Method for manufacturing conical riser of direction column of motorcycle by adopting cold extrusion process

A cold extrusion, motorcycle technology, applied in the direction of metal extrusion dies, etc., can solve the problems that the wall thickness of raw materials should not be too large, the qualified rate of finished products will be affected, and cracks will easily occur in reaming. The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, carry out according to the following steps:

[0020] (1) blanking, get figure 1 The straight steel pipe blank shown in the figure is a steel pipe blank of a certain length with the same outer diameter and the same inner diameter. The straight steel pipe blank is decontaminated and derusted, and saponified to make the surface smooth;

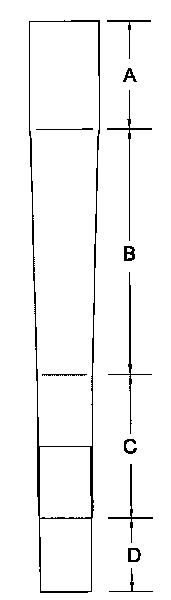

[0021] (2) Put the straight steel pipe blank into the cold extrusion die cavity, start the press, align the 5 ends of the punch on the press with the end face of the straight steel pipe blank, and only slowly apply the shaft to the straight steel pipe blank. The straight steel pipe blank is continuously extruded in one cold extrusion die cavity, or is gradually extruded in two to three steps. figure 2 Tapered riser stock shown; see Figure 4 , the cold extrusion die cavity is sequentially connected by the largest equal-diameter cavity 1, the tapered cavity 2, the smaller equal-diameter cavity 3, and the smallest equal-diam...

Embodiment 2

[0024] In the cold extrusion process of this embodiment, the straight steel pipe blank is gradually extruded into a tapered riser blank in two to three cold extrusion die cavities. The compression mold cavities can be located on the same pair of molds, or on different molds. All the other procedures are the same as in Example 1.

[0025] Figure 6 , Figure 7 It shows the die structure applied to this embodiment, with two cold extrusion die cavities on the same secondary die, and the straight steel pipe blank is initially shaped into a tapered section in the first die cavity 7 to obtain a tapered vertical Pipe semi-formed parts; the second cavity 8 continues to extrude the tapered riser semi-formed parts, further shrinks the tapered riser semi-formed parts, and then forms the largest equal-diameter section, conical section, and smaller equal-diameter segment and the smallest equal-diameter segment. Figure 7 The double dotted line in is the formed conical riser blank.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com