Mg-Li-Al-Zn-Y cast magnesium lithium alloy and preparation method thereof

A technology for lithium alloy and magnesium casting, applied in the field of Mg-Li-Al-Zn-Y cast magnesium-lithium alloy and its preparation, can solve the problem of good structure and performance stability, small strengthening effect, poor alloy structure and performance stability, etc. problems, to achieve the effect of simple preparation process, avoiding volatilization and oxidation, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of Mg-Li-Al-Zn series cast magnesium-lithium alloy, comprises the following steps:

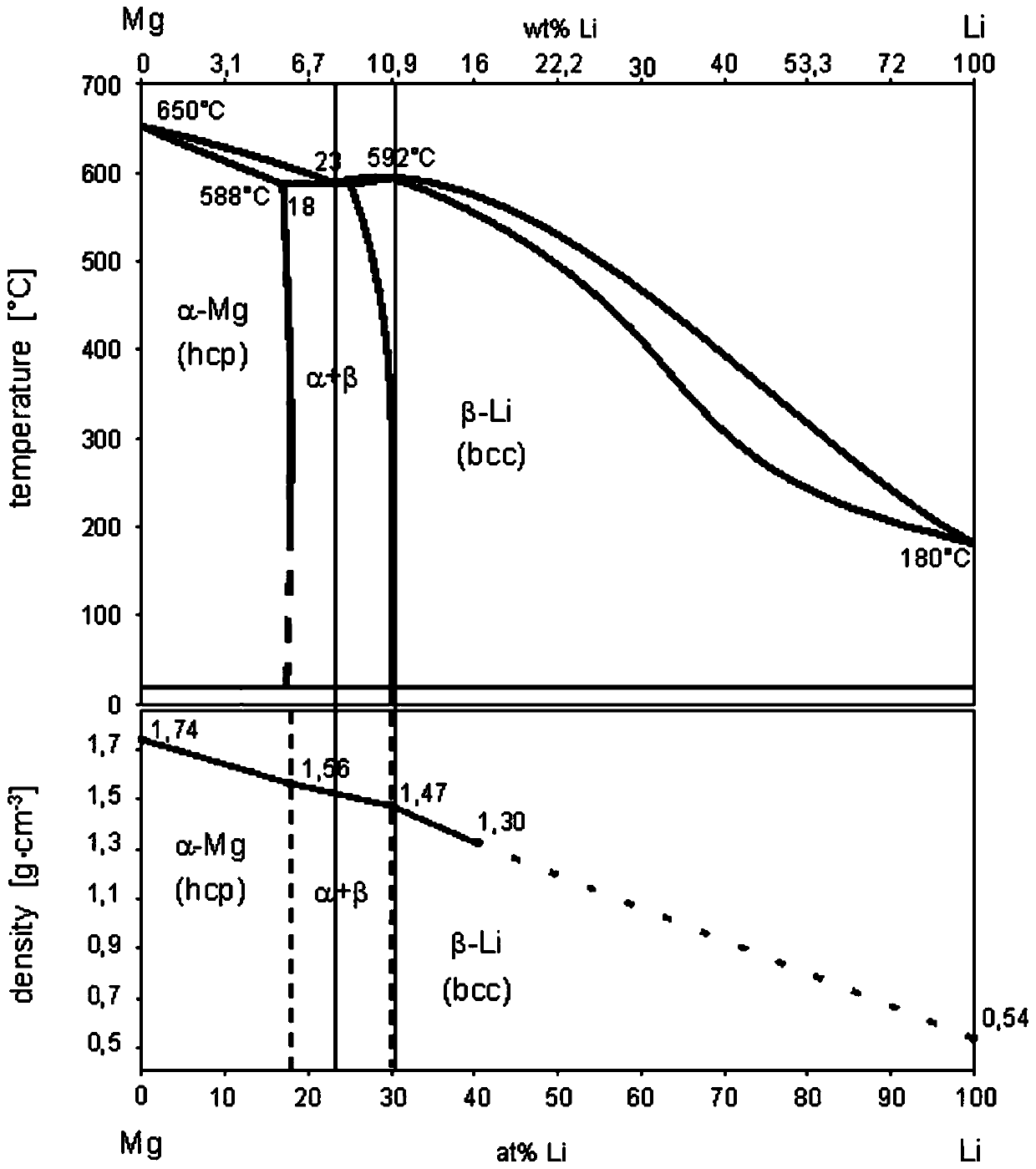

[0032] Step 1, according to the mass fraction Li: 8-11%, Al: 3-4%, Zn: 2.5-3.5%, Y: 0.5-1.2%, weigh Mg, Li, Al, Zn and Mg-20Y, first Vacuumize the induction heating furnace, and after the pressure is lower than 20Pa, fill the smelting environment with argon, so that the pressure in the smelting environment does not exceed atmospheric pressure, and melt Mg, Li, Al, Zn and Mg-20Y under a protective atmosphere to obtain molten State Mg-Li-Al-Zn-Y alloy; Stir at 715±15°C for 3-5min, then keep it warm for 10-12min; the purity of Mg, Li, Al, Zn and Mg-20Y master alloy is not less than 99%

[0033] Step 2, casting the molten Mg-Li-Al-Zn-Y alloy obtained in the step into a preheated mold, and after the ingot is fully cooled, take it out and air-cool it to obtain the cast alloy; the preheating temperature of the mold is 300- 320°C, the ingot is cooled with the mold...

