Device and method for monitoring dynamic torque of frame-free torque motor under suspension state

A torque motor and dynamic torque technology, applied in the field of measurement devices, can solve the problems of inability to accurately measure the real-time dynamic torque of torque motors, inability to accurately measure angular acceleration and friction torque, and inaccurate dynamic torque measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

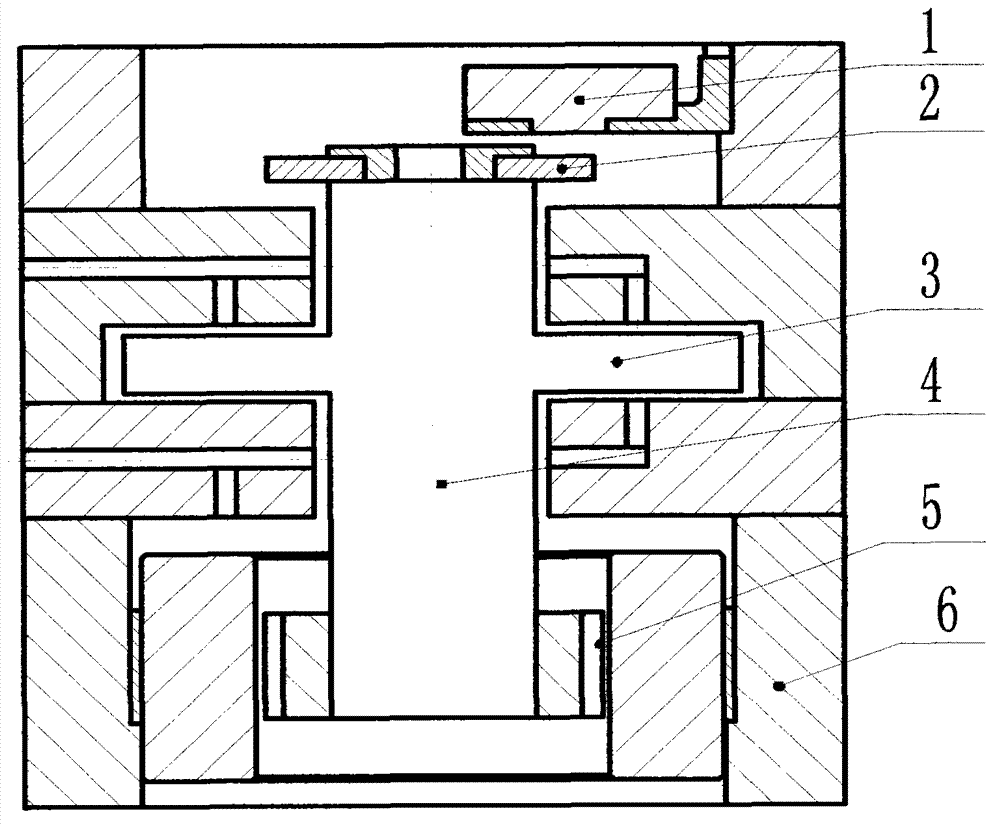

[0032] Such as figure 1 As shown, it is a schematic diagram of the installation structure when the present invention is used to monitor the dynamic torque of the frameless torque motor under the air-floating state. The measured frameless torque motor (5) directly drives the air-floating main shaft (4), and the air-floating main shaft (4) passes through The support of the air bearing (3) realizes a nearly frictionless suspension state, the circular grating disk (2) is fixedly connected with the coaxial line of the air bearing main shaft (4), and rotates synchronously with the air bearing main shaft (4); the reading head (1 ) is aligned with the grating ruler on the circular grating disc (2), so as to ensure that the dynamic angular displacement data of the air bearing spindle (4) driven by the frameless torque motor (5) can be collected correctly in real time; the reading head (1) passes The data line forms an electrical connection with the signal conversion and preprocessing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com