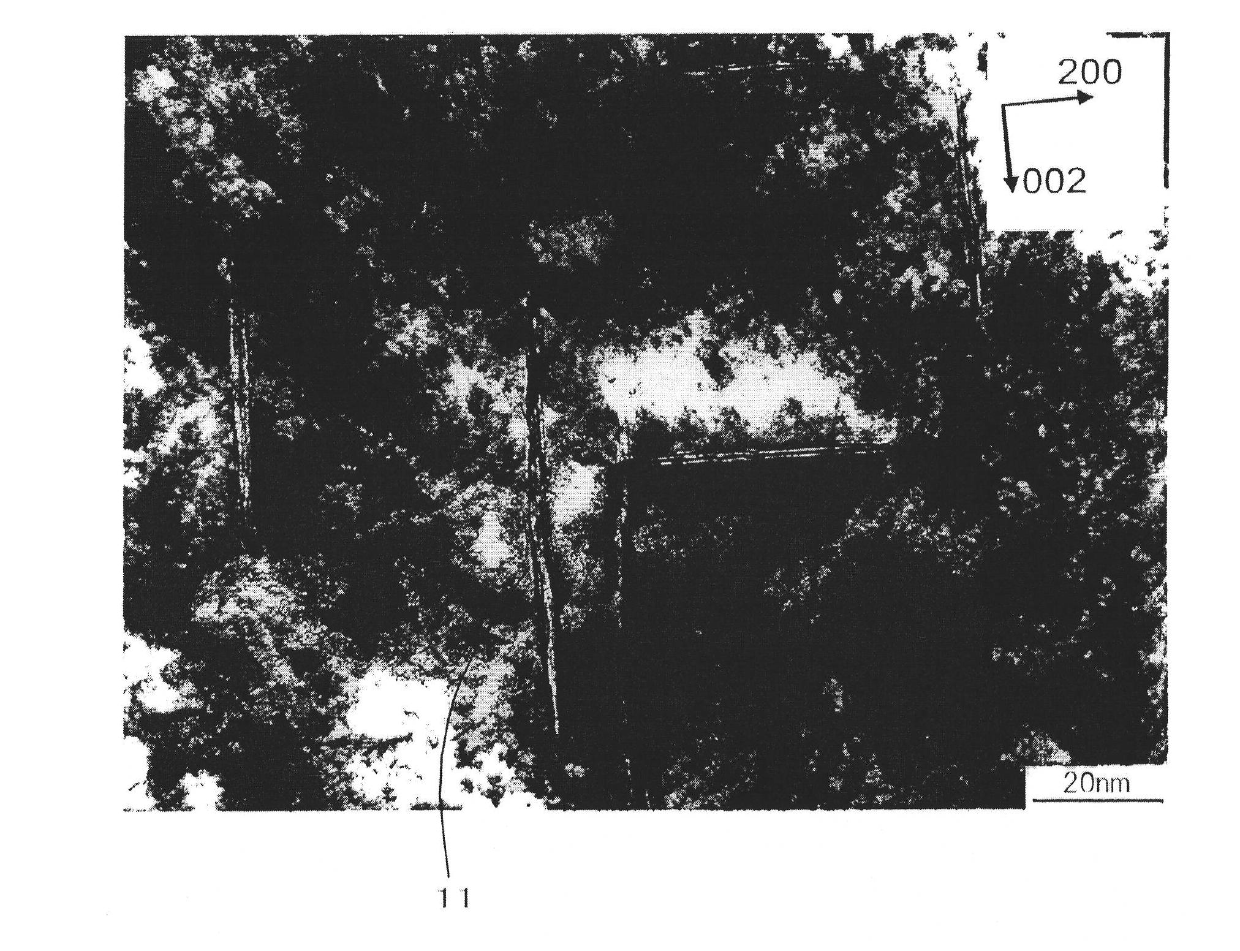

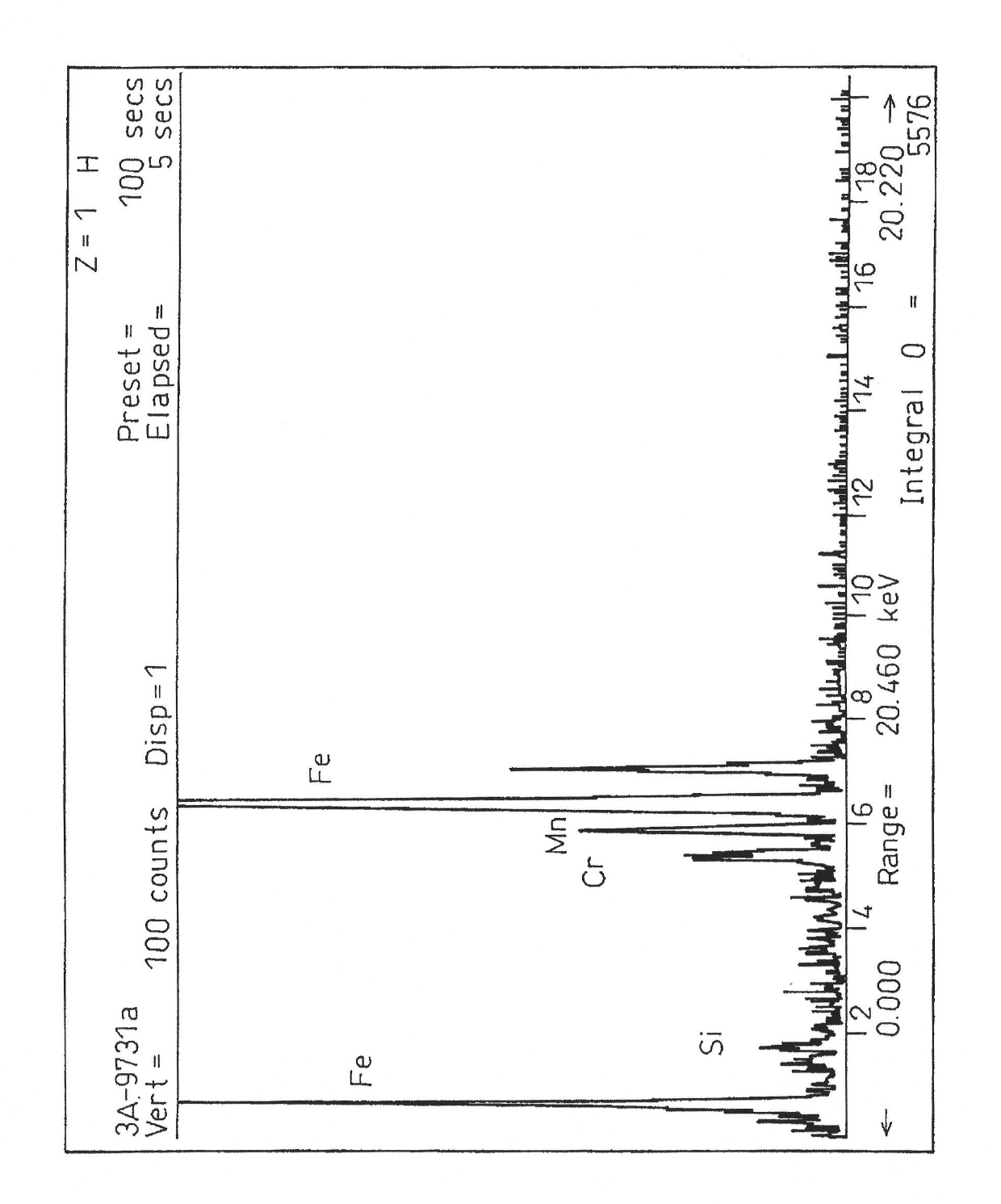

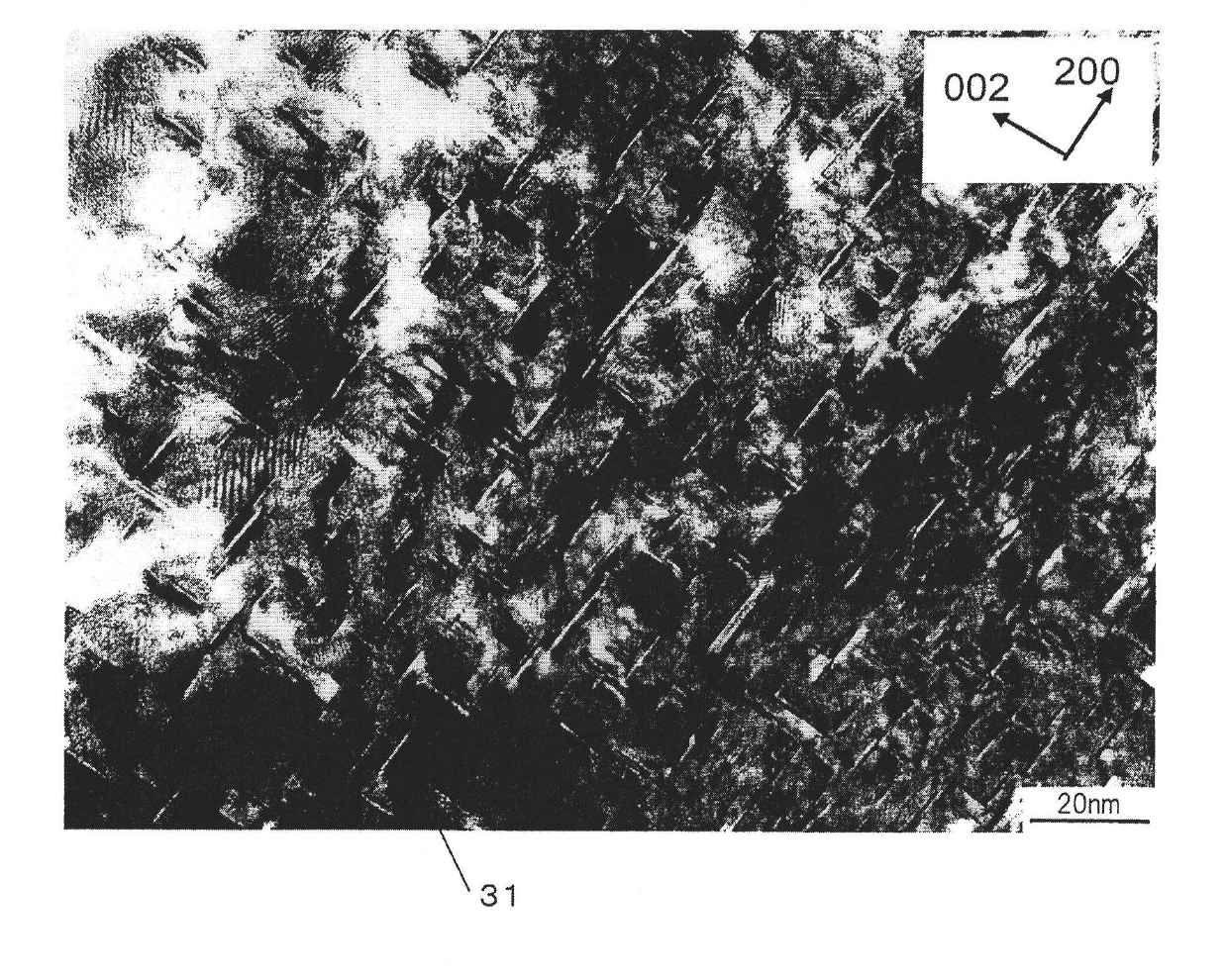

Steel for nitrocarburizing and nitrocarburized parts

InactiveCN102089452AHeat treatment deformation is smallImprove fatigue strengthSolid state diffusion coatingMetal layered productsCase hardening

The present invention relates to a steel material giving more effective case hardening for improving the fatigue strength and is characterized by containing, by mass %, C: 0.01 to 0.3%, Si: less than 0.1%, Mn: 0.4 to 3%, Cr: 0.5 to 3%, and Al: 0.01 to 0.3%, further containing one or both of Mo: 0.2 to 1.5%, and V: 0.05 to 1.0%, having a balance of Fe and unavoidable impurities, and comprising a structure having 50% or more of bainite.

