Mg-Gd-Y rare earth magnesium alloy cast ingot homogenization heat treatment method

A homogeneous heat treatment and alloy ingot technology, which is applied in the field of magnesium alloy material preparation, can solve the problems of impact, large casting stress, and inapplicability, and achieve the effect of simple and clear process, elimination of internal stress, and accurate requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

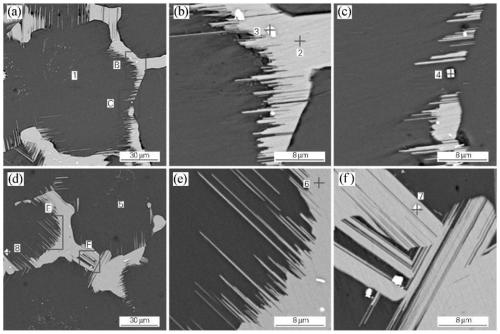

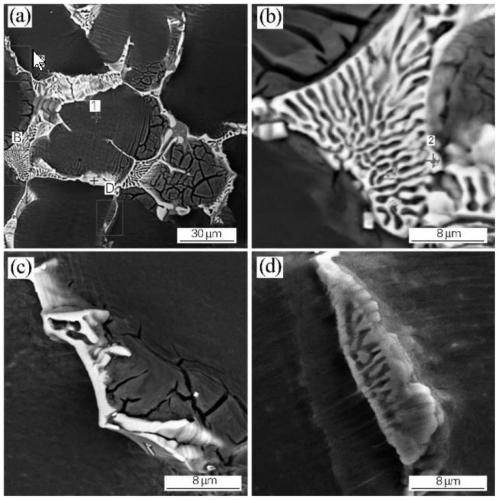

Image

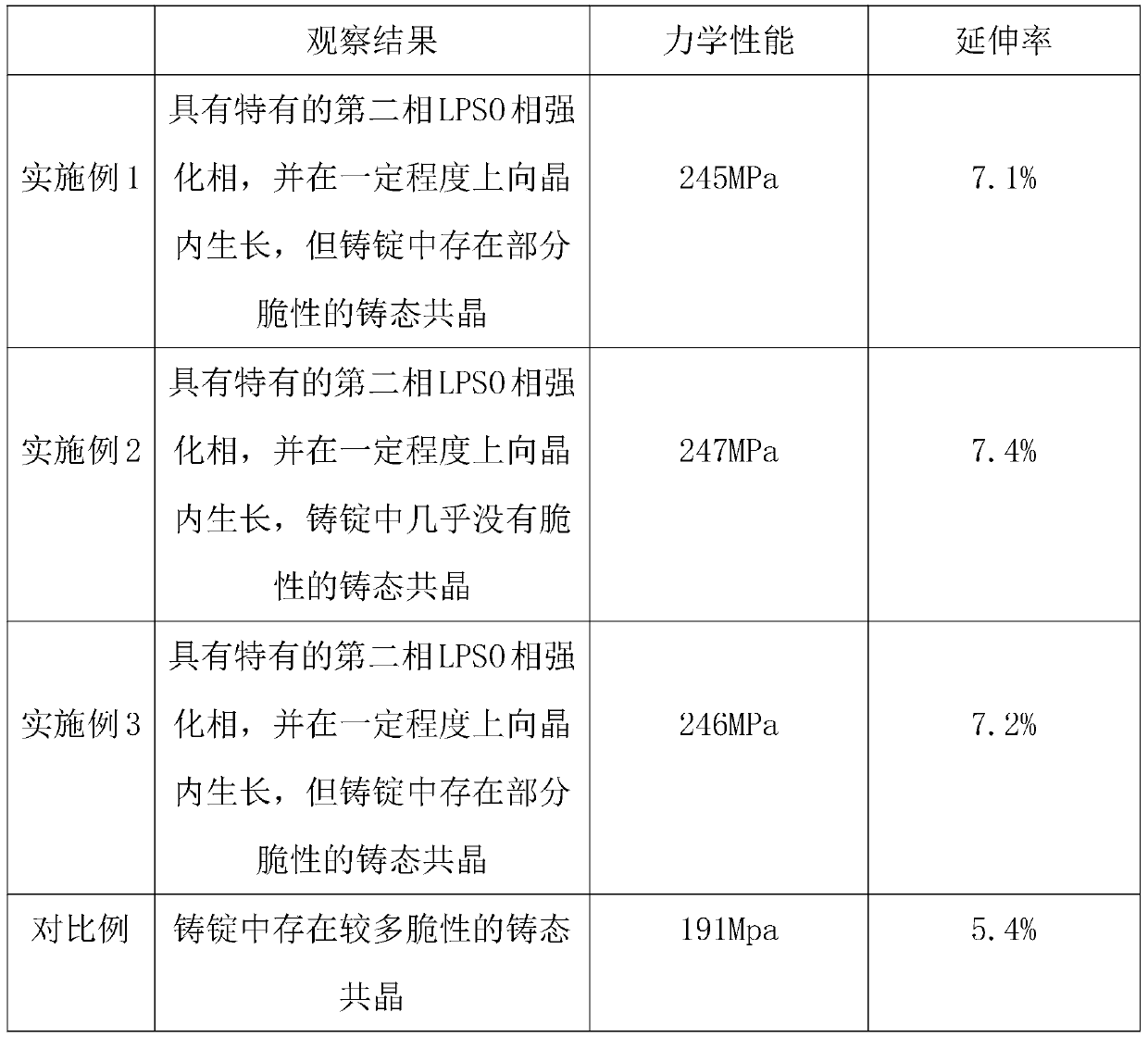

Examples

Embodiment 1

[0026] The invention provides a method for homogenizing heat treatment of a Mg-Gd-Y rare earth magnesium alloy ingot, which specifically includes the following steps:

[0027] Step 1: According to the composition requirements of the magnesium alloy, add pure metals and intermediate metals containing different elements into the melting furnace, turn on the resistance heating device of the melting furnace and heat to 760°C, so that each component is melted into a uniform metal melt , heat preservation until the alloy components are melted into a uniform metal melt with a specified composition for casting;

[0028] Step 2: Preheat the heat treatment furnace to 500-520°C at a heating rate of 100°C / h;

[0029] Step 3: After the molten metal in step 1 is cast into a magnesium alloy billet, it is rapidly cooled to 200°C by blast cooling, and then quickly transferred to a preheated heat treatment furnace;

[0030] Step 4: Keep the magnesium alloy billet transferred to the preheated h...

Embodiment 2

[0034] The invention provides a method for homogenizing heat treatment of a Mg-Gd-Y rare earth magnesium alloy ingot, which specifically includes the following steps:

[0035] Step 1: According to the composition requirements of the magnesium alloy, add pure metals and intermediate metals containing different elements into the melting furnace, turn on the resistance heating device of the melting furnace and heat to 760°C, so that each component is melted into a uniform metal melt , heat preservation until the alloy components are melted into a uniform metal melt with a specified composition for casting;

[0036] Step 2: Preheat the heat treatment furnace to 500-520°C at a heating rate of 100°C / h;

[0037] Step 3: After the molten metal in step 1 is cast into a magnesium alloy billet, it is rapidly cooled to 200°C by blast cooling, and then quickly transferred to a preheated heat treatment furnace;

[0038] Step 4: Insulate the magnesium alloy billet transferred to the preheat...

Embodiment 3

[0042] The invention provides a method for homogenizing heat treatment of a Mg-Gd-Y rare earth magnesium alloy ingot, which specifically includes the following steps:

[0043] Step 1: According to the composition requirements of the magnesium alloy, add pure metals and intermediate metals containing different elements into the melting furnace, turn on the resistance heating device of the melting furnace and heat to 760°C, so that each component is melted into a uniform metal melt , heat preservation until the alloy components are melted into a uniform metal melt with a specified composition for casting;

[0044] Step 2: Preheat the heat treatment furnace to 500-520°C at a heating rate of 100°C / h;

[0045]Step 3: After the molten metal in step 1 is cast into a magnesium alloy billet, it is rapidly cooled to 200°C by blast cooling, and then quickly transferred to a preheated heat treatment furnace;

[0046] Step 4: Keep the magnesium alloy billet transferred to the preheated he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com