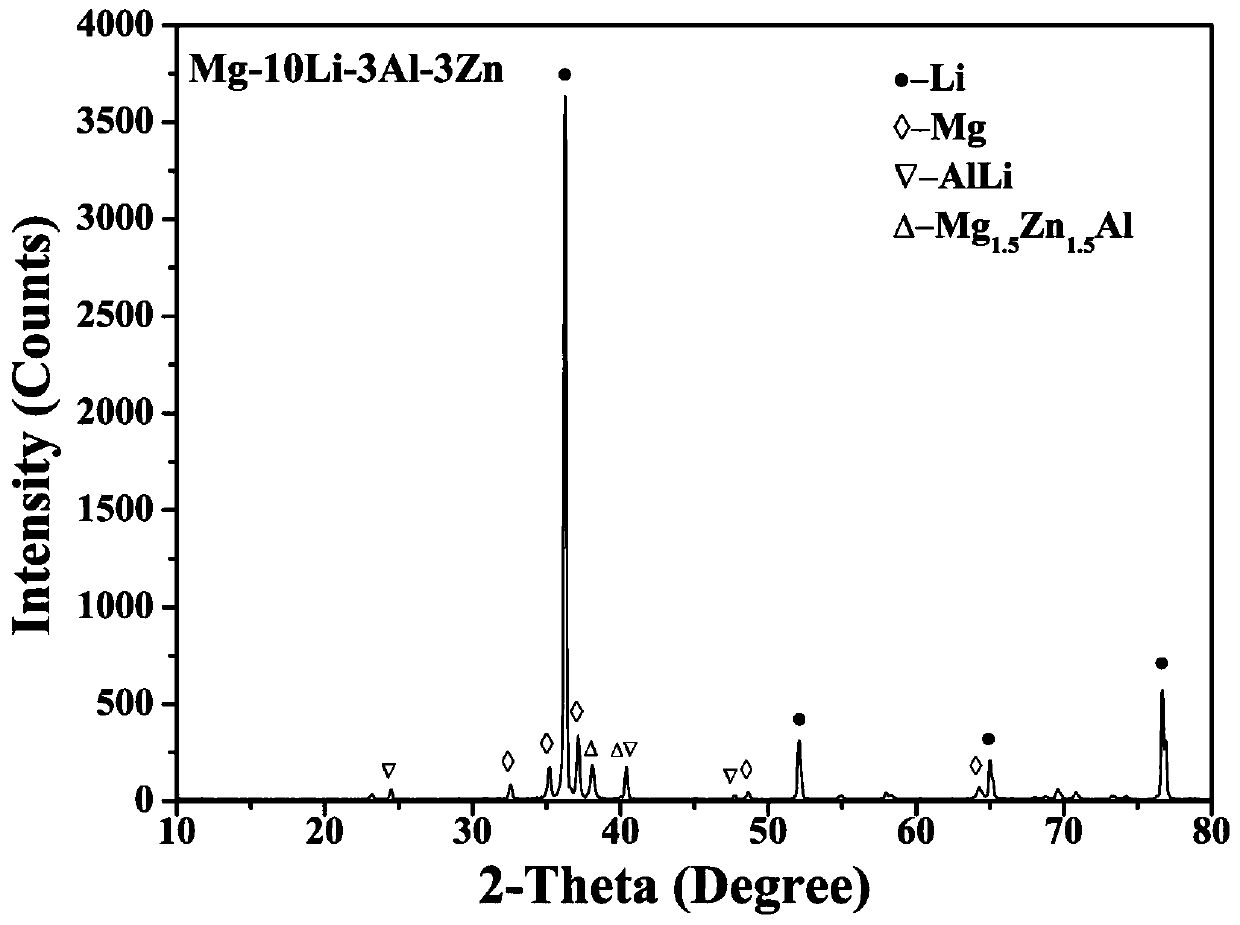

Embodiment 1

[0035] According to the composition of the Mg-Li-Al-Zn-Y system, in this embodiment, the alloy composition is Mg-10Li-3Al-3Zn; calculate and weigh the raw materials Mg, Li, Al and Zn, and the purity is greater than 99%. The raw materials are put into a crucible, vacuumed and then ventilated with argon, melted and stirred for 3 minutes at 715±15°C using magnesium alloy induction casting equipment, and cast at 715±15°C into a mold with a temperature of 300°C±5°C. The ingot is fully cooled to 200-220°C and taken out for air cooling to obtain an alloy ingot.