Owner:NIPPON STEEL CORP

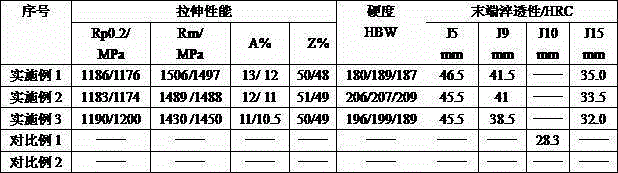

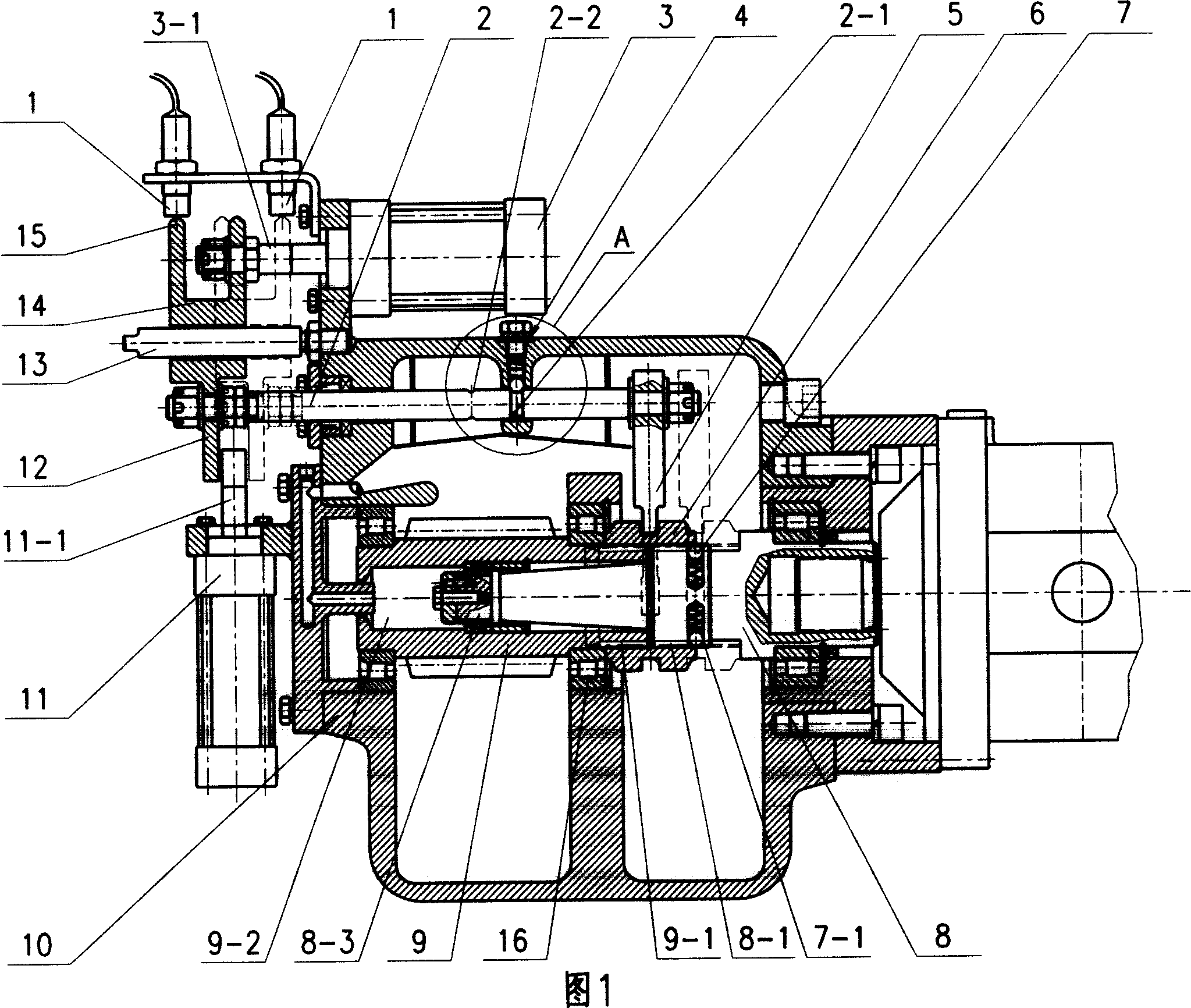

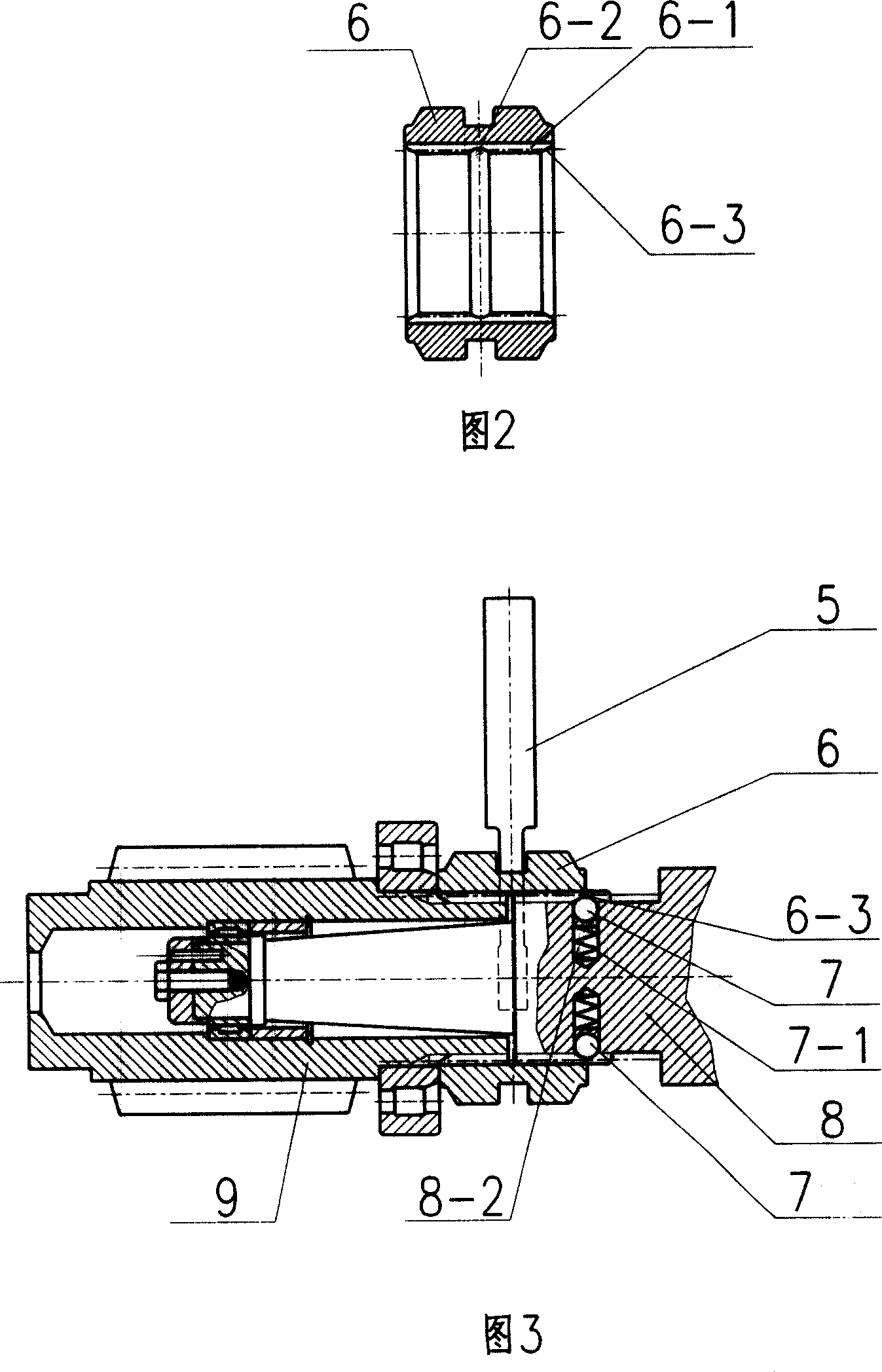

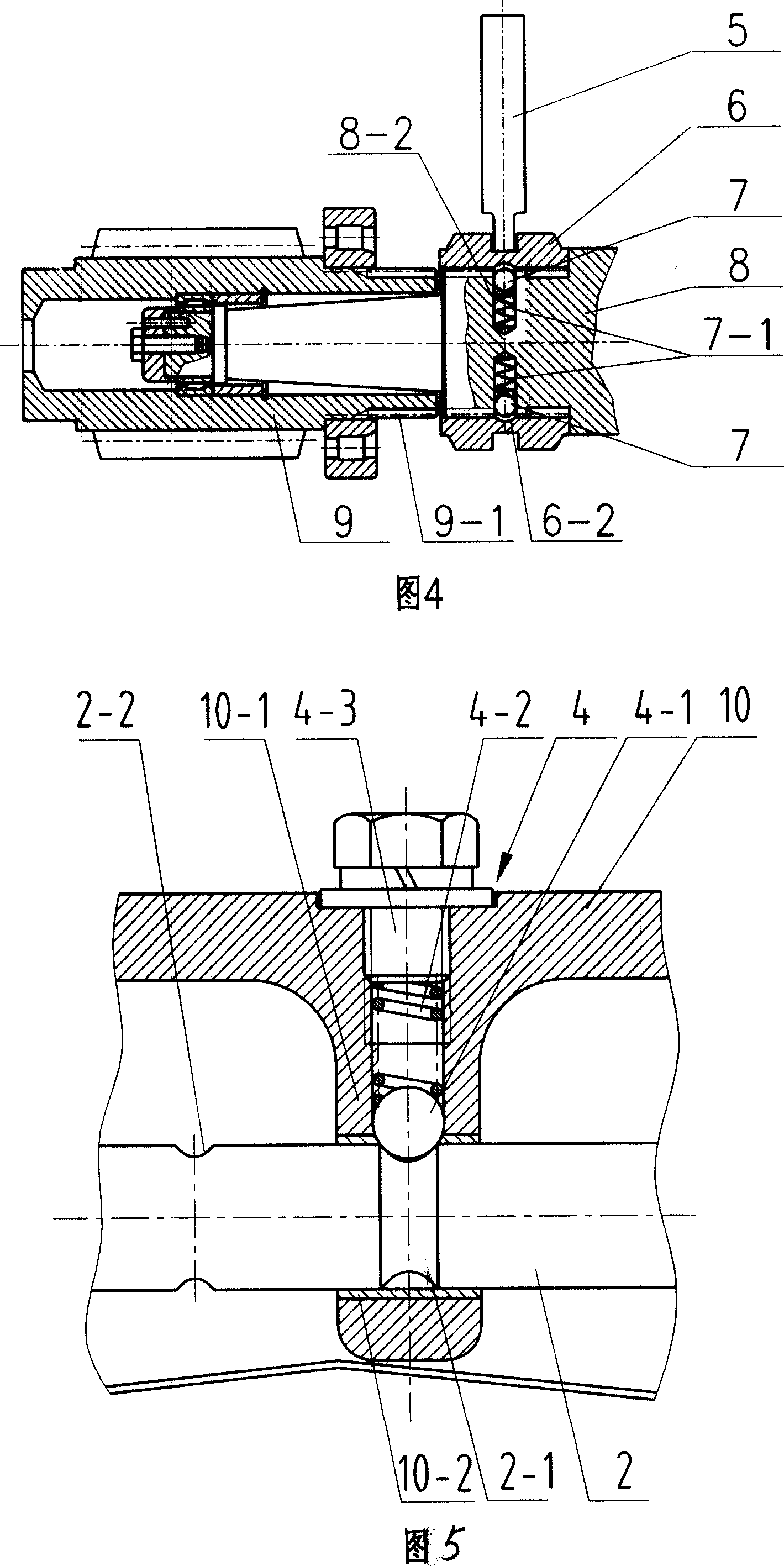

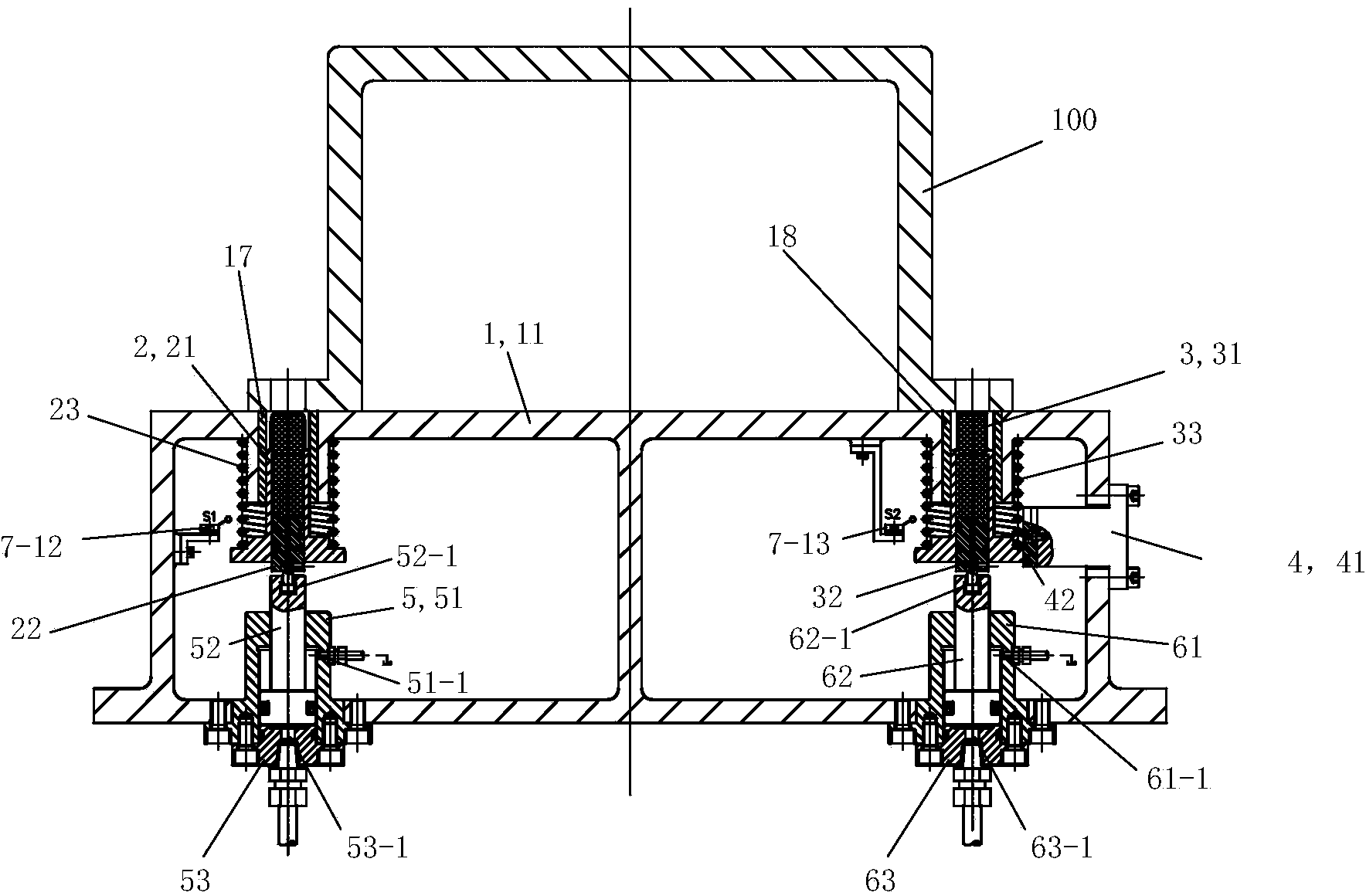

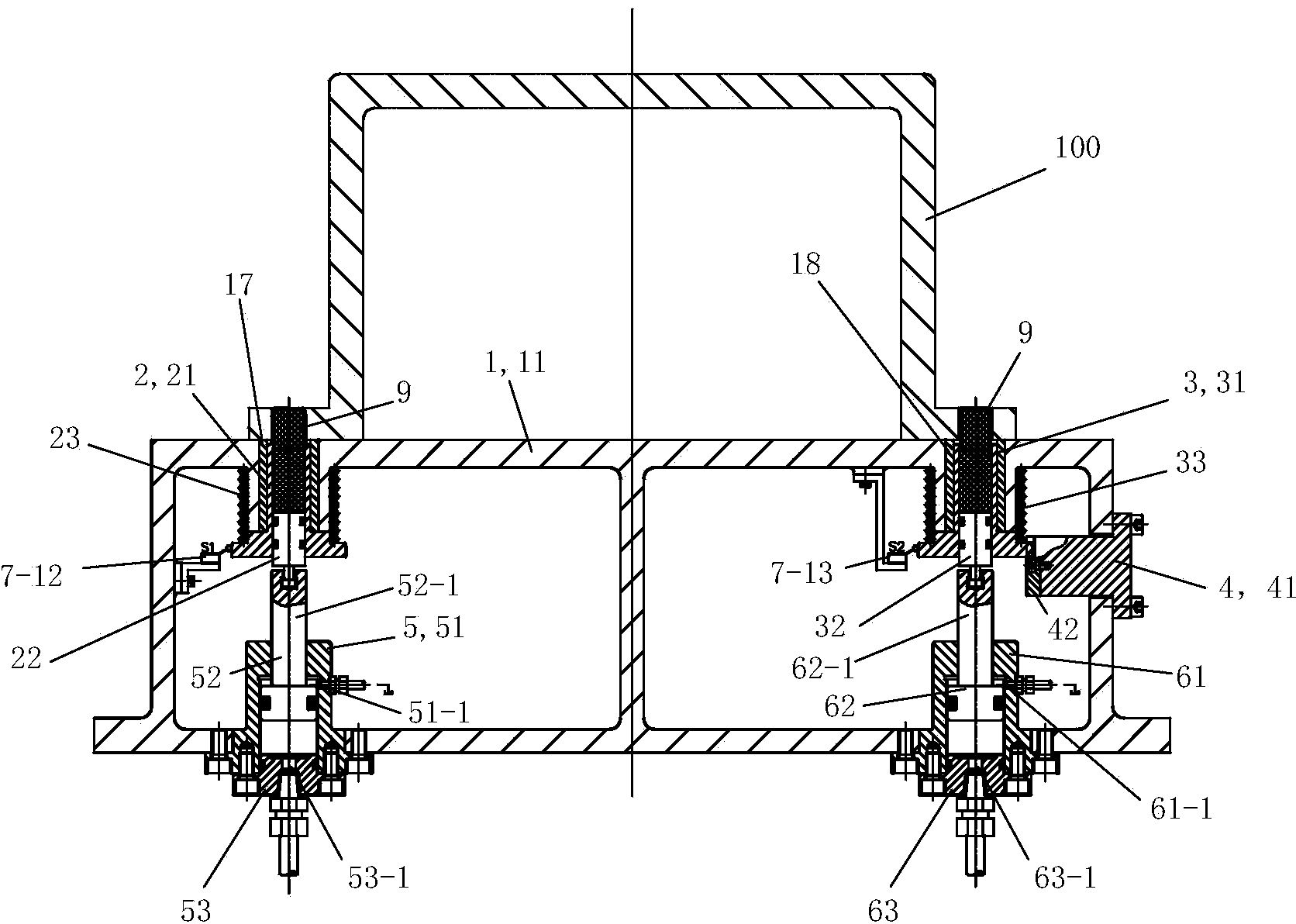

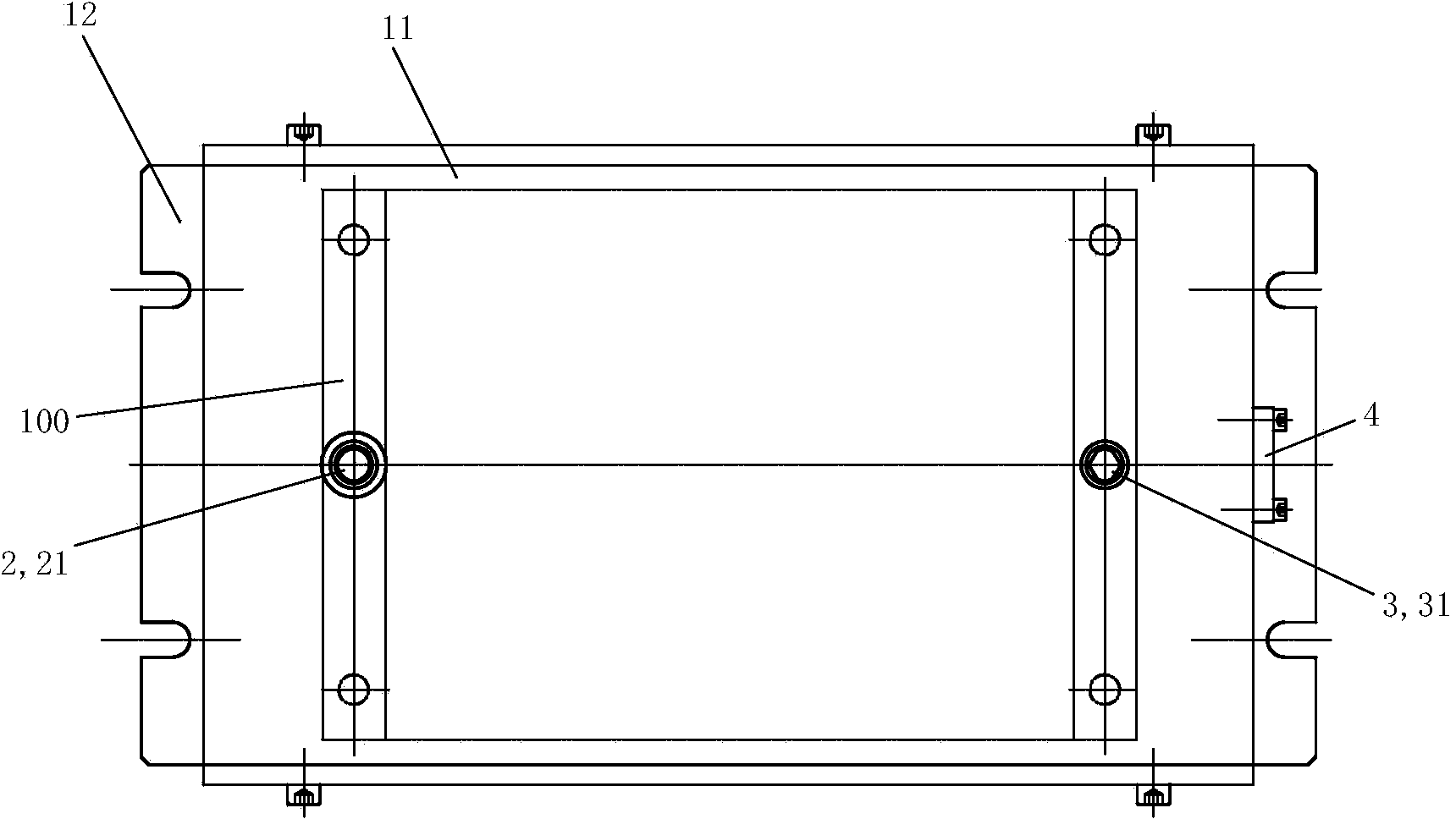

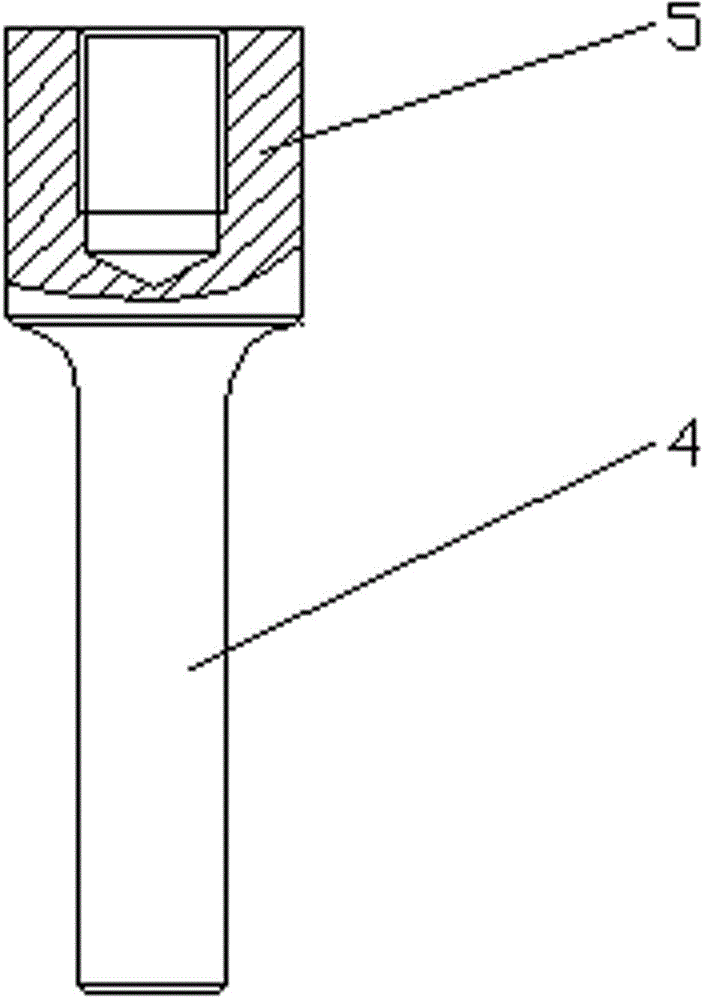

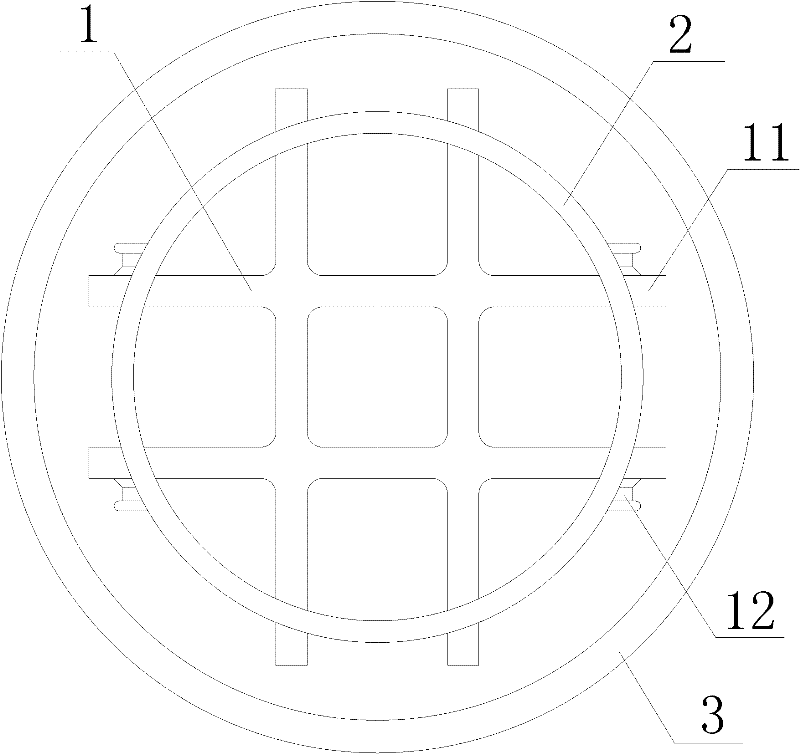

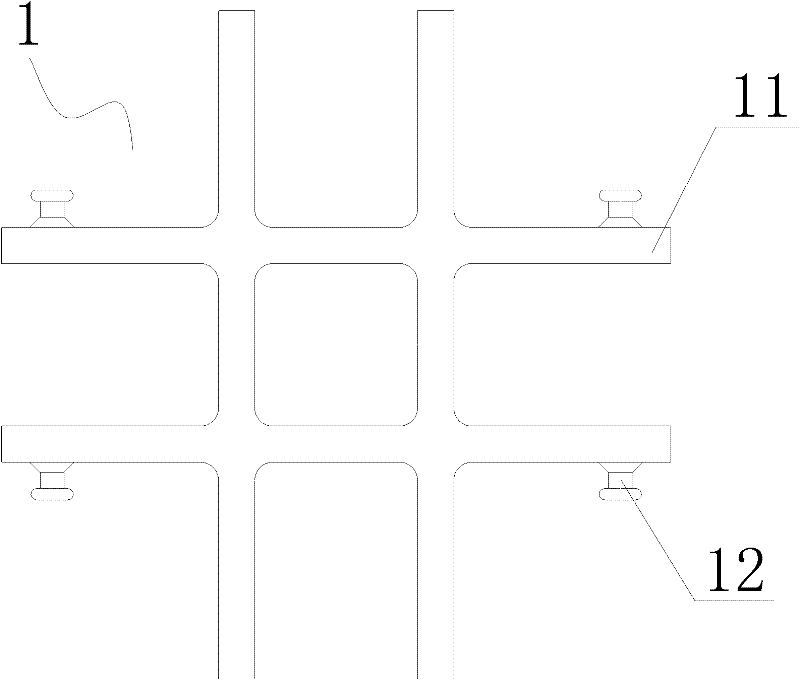

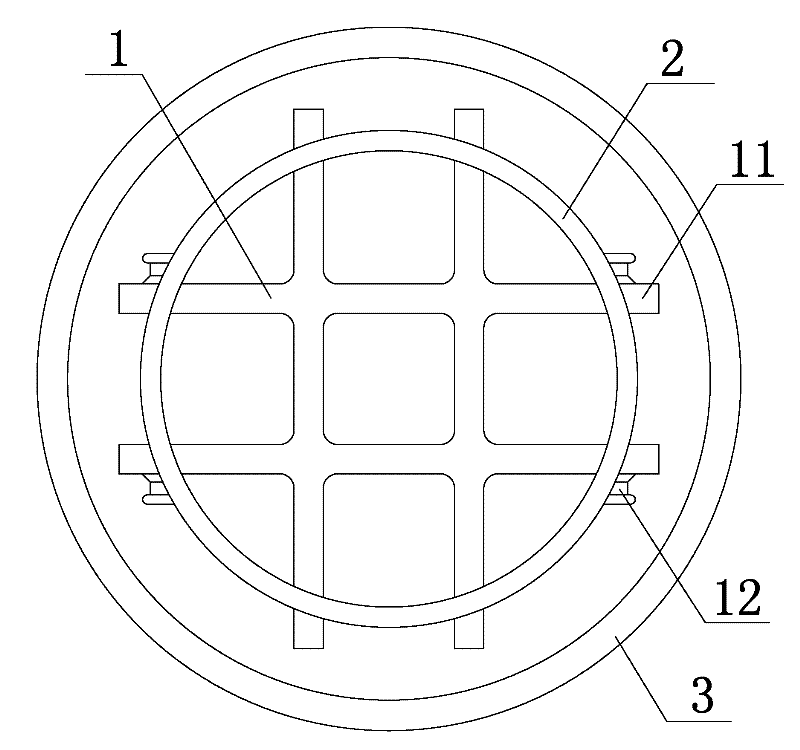

One-face two-pin precise positioning system and control method thereof

InactiveCN103962868AHigh positioning accuracySimple structureWork clamping meansPositioning apparatusControl systemEngineering

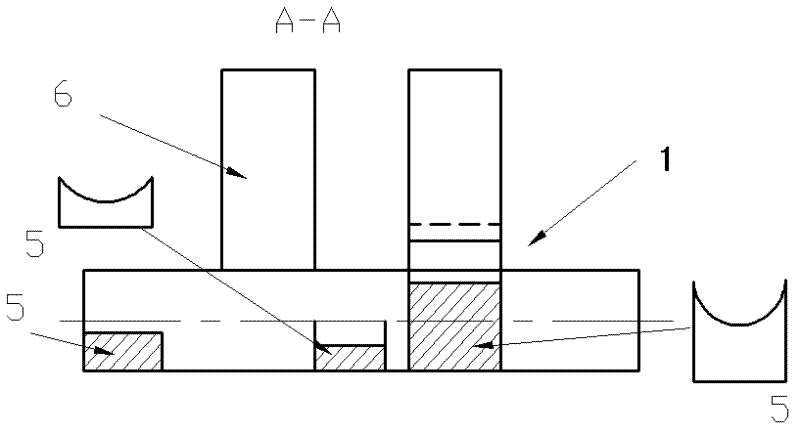

The invention discloses a one-face two-pin precise positioning system. The one-face two-pin precise positioning system is characterized by comprising a worktable, a round pin positioning device, a diamond pin positioning device and a control system; the control system comprises a first power device and a second power device, the first power drive drives a first plunger to move in a plunger hole of a round pin, the round pin is driven to move upwards by upwards extruding hydraulic plastics, the positioning portion of the round pin is inserted into a corresponding positioning hole of a workpiece, the positioning portion of the round pin generates corresponding plastic deformation and expands, and the gap between the round pin and the corresponding positioning hole in the workpiece is reduced. The second power device drives a second plunger to move in a plunger hole of a diamond pin, the diamond pin is driven to move upwards by upwards extruding the hydraulic plastics, the positioning portion of the diamond pin is inserted into a corresponding positioning hole of the workpiece, the positioning portion of the diamond pin generates corresponding plastic deformation and expands, and the gap between the diamond pin and the corresponding positioning hole in the workpiece is reduced.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

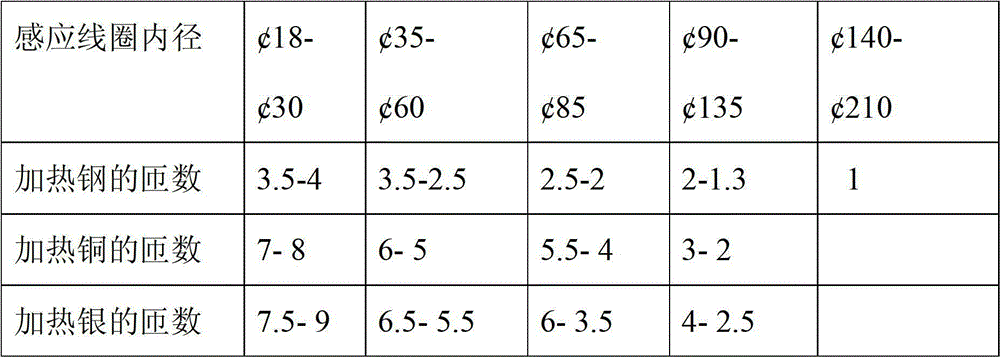

Induction brazing welding method for metal part

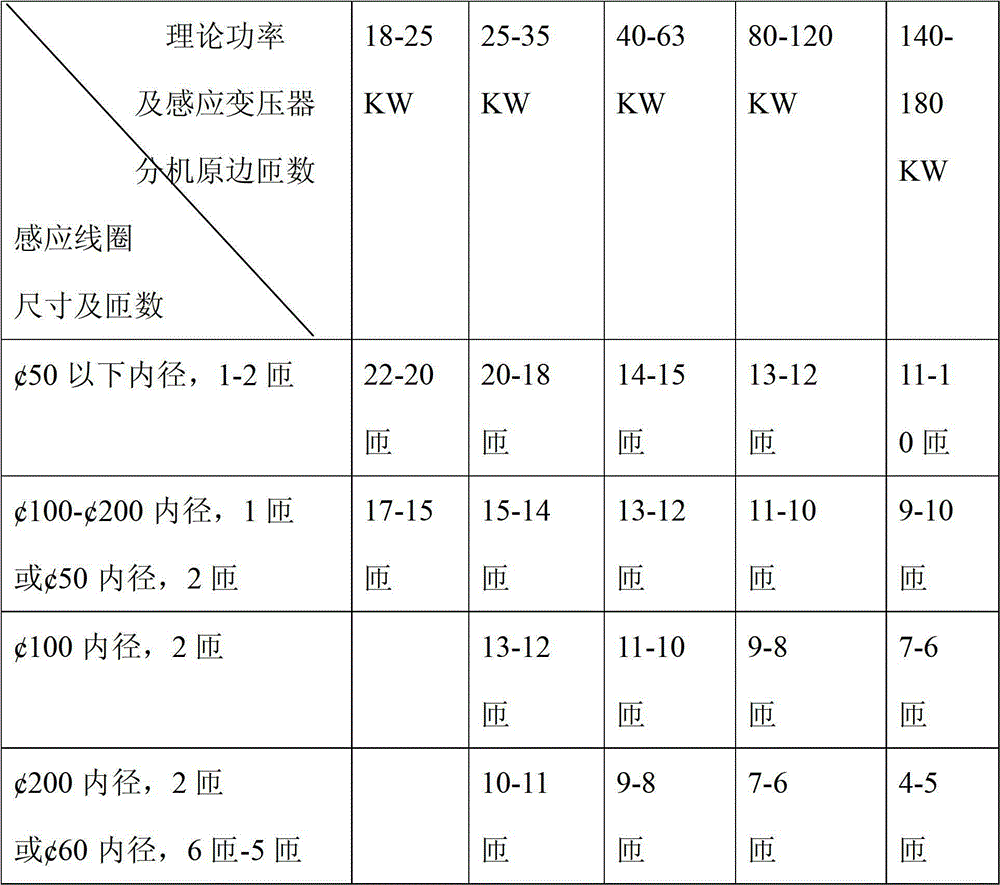

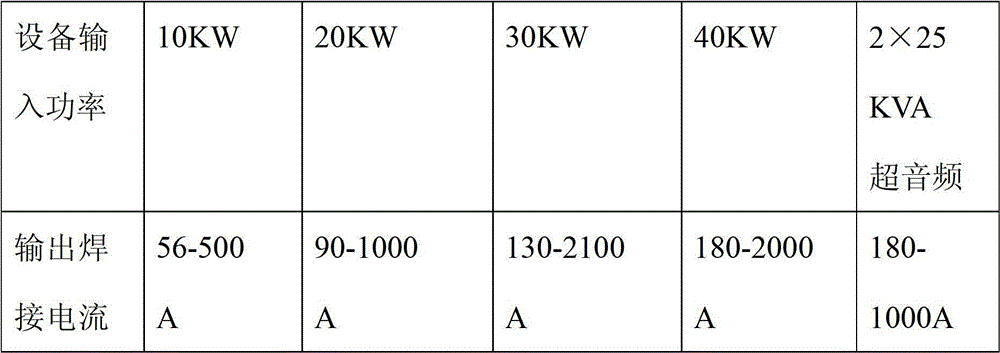

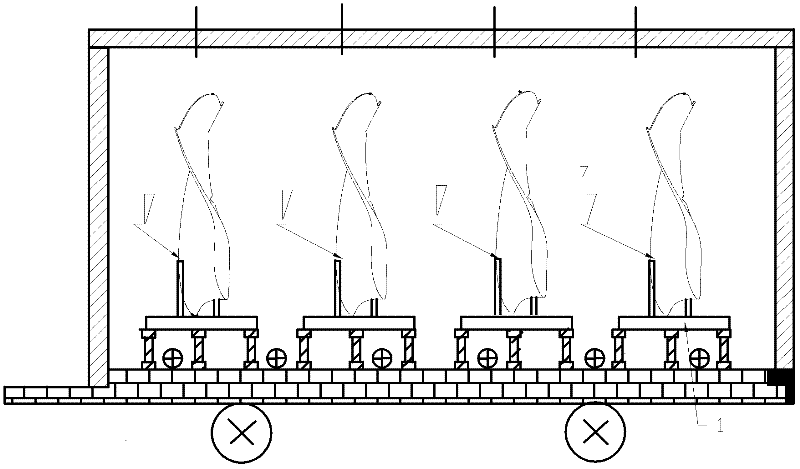

