Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Expand the range of industrial applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

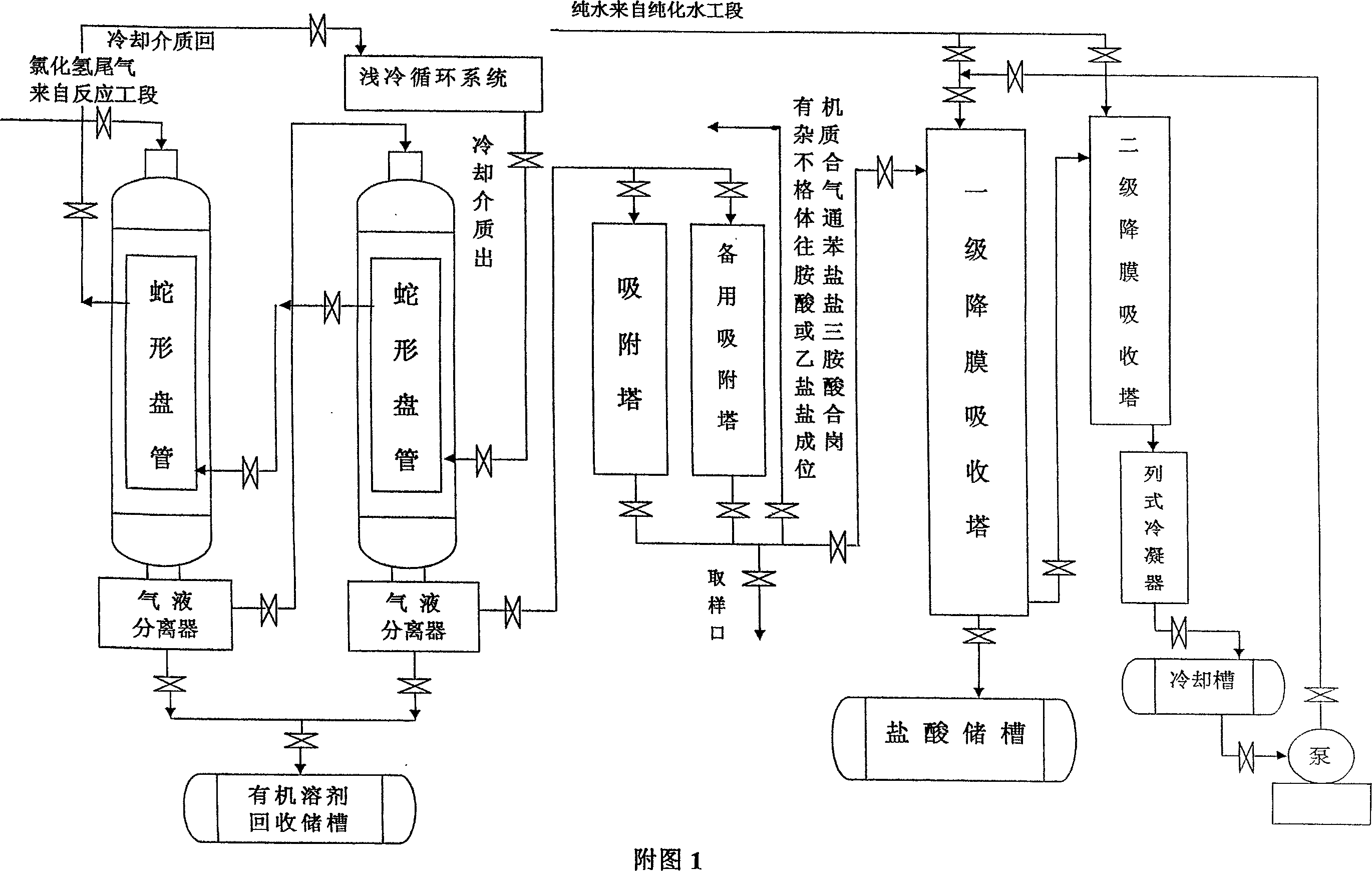

Process for preparing high purity hydrochloric acid by circularly absorbing hydrogen chloride by-product

InactiveCN1951801ASatisfied with the resultExpand the range of industrial applicationsChlorine/hydrogen-chloride purificationActive particlesPolypropylene

The invention discloses a preparing method of high-purity alcaine technology through circulating and adsorbing by-product of hydrogen chloride, which comprises the following steps: aerating hydrogen chloride gas with organic impurity in the condenser at -10- -40 deg.c and gas-liquid separator; adsorbing gas with little impurity through active particle charcoal; aerating adsorbed gas into one-grade and two-grade graphite falling-film; adsorbing through pure water to obtain the high-purity alcaine; adsorbing non-adsorbed hydrogen chloride through cold water; putting hydrogen chloride and diluted acid in the graphite polypropylene falling-film adsorbing tower into cooling groove; utilizing circulating pump to transmit the inlet of one-grade falling-film adsorbing tower; circulating the adsorption.

Owner:ZHEJIANG UNIV OF TECH

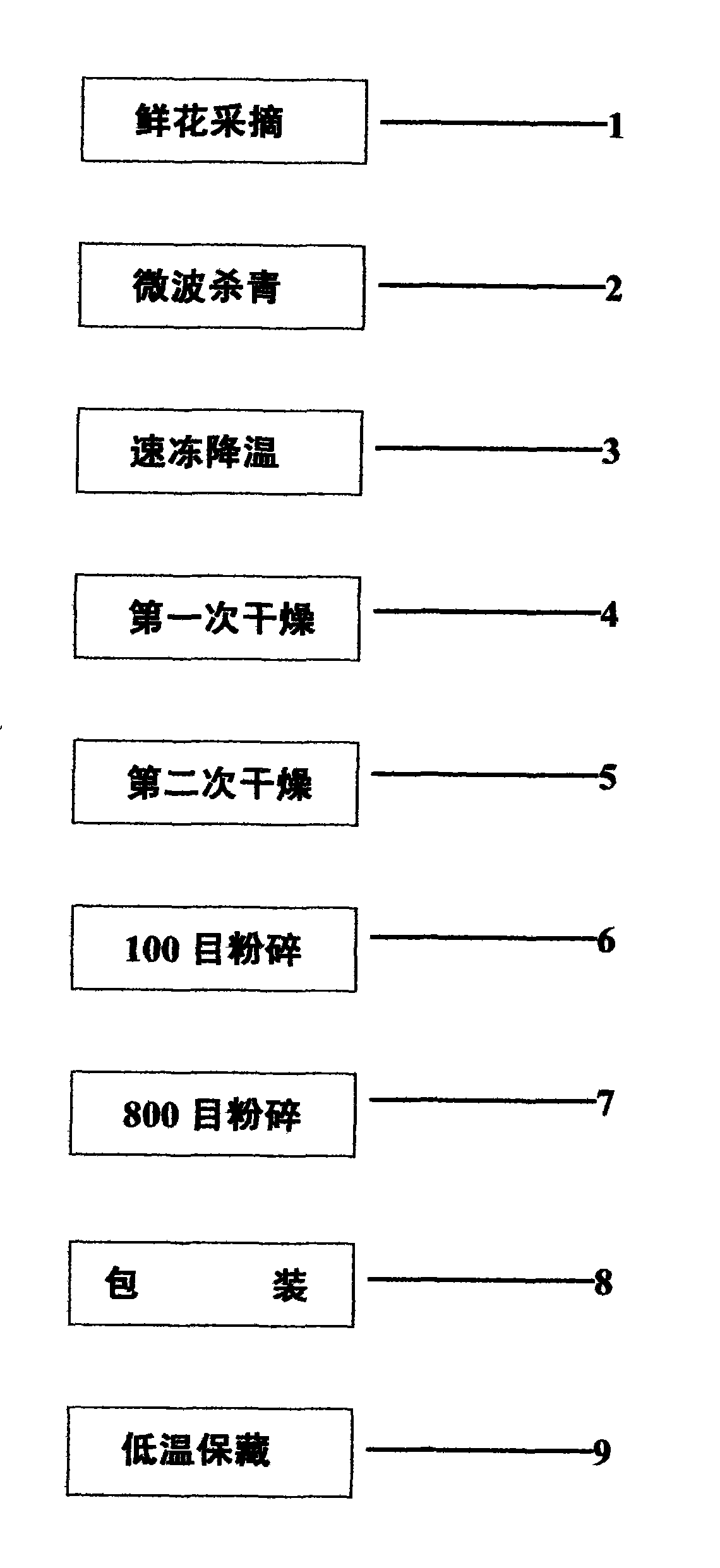

Honeysuckle micro powder tea

InactiveCN102113594ANo industrial pollutionNo pesticide residueTea substituesChlorogenic acidMicrometer

The invention relates to honeysuckle tea, in particular to honeysuckle micro powder tea, and provides honeysuckle micro powder tea with a particle size of 18 micrometers. The honeysuckle micro powder tea is characterized in that the tea contains as high as more than or equal to 5 percent of chlorogenic acid, has pale green color and faint scent smell, and avoids precipitates and granular sensation after being infused. A production method comprises the following steps of: picking fresh flowers, green-removing by using microwaves, quick freezing and cooling, performing secondary drying, crushing twice and refrigerating at low temperature. Due to the function of clearing heat and detoxicating and resisting bacteria in broad spectra, the honeysuckle micro powder tea has excellent inherent quality and shape characteristic.

Owner:李全才 +2

Metho of raising compatibility between ABS and polymethyl methacrylate

The present invention is method of raising compatibility between ABS and polymethyl methacrylate (PMMA). The present invention prepares ABS / PMMA alloy with ABS 100 weight portions, PMMA 25-30 weight portions, and MBS 3.8-5 weight portions, and through one smelting, mixing and extruding process. The present invention has simple preparation process and low cost, and the ABS / PMMA alloy with MBS as modifier has raised ABS-PMMA compatibility, homogeneous hardness distribution, raised stretching and bending performance and expanded industrial application range.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

