Heat treatment process of gear steel for automobile gearbox

A technology for automobile gearboxes and gear steels, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve problems such as easy cracking, achieve good wear resistance, improve mechanical properties and wear resistance, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

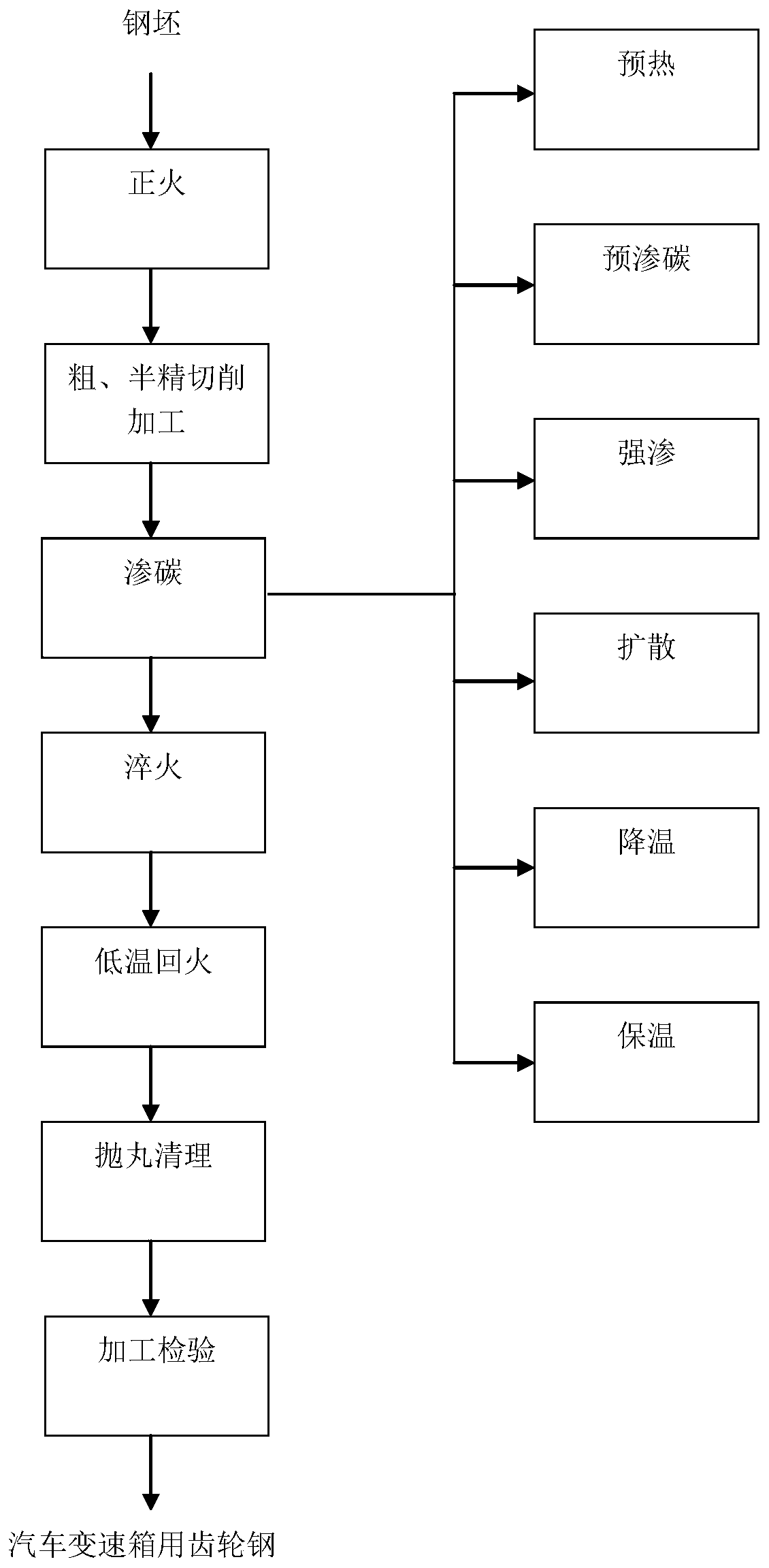

[0027] The invention provides a heat treatment process of gear steel for automobile gearbox, including normalizing process, rough and semi-finishing process, carburizing process, quenching process, low temperature tempering process, shot blasting and processing inspection process, specifically Include the following steps:

[0028] (1) The chemical composition of the billet used in the normalizing process is calculated by weight percentage: C: 0.18%, Si: 0.20%, Mn: 0.93%, P: 0.008%, S: 0.005%, Al: 0.025%, Ti : 0.03%, Cr: 1.08%, Ni: 0.05%, and the rest are Fe and unavoidable impurities. The temperature in the normalizing section is 880°C, keep warm for 0.5h, then quickly cool to 680°C and keep warm for 1h, the quick cooling adopts air cooling or spray cooling, and the cooling rate is 30°C / s;

[0029] (2) The oil is cooled to room temperature, and then subjected to rough and semi-finish cutting; the room temperature refers to 20°C.

[0030] (3) The temperature of the control pr...

Embodiment 2

[0037] The invention provides a heat treatment process of gear steel for automobile gearbox, including normalizing process, rough and semi-finishing process, carburizing process, quenching process, low temperature tempering process, shot blasting and processing inspection process, specifically Include the following steps:

[0038] (1) The chemical composition of the billet used in the normalizing process is calculated by weight percentage: C: 0.19%, Si: 0.22%, Mn: 0.95%, P: 0.01%, S: 0.008%, Al: 0.027%, Ti : 0.04%, Cr: 1.10%, Ni: 0.08%, and the rest are Fe and unavoidable impurities. The temperature in the normalizing section is 880°C, keep warm for 0.8h, then quickly cool to 700°C and keep warm for 1.5h, the quick cooling adopts air cooling or spray cooling, and the cooling rate is 40°C / s;

[0039] (2) The oil is cooled to room temperature, and then subjected to rough and semi-finish cutting; the room temperature refers to 20°C.

[0040](3) The temperature of the control pr...

Embodiment 3

[0047] The invention provides a heat treatment process of gear steel for automobile gearbox, including normalizing process, rough and semi-finishing process, carburizing process, quenching process, low temperature tempering process, shot blasting and processing inspection process, specifically Include the following steps:

[0048] (1) The chemical composition of the billet used in the normalizing process is calculated by weight percentage: C: 0.20%, Si: 0.24%, Mn: 0.97%, P: 0.012%, S: 0.01%, Al: 0.030%, Ti : 0.05%, Cr: 1.14%, Ni: 0.10%, and the rest are Fe and unavoidable impurities. The temperature in the normalizing section is 880°C, keep warm for 01h, then quickly cool to 720°C and keep warm for 2h, the quick cooling adopts air cooling or spray cooling, and the cooling rate is 50°C / s;

[0049] (2) The oil is cooled to room temperature, and then subjected to rough and semi-finish cutting; the room temperature refers to 20°C.

[0050] (3) The temperature of the control preh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending fatigue strength | aaaaa | aaaaa |

| bending fatigue strength | aaaaa | aaaaa |

| bending fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com