Rare earth yttrium doped magnesium-lithium alloy and preparation method thereof

A magnesium-lithium alloy and yttrium-doped technology, which is applied in the field of alloy smelting, can solve problems such as imperfect smelting process, poor high-temperature mechanical properties, and poor corrosion resistance, and achieve the effects of simple smelting equipment, reduced combustion, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

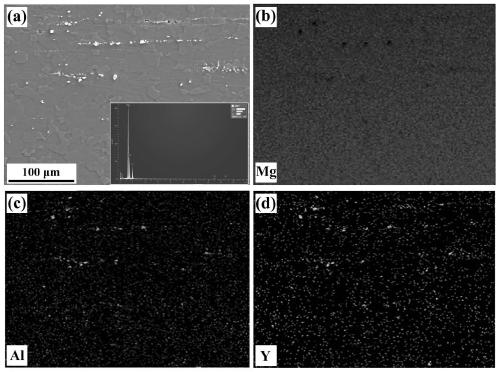

[0058] A Mg-4Li-1Al-0.5Y alloy ingot, the mass percentage of each component is: Li 4.0%, Al 1%, Y0.5%, the balance is Mg and impurities; wherein the total content of the impurities is low at 0.02wt.%.

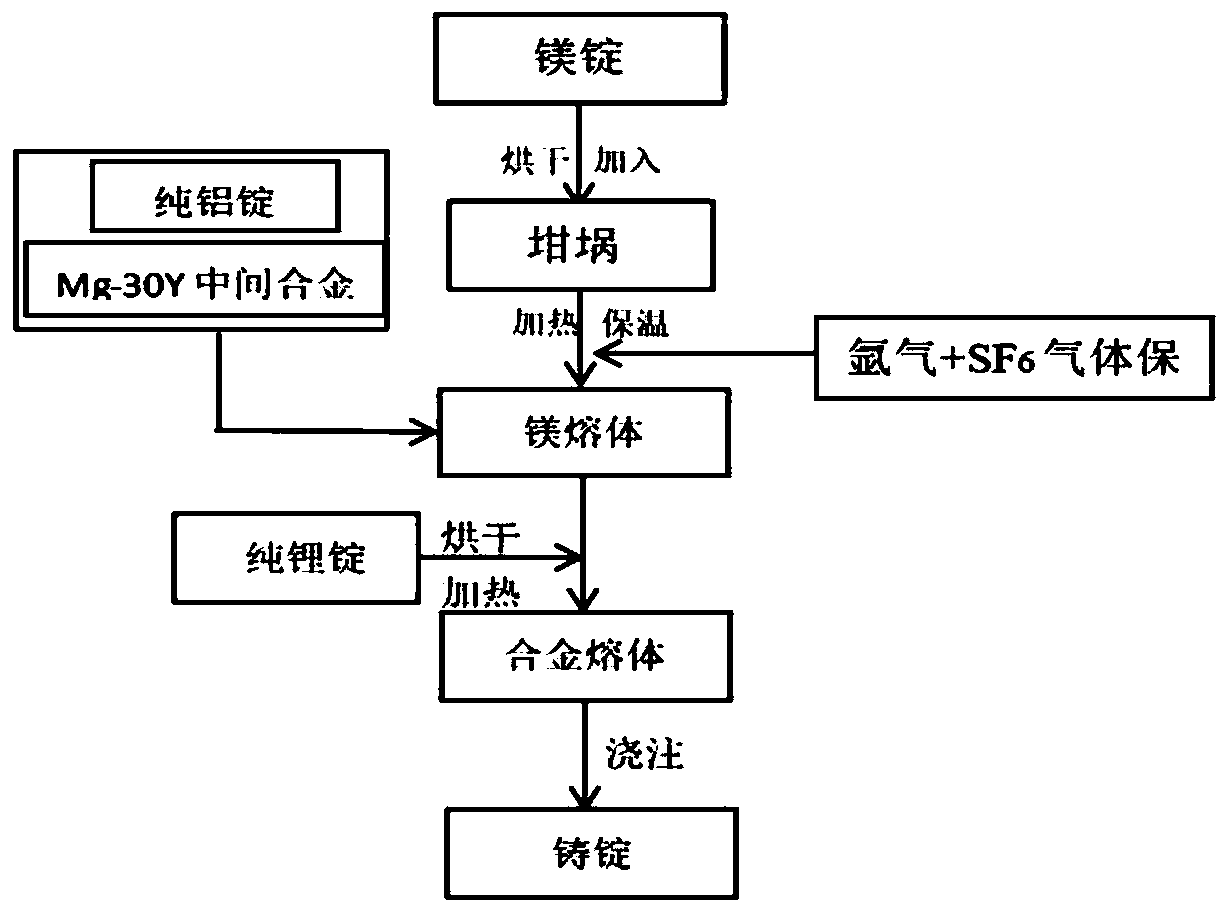

[0059] And the preparation method of the Mg-4Li-1Al-0.5Y alloy ingot is as follows:

[0060] Weigh magnesium ingots, aluminum ingots, Mg-30Y master alloys and lithium ingots according to the composition ratio of the Mg-4Li-1Al-0.5Y alloy. After melting, stir mechanically for 10 minutes, raise the temperature to 710°C and keep it warm for 20 minutes, and pour to obtain magnesium-lithium alloy ingots. The magnesium-lithium alloy ingot was kept at 350°C for 2 hours, extruded at an extrusion ratio of 13:1, and annealed at 350°C for 1 hour to obtain a magnesium-lithium alloy doped with rare earth yttrium. On the annealed alloy, according to the national standard, the mechanical properties of the alloy at room temperature were tested by processing the tensile sample.

[0061] The ...

Embodiment 2

[0064] A Mg-3.9Li-0.8Al-0.2Y alloy ingot, the mass percent of each component is: Li 3.9%, Al 0.8%, Y 0.2%, and the balance is Mg and impurities; wherein the total of the impurities The content is less than 0.02wt.%.