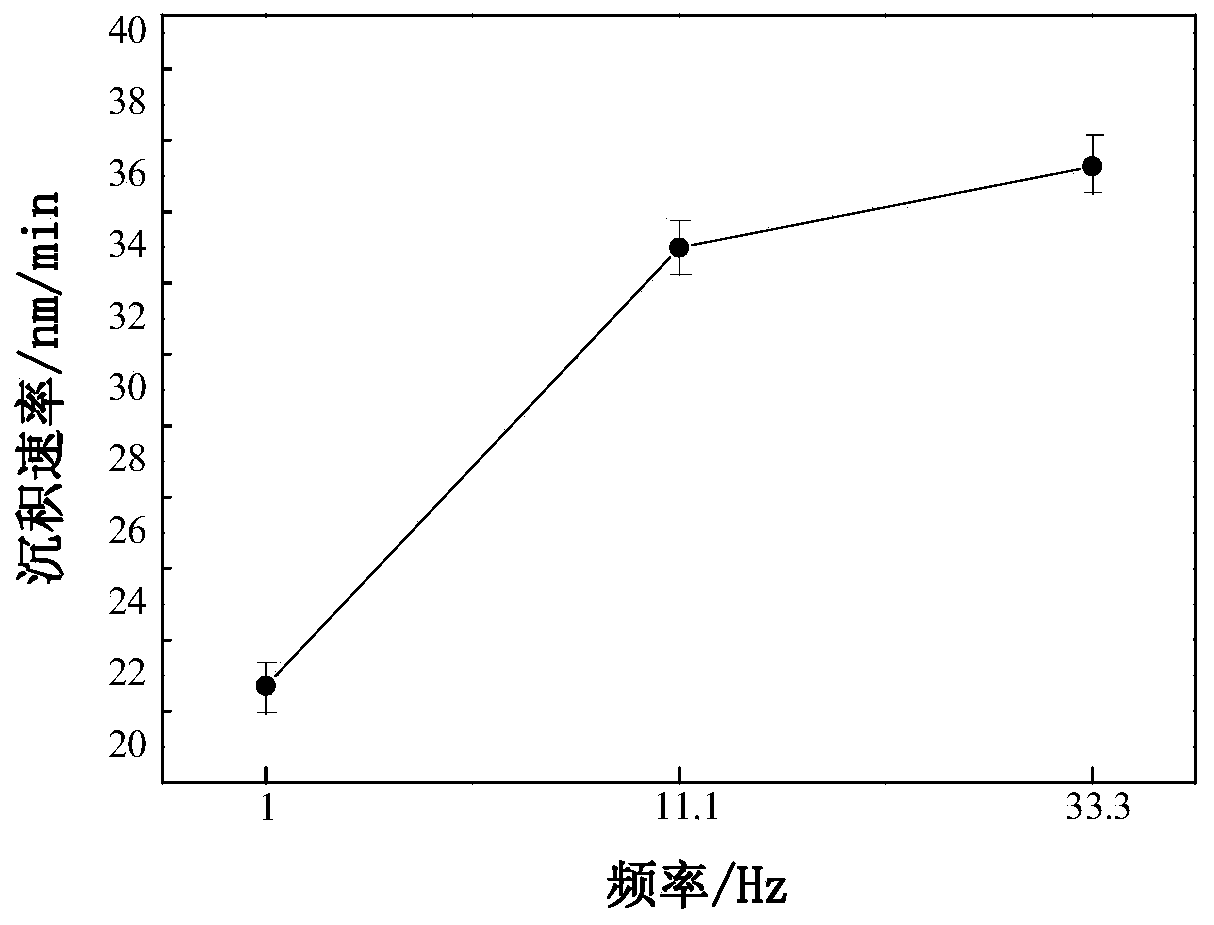

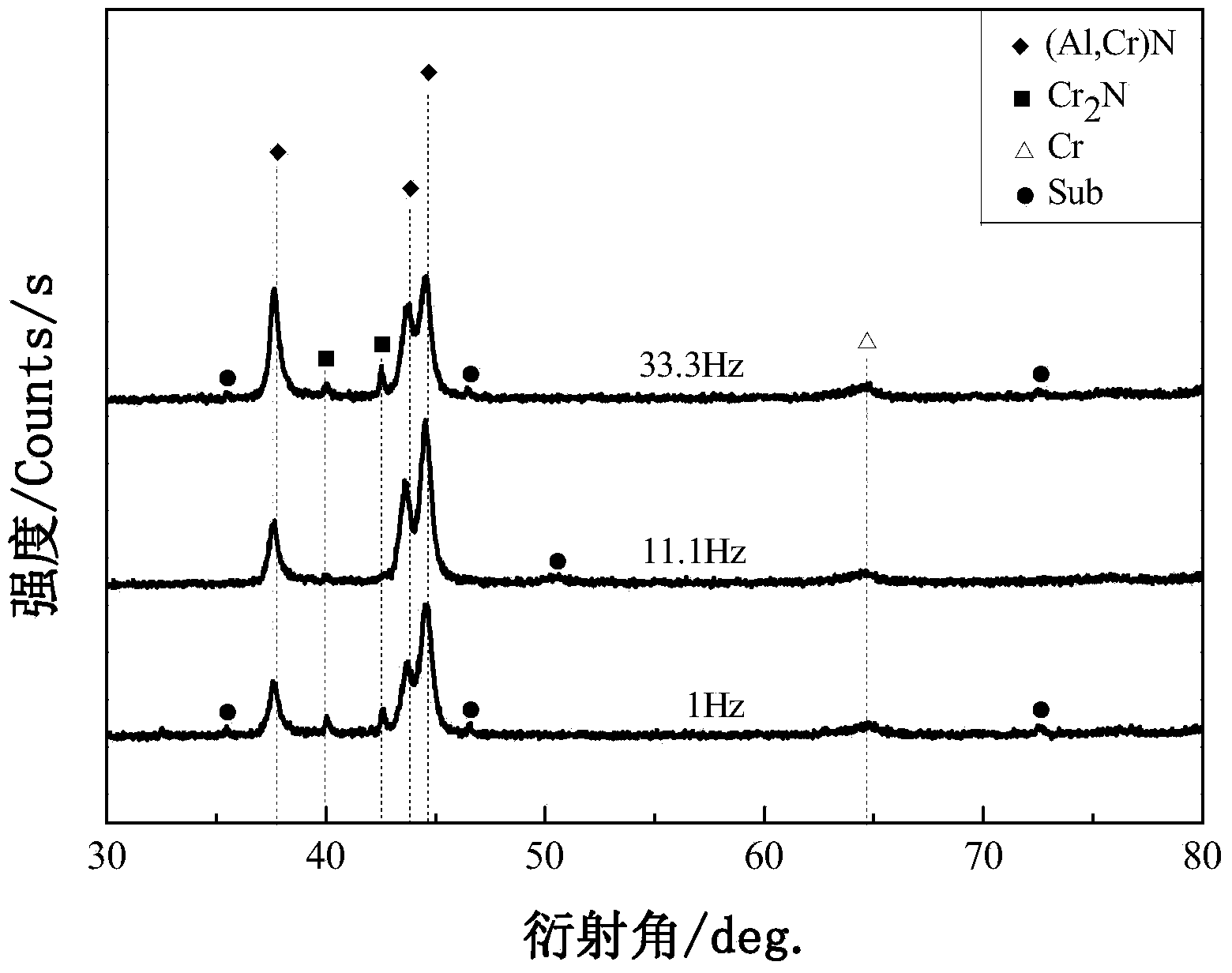

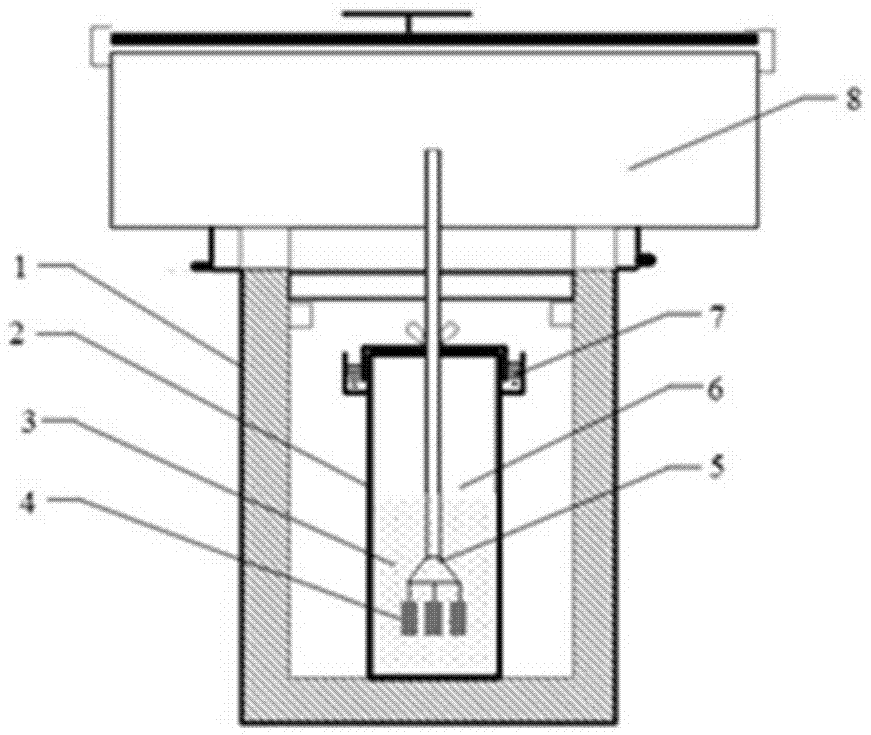

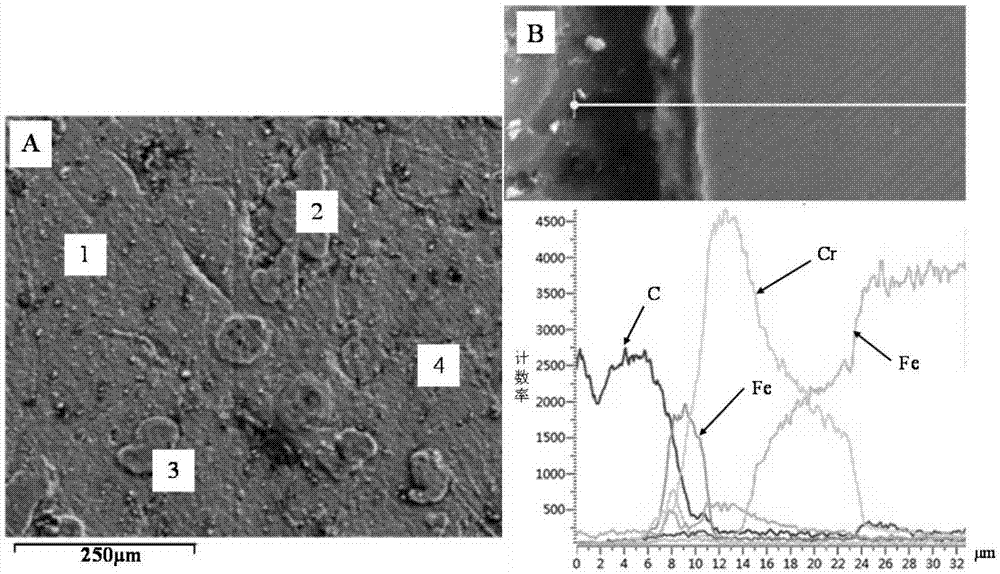

Multi-arc ion plated hard coating prepared by adopting frequency-modulation electromagnetic coil, and method

ActiveCN103952671AHigh hardnessHigh bonding strengthVacuum evaporation coatingSputtering coatingAlloyFrequency modulation

The invention discloses a multi-arc ion plated hard coating prepared by adopting a frequency-modulation electromagnetic coil, and a method. The method comprises the following steps: washing and putting a hard alloy matrix in a deposition chamber; leading into Ar gas, applying negative bias pressure onto the matrix for performing glow washing; and regulating the frequency of the electromagnetic coil to be 1-35Hz, starting a metal Cr target to obtain a Cr interfacial bonding layer, depositing a CrN transition layer, and opening a Cr metal target and an AlCr alloy target to prepare AlCrN working layer. By additionally arranging the electromagnetic coil with adjustable frequency in the deposition process, the hard coating with high hardness, high bonding strength and high wear resistance can be obtained, the multi-arc ion plated hard coating depositing technology is improved, the research content of multi-arc ion plating technology in practical industrial production can be enriched, a hard coating deposition tool is applicable to processing a high-hardness steel material under high-speed cutting condition, and the industrial application range of the multi-arc ion plated hard coating can be extended.

Owner:ANHUI DUOJINTUCENG TECH CO LTD

Amino compound-supported composite denitration catalyst, and preparation method and application thereof

ActiveCN107213917AImprove denitrification efficiencyHigh selectivityGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsInorganic saltsNitrogen

The invention relates to an amino compound-supported composite denitration catalyst, and a preparation method and an application thereof. The catalyst is prepared from 50-90 wt% of a carrier, 5-25 wt% of metal oxide and 5-25 wt% of an amino compound. The method comprises the following steps: weighing the carrier and a metal inorganic salt precursor, impregnating the carrier in an aqueous solution of a metal inorganic salt through an isopyknic impregnation technology, stirring the obtained solution, drying the stirred solution, introducing nitrogen, calcining the dried solution, weighing and dissolving the amino compound, impregnating the obtained calcined solid sample in the aqueous solution of the amino compound, and standing and drying the obtained solution to obtain the composite denitration catalyst. A fixed bed reactor is filled with the prepared composite catalyst, and normal pressure smoke is introduced and is denitrated. The catalyst has the characteristics of good economic property, energy saving, environmental protection, high denitration efficiency, and realization of repeated use of the recovered support amino compound, and is extremely suitable for the field of low temperature denitration of fixed sources.

Owner:EAST CHINA UNIV OF SCI & TECH

Process method for obtaining acetylene gas from semi-coke via calcium carbide and further producing ethylene by hydrogenation

ActiveCN103992200AExpand the range of industrial applicationsRich production methodsHydrocarbon by hydrogenationCalcium carbidePtru catalystHydrogenation reaction

The invention relates to a process method for obtaining acetylene gas from semi-coke via calcium carbide and further producing ethylene by hydrogenation. A process for producing methanol or dimethyl ether from coal-based or natural gas-based synthetic gas and further producing low-carbon olefins mainly comprising ethylene and propylene has the disadvantages of long process flow, complex process and large investment. The process method provided by the invention comprises the steps of drying and screening semi-coke, then mixing with lime powder, producing calcium carbide in a closed calcium carbide furnace and obtaining hydrogen from tail gas of the calcium carbide furnace through PSA; enabling obtained calcium carbide to react with water to produce acetylene gas; mixing acetylene gas with hydrogen according to a proportion, then compressing, entering an acetylene gas hydrogenation reactor, performing acetylene gas hydrogenation reaction under the action of a palladium-series silver-added additive catalyst, cooling the gas after reaction and then purifying through a rectification device to obtain ethylene gas. According to the ethylene production process provided by the invention, the supply-demand contradiction of semi-coke and calcium carbide can be relieved, the range of industrial applications of semi-coke and calcium carbide is expanded, the ethylene production method is enriched and the shortcomings of long process flow, high investment and large water demand of the existing ethylene production method are overcome.

Owner:榆林科大高新能源研究院有限公司

Industrial-video small digital identification method based on template matching and SVM

ActiveCN106960196AHigh precisionImprove recognition rateCharacter recognitionTemplate matchingIdentification rate

The invention discloses an industrial-video small digital identification method based on template matching and SVM. The method is used to solve problems that robustness can not be guaranteed in an identification method and an identification rate is low under an industrial-production multi-scenario mode. The method comprises the following steps of carrying out gamma reverse correction on collected video images so that the images are returned to an original state; carrying out RGB minimum component binary on a sample and cutting according to horizontal vertical projection; using template matching based on a structure characteristic and SVM cascade identification based on an HOG characteristic, identifying a digital sample; and according to a production site output condition, outputting an identification result according with a demand through a serial port. Through using the method to carry out small digital identification in an industrial field monitoring video, there are advantages that self-adaption performance is good; an identification rate is high; an identification speed is fast; and operation is simple and so on. Compared to an existing identification method, by using the method of the invention, under a same industrial speed, a small digital identification rate is increased by 30%; and according to different output conditions, the method can be applied to various industrial scenes.