The invention discloses an induction brazing welding method for a metal part. The method utilizes induction brazing welding equipment and then is implemented according to the following steps of: a step 1 of selecting the induction brazing welding equipment and determining related parameters; a step 2 of carrying out weldment surface processing, i.e. roughening the welding surface of a weldment, processing the metal-plated surface of the weldment, carrying out matched selection between the weldment and a soldering flux, a brazing filler metal, a welding temperature and a brazing clearance and selecting each process parameter of induction brazing; a step 3 of assembling and fixing the weldment; and a step 4 of implementing welding. According to the induction brazing welding method disclosed by the invention, the induction welding and the induction brazing welding of structures of different materials, pipe fittings, sheets, tube plates and the like are implemented, the sealing performance of a weld joint is improved, the intensity of the weld joint is reduced, the electrical conductivity is obviously improved, and the weld joint has a reliable quality.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

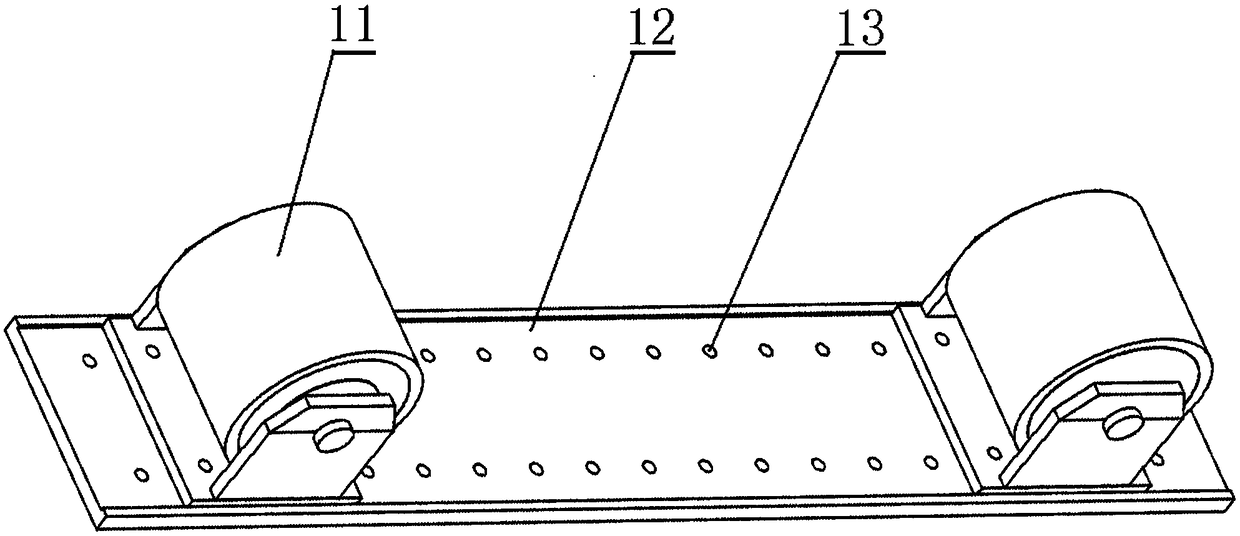

High and medium-temperature heat treatment deformation preventing device for large turbine blades

ActiveCN102560053AUnique structureWon't fallFurnace typesHeat treatment furnacesWater turbineTurbine blade

The invention relates to a deformation preventing device, in particular to a high and medium-temperature heat treatment deformation preventing device for large turbine blades. The device is characterized by being formed by assembling a casting support frame and supporting cushion blocks for supporting the casting support frame; the casting support frame is formed by assembling a U-shaped groove in the middle, groove walls on two sides of the U-shaped groove and a triangular side support which is fixed at each of two ends of the outer side of each groove wall; three cross beams with arc-shapedtops and different heights are fixed in the U-shaped groove at intervals; and two groove columns are fixed at each edge of the U-shaped groove. The device can make up the defects of the conventional blade heat treatment technology and prevent deformation of the blades in the heat treatment process according to the conventional heat treatment process mode, the characteristics of a trolley furnace and the overall dimension of the blades of different types.

