Method for preparing Cr doped ZnO-based diluted magnetic semiconductor film material

A technology of dilute magnetic semiconductor and thin film materials, which is applied in the application of magnetic film to substrate, the magnetism of inorganic materials, and the coating process of metal materials. It can solve the problems of complex preparation process, low repeatability, and high cost, and achieve deposition The effect of high rate, broad research value and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

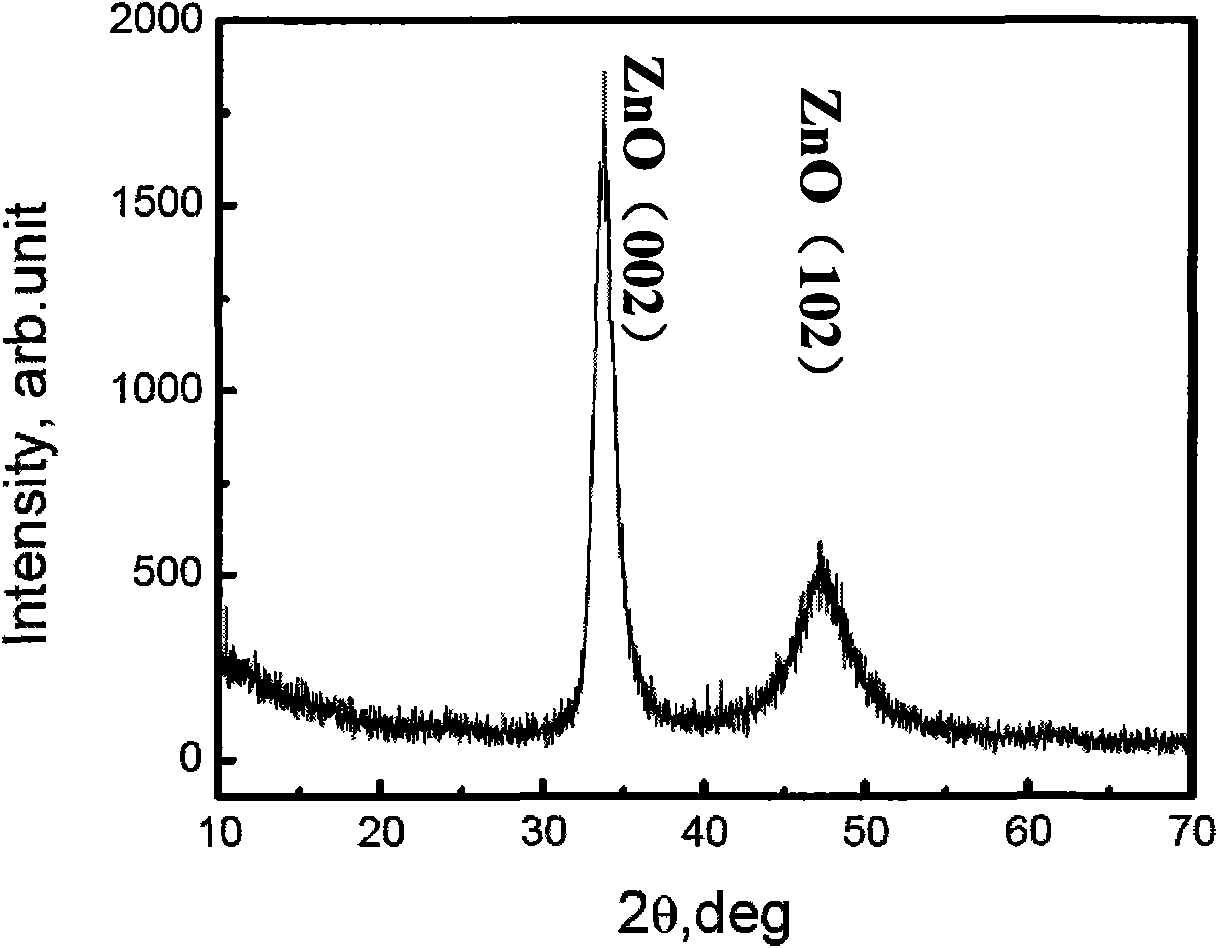

[0021] The Si substrate was ultrasonically cleaned in alcohol for 5 minutes, then washed with deionized water, dried and placed in a vacuum chamber. The distance between the substrate and the target was 55mm. The target was chromium with a purity of 99.99% and zinc oxide with a purity of 99.99%. Target co-sputtering. Vacuum to 10 -5 Pa. The working gas during the sputtering process is high-purity argon with a flow rate of 10cm 3 / min, the working pressure during the sputtering process is 10 -1 Pa. Bombard the substrate holder with an incident power of 50W for 15 minutes in an argon atmosphere to remove the oxide layer and other impurities on the surface of the substrate. Turn on the Cr target and the ZnO target so that their powers are 30W and 250W respectively, remove the baffle above the target, and start sputtering for 60 minutes and apply a DC bias of -100V to the substrate.