Owner:XIDIAN UNIV

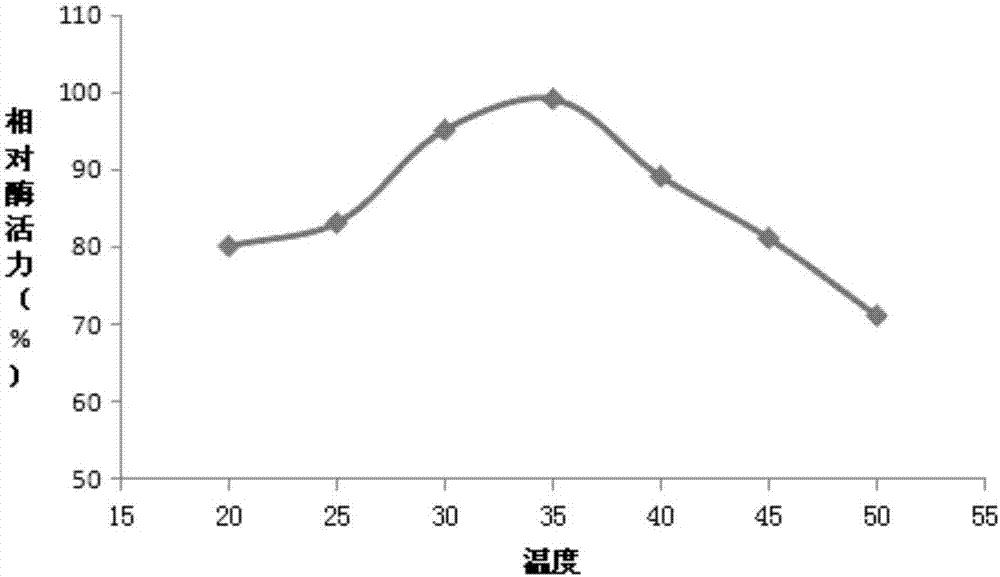

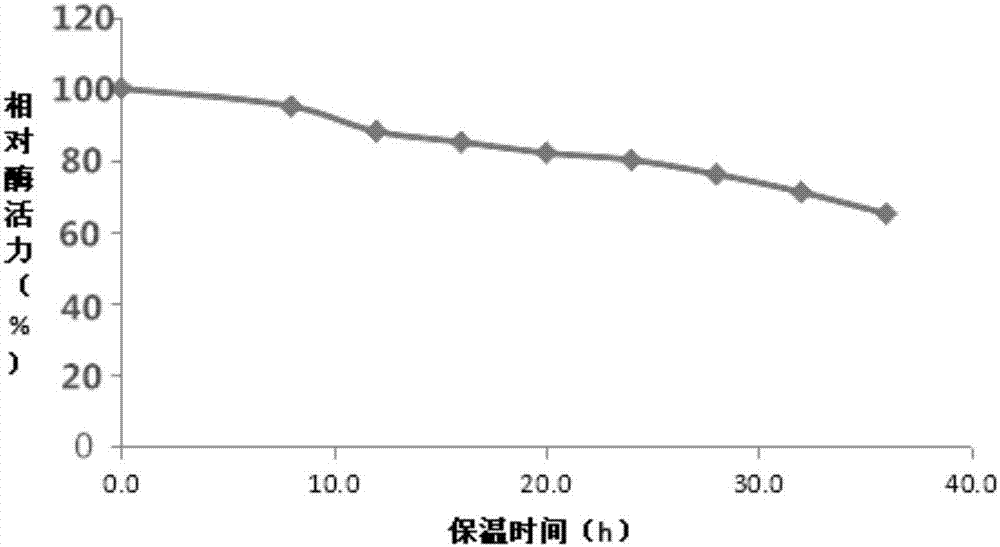

Pseudomonas of high yield lipase and enzyme production method by fermentation of pseudomonas

ActiveCN107488615AImprove fermentation capacityIncrease productivityBacteriaHydrolasesMicroorganismHydrogen

The invention belongs to the technical field of microorganisms and particularly relates to particularly relates to a pseudomonas of high yield lipase and an enzyme production method by fermentation of the pseudomonas. The pseudomonas is particularly pseudomonas sp. LD-14 and has a strain collection number of CGMCC (China General Microbiological Culture Collection Center) No. 14414. Enzyme activity of fermentation liquid of the lipase produced by fermentation of the pseudomonas sp. LD-14 reaches 25000-26000U / mL; the most suitable pH (potential of hydrogen) scope of the produced lipase is 8.5-10.0; most suitable operative temperature scope is 30-40 DEG C; the residual enzyme activity is 80% after heat preservation at 20 DEG C for 1d; and the lipase has significant low temperature resistance and alkali resistance and can be widely applied in industrial production.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

Low-silicon micro-sodium white sapphire micro powder used for electronic insulating ceramic and preparation method of low-silicon micro-sodium white sapphire micro powder

InactiveCN105585312AImprove fire resistanceImprove mechanical propertiesAluminum fluoridePhysical chemistry

The invention provides low-silicon micro-sodium white sapphire micro powder used for electronic insulating ceramic and a preparation method of the low-silicon micro-sodium white sapphire micro powder. The problems that products are poor in mechanical performance, fire resistance, insulativity and the like are solved by decreasing the content of Na2O and Si in the products. The low-silicon micro-sodium white sapphire micro powder is prepared by adding compound mineralizer with industrial aluminum oxide as the raw material, and conducting ball milling, high-temperature melting and crystallizing, breaking, grinding and acid pickling, wherein the compound mineralizer comprises boric acid, ammonium chloride and aluminum fluoride, and crystals are in the irregular particle shape. By means of the prepared low-silicon micro-sodium white sapphire micro powder, the Na2O content of the low-silicon micro-sodium white sapphire micro powder can be decreased to 0.1% (w / w) or below, the content of Si is decreased to 0.02% (w / w) or below, the content of Na2O and silicon is remarkably lower than the content of sodium and silicon in the traditional white sapphire products, and the fire resistance degree and mechanical performance of white sapphire are improved; meanwhile, the insulating performance is enhanced, and therefore the low-silicon micro-sodium white sapphire micro powder can be used for the fields of high-end abrasive materials, electronic insulating ceramic and high-grade fireproof materials, and the industrial application range is widened.

Owner:ZIBO JINJIYUAN ABRASIVES

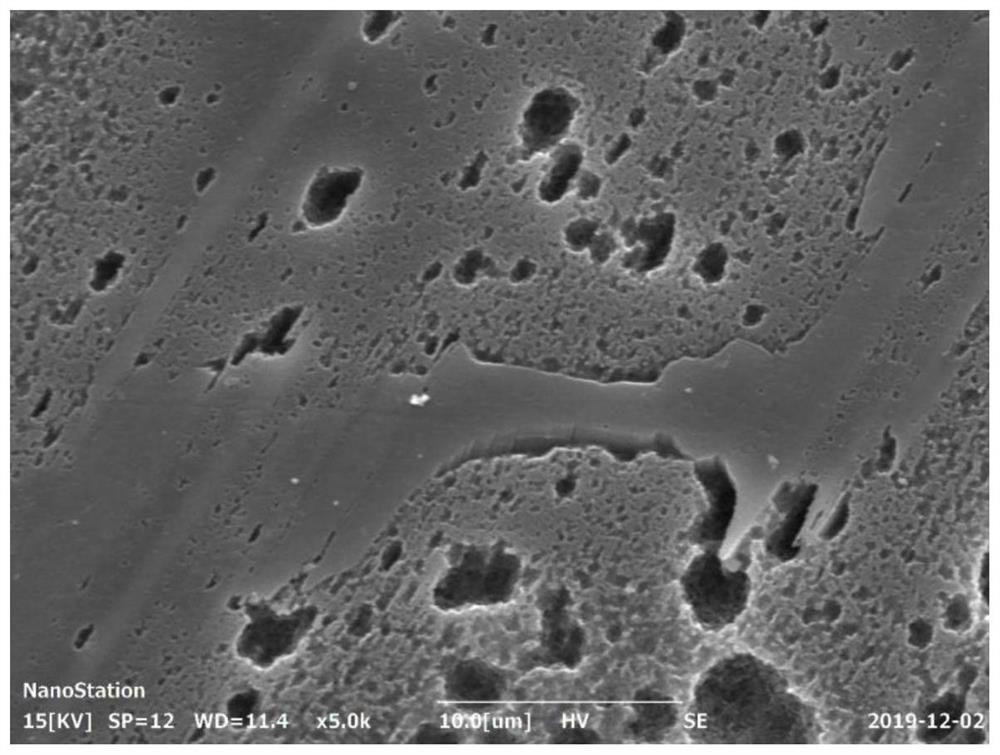

Metal base material coated with carbide coating and preparing method of metal base material

The invention discloses a metal base material coated with a carbide coating and a preparing method of the metal base material. The preparing method includes the following steps that under the inert atmosphere or vacuum atmosphere, the metal base material is added into fluoride fused salt containing a permeating agent and in the molten state, and heat preservation reacting is carried out; and the permeating agent is one or more of simple substances or oxides of chromium, vanadium, niobium, titanium, silicon and zirconium. The preparing method is simple in process, free of strict limitation to processes like the material mixing sequence, and wide in applicability. The carbide coating prepared on the surface of the metal base material is compact, even and controllable in thickness, firm metallurgical bonding is formed between the coating and a base, the bonding force is high, the surface performance of the base material is improved, and excellent performance like high hardness, the high-wearing feature, occlusal force resistance, high-temperature oxidation resistance, environment corrosion resistance and the like are achieved; and the material surface performance is improved, the service life of hardware is prolonged, and the industrial application scope of the metal material is expanded.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

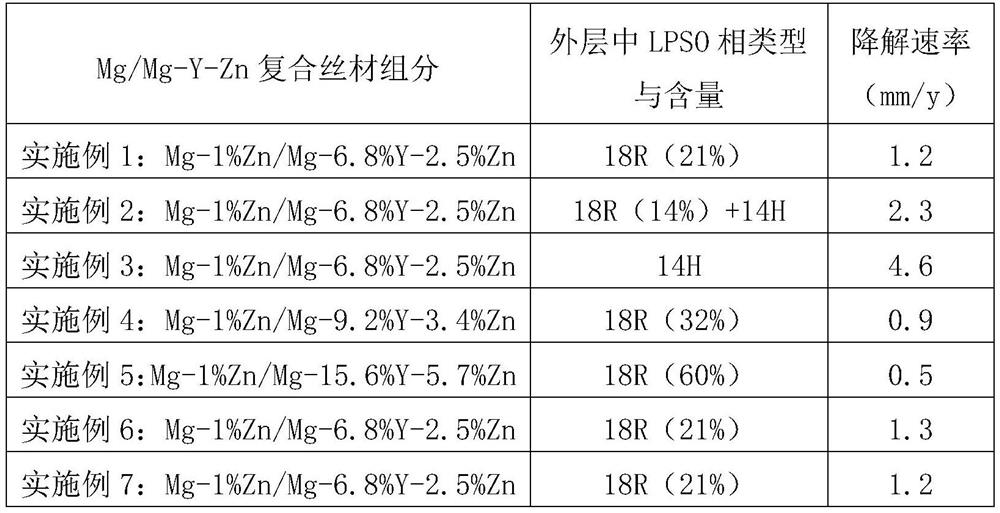

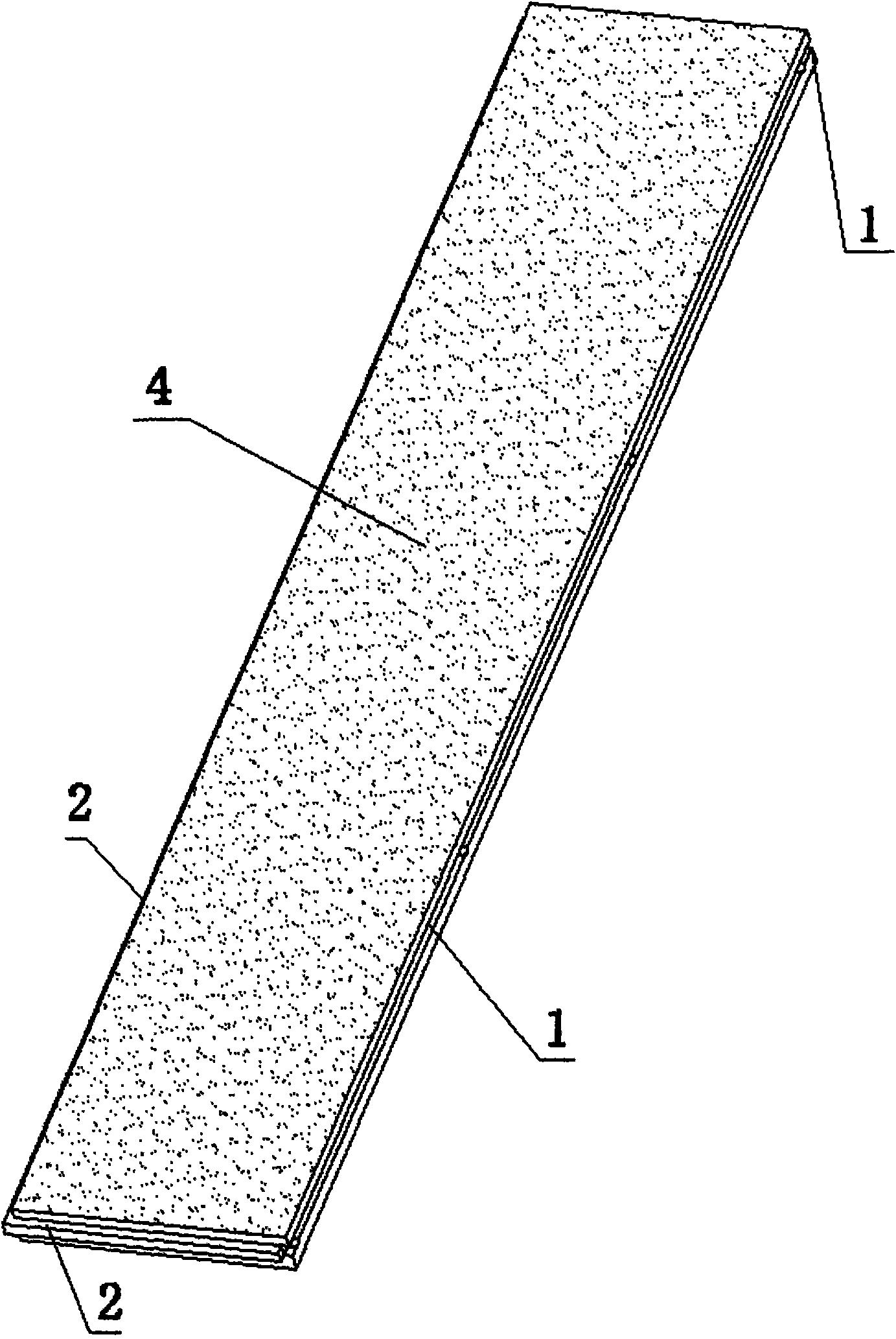

Degradable controllable magnesium-based alloy wire and preparation method thereof