Owner:KOCEL EQUIP

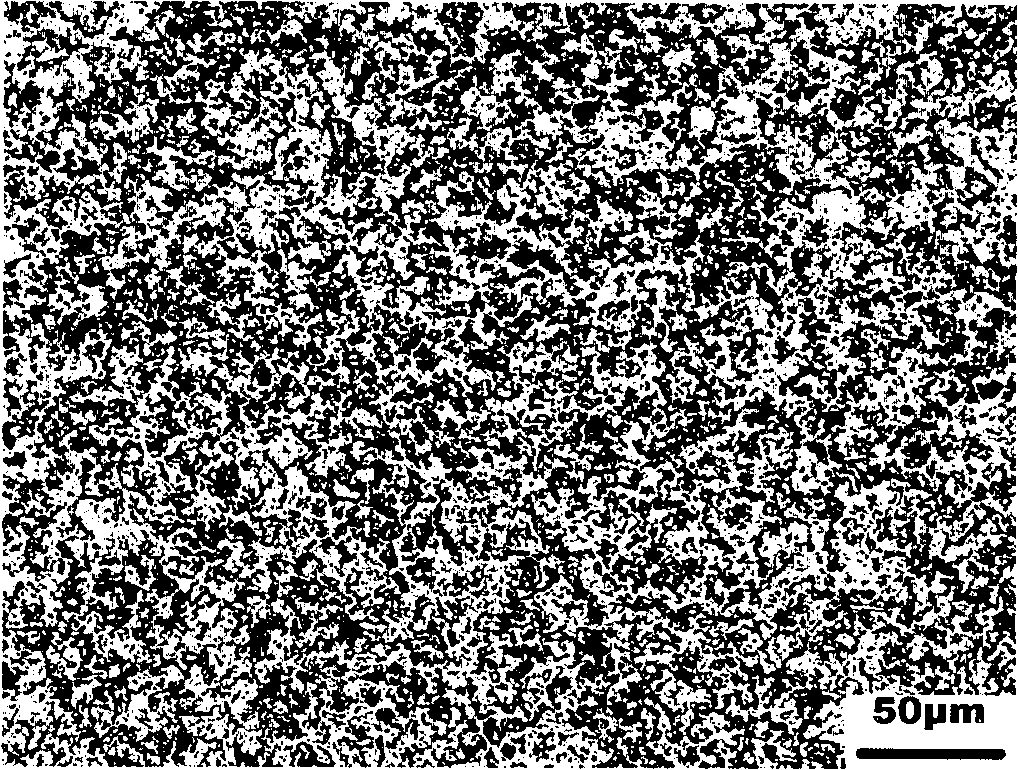

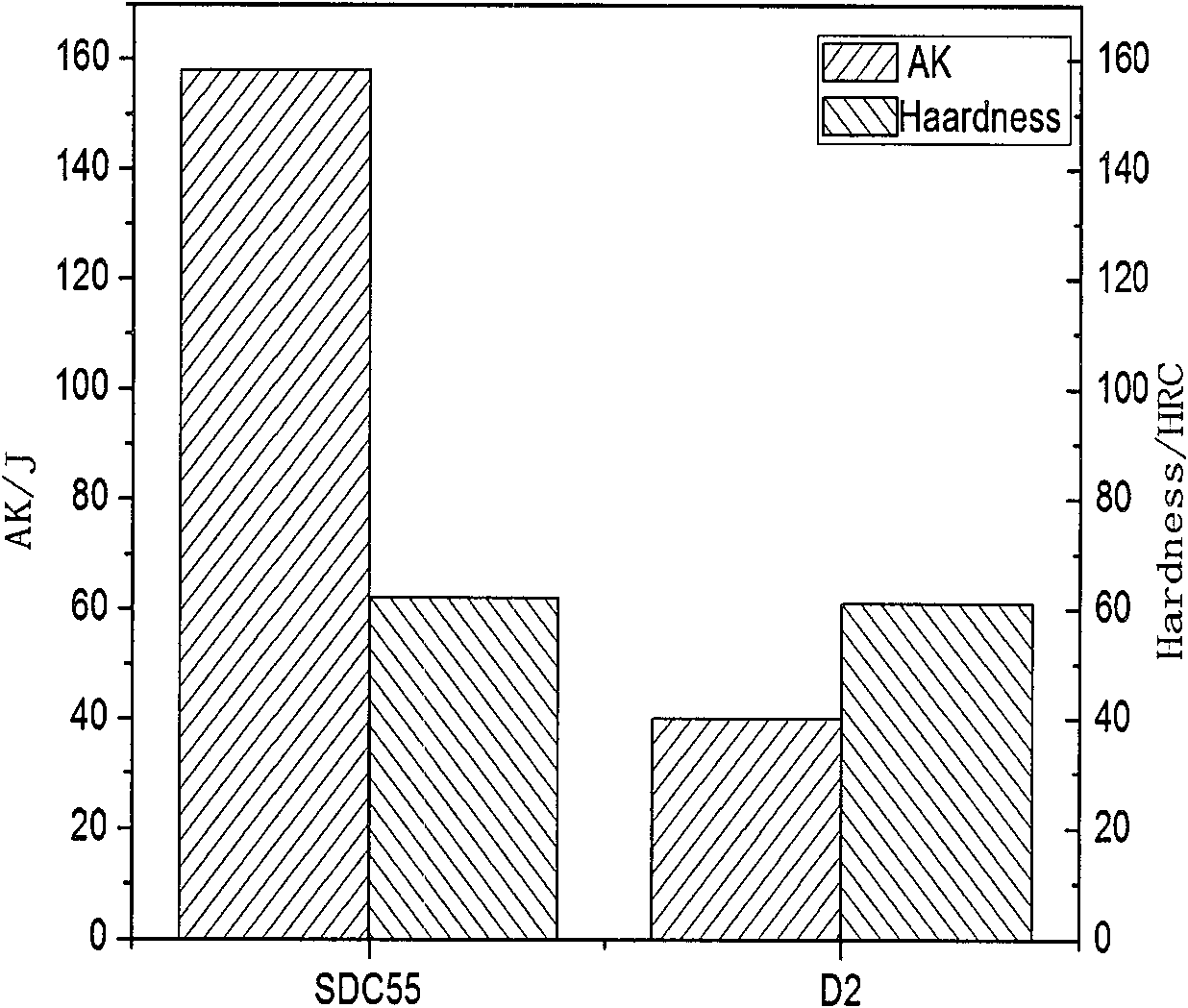

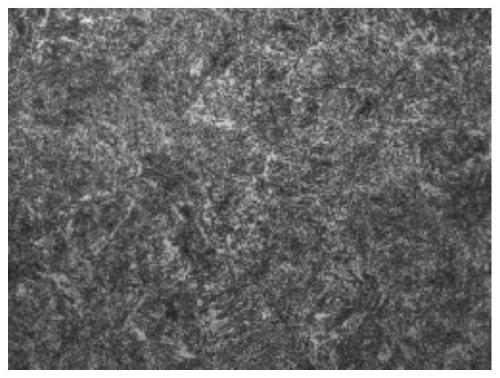

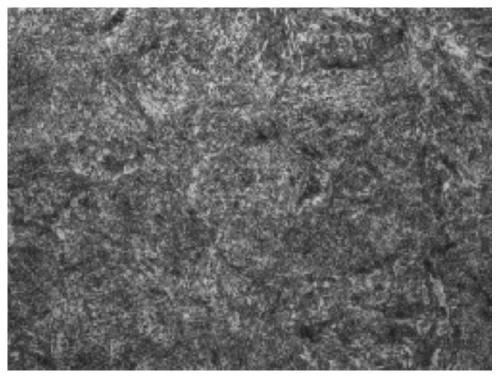

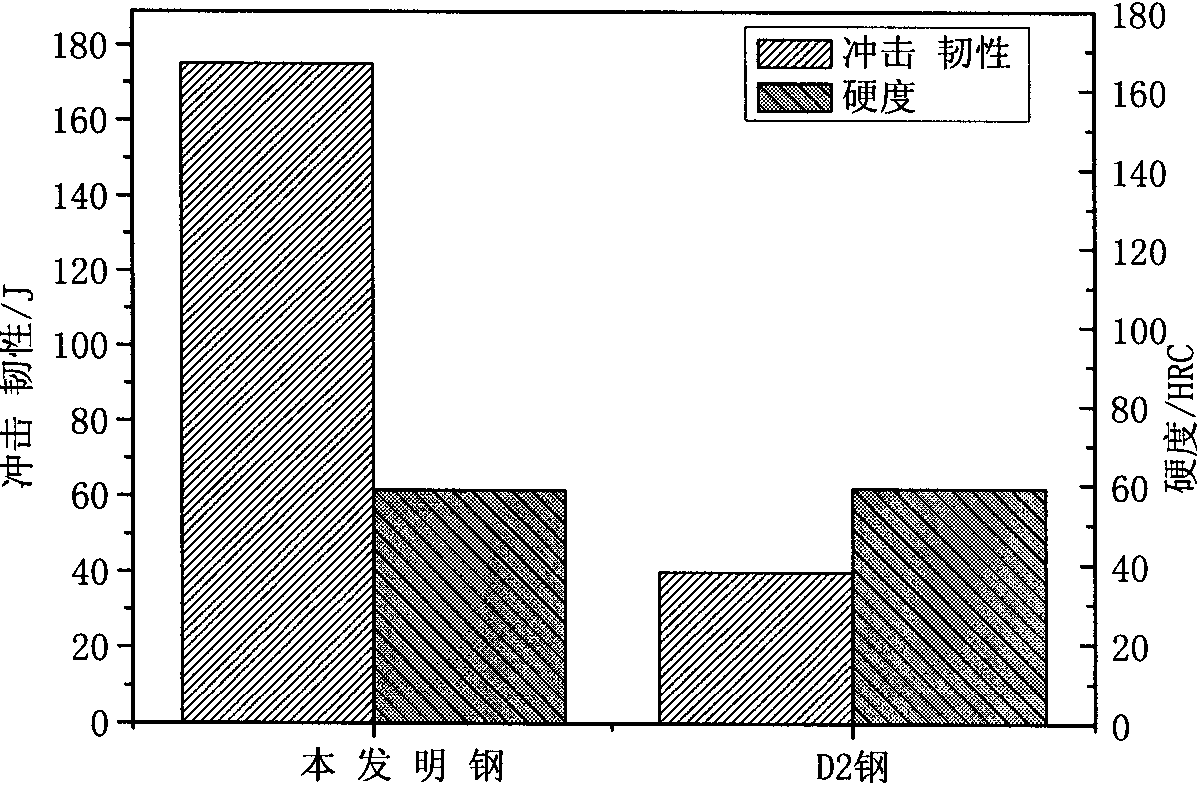

High-hardness high-toughness cold work die steel as well as preparation method thereof

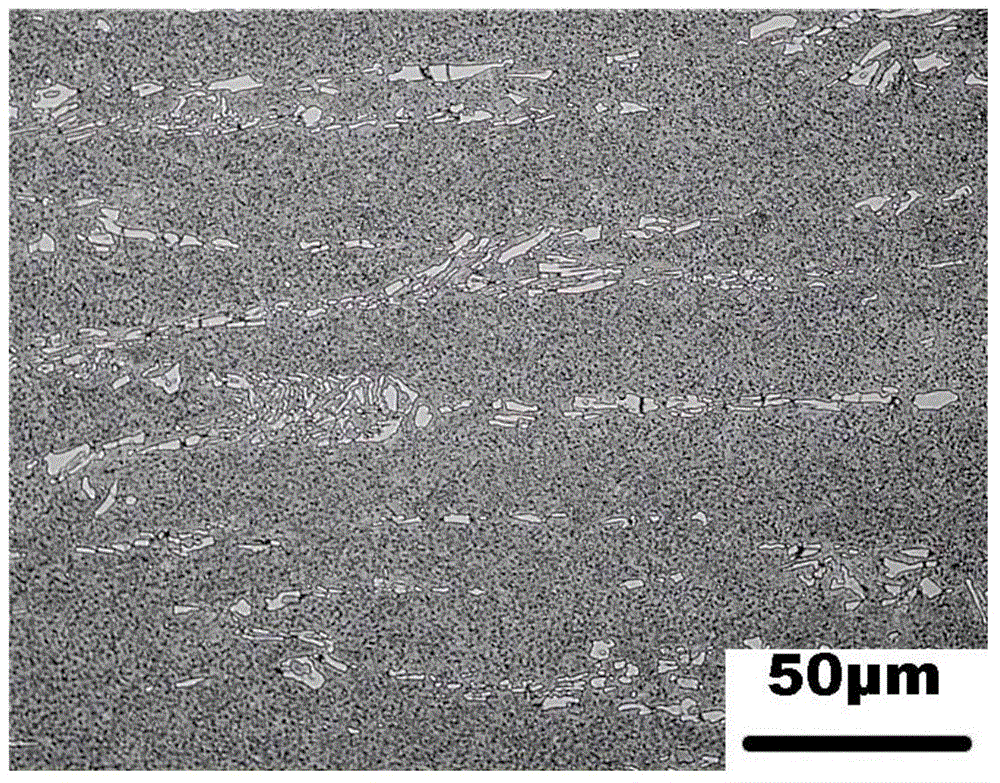

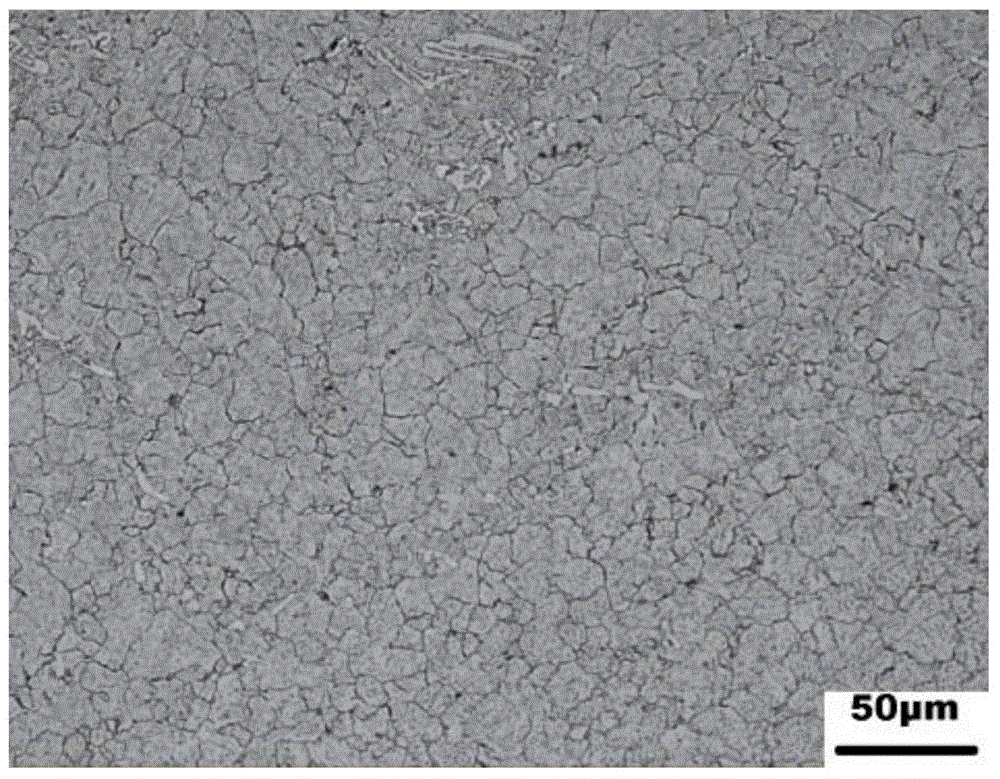

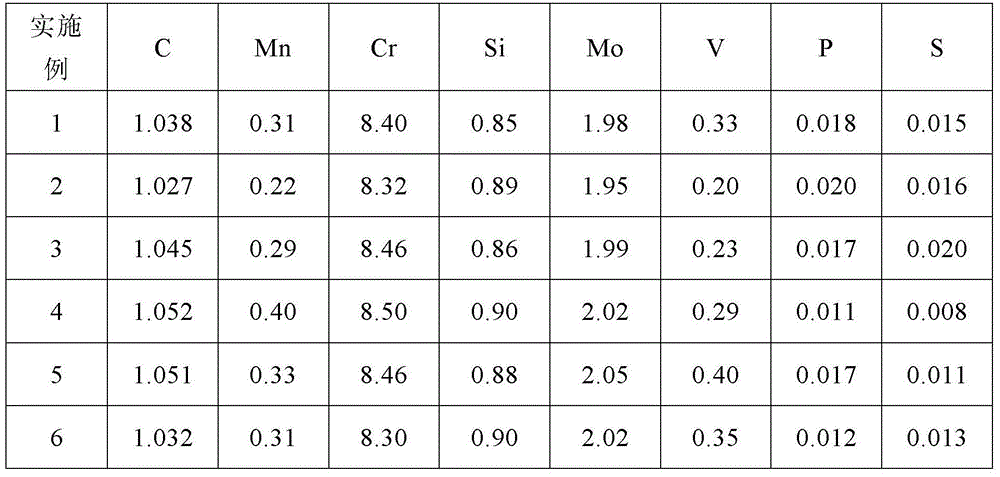

The invention relates to high-hardness high-toughness cold work die steel as well as a preparation method thereof. The high-hardness high-toughness cold work die steel comprises the following chemical components in percentage by weight: 1.025-1.055% of C, 0.85-0.90% of Si, 0.20-0.40% of Mn, less than 0.02% of P, less than 0.02% of S, 8.30-8.50% of Cr, 1.95-2.05% of Mo, 0.20-0.40% of V and the balance of Fe and inevitable impurities, wherein the elements satisfy the following relationship: C=0.1(Cr+Mo). The preparation method comprises the following steps: smelting and pouring to obtain a steel ingot which serves as a consumable electrode and is placed in an electroslag remelting device for electroslag remelting and then re-solidifying to form the steel ingot; and heating the re-solidified steel ingot to 1200-1220 DEG C and then forging, quenching and tempering to obtain the cold work die steel. The impact energy of the steel is greater than or equal to 76J and the hardness of the steel is greater than or equal to 63HRC, and the steel has relatively good hardness and toughness match.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Steel for ball screw bearing and manufacturing method thereof

ActiveCN110983178AImprove composition segregationConvenient spacingShaftsBearing componentsTemperingAustenite grain

The invention relates to steel for a ball screw bearing. Alloy components of the steel comprise, by mass, 0.45-0.60% of C, 0.15-0.40% of Si, 0.50-0.80% of Mn, 0.15-0.40% of Cr, 0.002-0.006% of B, 0.02-0.07% of V, less than or equal to 0.015% of S, less than or equal to 0.025% of P, less than or equal to 0.10% of Mo, less than or equal to 0.08% of Al, less than or equal to 0.0010% of Ca, less thanor equal to 0.0010% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb, and the balance Fe and inevitable impurities. A preparation process of a bar product comprises the steps of molten steel smelting, continuous casting, cogging-down, hot rolling, tempering, stress relief annealing and the like. The final properties meet the conditions that the surface hardness of the bar reaches 220-260 HBW, the metallographic structure of the bar is a uniform sorbite structure, the austenitic grain size of the bar is higher than or equal to the seven-level, the yield strength of the bar is 600-800 MPa, the tensile strength of the bar is 800-900 MPa, and the percentage elongation of the bar is greater than orequal to 15%.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