[0022] From figure 1 It can be seen that the prepared film is ZnO, and the M-H curve of the...

Embodiment 2

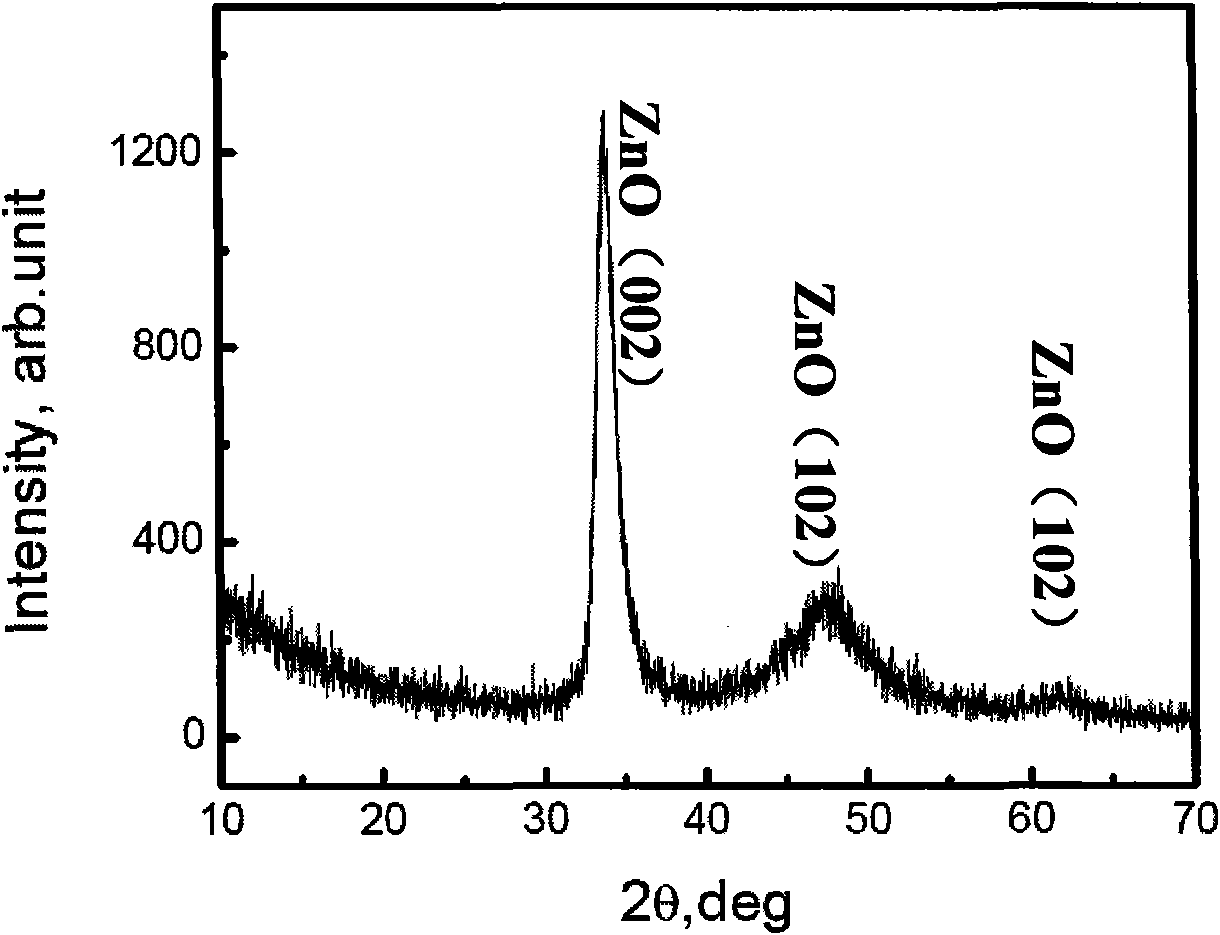

[0024]The Si substrate was ultrasonically cleaned in alcohol for 5 minutes, then washed with deionized water, dried and placed in a vacuum chamber. The distance between the substrate and the target was 55mm. The target was chromium with a purity of 99.99% and zinc oxide with a purity of 99.99%. target co-sputtering. Vacuum to 10 -5 Pa. The working gas during the sputtering process is high-purity argon with a flow rate of 10cm 3 / min, the working pressure during the sputtering process is 10 -1 Pa. Bombard the substrate holder with an incident power of 50W for 15 minutes in an argon atmosphere to remove the oxide layer and other impurities on the surface of the substrate. Turn on the Cr target and the ZnO target so that their powers are 40W and 250W respectively, remove the baffle above the target, and start sputtering for 60 minutes and apply a DC bias of -100V to the substrate.

[0025] From figure 2 It can be seen that the prepared film is ZnO, and the M-H curve of the...

