Solid treatment method for improving strength performance of Mg-Zn-Y alloy

A treatment method and alloy strength technology, which is applied in the field of solid-state treatment to improve the strength and performance of Mg-Zn-Y alloys, can solve the problems of unfavorable LPSO strengthening, low alloy performance, and weakened mechanical properties of magnesium alloys, so as to achieve strength performance improvement, The effect of uniform distribution and refinement of alloy phase scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment adopts a solid-state treatment process including ingot chip making, chip cold pressing, hot pressing consolidation and extrusion molding. The specific treatment process is: the Mg 97 ZnY 2 The alloy ingot was cut on a common lathe to prepare chips. The cutting parameters were: tool rake angle 45°, chip speed 50 r / min, chip thickness 0.5 mm; And hold the pressure for 2 minutes; heat the mold and the sample to 400°C and keep it warm, and apply a pressure of 800MPa and keep it for 20 minutes to achieve viscoplastic bonding and diffusion bonding of the alloy. Finally, the sample is extruded to obtain a cylindrical bar, wherein the extrusion ratio is 10:1, the extrusion temperature is 400°C, and the extrusion pressure is 800MPa. The optical microstructure of the rod-shaped material after extrusion is as follows: Figure 6 , XRD picture as Figure 7 , the compression experiment curve is shown in Figure 8 , the tensile test curve is shown in Figure 9 . ...

Embodiment 2

[0043] The process flow of this embodiment is the same as that of Embodiment 1, the difference being that the parameters of each process are different.

[0044] This embodiment adopts including The solid-state treatment process of ingot chip making, chip cold pressing, hot pressing consolidation and extrusion molding. The specific treatment process is: the Mg 97 ZnY 2 The alloy ingot was cut on a common lathe to prepare chips. The cutting parameters were: tool rake angle 45°, chip speed 50 r / min, chip thickness 0.5mm; then put it into a mold for compaction at room temperature with a pressure of 800MPa. And hold the pressure for 3 minutes; heat the mold and the sample to 350°C and keep it warm, and apply a pressure of 400MPa and keep it for 30 minutes to achieve viscoplastic bonding and diffusion bonding of the alloy. Finally, the sample is extruded to obtain a cylindrical bar, wherein the extrusion ratio is 10:1, the extrusion temperature is 400°C, and the extrusion pres...

Embodiment 3

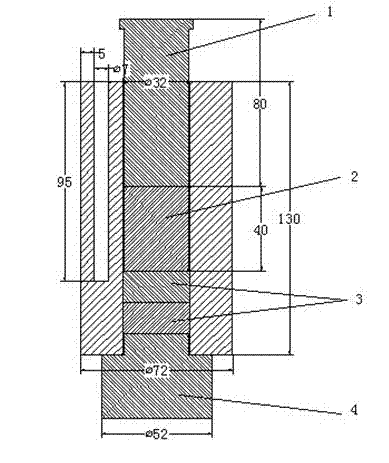

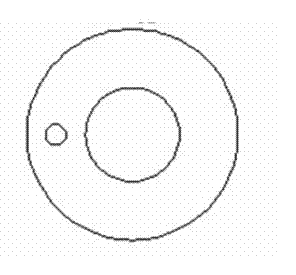

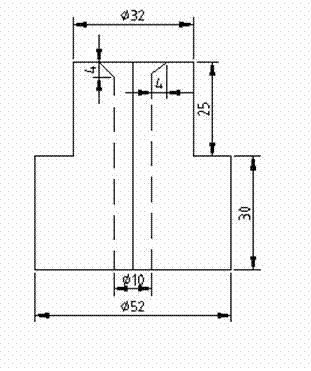

[0047] This embodiment adopts including The solid-state treatment process of ingot chip making, chip cold pressing, hot pressing consolidation and extrusion molding. The specific treatment process is: the Mg 97 ZnY 2 The alloy ingot was cut on a common lathe to prepare chips. The cutting parameters were: tool rake angle 45°, chip speed 50 r / min, chip thickness 0.5 mm; And hold the pressure for 5 minutes; heat the mold and the sample to 450°C and keep it warm, and apply a pressure of 800MPa and keep it for 20 minutes to achieve viscoplastic bonding and diffusion bonding of the alloy. Finally, the sample is extruded to obtain a cylindrical bar, wherein the extrusion ratio is 10:1, the extrusion temperature is 400°C, and the extrusion pressure is 800MPa. In the above process, the chips are cold-pressed and compacted, hot-pressed and consolidated and extruded in the same mold, as shown in Figure 1. Install the base and gasket, put the gasket into the mold, put 45g of magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com