The invention discloses a degradable controllable magnesium-based alloy wire and a preparation method thereof. The wire is composed of a magnesium alloy core body and a Mg-Y-Zn alloy outer layer whichare coaxially arranged, wherein the Mg-Y-Zn alloy consists of the following components in percentage by mass: 6.8-15.6% of Y, 2.5-5.7% of Zn and the balance of Mg. The preparation method comprises the following steps: preparing materials, moulding, composite casting, thermal treatment and a drawing process. Compared with an existing material, the magnesium-based alloy wire has the advantages that: elastic modus of the outer layer is similar to that of a magnesium alloy base body, a gradient structure is formed at an interface, good mechanical property and compatibility of deformation of the alloy are guaranteed; types and content of long-period orderly-stacked structure phases in the Mg-Y-Zn alloy outer layer are regulated within certain range, so that the wire has a controllable corrosion rate within a greater range, and can meet the requirements of the degradation rate of the degradable metal at different in-vivo parts.

Owner:HOHAI UNIV

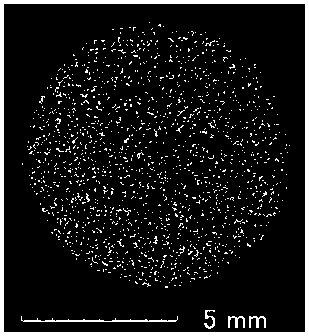

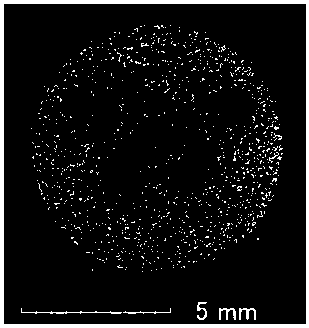

Method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy through reciprocation extrusion

ActiveCN107774732AReduce defectsNo ruptureExtrusion containersExtrusion control devicesUltimate tensile strengthThermal treatment

The invention discloses a method for preparing a nano quasi-crystal reinforced Mg-Zn-Y alloy through reciprocation extrusion. The method comprises the following steps: A, preparing cast Mg-Zn-Y alloyaccording to atom percentages of set component elements as follows: 0.5-6% of Zn, 0.08-1.2% of Y and the balance of Mg, and the content ratio of atoms of Zn and Y is (5-7):1; B, annealing the cast Mg-Zn-Y alloy for 8-20 hours at 380-420 DEG C, and performing furnace cooling; C, keeping the temperature of the annealed Mg-Zn-Y alloy at 300-400 DEG C for 2-4 hours, and performing thermal extrusion, wherein the extrusion temperature is 300-400 DEG C, and the extrusion ratio is (9-60):1; D, putting the Mg-Zn-Y alloy after thermal extrusion processing in the step C into a thermal treatment furnace,heating to 540-600 DEG C, keeping the temperature for 5-20 minutes, and performing quenching; and E, keeping the temperature of the Mg-Zn-Y alloy obtained in the step D at 200-380 DEG C for 2-4 hours,and performing reciprocation extrusion, thereby obtaining the alloy. By adopting the method, a magnesium alloy which is excellent in yield strength, tension strength and ductility can be prepared.

Owner:SOUTHWEST JIAOTONG UNIV

Fire retardant modified ABS resin with high surface hardness

This invention relates to flame-retardant modified ABS resin with high surface hardness. The modified ABS resin comprises: ABS 70-90 parts, glass microbeads 4-12 parts, epoxy resin 1-5 parts, compatibilizer 1-5 parts, bromine series flame retardant 1-9 parts, stibium series flame retardant 0.4-3 parts, and coupler 0.2-0.8 part. This invention improves the surface hardness and flame retardancy of ABS resin by adding flame retardants and reinforcer during blending, and retains the excellent physicochemical properties of ABS resin, thus expanding the industrial application range of ABS resin.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

ABS plastic floor board

InactiveCN101608499AReduce weightHigh flexural and compressive strengthFlooringPlastic injection moldingAcrylonitrile

The invention discloses an ABS plastic floor board, which is prepared by ABS plastic injection molding technology. ABS plastic is a terpolymer prepared from the following raw materials in percentage by weight: 5 to 30 portions of acrylonitrile, 10 to 30 portions of butadiene and 40 to 70 portions of styrene. The surface of the ABS plastic floor board forms a square or rectangular shape, while the upper surface is provided with antiskid skin lines, the edge is provided with convex and concave interfaces, and the lower surface is provided with a plurality of strip strengthening ribs. The ABS plastic floor board has the advantages of corrosion resistance, moisture resistance, high temperature resistance, wear resistance, inconductivity, easy cleaning, environment protection, no toxicity, no odor and the like.

Owner:SHANGHAI JIASHENG IND CO LTD

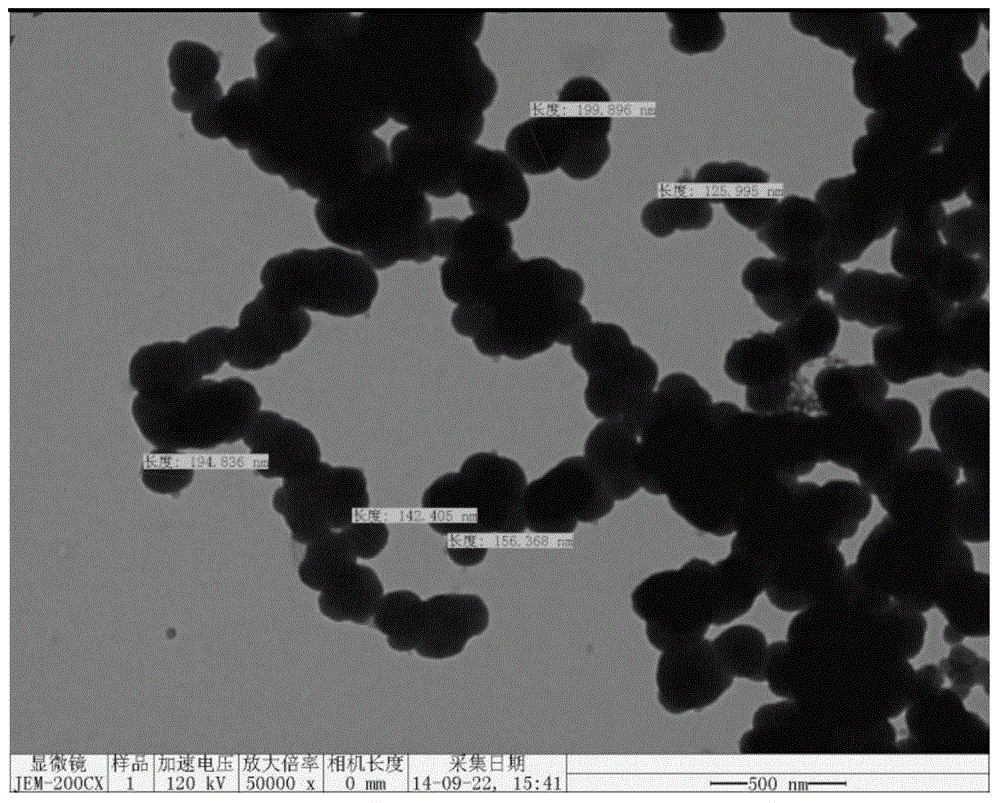

Amorphous state nanometer silicon dioxide micro powder and preparation method thereof

ActiveCN104355314AHigh silica contentReduce generationMaterial nanotechnologySilicaTetramethylammonium hydroxideSilanes

The invention discloses an amorphous state nanometer silicon dioxide micro powder and a preparation method thereof. The preparation method comprises the following steps: a reactant of tetramethylammonium hydroxide and silane and vinyl trimethoxy silane are used as a raw material, the tetramethylammonium hydroxide is used as a temporary catalyst, a low-temperature reaction is performed for 2-5 hours in an oil bath, then a solution is converted into gel through warming, decompressing and sucking filtration, the gel is calcined at the low temperature of 300-500 DEG C to prepare silicon dioxide coacervate, an obtained power body is amorphous state globular coacervate, and the particle diameter is 70-200 nm. The preparation method disclosed by the invention has the advantages that the reaction temperature is mild, the period is short, the calcining temperature is low, at the same time, technology equipment is simple, raw materials are easy to obtain, the discharge in the production process is extremely few, and the obtained amorphous state nanometer silicon dioxide micro powder has the advantages of high purity, uniform particle size and easy dispersal.

Owner:陕西宝塔山油漆股份有限公司

Tool cathode and method for improving flatness of electrolytic milling bottom surface

The invention relates to a tool cathode capable of improving the flatness of the bottom face subjected to electrolytic milling and grinding machining and a method and belongs to the field of electrolytic milling and grinding composite machining. A plurality of water outlet holes are distributed in the end face of the tool cathode and covered with an abrasive grain layer. The radii of the end facewater outlet holes are equal, and the circular centers of the water outlet holes are located on intersection points of a plurality of concentric circles and straight lines. The circular centers of theconcentric circles serve as the center of the end face of the tool cathode, and the radii of the concentric circles are increased sequentially. The straight lines all pass through the center of the end face of the tool cathode, the number of the straight lines is equal to the number of the concentric circles, and the included angles between all the adjacent straight lines are equal. All the end face water outlet holes are symmetrically distributed along the straight line. In work, because of the effect of the end face water outlet holes, an electrolyte rapidly flows towards the two sides of the machined bottom face of a workpiece, flowing of the electrolyte in the middle area of the machined bottom face of the workpiece is restrained, and finally the machined bottom face, with the good flatness, of the workpiece can be obtained. The flatness of the bottom face subjected to electrolytic milling and grinding machining can be effectively improved, and application and popularization of the technology are promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Asynchronous 3D printing method and device with enhanced skeleton

ActiveCN111823581AHigh tensile strengthIncreased shear strengthAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringMechanical engineering

The invention discloses an asynchronous 3D printing method and device with an enhanced skeleton, and belongs to the technical field of 3D printing rapid forming. The asynchronous 3D printing method comprises the steps: a printed semi-finished product is printed through fused deposition modeling firstly, the printed semi-finished product is provided with an inner shape follow-up cavity with the upper side being open; then a molten material is injected into the inner shape follow-up cavity of the printed semi-finished product from an opening, and pressure maintaining is conducted till the moltenmaterial is solidified to form the enhanced skeleton; and finally a 3D printed product with the enhanced skeleton is prepared. The asynchronous 3D printing device comprises a printing injection assembly, melting plasticizing assemblies, a transitional connecting assembly, a three-dimensional mobile platform and a control system; and flow-dividing and elongation converging components are designedin screw rods of the melting plasticizing assemblies to conduct flow-dividing converging and elongation flowing on the material to ensure that under the condition of the small draw ratio of the screwrod, the material is effectively plasticized and molten, and the molten material is homogenized. The asynchronous 3D printing method and device can form the 3D printed product through the same material without the aid of any heterogeneous material insert or chemical additive, and the strength of the 3D printed product is improved.

