Titanium reinforced high-cobalt martensitic aged anti-corrosion ultrahigh-strength steel and preparation method

An ultra-high-strength steel and martensitic technology, applied in the field of alloy steel, can solve the problems of stress corrosion resistance, strength reduction, and inability to increase strength, and achieve good stress corrosion resistance, high strength, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

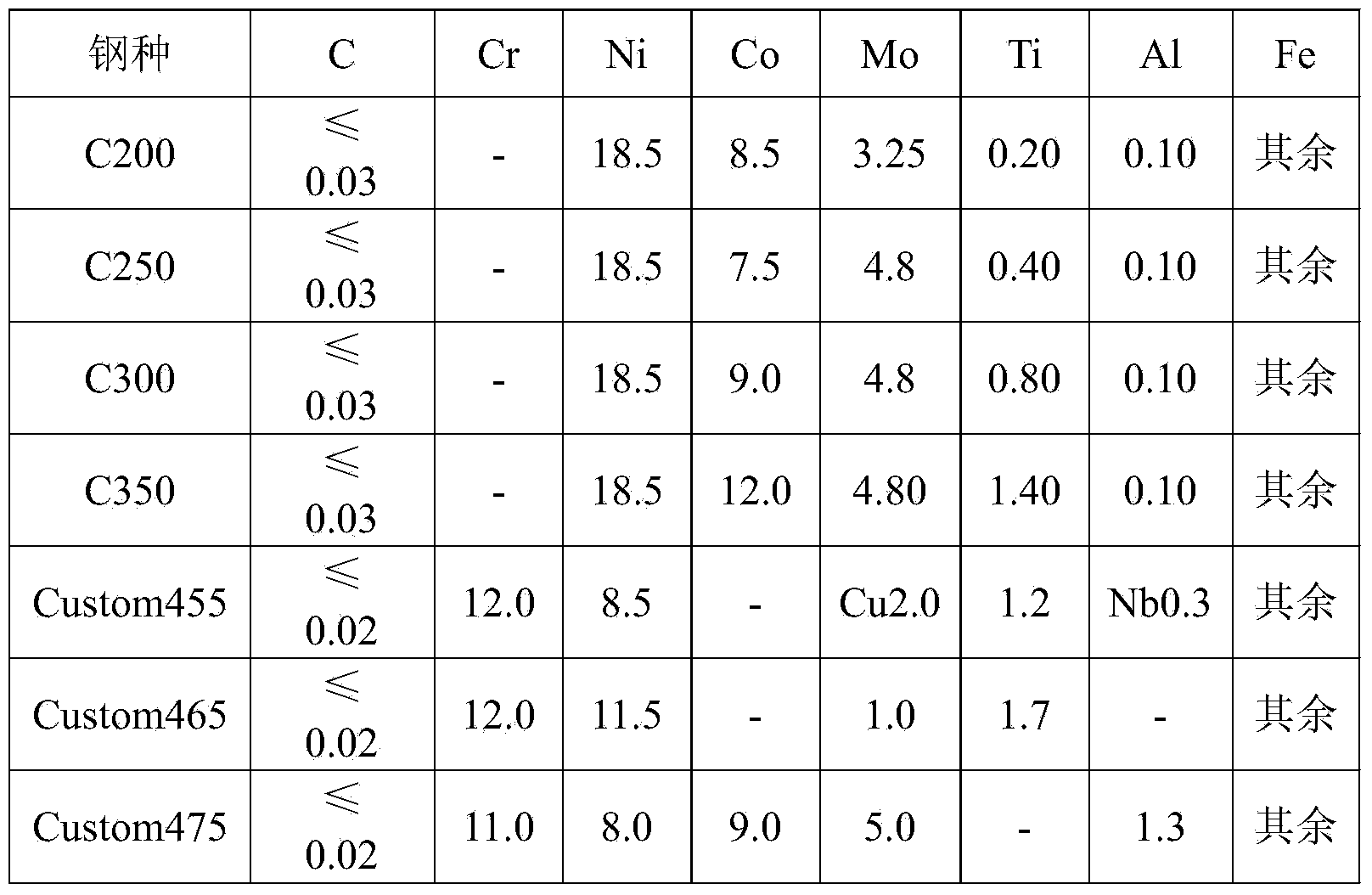

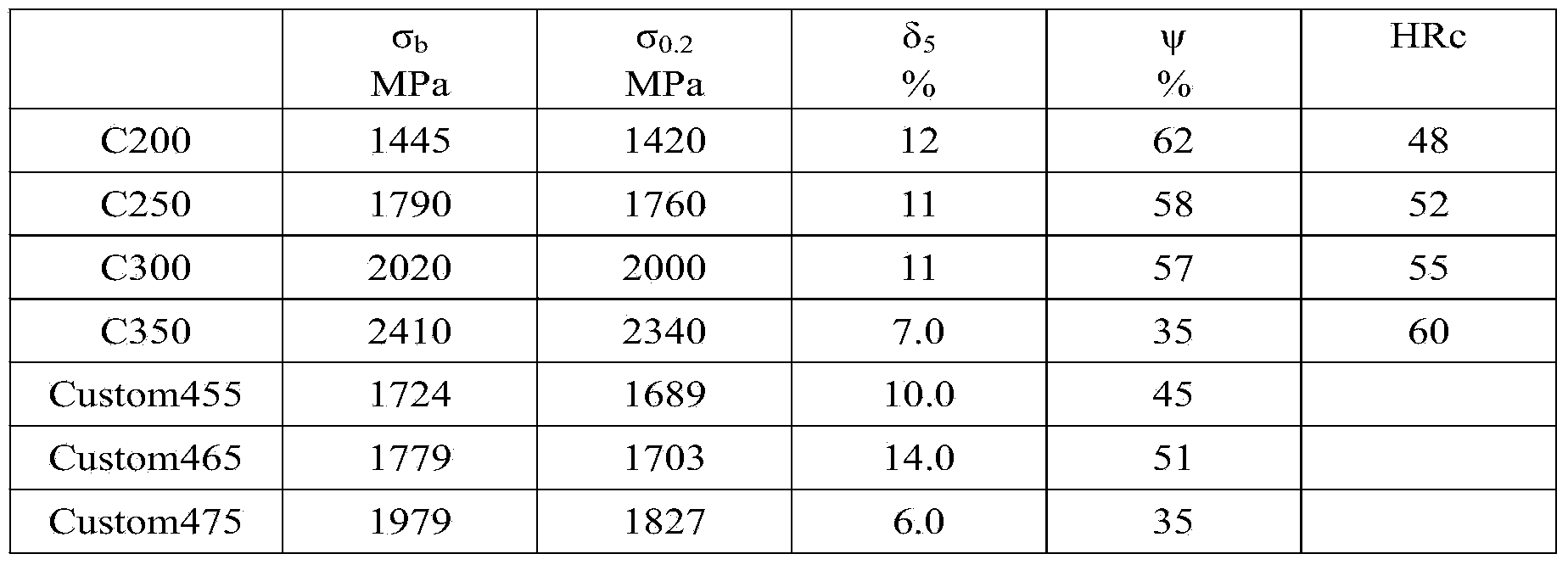