[0036] The density of the magnesium-lithium alloy prepared by this example is 1.52g / cm 3 , The tensile strength is 180MPa, and the specified plastic elongation strength is 137MPa.

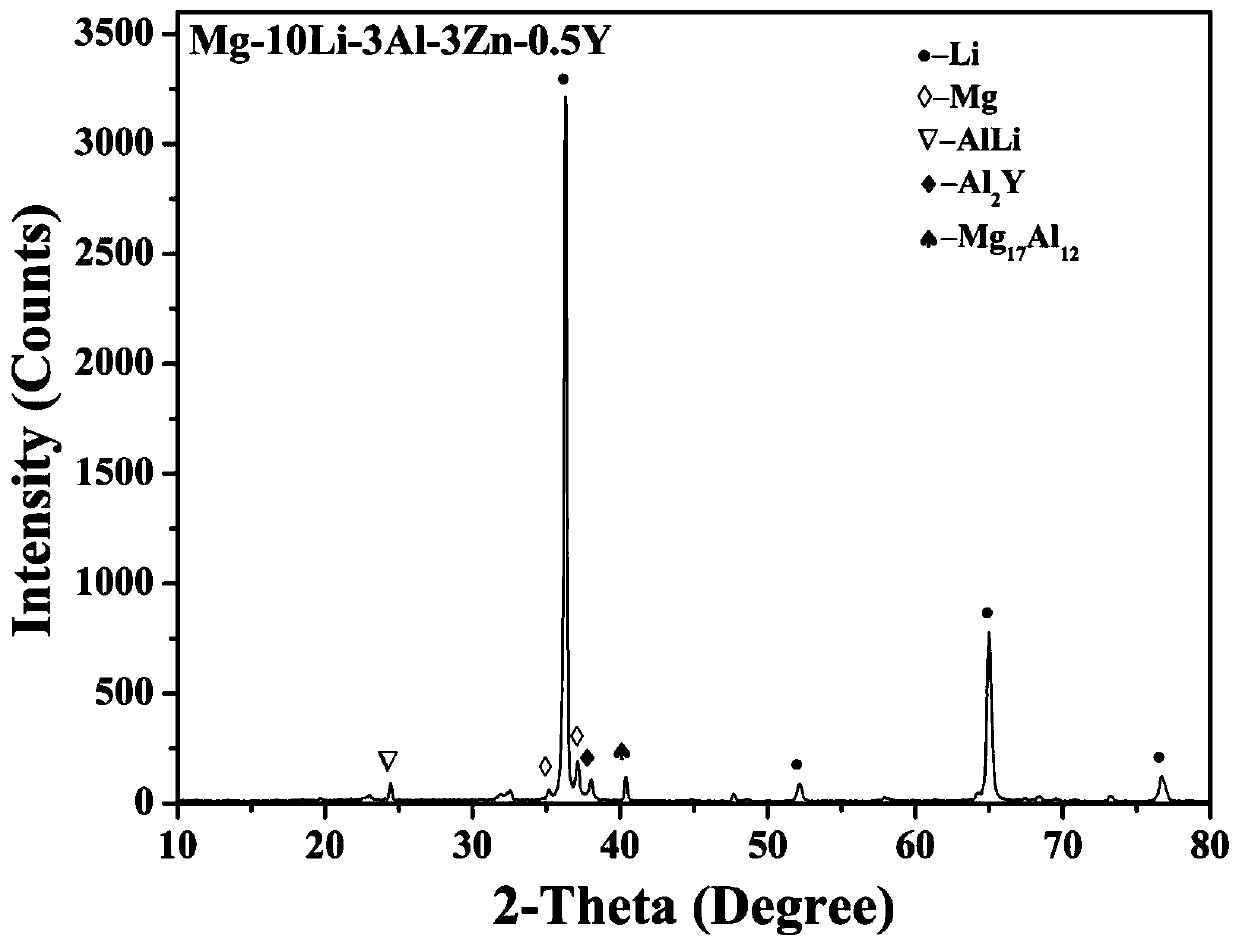

Embodiment 2

[0038]According to the composition of the Mg-Li-Al-Zn-Y system, in this example, the alloy composition is Mg-10Li-3Al-3Zn-0.5Y; calculate and weigh the middle of the raw materials Mg, Li, Al, Zn and Mg-20Y alloy, the purity of which is greater than 99%, put the raw materials into the crucible, vacuumize and pass argon, use magnesium alloy induction melting equipment to melt and stir at 700-730°C for 5min, and cast at 700-730°C to a temperature of 310°C In the mold of ±5°C, the ingot is fully cooled to 200-220°C, taken out and air-cooled to obtain an alloy ingot.

[0039] The density of the magnesium-lithium alloy prepared by this example is 1.52g / cm 3 , The tensile strength is 244MPa, and the specified plastic elongation strength is 228MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Plastic elongation strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com