Owner:QINGDAO UNIV OF SCI & TECH

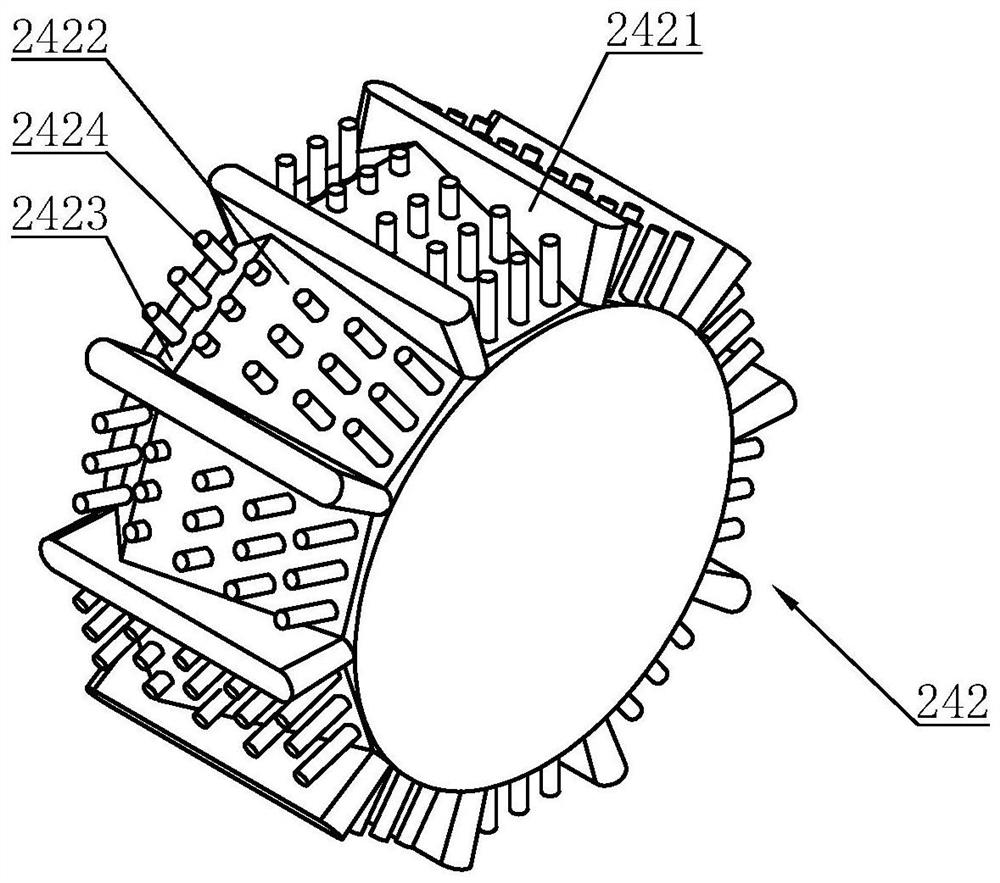

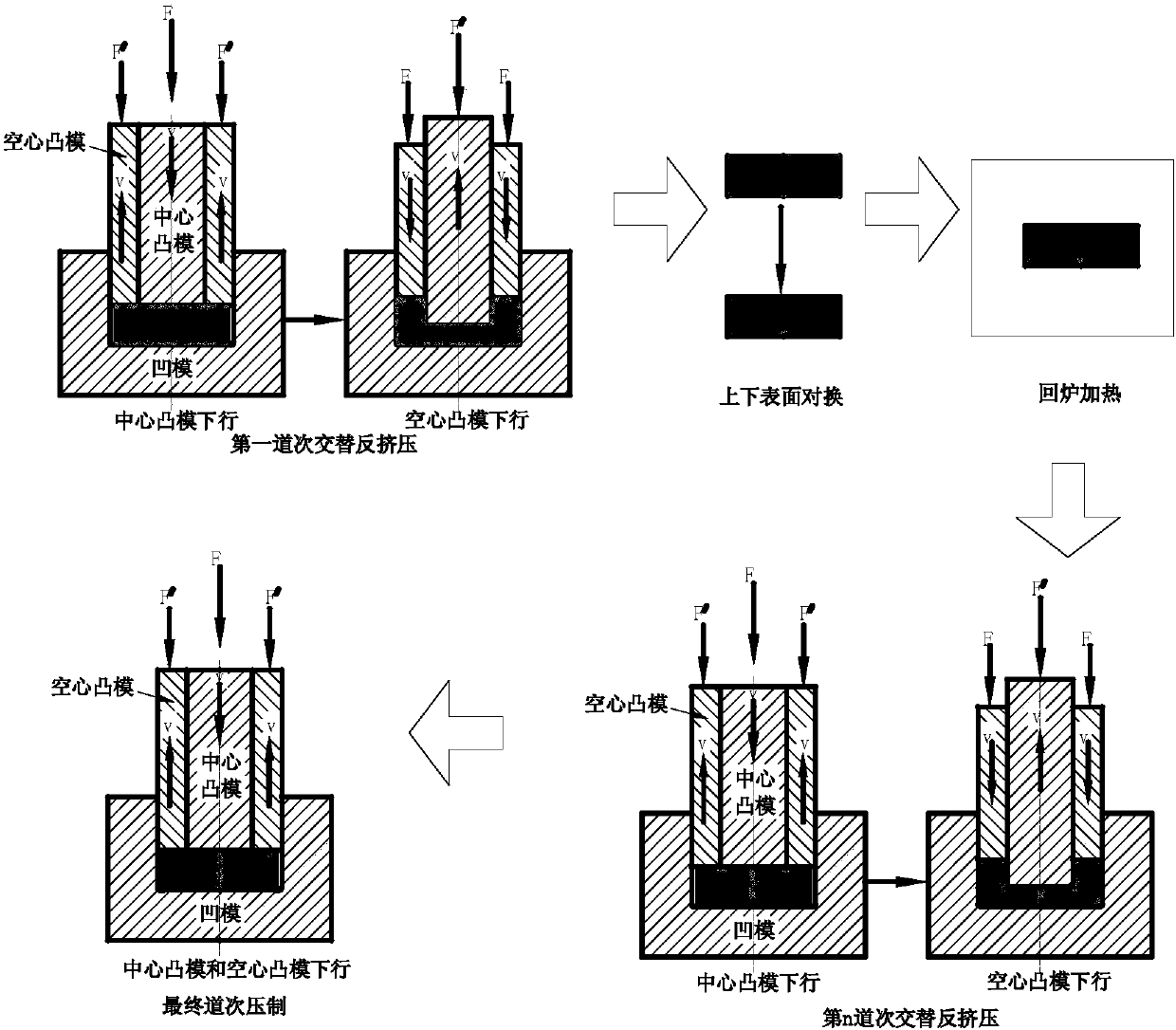

A method for preparing fine-grained magnesium alloy by alternate reverse extrusion

A method for preparing fine-grained magnesium alloy by alternating reverse extrusion, belonging to the field of magnesium alloy processing technology. Method: 1) Cut the magnesium alloy cylindrical rod; 2) Heat treatment of the bar material; 3) Preheat the mold; 4) Alternate reverse extrusion: Perform 3 to 6 passes of reverse extrusion on the magnesium alloy cylindrical rod. Magnesium alloy deformed parts are produced; the operation sequence of each pass of reverse extrusion is the same; between every two passes of reverse extrusion, the billet is reheated, and the billet is turned over for the next pass of reverse extrusion; among them, the first reverse extrusion Extrusion, place the magnesium alloy cylindrical rod at the bottom of the die, the center punch goes down and then is unloaded, and then the hollow punch goes down; 5) Final pass forging: the center punch and the hollow punch are extruded down at the same time to obtain fine Crystalline magnesium alloy. The method of the present invention prepares fine-grained magnesium alloy materials with significantly improved strength and plasticity and an average grain size of less than 10 μm through alternating reverse extrusion; the equipment is simple, low cost, high efficiency, easy to operate, and industrialized in sight.

Owner:NORTHEASTERN UNIV LIAONING

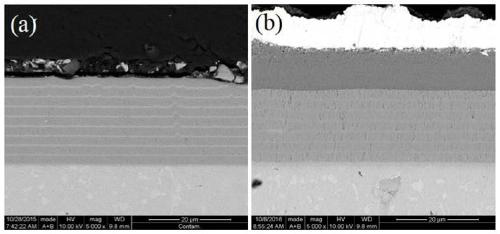

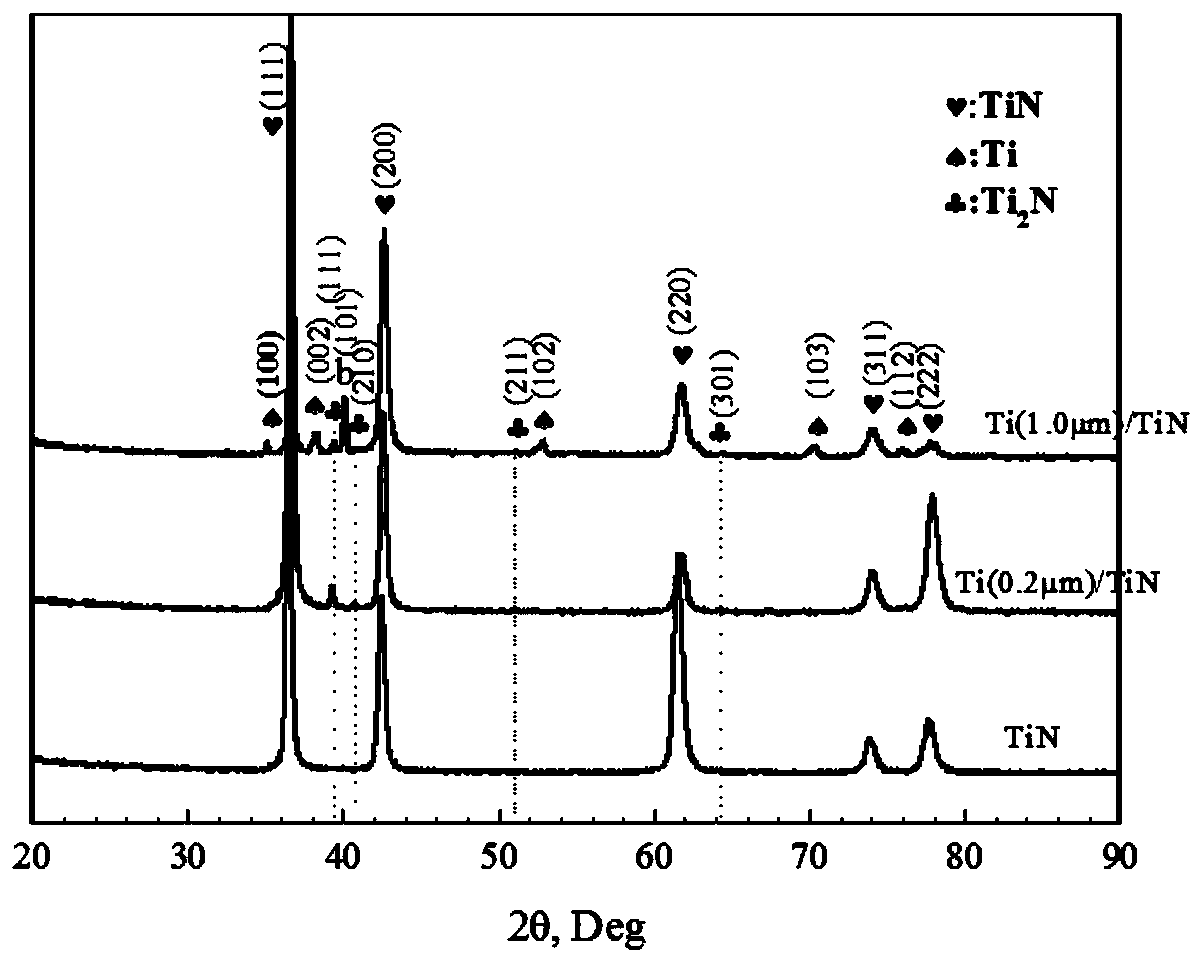

Medium-high temperature oxidation resistant Ti/TiN multilayer coating and preparation method

ActiveCN110257766ASimple preparation processImprove production efficiencyVacuum evaporation coatingSputtering coatingAlloy substrateOxidation resistant

The invention relates to the field of metal material surface high temperature protective coatings, in particular to a medium-high temperature oxidation resistant Ti / TiN multilayer coating and a preparation method. The Ti / TiN multilayer coating is formed in the mode that Ti sublayers and TiN sublayers are deposited on a titanium alloy substrate sequentially alternately, the first layer and the last layer are both TiN layers, the thickness of each Ti sublayer is 0.05-1.0 [mu]m, the thickness of each TiN sublayer is 1.8-2.2 [mu]m, and the total layer number is an odd number between 9 and 21. Preparation steps of the Ti / TiN multilayer coating comprise pretreatment, ion cleaning and sublayer deposition. According to the medium-high temperature oxidation resistant Ti / TiN multilayer coating and the preparation method, the problems that a nitride coating is too thick, and cracking, peeling and the like are liable to appear due to too high internal stress and brittleness can be solved, bonding strength of the coating and the substrate is good, and the Ti / TiN multilayer coating is compact in structure, has good medium-high temperature oxidation resistance, and can provide a selection scheme for high temperature protection of military aircraft parts.