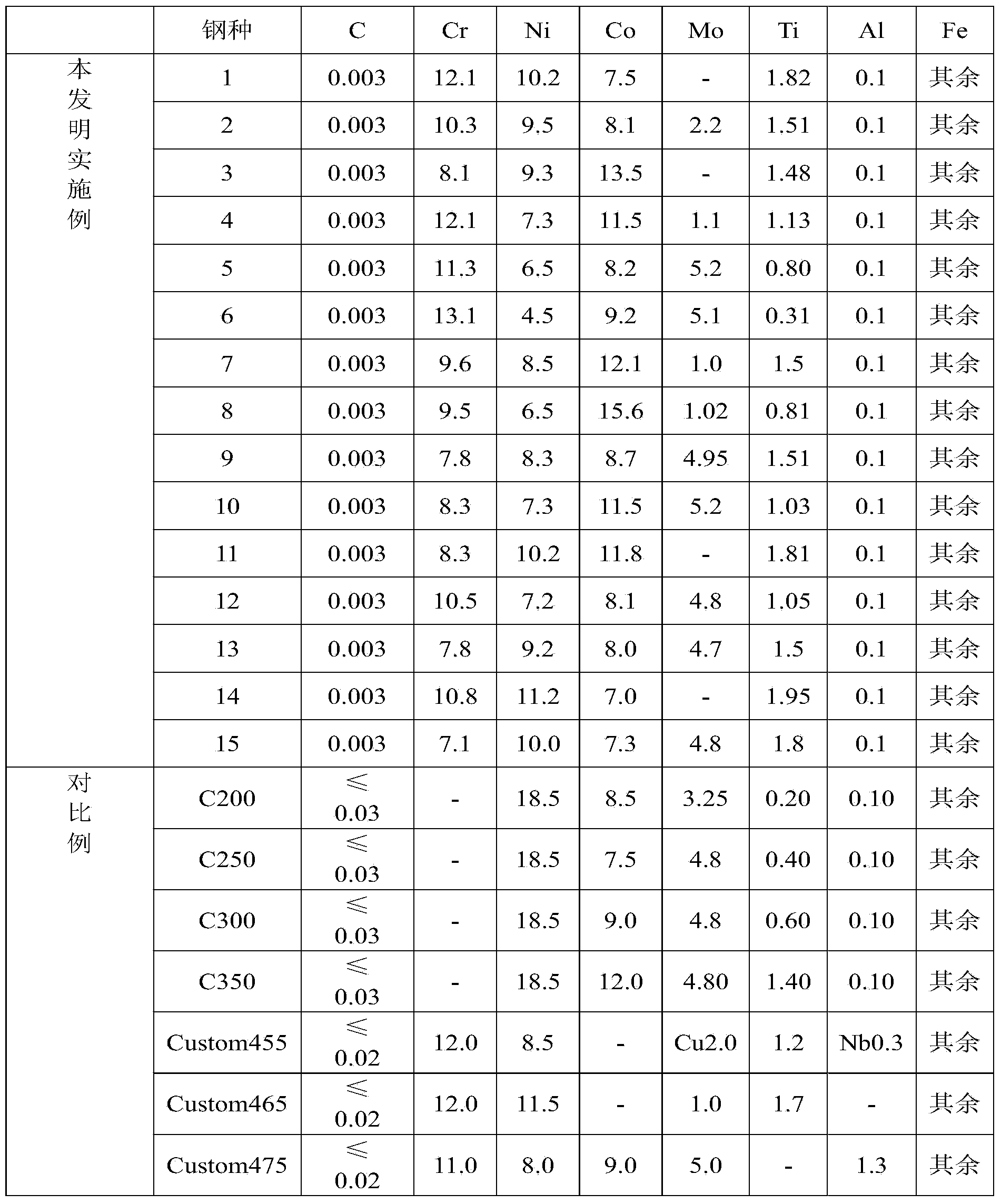

[0052] According to the chemical composition scope of steel of the present invention, adopt 25 kilograms of vacuum induction furnaces to prepare 15 furnaces of 21 kilograms of alloy ingots, its concrete chemical composition is shown in Table 3, and furnace number is 1 # ~15 # .

[0053] After 10 furnaces of steel were smelted and cast into steel ingots, the high-temperature homogenization treatment system was first carried out before forging: after 6 hours of heat preservation at 1200 ° C, the temperature was lowered for forging, and the forging heating temperature was 1150 ° C. The dimensions of forged test rods are: φ15×2000mm, 15×15×2000mm and 25×45×L.

[0054] After forging, the test bar is firstly subjected to solution heat treatment: solution treatment at 1000℃×1h, air cooling, and then sent to the sample section for processing tensile, impact and fracture toughness sample blanks. The final heat treatment is solid solution, deep cooling and aging heat treatment: soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com