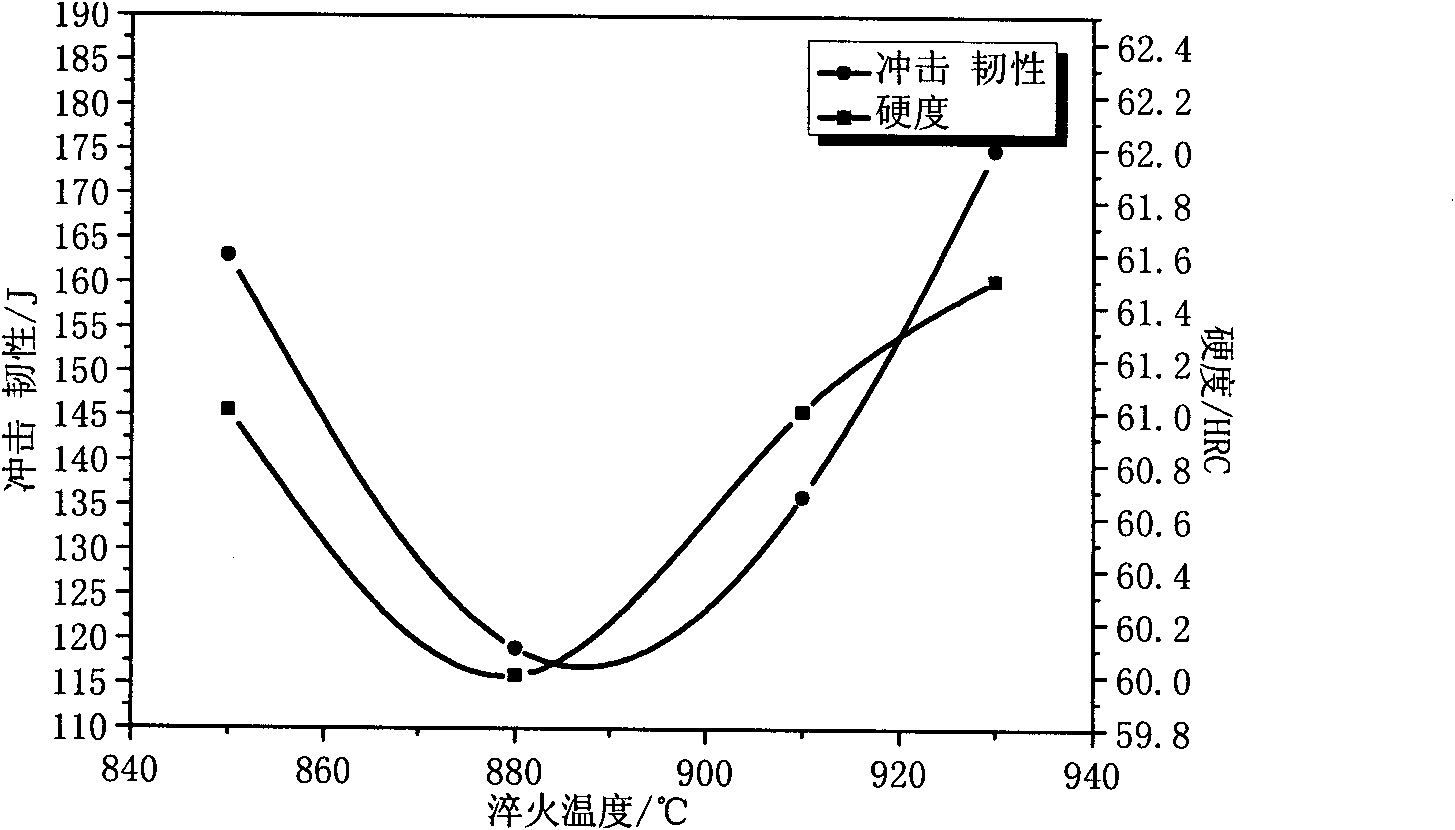

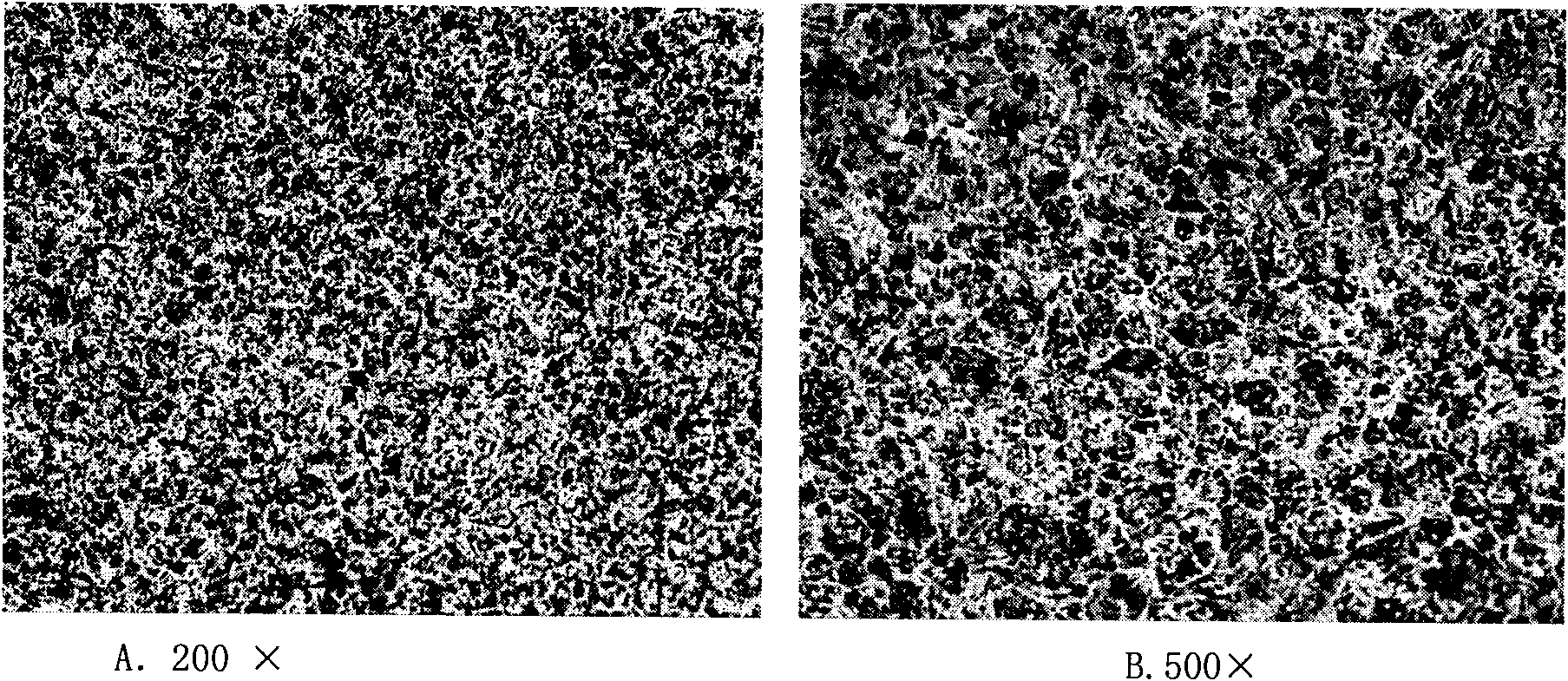

Low alloy die steel

The invention relates to a low alloy die steel material which comprises the following components by weight: 0.68-0.78% of C, 0.7-1.0% of Si, 0.7-1.1% of Mn, not more than 0.02% of P, not more than 0.02% of S, 2.2-2.5% of Cr, 0.2-0.3% of Mo, 0.15-0.35% of V, 0.3-0.4% of Ni, the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: performing smelting and casting of the components to obtain a steel ingot; adding the steel ingot into a radial forging machine heating furnace at 600-800 DEG C, heating to 1200-1230 DEG C with a heating speed of 60-120 DEG C / h, then performing thermal insulation for 3-5 hours; forging in a forging machine to obtain steel materials with an initial forging temperature of 1050-1100 DEG C and a final forging temperature of not less than 850 DEG C. After the obtained die steel is subject to quenching at 910-950 DEG C and tempering heat treatment at 160-200 DEG C, the impact toughness is above 135 J / cm2, and the hardness HRC is above 62.

Owner:宝武特种冶金有限公司

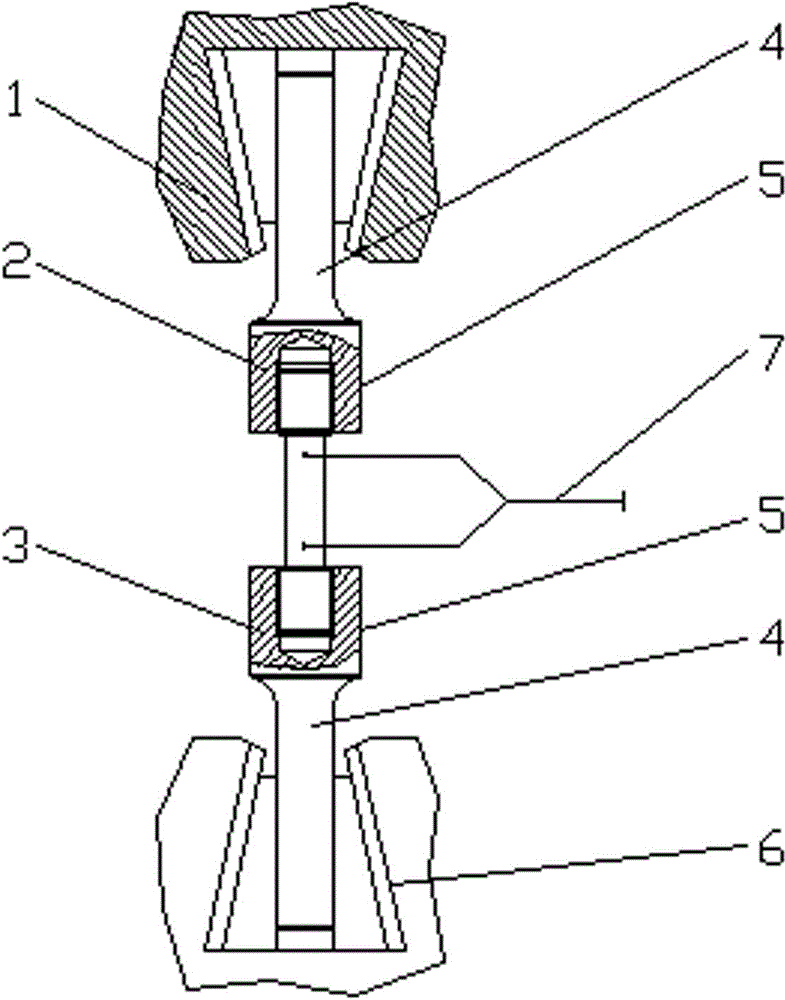

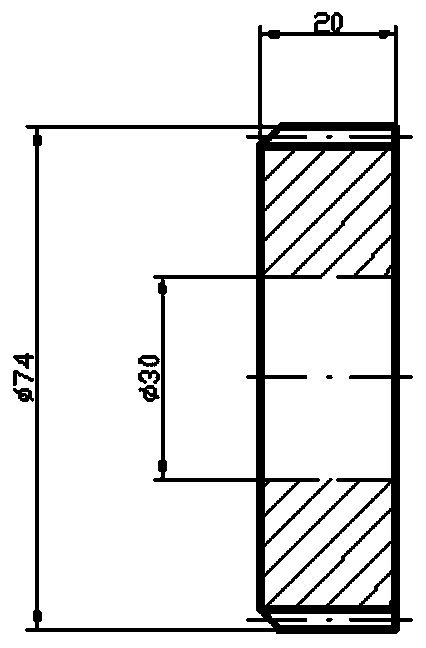

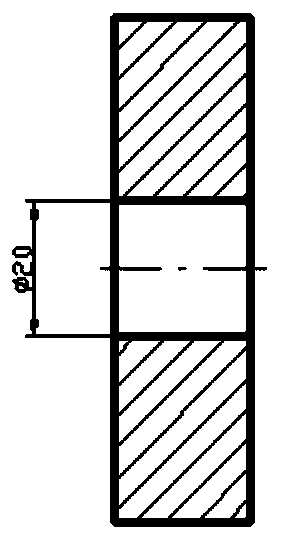

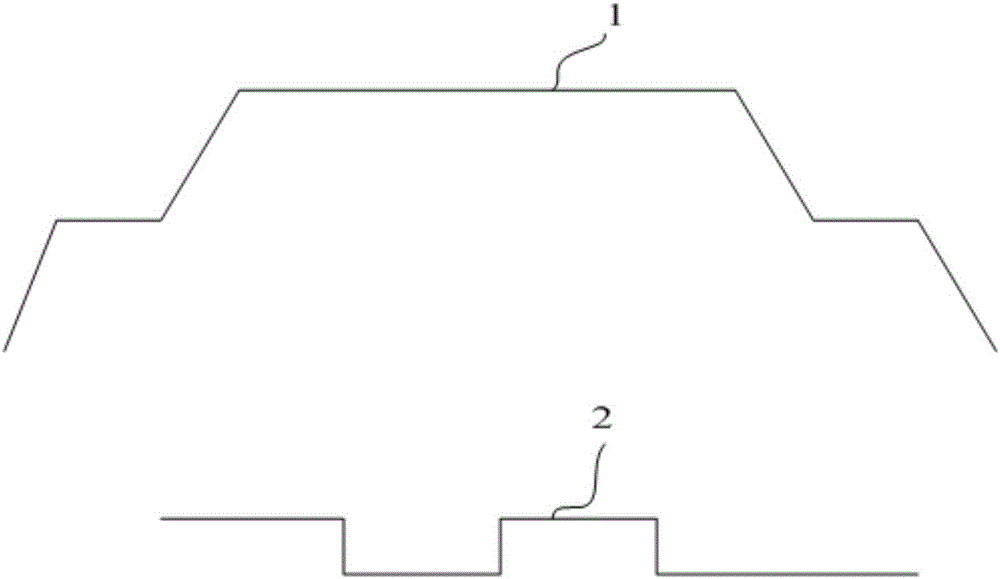

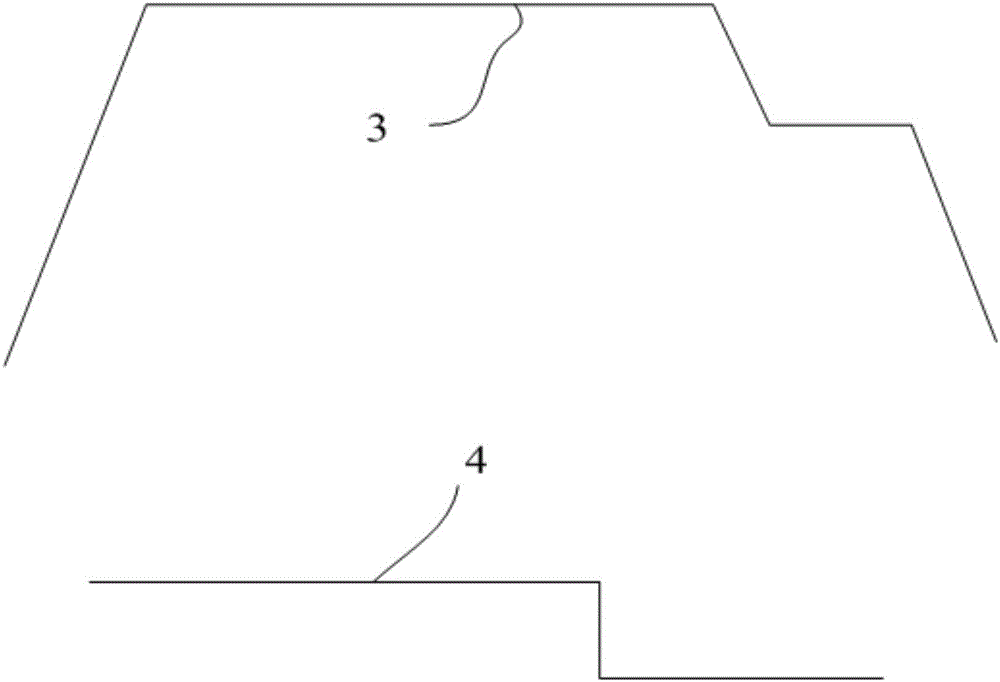

Processing inspection fixture for special steel tensile sample and inspection method

InactiveCN104865121AReduce consumptionReduce lossMaterial strength using tensile/compressive forcesEngineeringTower

The invention relates to a processing inspection fixture of a special steel tensile sample and an inspection method. The processing inspection fixture comprises an upper fixture and a lower fixture, wherein each of the upper fixture and the lower fixture is of a tower-shaped threaded sleeve structure, and is composed of clamping ends and threaded sleeves; the other ends of the upper and lower clamping ends are respectively mounted in a upper tester jaw and a lower tester jaw; the upper fixture and the lower fixture respectively fix one end of a tensile finished product sample with a threaded head; meanwhile, a tester extensometer is clamped on the tensile finished product sample with the threaded head. According to the invention, the technical problems that the short special steel tensile sample cannot clamp the extensometer and the clamp slipping affects the accuracy of inspection results are solved; the fixture is convenient and rapid to replace, can be recycled, and has long service life; the tensile batch inspection of the special steel products can be completed at low cost by using the processing inspection fixture for the special steel tensile sample and the inspection method.

Owner:SGIS SONGSHAN CO LTD

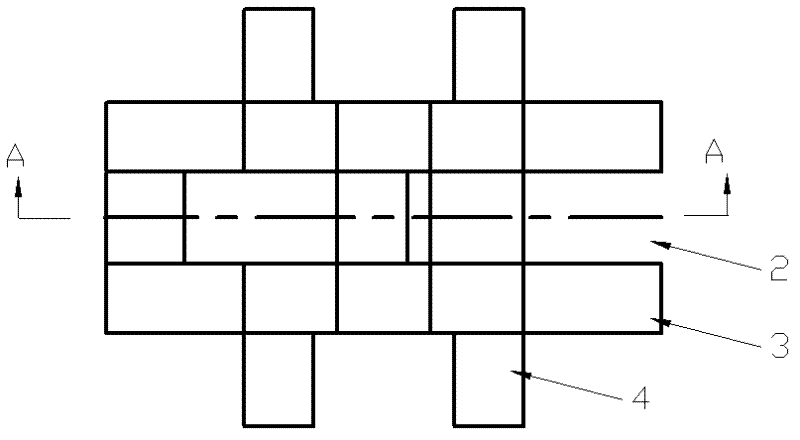

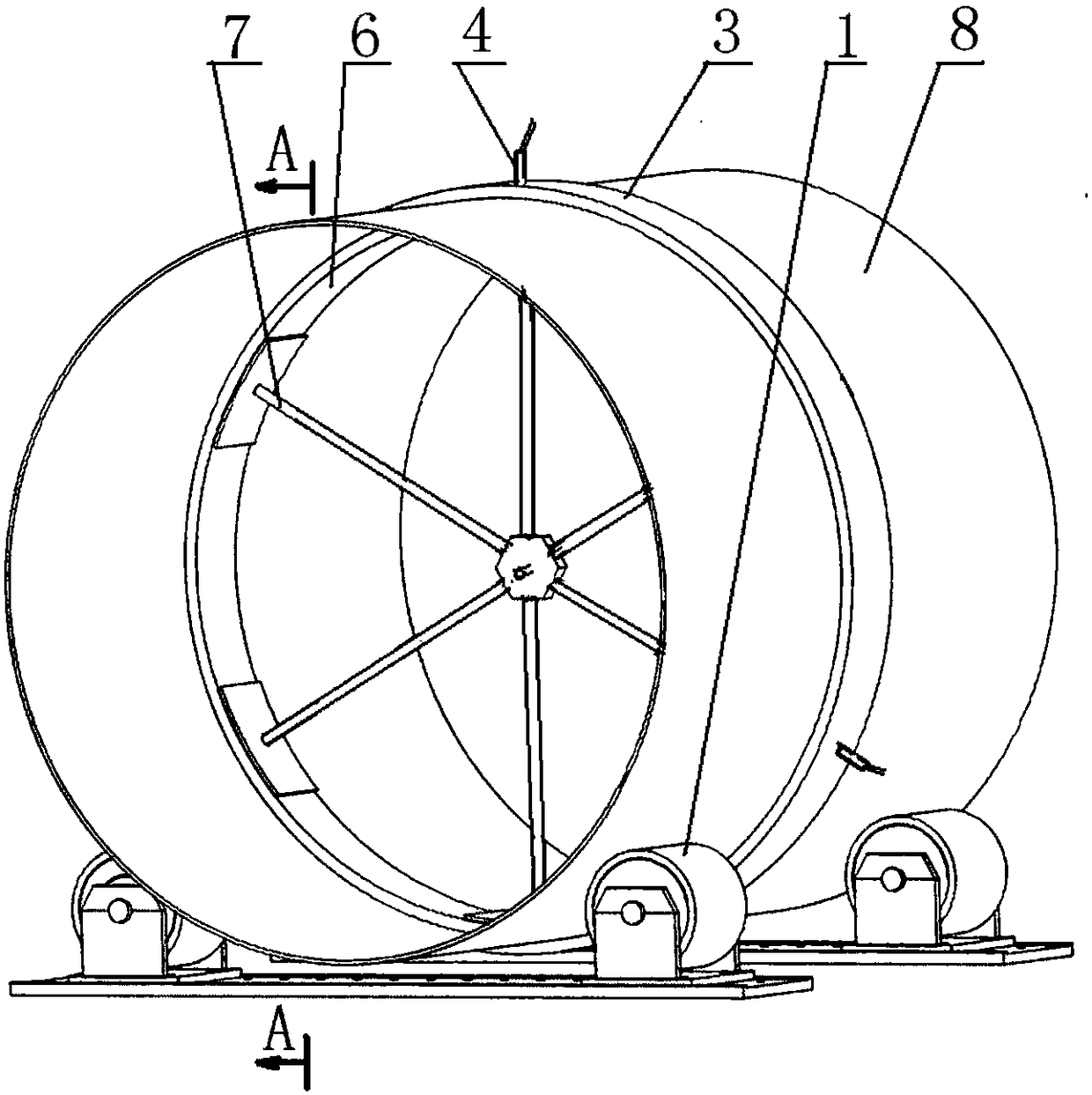

Method and tool for reducing deformation in large-scale thin-wall cylindrical forging heat treatment

InactiveCN102534164AHeat treatment deformation is smallIncrease contact areaFurnace typesHeat treatment furnacesSupport pointHot Temperature

The invention discloses a method for reducing deformation in large-scale thin-wall cylindrical forging heat treatment, which comprises the following steps: firstly laying #-shaped padding iron in a heat treatment furnace, wherein the #-shaped padding iron is used as a supporting tool, adjusting the levelness of the #-shaped padding iron to allow the #-shaped padding iron to be in a horizontal state, finally vertically putting a large-scale thin-wall cylindrical forging on the #-shaped padding iron to allow the forging to pass through the center of the #-shaped padding iron and to allow the axis of the forging to be superposed with a straight line which is perpendicular to the horizontal plane where the #-shaped padding iron is located; the method provides uniform supporting points and a flat supporting surface, increases the contact area of the forging and the tool, and thus significantly reduces the heat treatment deformation generated during high temperature heating of the large-scale thin-wall cylindrical forging. The invention also discloses a tool for reducing deformation in large-scale thin-wall cylindrical forging heat treatment, and the supporting tool is the #-shaped padding iron; the tool is simple in structure, convenient for processing, and can improve the condition of non-uniform supporting of the forging during heat treatment.