Owner:HENAN INST OF SCI & TECH

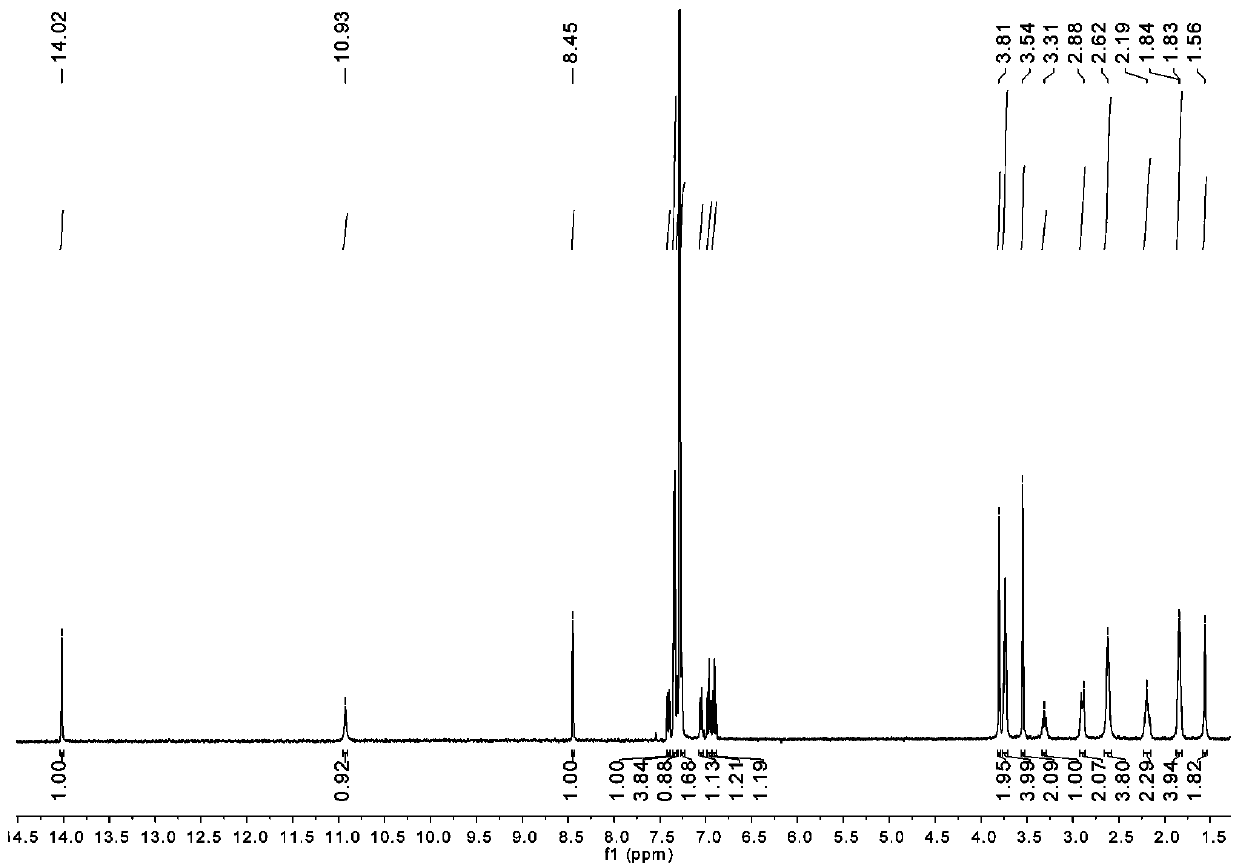

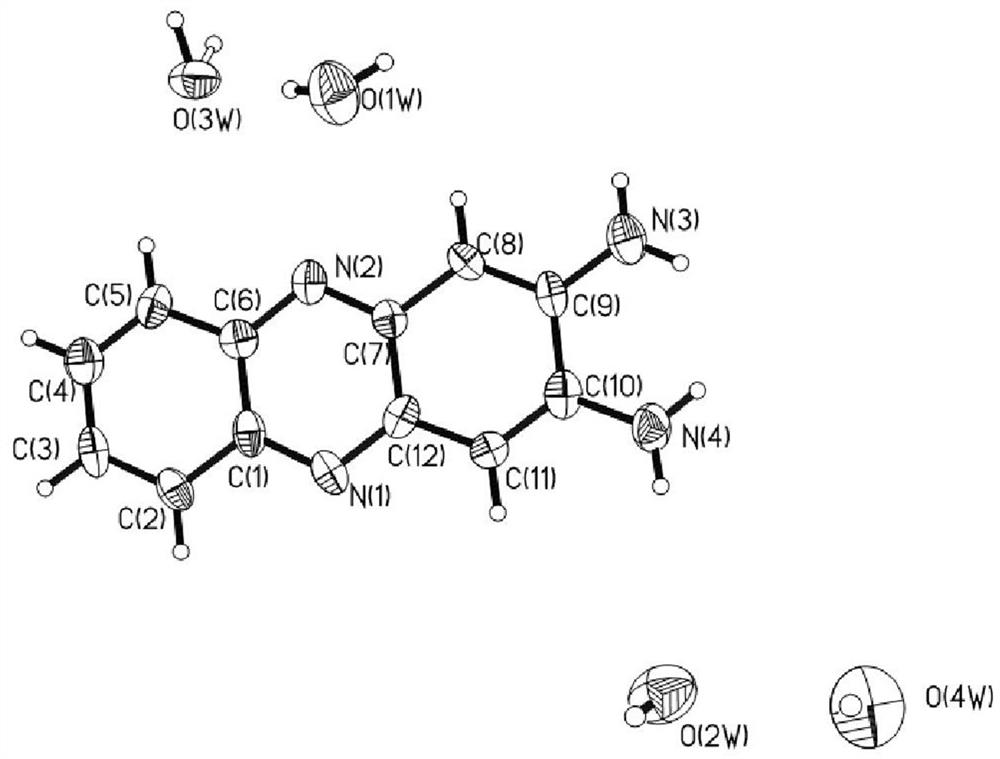

Dual-core metal organic complex with asymmetric structure and preparation and applications thereof

ActiveCN110143978AEffective control of stereoEffective control of electronic effectsGroup 3/13 element organic compoundsDual coreRing-opening polymerization

The invention discloses a dual-core metal organic complex with an asymmetric structure, which is represented by the formula (I). The organic complex can be used as a catalyst for ring-opening polymerization of cyclic esters and is applied to ring-opening polymerization of different cyclic esters. Due to the cooperation between dual metals, only a small amount of the metal organic complex can catalyze the ring-opening polymerization of cyclic esters efficiently, and the catalysis efficiency and catalytic activity are high. Due to the asymmetric structure of the catalyst, the stereo-selectivityof the polymerization reactions can be adjusted in a greater range; corresponding polymers have abundant structural characteristics and multiple physical and chemical properties; and the application range is enlarged.

Owner:TAIYUAN UNIV OF TECH

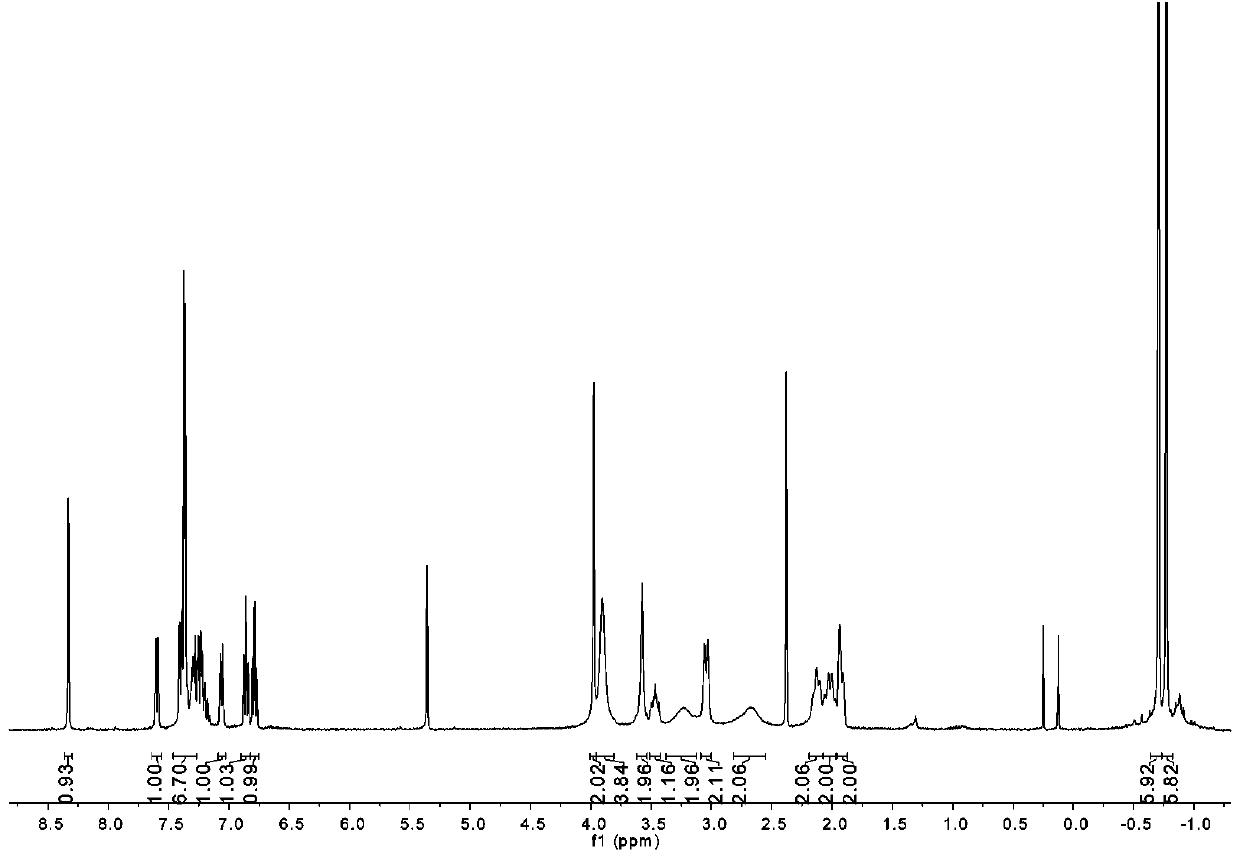

Method for fermentation production of lactase by aspergillus oryzae and lactase produced by method

ActiveCN109295037AImprove fermentation capacityIncrease productivityMicroorganism based processesGlycosylasesLactaseSubmerged fermentation

The invention discloses a method for fermentation production of lactase by aspergillus oryzae and the lactase produced by the method, and belongs to the bioengineering technical field. The strain is specifically aspergillus oryzae CA-08 and has the preservation number of CGMCC No.14137. The strain is deeply fermented in a liquid 50 L tank, is supplemented with materials and is subjected to fermentation culture for 105 h, and the enzyme production average level is 100762 U / mL. The established method for liquid fermentation of the lactase has the optimum pH range for production of the lactase of4.0-7.0, the optimum action temperature is 80 DEG C, the residual enzyme activity is 89.5% after heat preservation is carried out for 1 h at the temperature of 80 DEG C, and the residual enzyme activity is 58.9% after heat preservation is carried out for 2 h at the temperature of 80 DEG C. The lactase has good heat resistance and can be widely applied in industrialized production.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

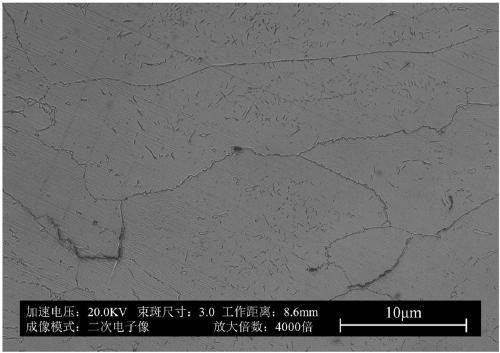

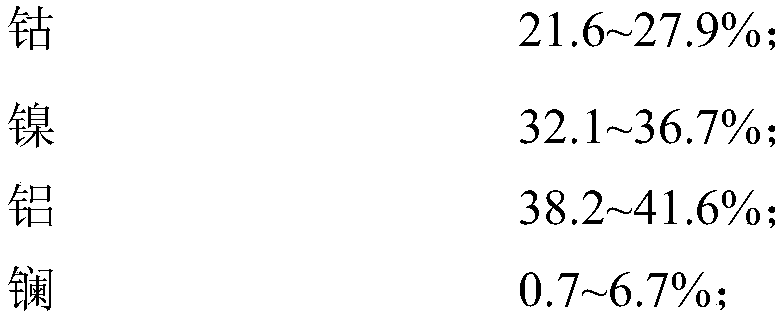

Magnetic memory alloy with large strain and preparation method thereof

ActiveCN109097610AImprove mechanical propertiesExcellent large magnetic strainInductances/transformers/magnets manufactureMagnetic materialsGrain boundary migrationMagnetic memory

The invention provides a magnetic memory alloy with large strain and a preparation method thereof and belongs to the field of shape memory alloys. The alloy has the capacity of generating high magnetic strain under control of an external magnetic field at the room temperature condition, and is a magnetic control shape memory alloy capable of driving martensite twin grain boundary migration and reverse migration through changes of the external magnetic field so as to generate recoverable strain at the room temperature condition. The chemical formula of the alloy is CoxNiyAlzLaj, wherein x is larger than or equal to 21.6 and smaller than or equal to 27.9, y is larger than or equal to 32.1 and smaller than or equal to 36.7, z is larger than or equal to 38.2 and smaller than or equal to 54.6,j is larger than or equal to 0.7 and smaller than or equal to 6.7, the sum of x, y, z and j is 100, and x, y, z and j represent Mole percentages. Compared with an existing material, by forming an ultrafine Al3La metal intermediate phase in a matrix of the memory alloy, the alloy has a wide magnetic strain temperature range, high magnetic strain capacity and good mechanical properties, and has important application to the field of high-precision drivers, actuators and the like used at the room temperature condition.

