Method for obtaining circumferential load distribution of friction plate tooth part through variable-contact-rigidity testing

A circumferential load and friction plate technology, applied in the field of test simulation, can solve problems such as the inability to fully reflect the teeth, the contact force is not the same, and the stress distribution characteristic curve cannot be obtained, so as to reduce the data processing link, improve the accuracy, test simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

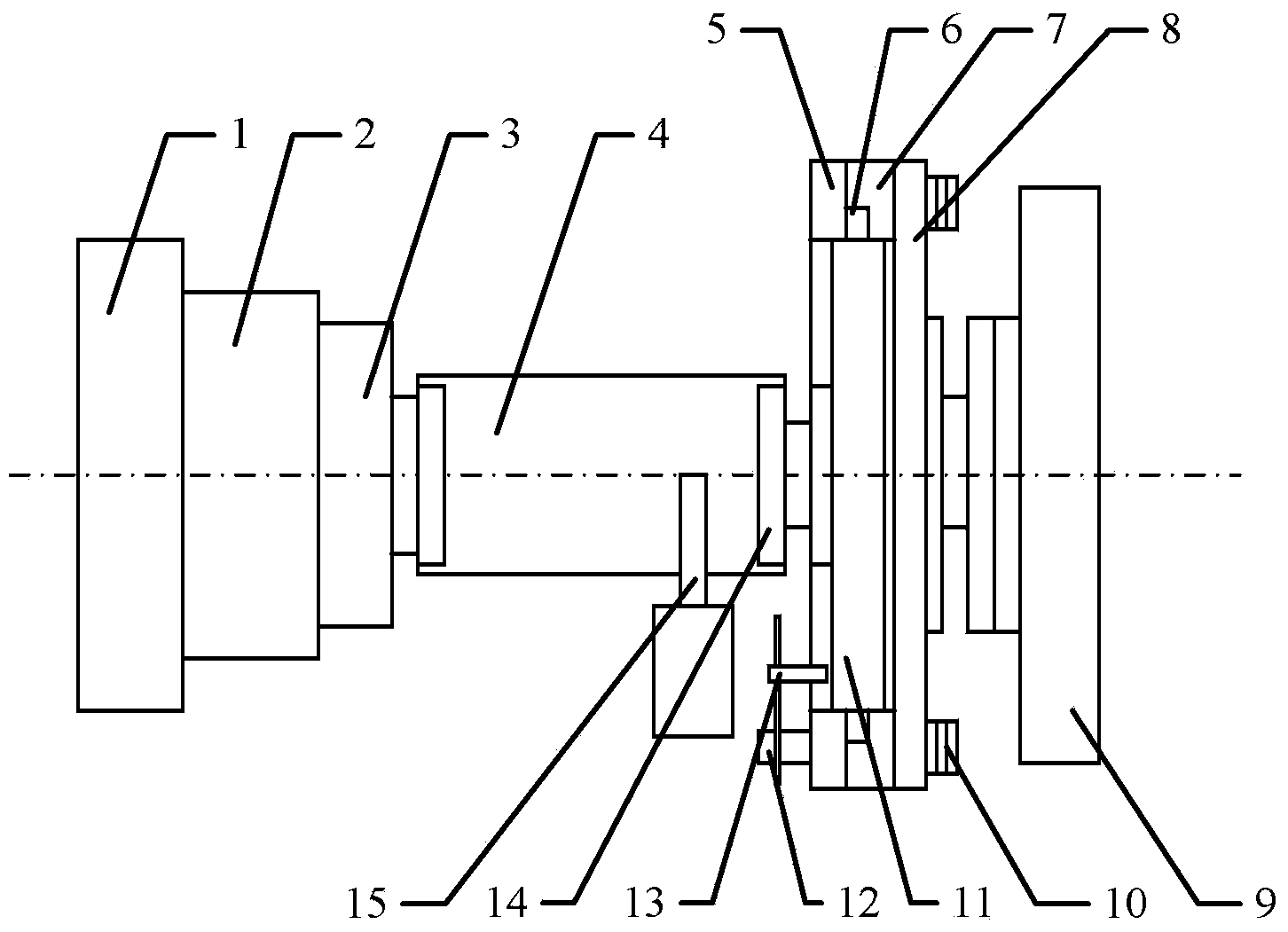

[0026] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] The clutch friction pair is one of the important basic components of the transmission system. In actual engineering, pitting, cracks and even fractures often occur on the meshing teeth during power transmission of the friction pair. In order to explore the reasons for the above-mentioned damages in the meshing transmission of the friction pair teeth, it is necessary to study the circumferential load distribution characteristics and changing rules of the friction pair tooth strength in the meshing transmission process. To obtain the above characteristic parameters, corresponding experimental tests must be carried out.