[0065] And the preparation method of the Mg-3.9Li-0.8Al-0.2Y alloy ingot is as follows:

[0066] Weigh the magnesium ingot, aluminum ingot, Mg-30Y master alloy and lithium ingot according to the composition ratio of Mg-3.9Li-0.8Al-0.2Y alloy, and place the raw materials of each composition ratio in the crucible under solvent and protective gas , after melting, stir mechanically for 10 minutes, raise the temperature to 710°C and keep it warm for 20 minutes, and cast the magnesium-lithium alloy ingot. The magnesium-lithium alloy ingot was kept at 350°C for 2 hours, extruded at an extrusion ratio of 13:1, and annealed at 350°C for 1 hour to obtain a magnesium-lithium alloy doped with rare earth yttrium. On the annealed alloy, according to the national standard, th...

Embodiment 3

[0070] A Mg-4.2Li-1Al-1Y alloy ingot, the mass percentage of each component is: Li 4.2%, Al 0.8%, Y1%, the balance is Mg and impurities; wherein the total content of the impurities is less than 0.02 wt.%.

[0071] And the preparation method of the Mg-4.2Li-1Al-1Y alloy ingot is as follows:

[0072] Weigh magnesium ingots, aluminum ingots, Mg-30Y master alloys and lithium ingots according to the composition ratio of the Mg-4.2Li-1Al-1Y alloy, and place the raw materials of each composition ratio in a solvent and protective gas in a crucible. After melting, stir mechanically for 10 minutes, raise the temperature to 710°C and keep it warm for 20 minutes, and pour to obtain magnesium-lithium alloy ingots. The magnesium-lithium alloy ingot was kept at 350°C for 2 hours, extruded at an extrusion ratio of 13:1, and annealed at 350°C for 1 hour to obtain a magnesium-lithium alloy doped with rare earth yttrium. On the annealed alloy, according to the national standard, the mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com