Owner:HOHAI UNIV +1

Preparation method of pure spinning regenerated cellulose fiber card sliver

ActiveCN109594248AImprove smoothnessGood flexibilityTextile treatment by spraying/projectingVegetal fibresCellulose fiberEngineering

The invention belongs to the technical field of spinning methods, in particular to a preparation method of a pure spinning regenerated cellulose fiber card sliver. The preparation method comprises thefollowing steps: regenerated cellulose fiber pretreatment; A002D bale plucker; A036B cotton slitter; A092A cotton feeding machine; A076C lapper; A186G carding machine; pure spinning regenerated cellulose fiber card sliver. The level of difficulty of manufacturing different fibers in the blending technology is lowered, and the industrial application range of regenerated cellulose fiber is improved.

Owner:JIHUA 3542 TEXTILE CO LTD

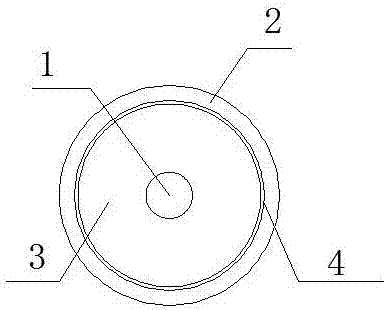

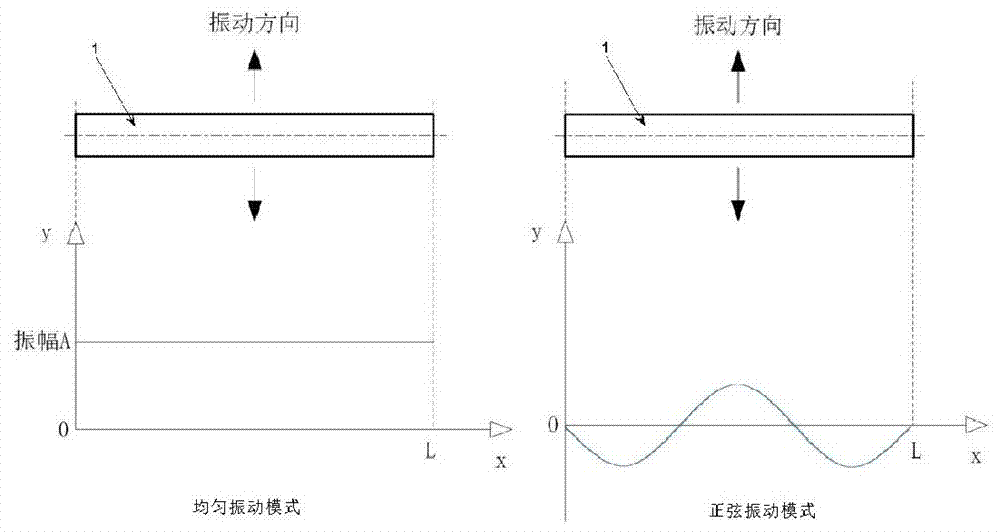

Tubular ultrasonic separation cavity

InactiveCN107324446AOvercome deficienciesSolve the blockageWater/sewage treatment with mechanical oscillationsEnergy based chemical/physical/physico-chemical processesSeparation technologyEngineering

The invention relates to a tubular ultrasonic separation cavity. The tubular ultrasonic separation cavity comprises a columnar ultrasonic vibration source and a tubular reflector, and is characterized in that the columnar ultrasonic vibration source is arranged in the tubular reflector, an annular cavity is formed between the columnar ultrasonic vibration source and the tubular reflector, and an acoustic reflection material is arranged on the inner wall of the tubular reflector. By the arrangement of the tubular ultrasonic separation cavity, the defects of a traditional solid-liquid separation method are overcome, for example, the problem of filter screen blockage in a filtration method is solved; the problem of low treatment capacity of an existing ultrasonic solid-liquid separation device is solved, and thus the industrial application range of the ultrasonic solid-liquid separation technology is further broadened.

Owner:SHENZHEN CHENGDAOTONG ENVIRONMENTAL PROTECTION TECH +1

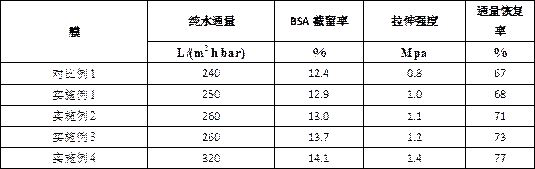

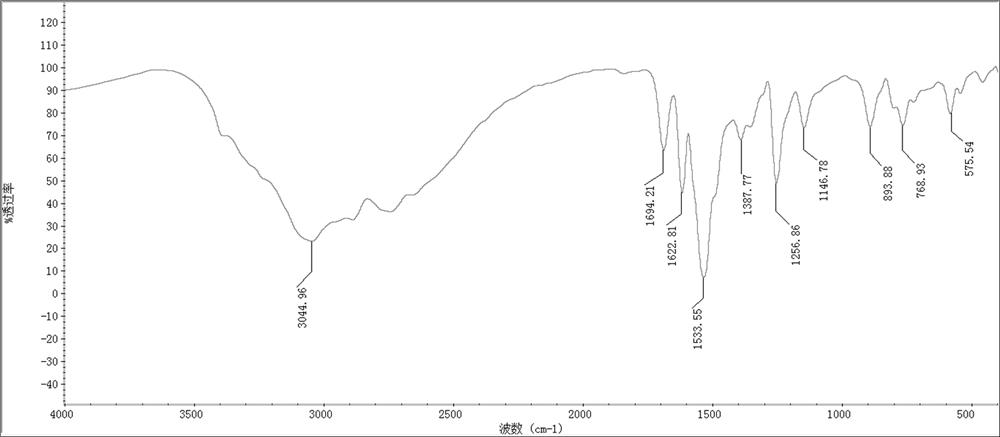

Cellulose acetate filter membrane and preparation method thereof

PendingCN113230908AGood hydrophilic and lipophilicGood dispersionSemi-permeable membranesHydrophobic polymerOrganosolv

The invention discloses a preparation method of a cellulose acetate filter membrane. The preparation method comprises the following steps: S1, modifying cellulose nanocrystals with dopamine; s2, preparing a cellulose acetate filter membrane: respectively dissolving cellulose acetate and the polydopamine-coated cellulose nanocrystals in DMAc to form a solution and a dispersion liquid so as to obtain a cellulose acetate membrane casting solution, coating a glass plate with the cellulose acetate membrane casting solution, and carrying out phase transfer to form a membrane, and stripping to obtain the polydopamine coated cellulose nanocrystal enhanced cellulose acetate filter membrane. The PDA is coated on the surface of the CNCs, so that the hydrophilicity and lipophilicity of the CNCs are improved, and the dispersity of the CNCs nano material in an organic solvent and the hydrophobic polymer matrix is improved. The PDA-coated CNCs filler is added into the CA filter membrane, so that the interface bonding force between the CNCs filler and a CA matrix is enhanced, the mechanical property and hydrophilicity of the CA membrane are improved, the tensile strength of the CA filter membrane can be remarkably improved by adding a small amount of PDA-coated CNCs, meanwhile, the filtering performance and the anti-pollution capacity of the CA membrane are improved.