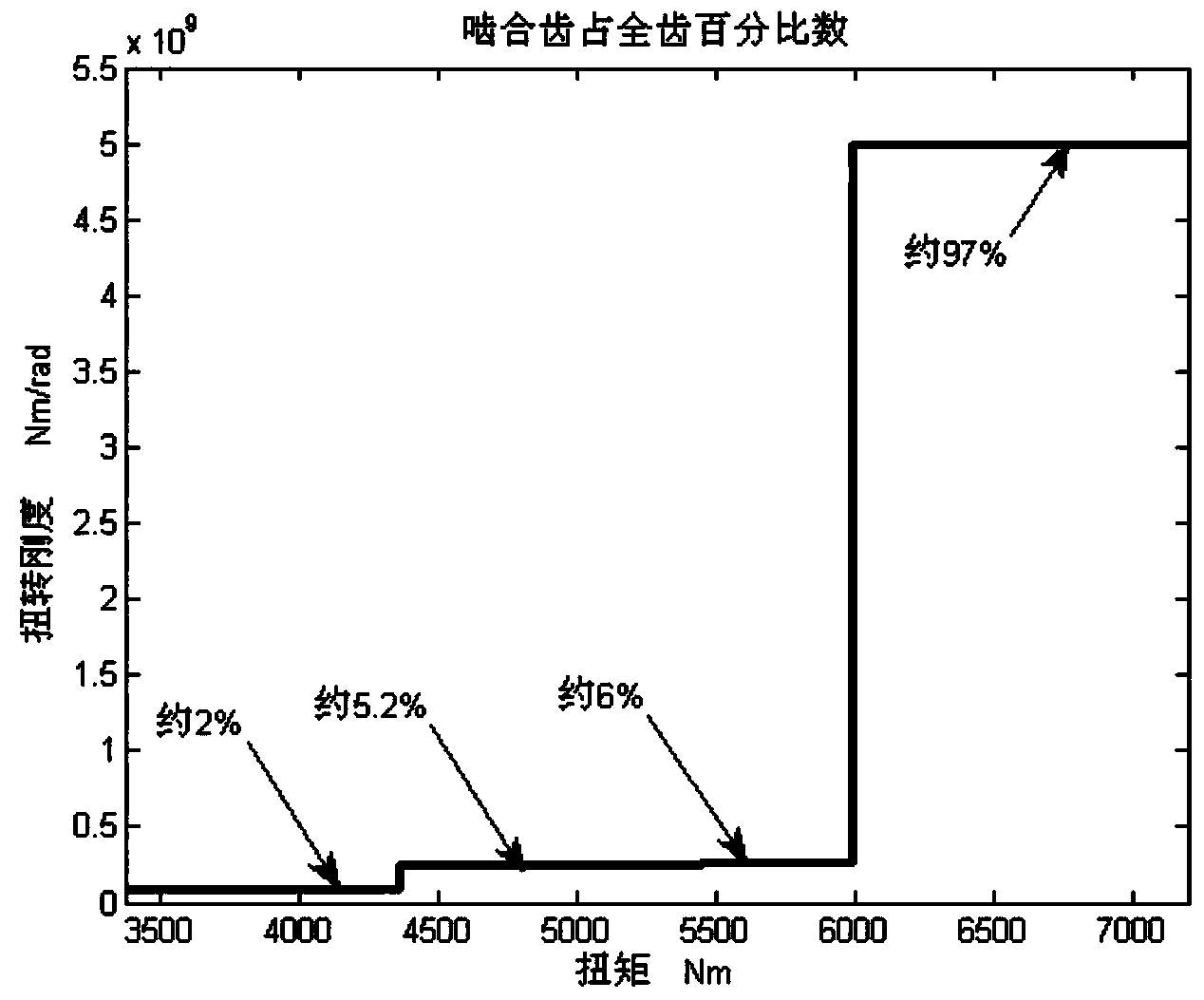

[0028] According to the limit value required by the transmission device for the power transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com