Embodiment 3

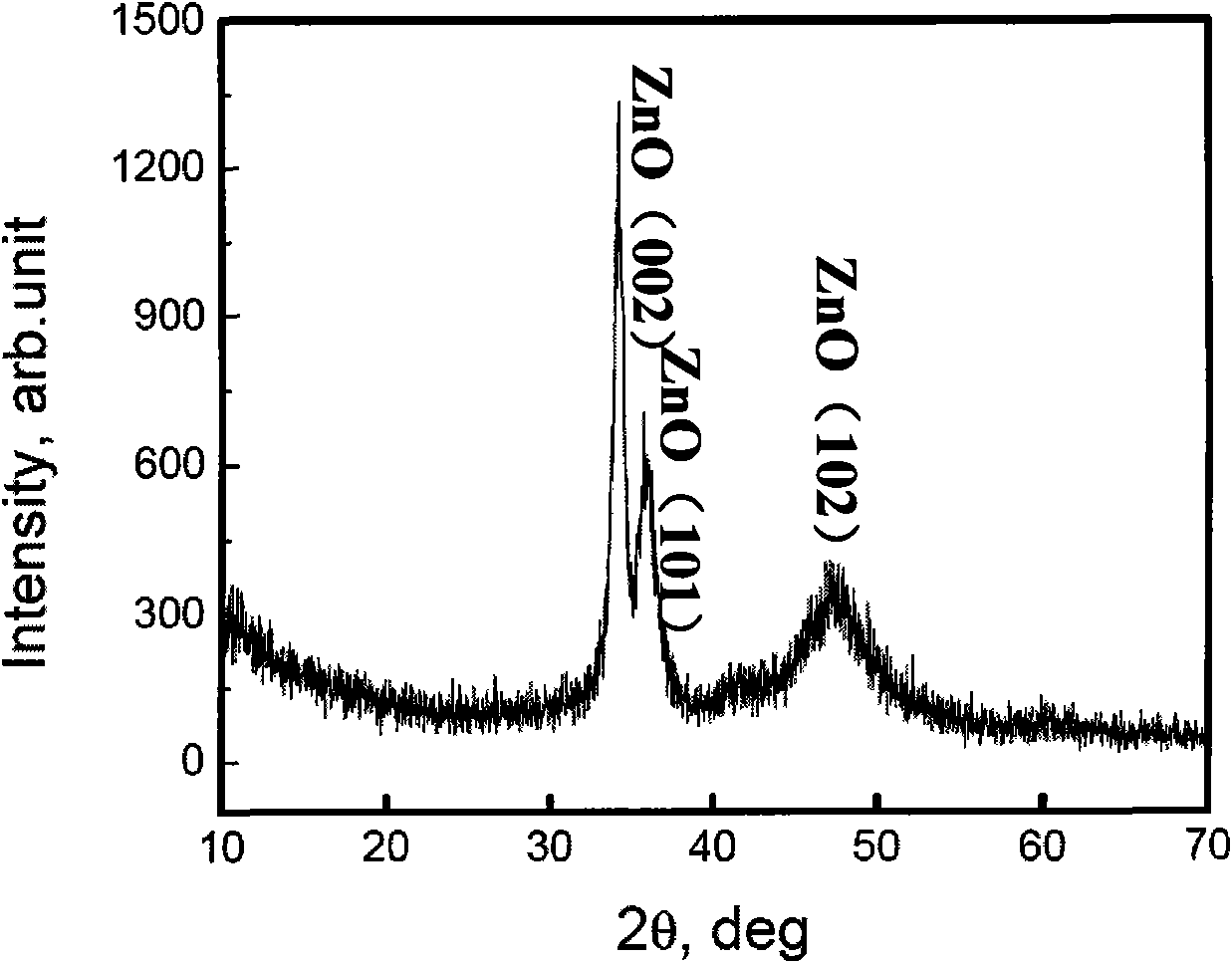

[0027] The Si substrate was ultrasonically cleaned in alcohol for 5 minutes, then cleaned with deionized water, dried and placed in a vacuum chamber. The distance between the substrate and the target was 60mm. The target was chromium with a purity of 99.99% and zinc oxide with a purity of 99.99%. target co-sputtering. Vacuum to 10 -5 Pa. The working gas during the sputtering process is high-purity argon with a flow rate of 10cm 3 / min, the working pressure during the sputtering process is 10 -1 Pa. Bombard the substrate holder with an incident power of 50W for 15 minutes in an argon atmosphere to remove the oxide layer and other impurities on the surface of the substrate. Turn on the Cr target and the ZnO target so that their powers are 50W and 250W respectively, remove the baffle above the target, and start sputtering for 60 minutes and apply a DC bias of -100V to the substrate.

[0028] From image 3 It can be seen that the prepared film is ZnO, and the M-H curve of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com