Plastic container

A technology for plastic containers and containers, applied in the field of plastic bottles, can solve the problems of large structural height and no significant internal volume, and achieve the effect of improving strength or stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description of the drawings, the same reference numerals denote the same components or features, respectively.

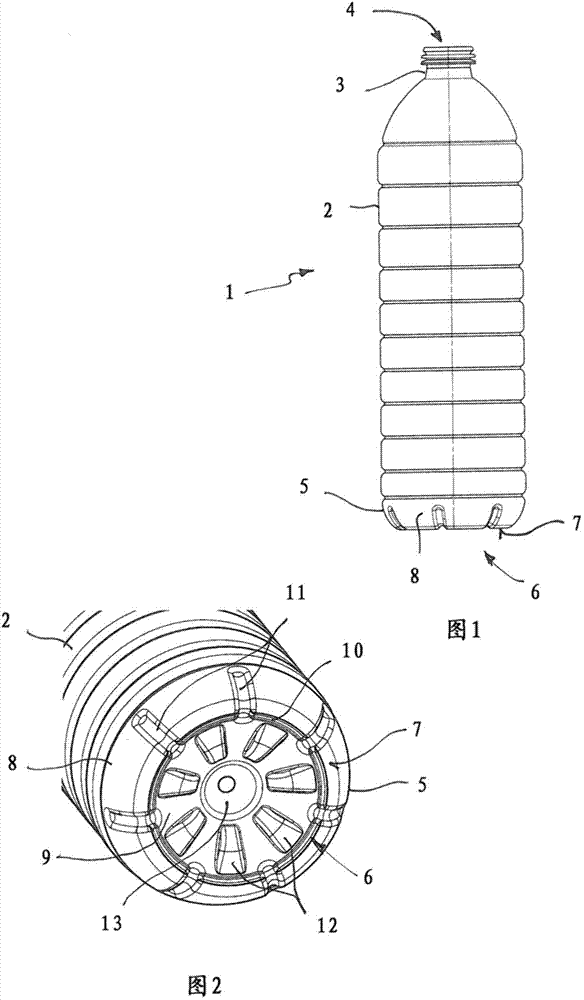

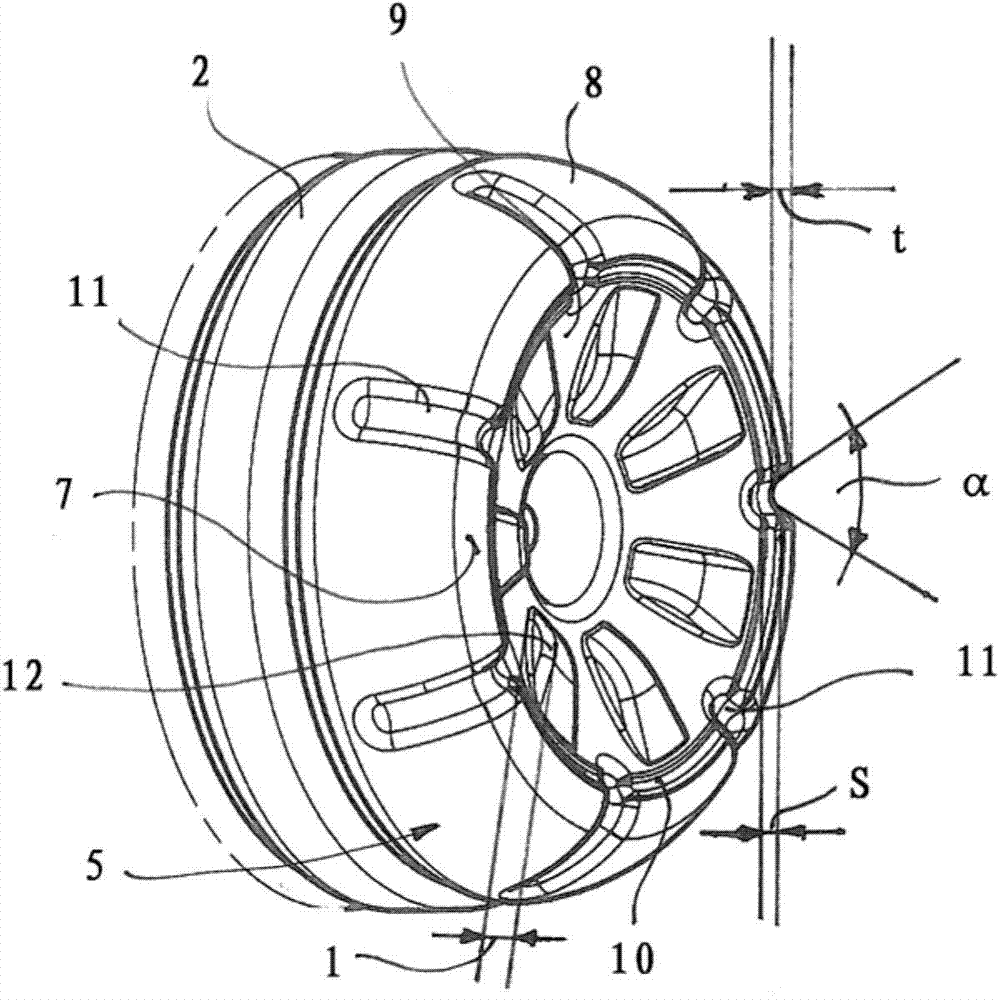

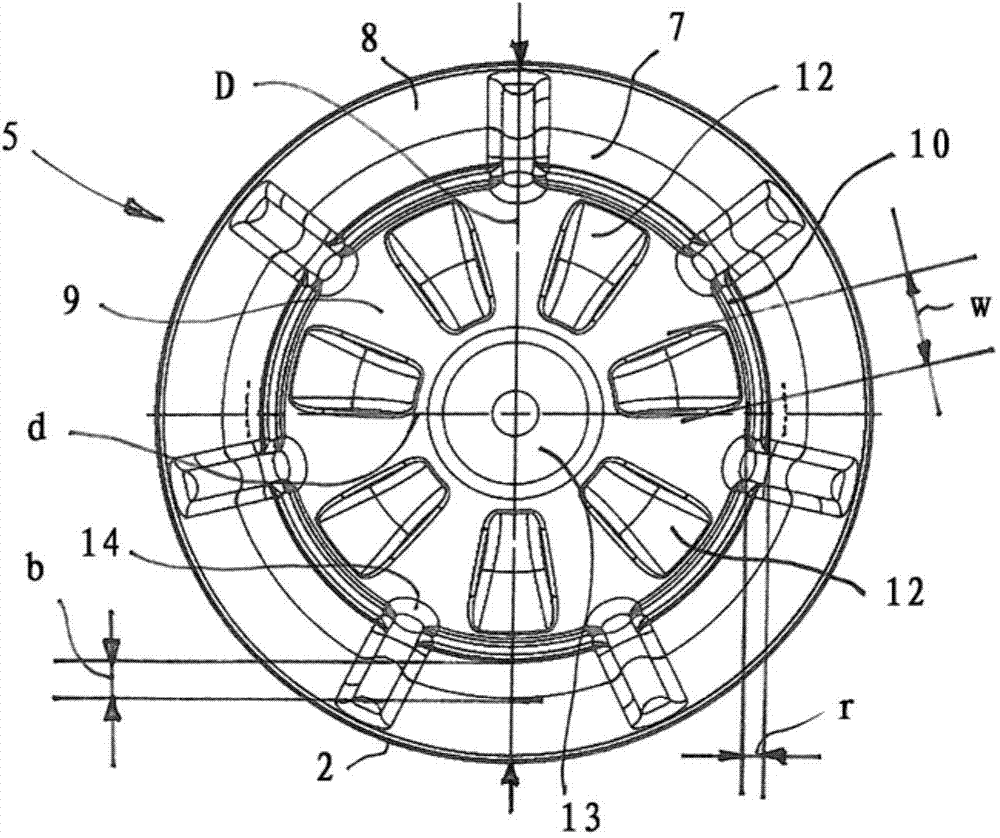

[0035] exist figure 1 The plastic container, in particular the plastic bottle, shown in , bears the reference numeral 1 as a whole. The plastic container 1 has a container body 2 with a longitudinal axis, to which one longitudinal end a container neck 3 is connected, said container neck having a pouring opening 4 . A bottom section 5 is connected to the other longitudinal end of the container body 2, said bottom section having a container bottom 6 with a seating surface 7 and a laterally raised edge region 8 which transitions into the container body 2 in. The plastic container 1 shown is, for example, a plastic bottle for cooking oil. Plastic containers 1 of this type are usually produced in the stretch-blow molding process from previously produced elongate blanks or preforms with an essentially circular cross section. Blanks are usually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com