Owner:SHANGHAI HEAVY MACHINERY PLANT

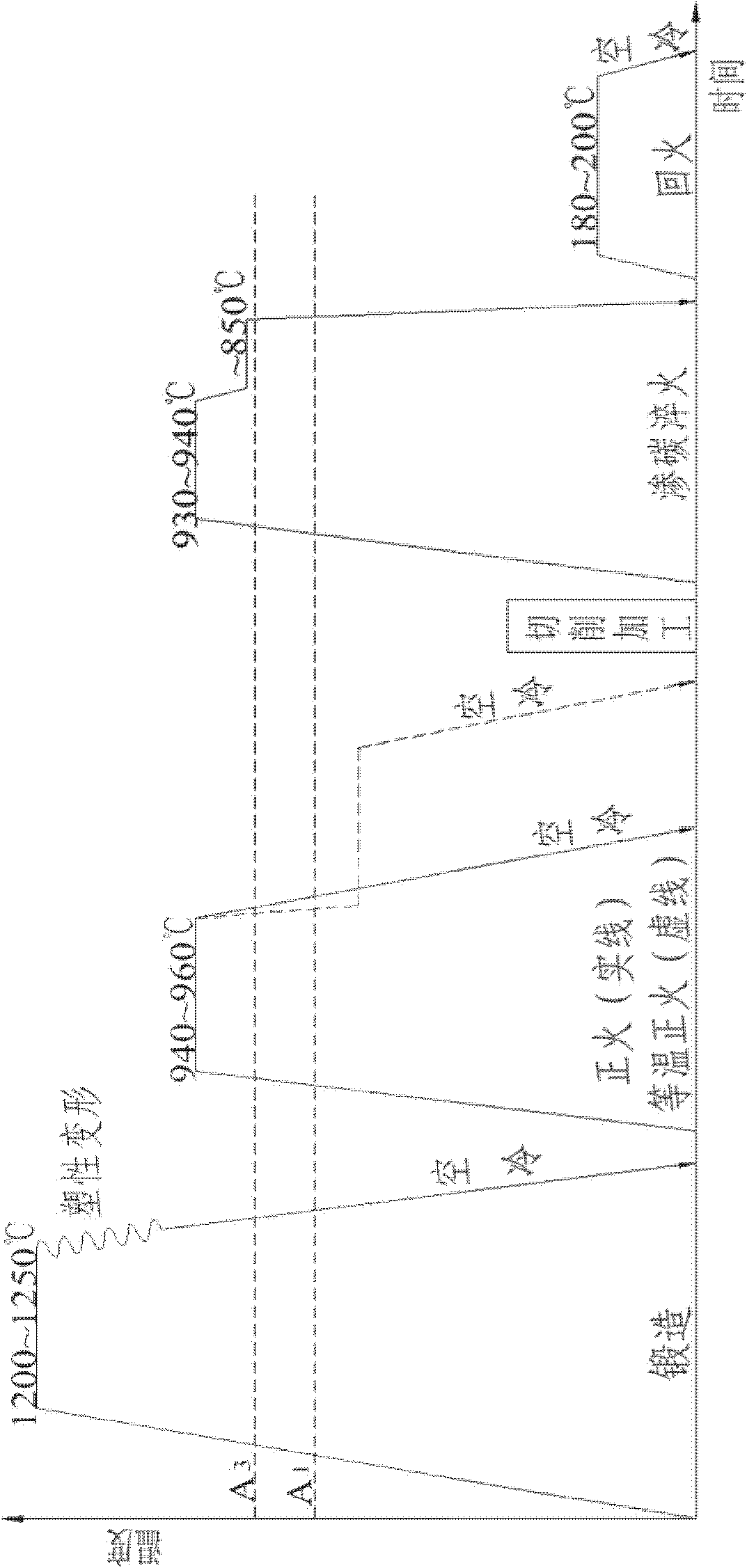

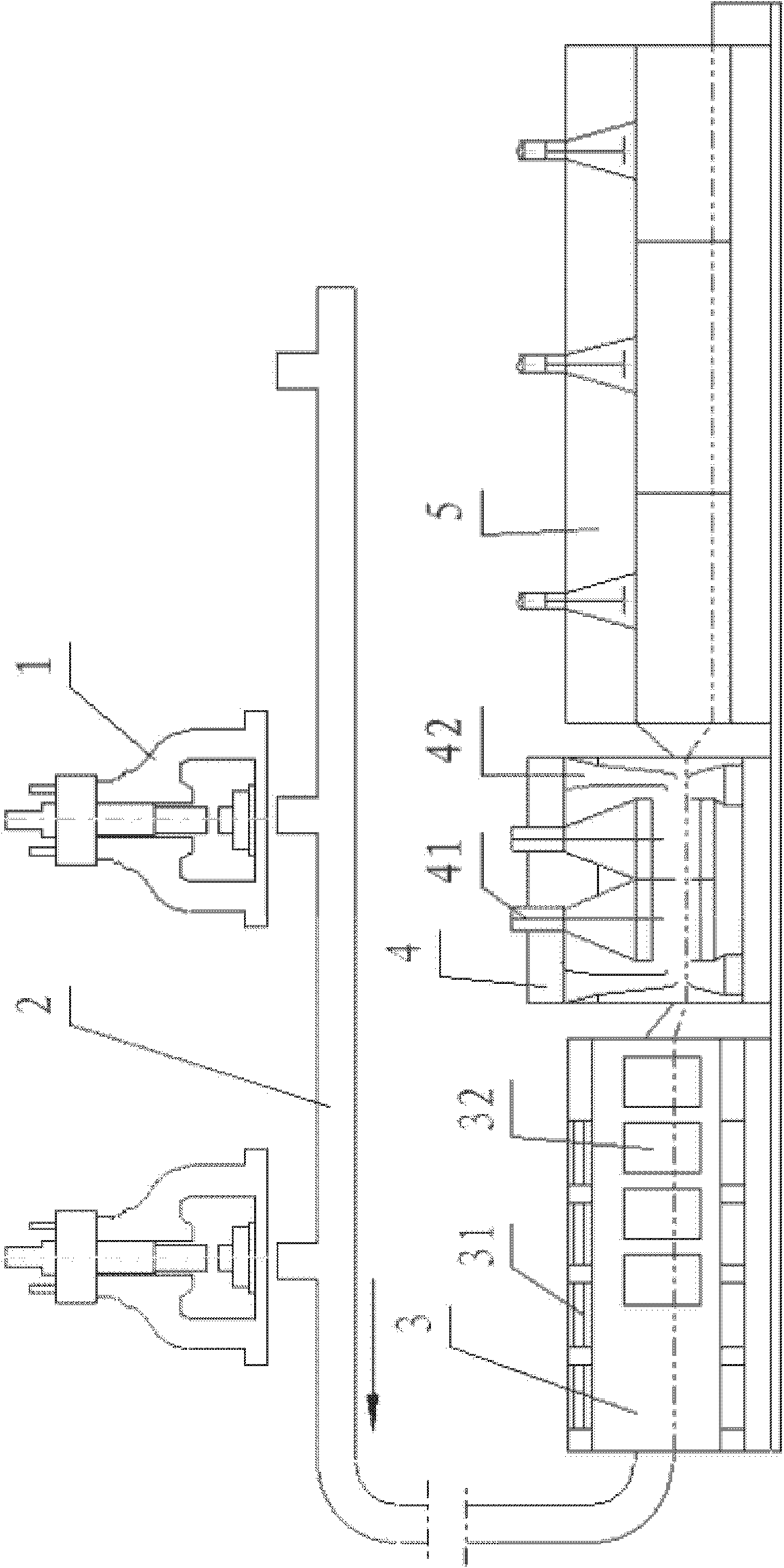

Forging waste heat isothermal normalizing device and method

ActiveCN102286655AReduce energy consumptionExcellent forging billet qualityHeat treatment process controlCooling chamberAlloy

The invention provides a method and a device for carrying out isothermal normalizing heat treatment on alloy cemented steel parts utilizing forging waste heat. The method comprises the following steps: after finish forging of a forged steel blank, slowly cooling the forged steel blank from the final forging temperature to a pre-cooling temperature T1 at a pre-cooling rate V1, insulating heat for t1, then rapidly cooling to a forced cooling temperature T2 at a forced cooling rate V2, carrying out isothermic transition at the isothermic temperature of Tiso for isothermic time tiso, and then cooling to room temperature in a random cooling mode. The invention also provides a device for isothermal normalizing of cemented steel parts utilizing forging waste heat, and the device is composed of atransmission mechanism, a slow cooling chamber, a rapid cooling chamber, an isothermal furnace, a control system, a transmission system and process parameter calculation and correction software. The calculated process parameters can be used for precise control and operation of the device, thereby guaranteeing that the normalizing quality of steel parts is superior or at least equal to the heat treatment quality using conventional normalizing and isothermal normalizing.

Owner:浙江万能达炉业有限公司

Steel for ball screws and manufacturing method thereof

PendingCN110484837ALow content of harmful elementsGuaranteed amount of residual aluminumBall screwWater immersion

The invention relates to steel for ball screws. The steel for ball screws comprises, by mass: 0.45%-0.60% of C, 0.15-0.40% of Si, 0.90-1.10% of Mn, 0.70-1.20% of Cr, less than or equal to 0.015% of S,less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, 0.15-0.40% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.05% of Al, less than or equal to 0.0010% of Ca, lessthan or equal to 0.003% of Ti, less than or equal to 0.0010% of O, 0.0050-0.0090% of N, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, lessthan or equal to 0.002% of Pb, and the balance Fe and inevitable impurities. The delivery state of the steel is as follows: high-temperature quenching and tempering are carried out, and the hardness meets 220-280 HBW, and the microscopic structure is of a sorbite and bainite structure, and is subjected to SEP 1927 water immersion high-frequency flaw detection, so that the defect length is requirednot to exceed 5 mm. The manufacturing process comprises the steps of electric furnace or converter, external refining, VD or RH vacuum degassing, continuous casting, continuous casting blank squaringto form an intermediate billet (a square billet), intermediate billet heating and rolling, finishing, quenched-tempered heat treatment (including high temperature quenching and tempering), surface lathing and warehousing.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

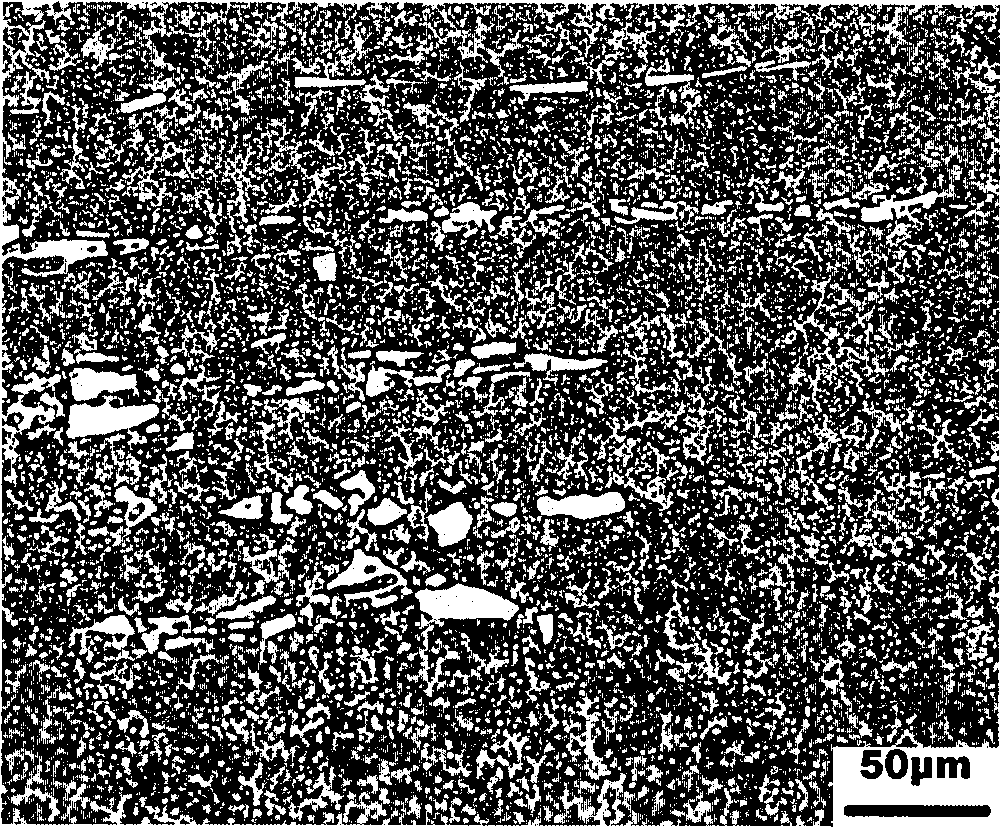

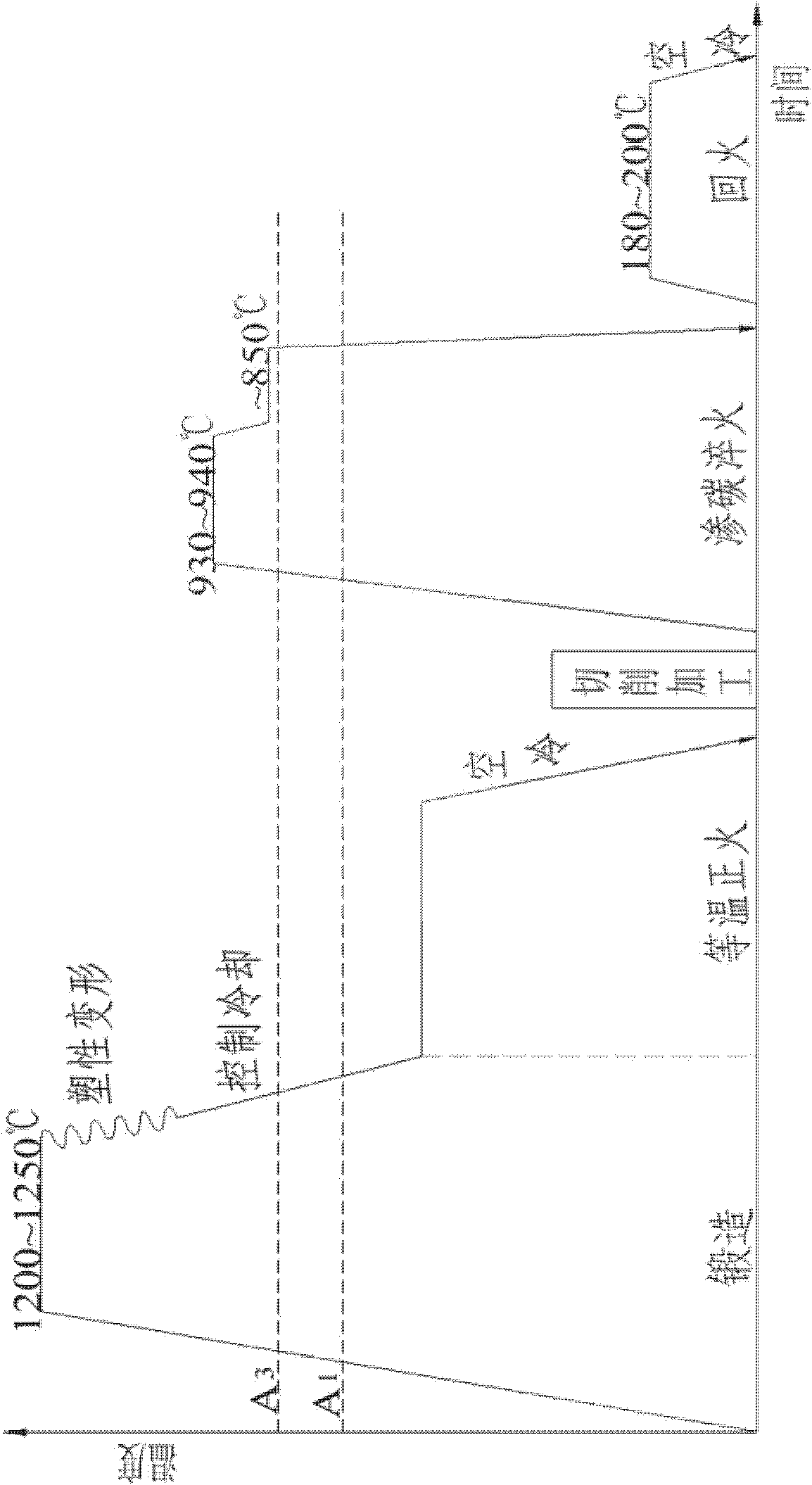

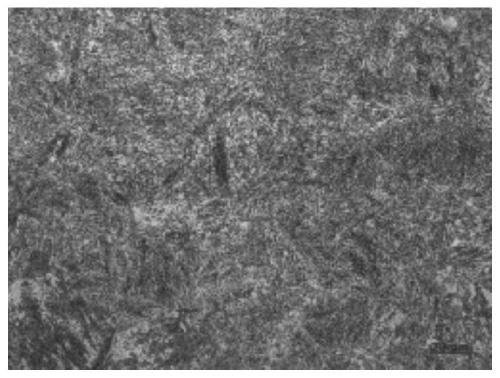

High-toughness cold-work mould steel and preparation method thereof

The invention relates to high-toughness cold-work mould steel and a preparation method thereof, belonging to the technical field of alloy steel manufacturing processes. The steel comprises the following chemical components in weight percentage: 0.5%-0.72% of C, 0.6%-0.8% of Si, 0.6%-1.0% of Mn, 2.0%-2.4% of Cr, 0.15%-0.25% of Mo, 0.1%-0.25% of V, 0.5%-0.8% of Ni and the balance of Fe. The preparation method of the cold-work mould steel comprises the following steps of: mixing the raw materials according to the a formula, smelting and pouring the batch mixtures in an induction furnace, and then carrying out electroslag remelting; and then forging and annealing, heating the mixtures to 850-930 DEG C for austenitization, and then carrying out secondary annealing at 180-200 DEG C after oil quenching to finally obtain the high-toughness cold-work mould steel. The cold-work mould steel has higher toughness matching and higher hardness and is a steel type suitable for manufacturing precise complex moulds.

Owner:SHANGHAI UNIV

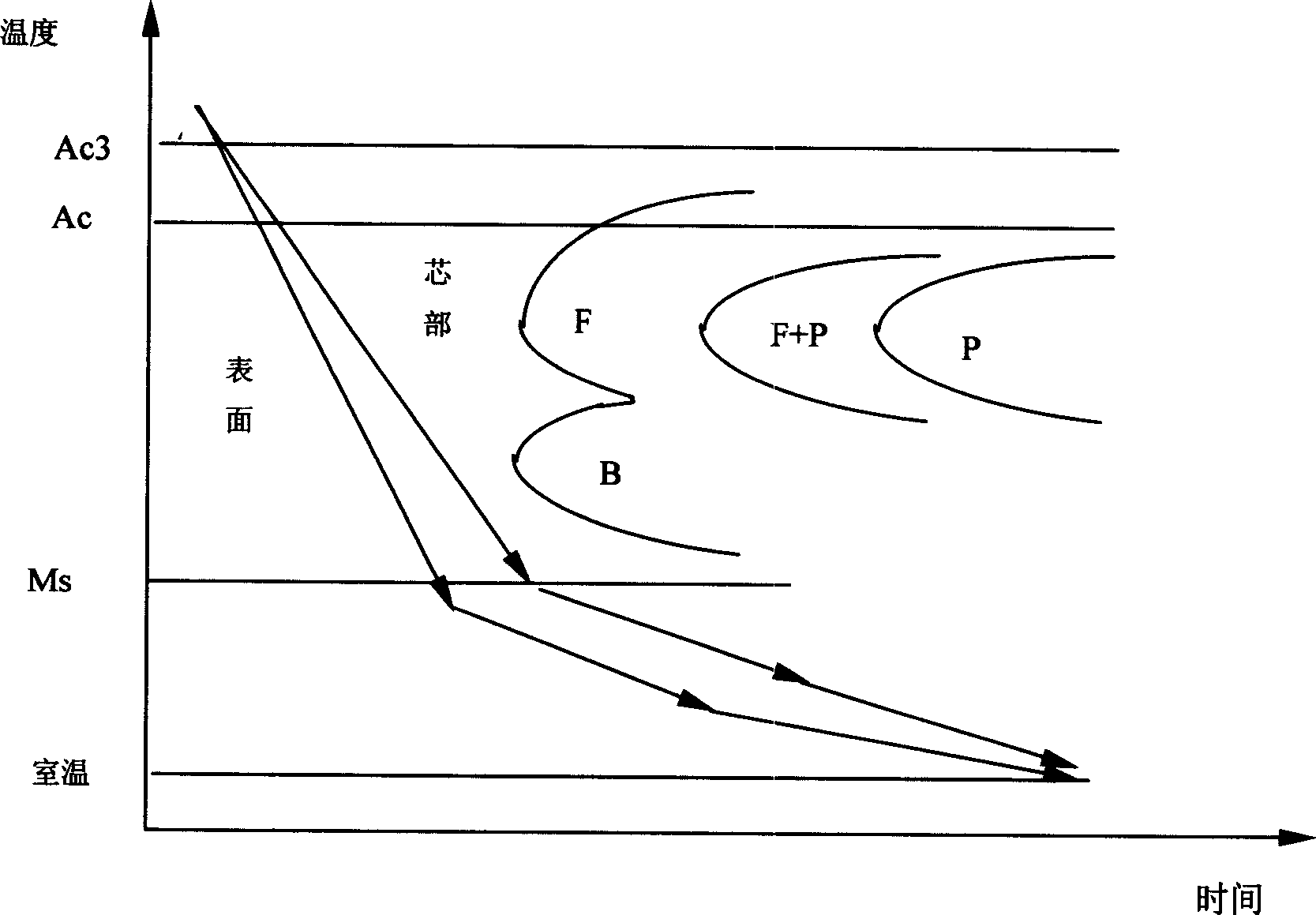

Process for stepped quenching by high pressure gas

A step quenching method by high-pressure gas features that in the initial gas quenching stage, the high-pressure gas medium which has high hardenability is used for avoiding the conversion of austenite structure to wards ferrite, bainite, or pearlite structure, and when the temp of workpiece is higher than the conversion temp of martensite, the low-pressure gas medium is used for ensuring the uniform structure conversion, so decreasing the deformation caused by heat treating.

Owner:SAIC MOTOR

Wet pan gear and manufacturing method thereof

ActiveCN101899610AReduce the amount addedLow costPortable liftingGearing elementsRare earthFerrosilicon

The invention relates to a long-life wet pan gear and a manufacturing method thereof. The wet pan gear is chemically made from 3.4-3.8% of C, 2.2-2.6% of Si, 0.6-0.9% of Mn, not more than 0.06% of P, not more than 0.03% of S, 0.4-0.7% of Cu, 0.05-0.2% of Mo, 0.4-0.6% of Cr and the balance of Fe. The manufacturing method comprises the following steps of: making a mold, smelting, casting, smelting into an alloy liquid at 1480-1500 DEG C, adding rare earth ferrosilicon magnesium alloy nodulizer, uniformly mixing, and pouring into the mold to cast a gear blank; thermally treating the blank at 900-920 DEG C for 2-4 h, heating the tooth part of the blank to 280-310 DEG C, and tempering for 2-3 h; and processing by a lathe so that the surface roughness Ra of the gear reaches 6.3-12.5. The strength and the wear resistance of the product are increased by 2-3 times higher than those of common spheroidal graphite cast iron, the tensile strength is 780-810 MPa, the yield strength is 580-610 MPa, the hardness HRC of the tooth part reaches 40-48, and the average service life of the product is long.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

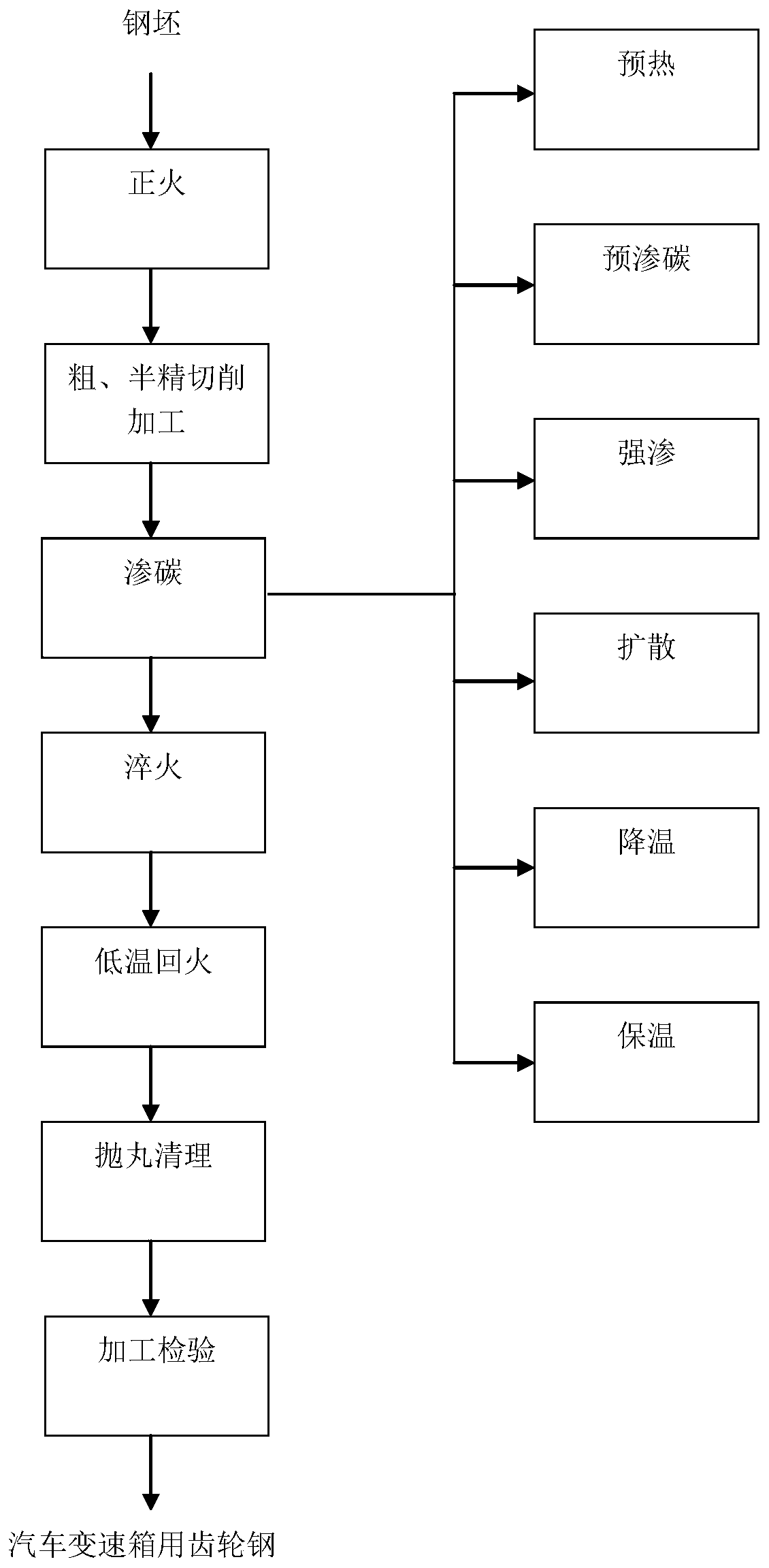

Heat treatment process of gear steel for automobile gearbox

InactiveCN111500834AImprove mechanical propertiesImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialTempering

The invention provides a heat treatment process of gear steel for an automobile gearbox. The heat treatment process comprises the steps of normalizing, coarse semi-finished cutting processing, carburizing, quenching, low temperature tempering, shot blasting and processing inspection; in the carburizing process, preheating and pre-carburizing processes are increased to clean impurities, oil stainsand the like attached to the surface of a billet, so that the internal temperature and external temperature of the billet is the consistent, a basis is laid for further temperature rise, heating timeis shortened, and energy consumption is reduced; the temperature and carburizing time in the carburizing process are controlled to obtain flat carbon concentration distribution, stress caused by carburizing heat treatment is reduced, and the mechanical property and wear-resisting property of the surface of the billet are effectively improved; and meanwhile, the billet ingredients, the heating temperature, heat preservation time, cooling speed and other process parameters are controlled, the billet is subjected to carbon potential rising and falling treatment, the process of normalizing, quenching and tempering is optimized, a production cycle is shortened, the energy consumption and production cost are reduced, and the heat treatment process is suitable for producing the gear steel for automobile gearboxes with various specifications.

Owner:江苏联峰实业有限公司

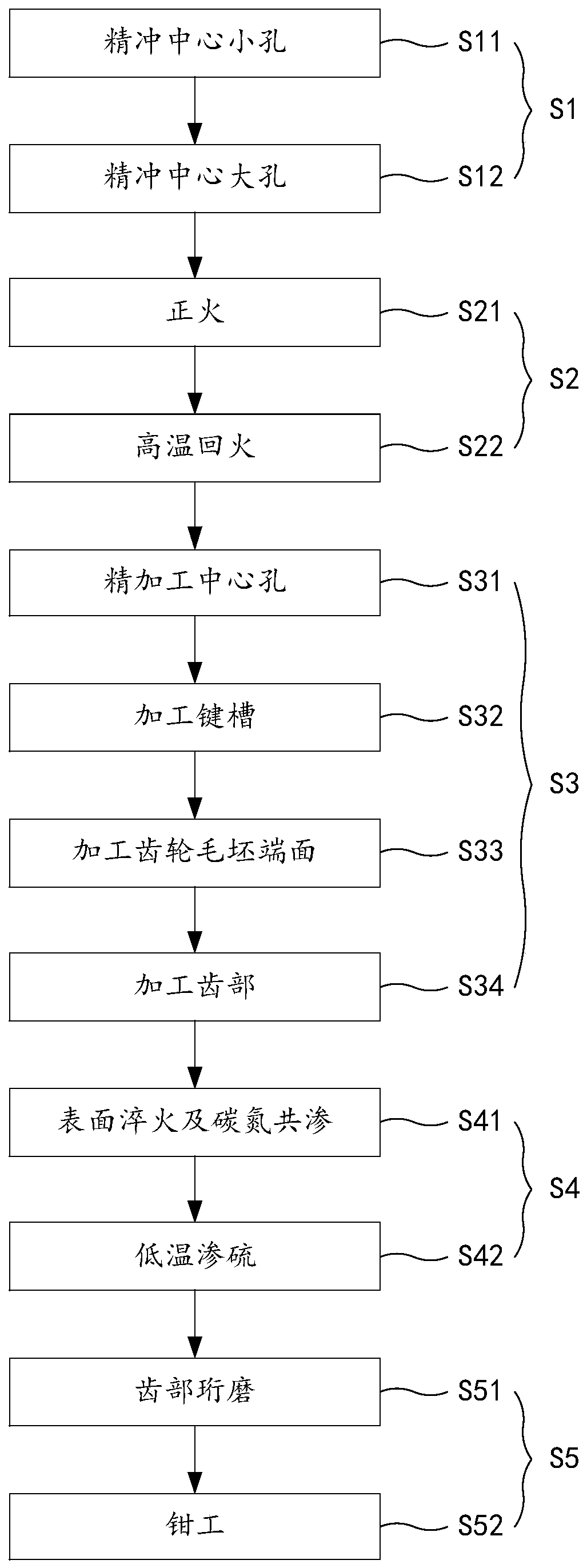

Automotive light gear and manufacturing process thereof

ActiveCN110408885AFast quenchingControllable organizational structurePortable liftingSolid state diffusion coatingWork in processWear resistance

The invention discloses a manufacturing process of an automotive light gear. The manufacturing process of the automotive light gear comprises the following steps of first, carrying out rough machiningon a gear raw material to obtain a gear blank with a central large hole; second, carrying out heat treatment on the gear blank; third, carrying out semifinishing on the gear blank to obtain a semi-finished product of gear with teeth; fourth, carrying out plasma surface hardening carbonitriding treatment and sulfurizing treatment on the semi-finished product of gear; and fifth, carrying out secondary finish machining on the semi-finished product of gear to obtain a finished product of gear. According to the manufacturing process of the automotive light gear, because of the tooth surface hardening carbonitriding treatment and sulfurizing treatment, the hardening time is shortened, energy consumption is reduced, the surface friction coefficient is decreased, and the surface abrasive resistance is improved.

Owner:NANJING INST OF TECH

Spheroidizing annealing steel for low-temperature-resistant high-strength ball screw and manufacturing method of spheroidizing annealing steel

ActiveCN114134411AImprove hardenabilityHigh yield strengthMetal rolling arrangementsFurnace typesBall screwUltimate tensile strength

The steel comprises the following chemical components in percentage by mass: 0.40 to 0.70 percent of C, 1.20 to 1.80 percent of Si, 1.00 to 1.60 percent of Mn, 0.80 to 1.20 percent of Cr, less than or equal to 0.025 percent of S, less than or equal to 0.025 percent of P, 0.10 to 0.60 percent of Ni, 0.30 to 0.80 percent of Cu, 0.10 to 0.40 percent of Mo, less than or equal to 0.05 percent of Al, less than or equal to 0.0010 percent of Ca, less than or equal to 0.003 percent of Ti, less than or equal to 0.0010 percent of O, less than or equal to 0.04 percent of As, less than or equal to 0.03 percent of Sn, less than or equal to 0.005 percent of Sb, less than or equal to 0.002 percent of Pb and the balance of Fe and inevitable impurities. The manufacturing process of the steel for the ball screw comprises the steps of electric furnace or converter, external refining, VD or RH vacuum degassing, continuous casting, continuous rolling, shearing or saw cutting, stack cooling, spheroidizing annealing, finishing and piece making and warehousing. Under the conditions of high yield strength (greater than or equal to 1380MPa) and tensile strength (greater than or equal to 1500MPa), the steel for the ball screw has low-temperature toughness (Charpy impact energy AKU2 at-40 DEG C is greater than or equal to 27J) far better than that of bearing steel.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

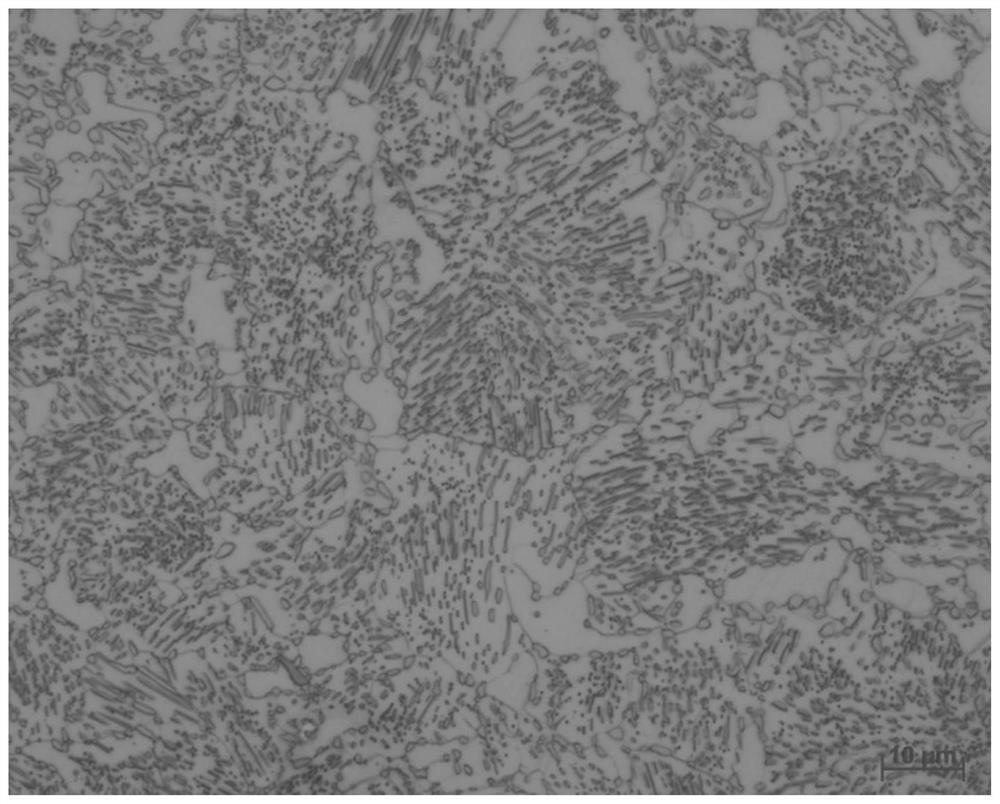

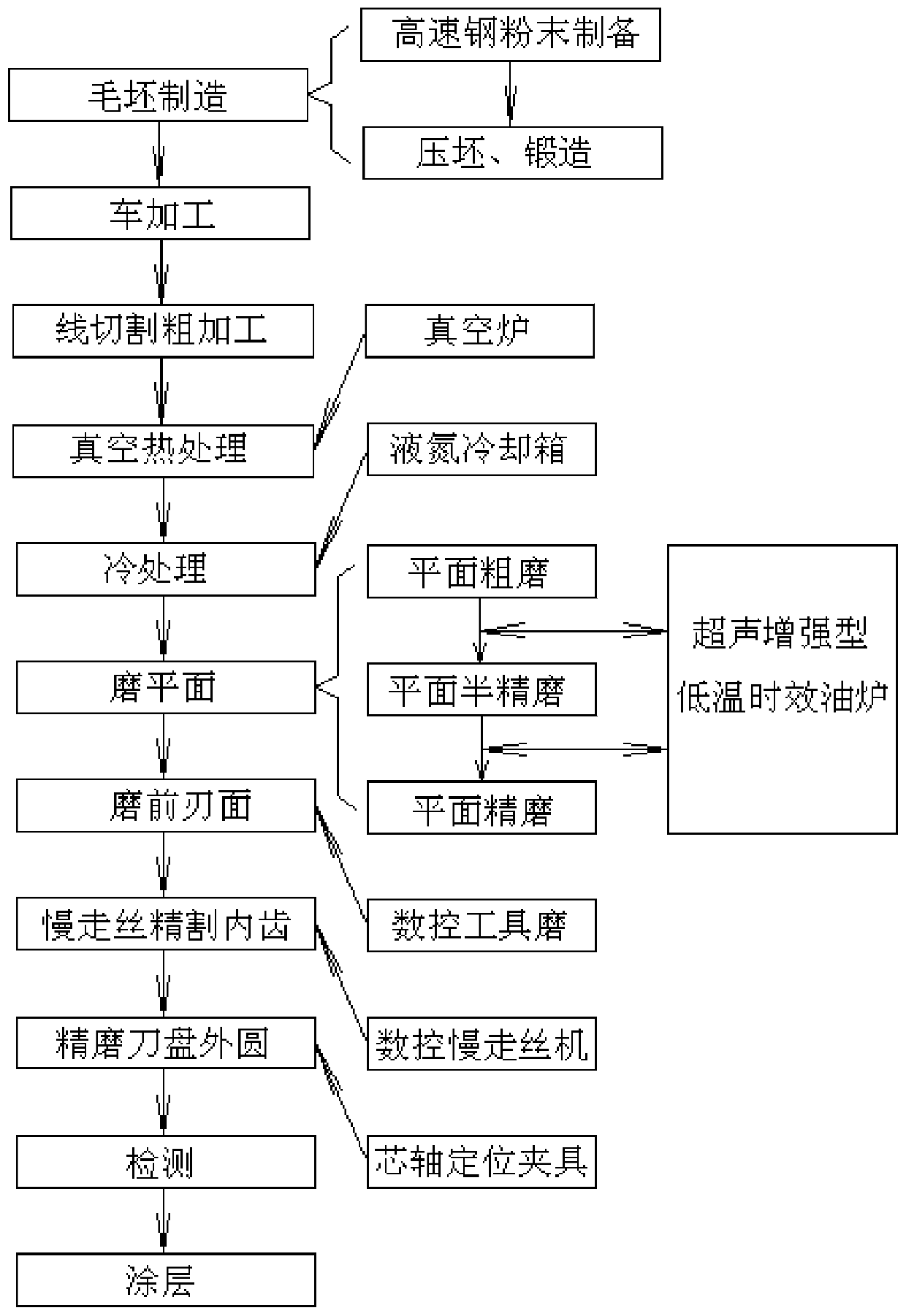

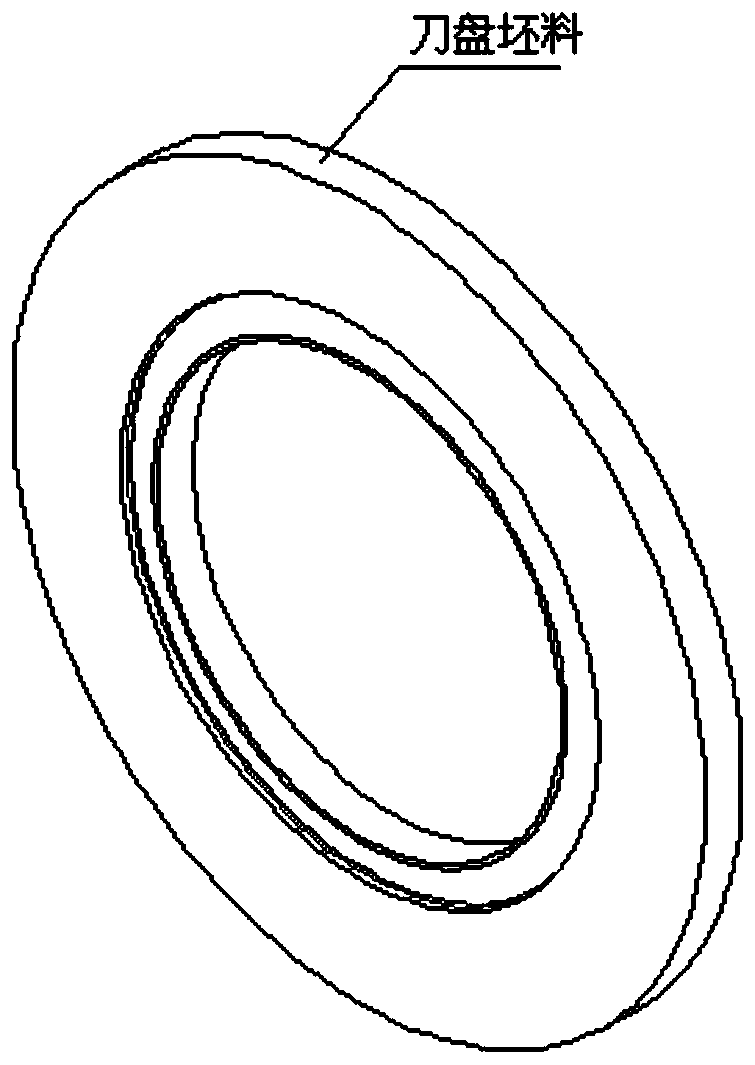

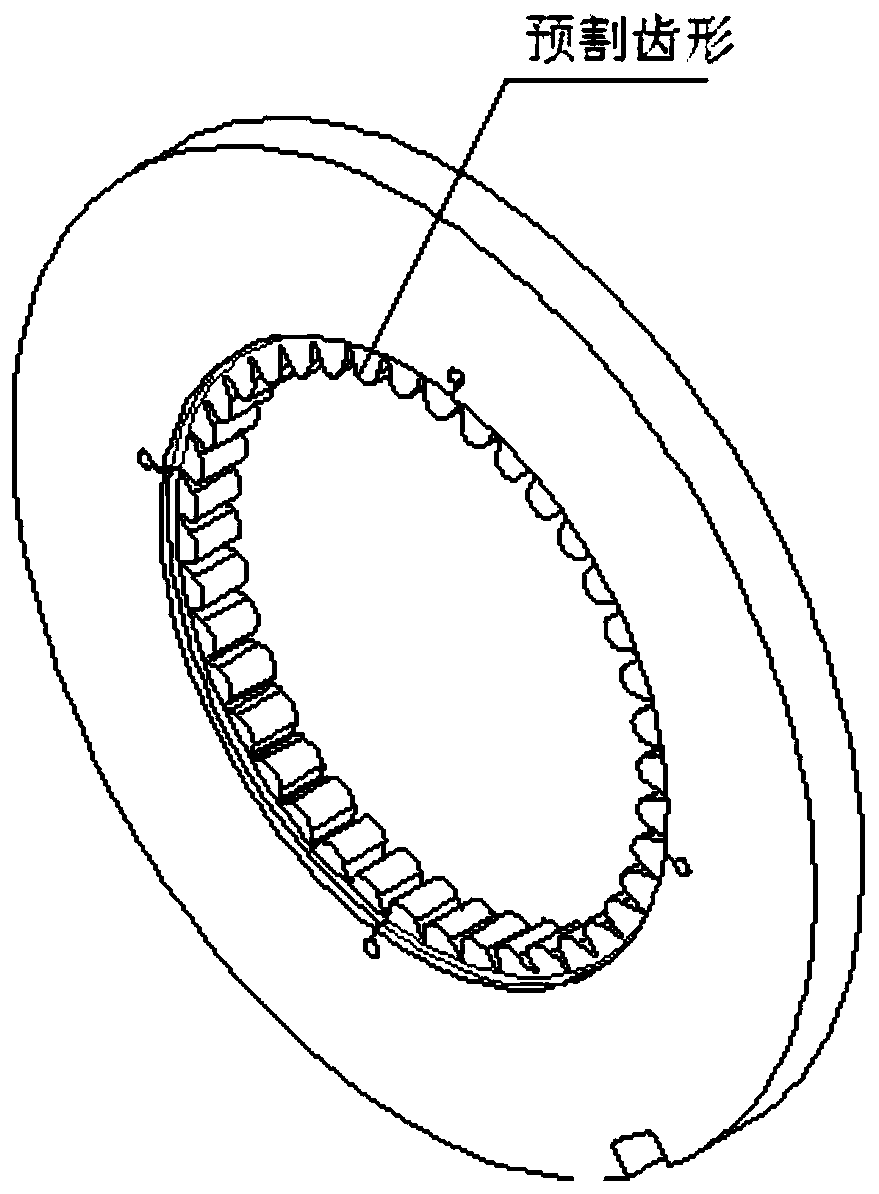

Manufacturing process of external gear drum type broach fine gear cutter disc

The invention relates to the technical field of metal cutting tool manufacturing, and particularly relates to a manufacturing process of an external gear drum type broach fine gear cutter disc. The process comprises the technological steps of blank manufacturing, turning machining, wire cutting rough machining, vacuum heat treatment, cold treatment, surface grinding, rake face grinding, walking wire slowly for inner tooth fine cutting, cutter fine grinding through cylindrical grinding and the like, wherein in the surface grinding working procedure, low-temperature stress-removing aging treatment procedures are arranged between the surface rough grinding and the surface semi-fine grinding and between the surface semi-fine grinding and the surface fine grinding correspondingly to eliminate the surface stress generated in the grinding process so as to reduce the deformation after the surface fine grinding. According to the process, the manufacturing precision of the drum type broach cutter disc is improved, the wear resistance of the cutter disc is improved, and the manufacturing cost of the cutter disc is reduced.

Owner:JIANGYIN SAITE PRECISION TOOL

Composite stepped carburizing and quenching technology of gear shaft

InactiveCN106835004AEliminate processing stressReduce the temperature difference between inside and outsideSolid state diffusion coatingFurnace typesTemperature differenceConcentration gradient

The invention belongs to the technical field of heat treatment, in particular to a composite stepped carburizing and quenching technology of a gear shaft. The composite stepped carburizing and quenching technology of the gear shaft includes the steps of entering furnace and heating, preserving heat, reheating, preserving heat of the stepped carburizing and quenching, reducing temperature and preserving heat, outing furnace and quenching, and the like. By adoption the composite stepped carburizing and quenching technology of the gear shaft, a constant temperature is firstly applied at a temperature below the critical point of the transformation before the workpiece is carburized, the temperature of the workpiece tends to be uniform inside and outside the temperature, thus, the internal and external temperature difference, the heating speed, and the thermal stress are reduced; and in carburizing stage, the stepped carburizing is adopted, that is, increase of cyclation and decrease of carbon concentration gradient, thus, the diffusion rate of carbon atoms is increased, the holding time of workpieces at high temperature is reduced, the deformation of heat treatment is reduced, and the requirements of metallurgical structure and mechanical properties are met.

Owner:ZHANGQIU HAILI MACHINERY MFG CO LTD

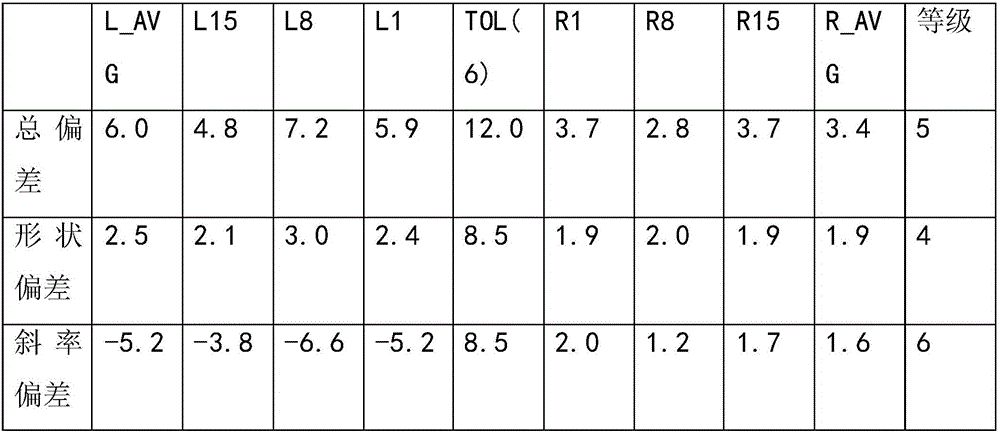

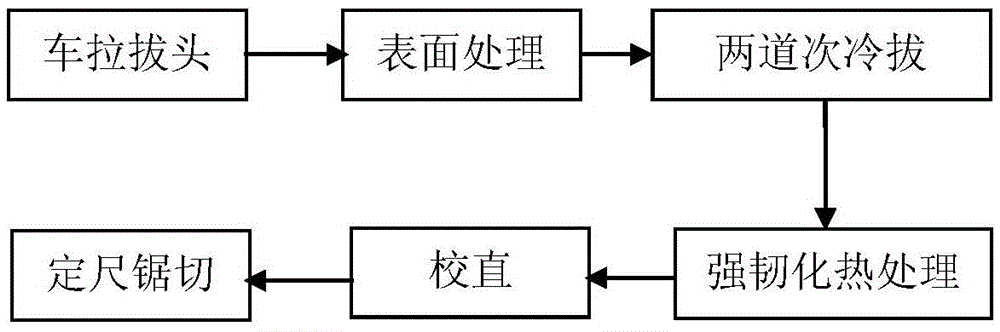

High-precision cold drawn pipe and manufacturing method thereof

The invention discloses a high-precision cold drawn pipe and a manufacturing method thereof. Low-alloy high-tensile structural steel is used as the blank. The high-precision cold drawn pipe is mainly composed of carbon, silicon, manganese, phosphorus, sulphur, niobium, vanadium, titanium, chromium, nickel, copper, nitrogen, molybdenum, aluminum and a trace of boron which are used for regulating the steelmaking quality and mechanical performance, and iron. The high-precision cold drawn pipe has high precision, high strength and high tenacity. The manufacturing method is simple. The manufactured steel pipe is high in precision, and is high in strength and tenacity compared with cold drawn pipes. By means of the method, the strengthened and toughened high-precision cold drawn pipe can be manufactured, it can be ensured that the tensile strength of cold drawn pipes made from the same materials exceeds the national standard 100 Mpa, and the test result of a V2 type notch impact sample exceeds 27 J.

Owner:XCMG HYDRAULICS CO LTD

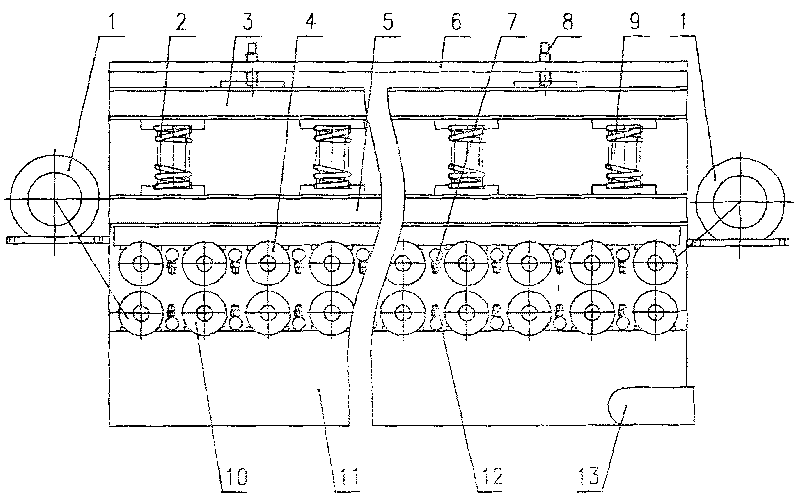

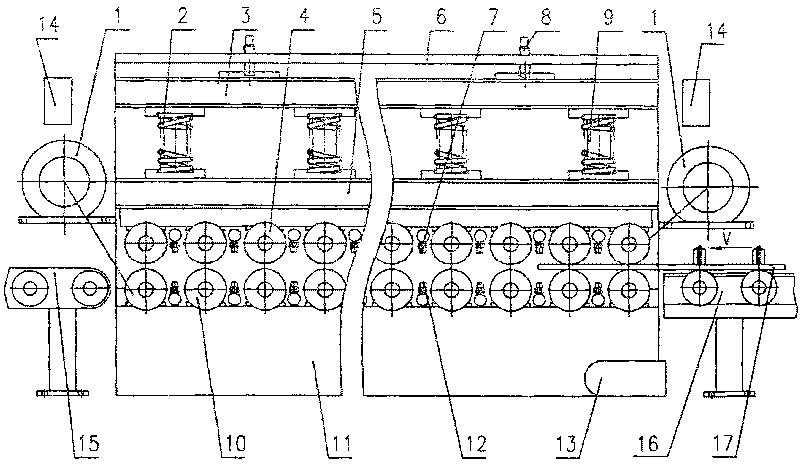

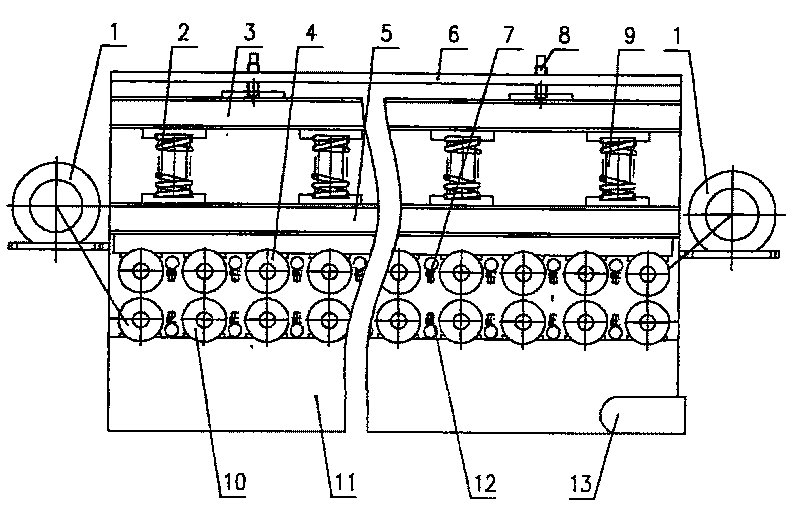

Quenching machining tool for heat treatment and cooling for track plate

InactiveCN101748266AHeat treatment deformation is smallUniform hardnessFurnace typesHeat treatment furnacesQuenchingHigh pressure

The invention relates to a device for performing quenching to a track plate, in particular to a quenching machining tool for heat treatment and cooling for a track plate. The quenching machining tool is invented and mainly aims to solve the problems of large deformation, uneven hardness and soft spots existing in the track plate since the track plate discharged from the furnace is put into the circulating water for quenching at present. The quenching machining tool comprises a box body, wherein a water drain pipe is arranged at the lower part of the box body, lower driving rollers are respectively installed at the upper part of the box body, all the lower driving rollers are connected through chains, lower water spray nozzles are respectively arranged among all the lower driving rollers, an upper driving roller bracket above the lower driving rollers is connected with an upper beam positioned above the upper driving roller bracket through a connecting rod in a sliding manner, a compression spring is arranged on the connecting rod, the upper beam is connected with a tool body through a leading screw, the tool body is fixedly connected with the box body, upper driving rollers are arranged below the upper driving roller bracket, all the upper driving rollers are connected through chains, upper water spray nozzles are respectively arranged among all the upper driving rollers, and the upper water spray nozzles and the lower water spray nozzles are respectively connected with a high pressure water pump respectively through pipelines; and an upper main driving roller on the right side and a lower main driving roller on the left side are connected with a speed reducer respectively through chains. The quenching machining tool has the advantages of small heat treatment deformation, even hardness and no soft spot.

Owner:辽鞍机械股份有限公司

Preparation method of wear-resistant ball for cement

InactiveCN106086611AEliminate internal defectsImprove wear resistanceAnti-corrosive paintsAdditivesWear resistantAlloy

The invention discloses a preparation method of a wear-resistant ball for cement. The preparation method comprises the following step that a wear-resistant ball workblank is obtained through pouring, wherein a wear-resistant ball workblank alloy comprises, by weight percentage, 3.2-3.4% of C, 0.9-1.2% of Si, 0.4-0.8% of Mn, 0.002-0.01% of P, 0.005-0.013% of S, 1.4-1.7% of Cr, 0.14-0.18% of RE, 0.15-0.35% of W, 0.04-0.12% of V, 1.25-1.45% of Ni, 0.03-0.06% of Te, 0.02-0.08% of Cu and the balance iron. According to the preparation method of the wear-resistant ball, internal defects of a material are effectively eliminated; wear resistance and fatigue strength of the wear-resistant ball are improved; meanwhile, the preparation method has the beneficial effects of being free of oxidation, free of decarburization, free of element depletion and the like; and heat treatment deformation of the wear-resistant ball can be reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

Large-pipe-diameter thin-wall pipe post-welded heat treatment device and using method thereof

PendingCN108517398AImprove insulation effectHeat dissipation is slowFurnace typesHeat treatment process controlTemperature controlEngineering

The invention discloses a large-pipe-diameter thin-wall pipe post-welded heat treatment device and a using method thereof, and belongs to the technical field of welding heat treatment. The device comprises steel pipe supporting seats (1), electric heating elements (2), insulating layers (3) on the electric heating elements (2), thermocouples (4), a binding material (5), an inner pipe wall heat preservation layer (6) and a supporting frame (7), wherein the electric heating elements (2) are basically equally and uniformly arranged along the outer circumference of a steel pipe (8), and each of the electric heating elements (2) and the corresponding thermocouple (4) are respectively connected with the corresponding heat treatment temperature control instrument. During use, the electric heatingelements (2) of the device is electrified and heated, so that an annular weld joint (9) of the steel pipe (8) and the nearby area are heated to the heat treatment temperature, cooling is carried outafter heat preservation, and then the post-welded heat treatment of the steel pipe is completed. By the adoption of the large-pipe-diameter thin-wall pipe post-welded heat treatment device and the using method thereof, a better welding heat treatment and heat preservation effect can be obtained, the heating temperature is controlled accurately, the heating temperature fluctuation is small, the heat treatment deformation can be reduced, and the performance uniformity after heat treatment can be improved.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com