Owner:SICHUAN UNIV

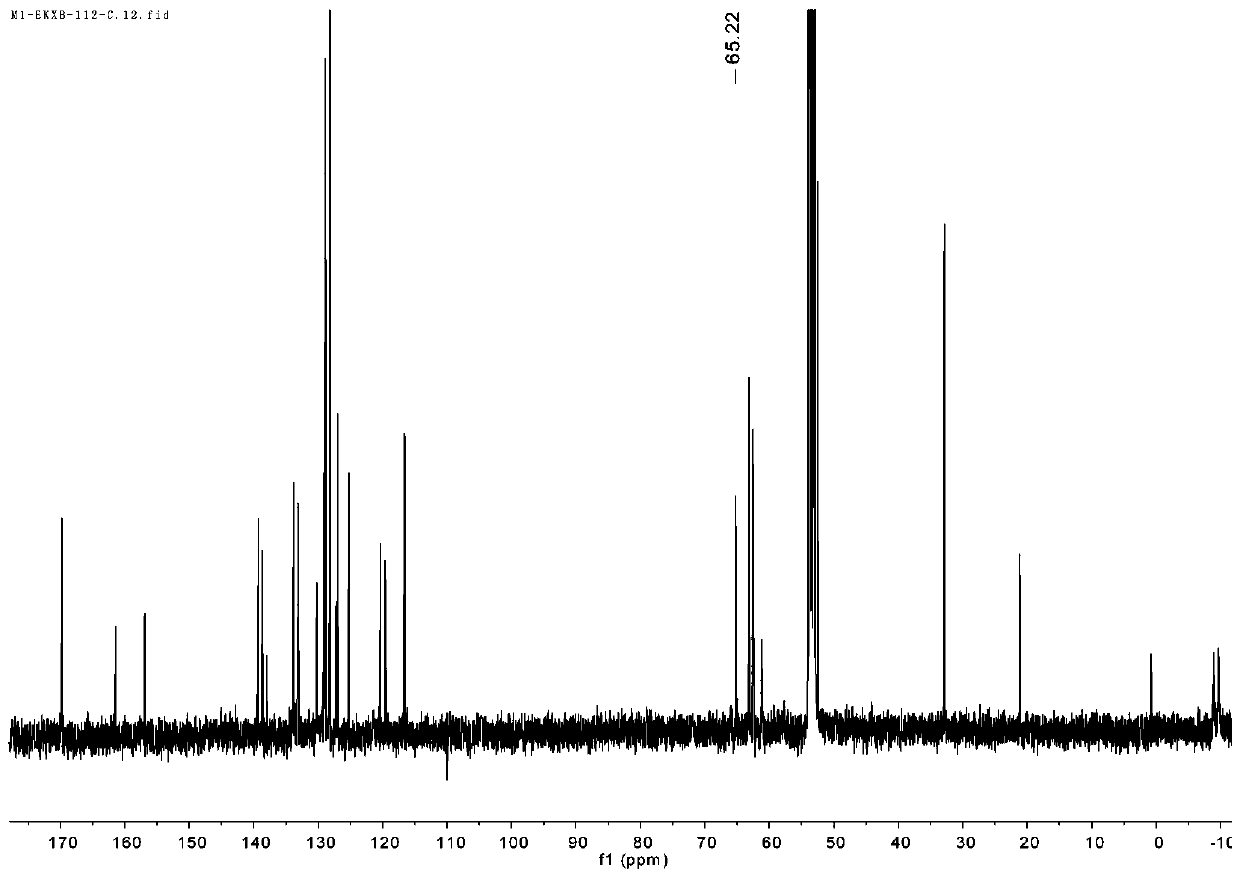

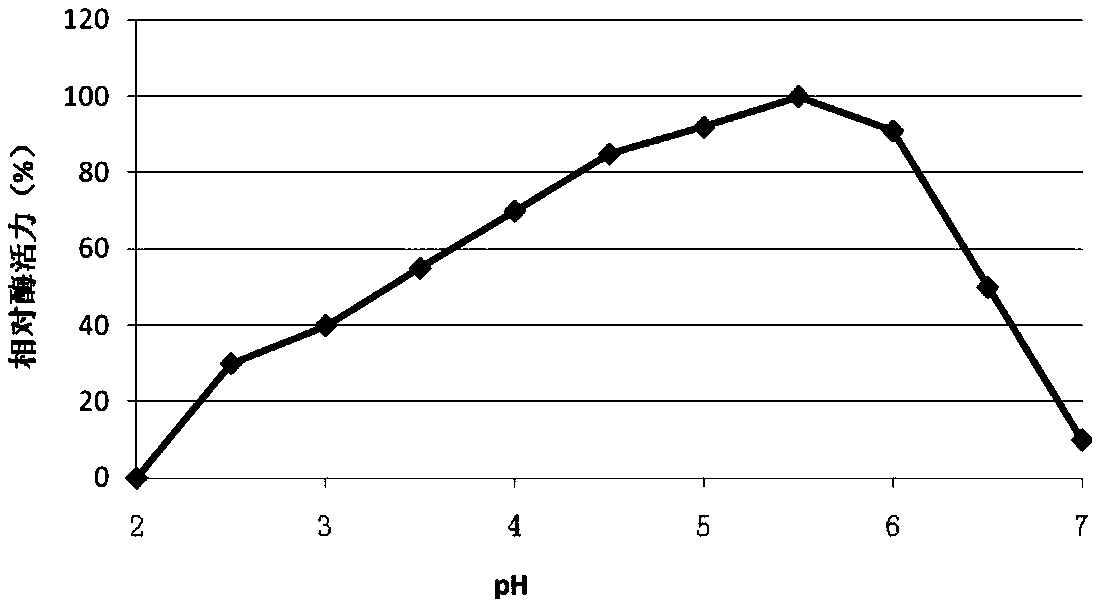

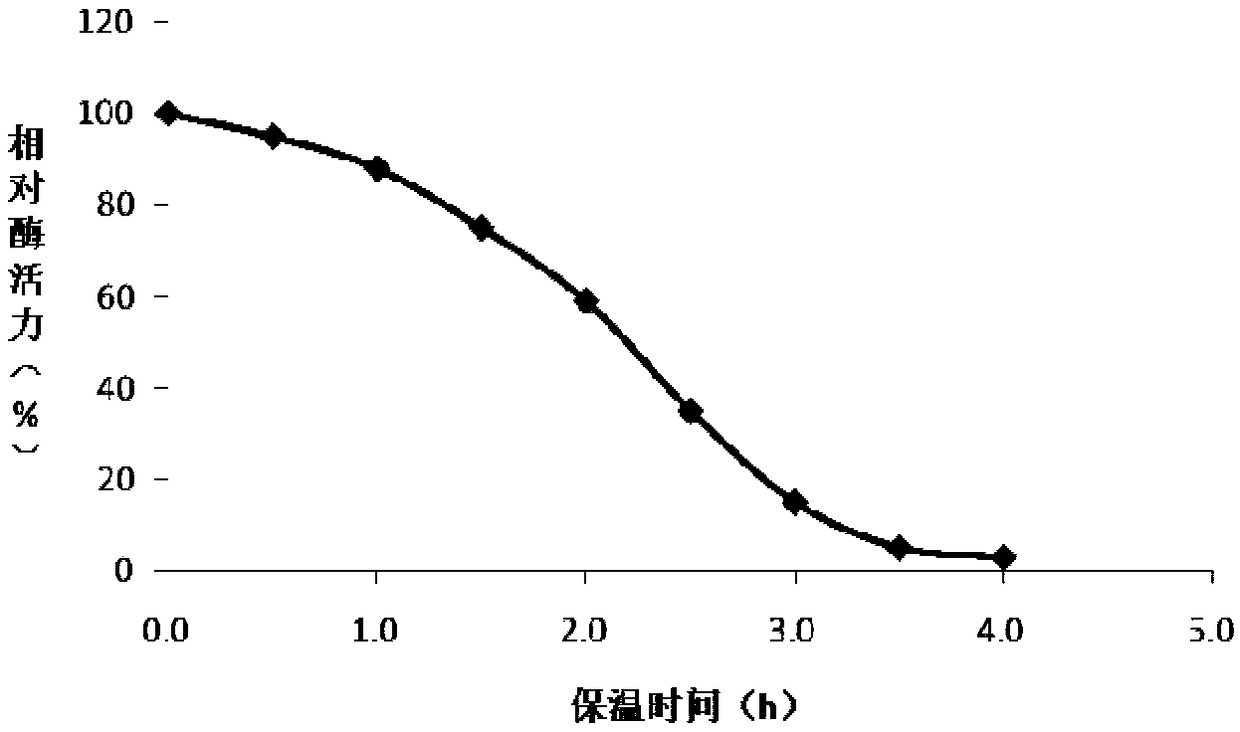

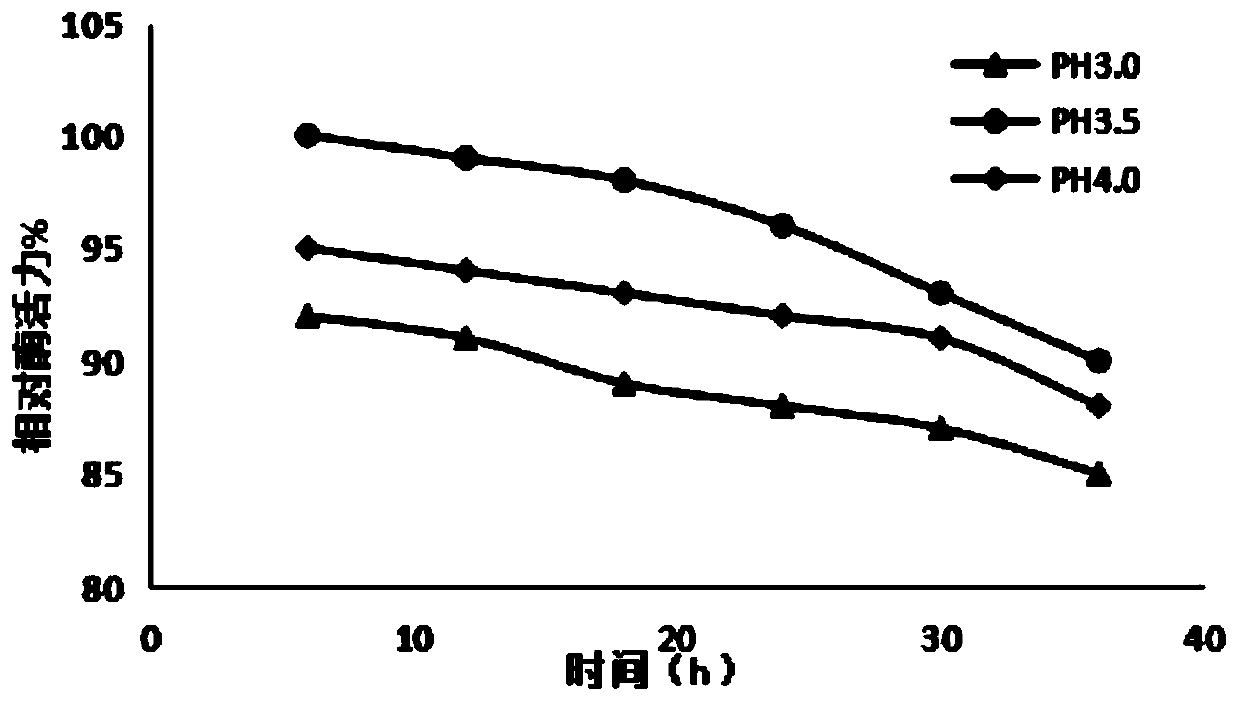

Liquid fermentation method for producing pectinase

ActiveCN110885760AImprove fermentation capacityIncrease productivityFungiMicroorganism based processesPectinaseMicrobiology

The invention, which belongs to the technical field of bioengineering, particularly relates to a method for producing pectinase. According to the method of producing pectinase through liquid fermentation, strain aspergillus niger LD-092 adopted by the method is obtained by carrying out Co60 ray mutagenesis treatment on an aspergillus niger original strain AJ213; and the preservation number of thestrain is CGMCC No.18559. The enzyme activity of pectinase produced by fermentation of the aspergillus niger LD-092 reaches 80000 to 85000U / mL; the optimum pH range of the pectinase obtained by fermentation is 2.5 to 4.0; the pectinase has the optimal action temperature range of 30 to 50 DEG C; the remarkable acid resistance is realized; the pectinase can be preserved for 36h in a PH range of 3.0to 4.0; and the enzyme activity is kept to be over 85%. The pectinase can be applied to the industrial production widely; the industrial application range of pectinase is extended substantially; and the application value of pectinase is improved.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

Method for rapidly synthesizing 2, 3-diaminophenazine through ultrasonic radiation catalysis

ActiveCN113121458AWide variety of sourcesSpeed up the reaction processOrganic chemistryAgainst vector-borne diseasesPtru catalystUltrasonic radiation

The invention provides a method for rapidly synthesizing 2, 3-diaminophenazine through ultrasonic radiation catalysis. The method specifically comprises the following steps: preparing an o-phenylenediamine raw material solution, preparing a catalyst transition metal salt solution, mixing the raw material solution and the transition metal salt solution, and carrying out ultrasonic radiation assisted reaction in an ultrasonic reactor, and washing and purifying the reaction product. According to the synthesis process, the target compound 2, 3-aminophenazine is rapidly and efficiently synthesized by adopting an ultrasonic radiation assisted reaction mode and taking a common low-valence chemical reagent o-phenylenediamine as the raw material, the whole process is environment-friendly and safe, and the reaction yield is relatively high so that the synthesis production cost of the 2, 3-aminophenazine is greatly reduced, and the application range of the 2, 3-aminophenazine is expanded.

Owner:HENAN UNIV OF SCI & TECH

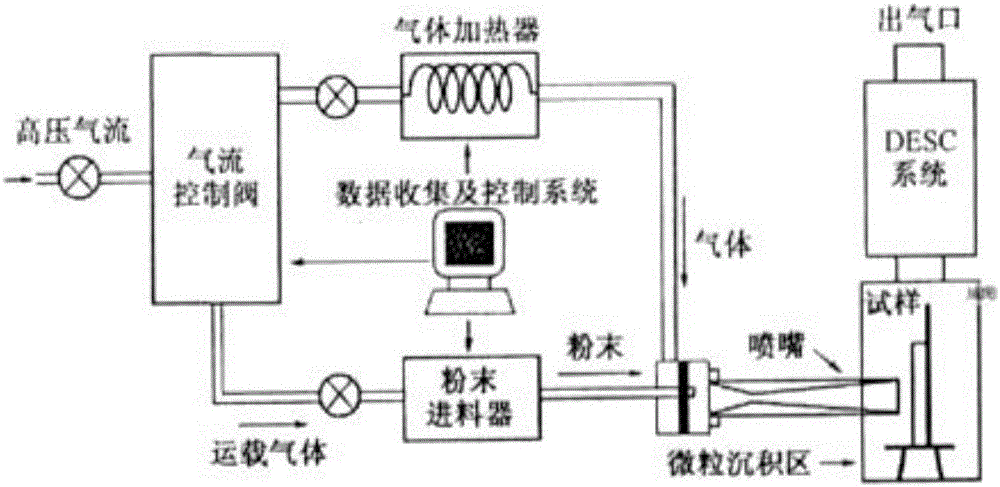

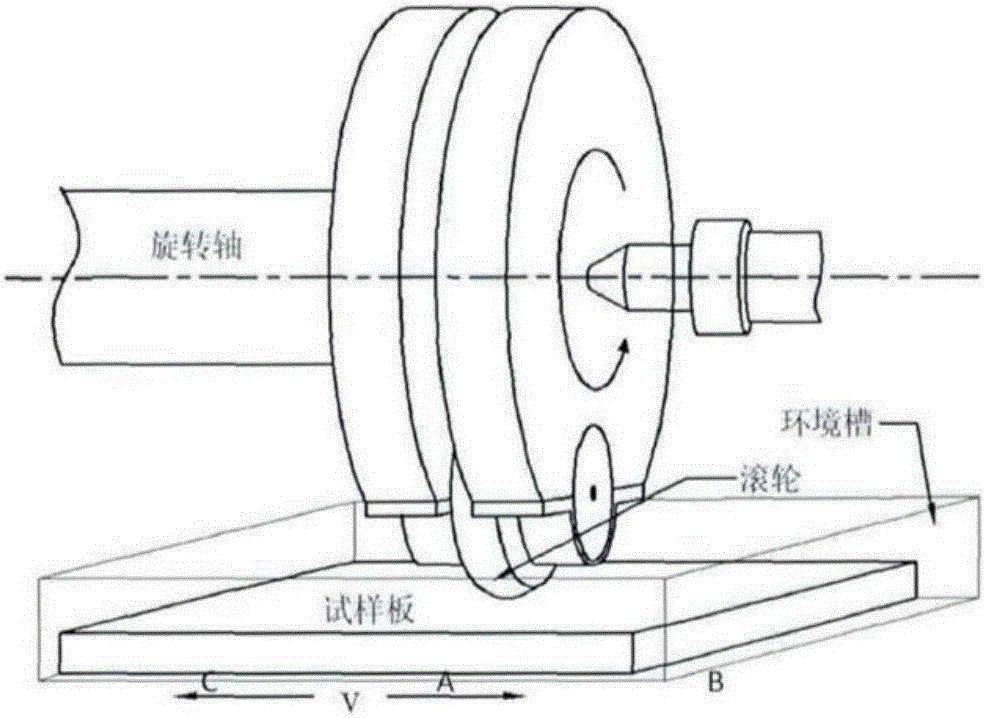

Friction stir welding method based on hawk energy and mixed surface nanocrystallization technology

InactiveCN106735858AReduce defective rateReduce surface roughnessNon-electric welding apparatusFriction weldingMicrometer

The invention provides a friction stir welding method based on a hawk energy and mixed surface nanocrystallization technology. According to the method, firstly, the surface of a base material to be welded is ground and polished; then supersonic particle bombardment surface nanocrystallization treatment is conducted, a nanometer layer with the thickness not lower than 50 micrometers is formed on the surface of the base material to be welded, and the average size of surface nanometer crystals is not greater than 50 nm; surface mechanical rolling is conducted on the surface of the base material to be welded; oil stains on the surface of the base material to be welded are removed with acetone, and then friction stir welding is conducted; trimmings on the upper surface of a joint are shoveled after welding is completed, and a transition zone is polished smoothly; and finally the surface of the welding joint is treated through a hawk energy technology, the surface roughness of the material is reduced to be in the range of 0.01-0.2 micrometers, and the surface microhardness is greater than 300 HV. According to the friction stir welding method, many nanometer layer zones can be formed in the friction stir welding joint, the S-shaped line formation rate caused by the roughness of the welding surface of the base material to be welded is reduced, the surface roughness of the welding joint is improved, and the comprehensive performance of the friction welding joint is improved.

Owner:中国人民解放军火箭军工程大学

High-lactase producing aspergillus oryzae and fermentation and enzyme producing method thereof

ActiveCN109321469AImprove fermentation capacityIncrease productivityFungiMicroorganism based processesLactaseLiquid state

The invention discloses a strain of high-lactase producing aspergillus oryzae and a fermentation and enzyme producing method thereof, and belongs to the technical field of bioengineering. The bacterial stain is specifically an aspergillus oryzae strain CA-08, and a preservation number is CGMCC No.14137. The bacterial strain is subjected to submerged fermentation through a liquid 50-L tank, throughsupplementing, fermentation culture is conducted for 105 h, and an enzyme-producing average is 100762 U / mL. According to the method of liquid-state lactase fermentation, an optimal pH range of produced lactase is 4.0-7.0, optimal operative temperature is 80 DEG C, after heat preservation is conducted at 80 DEG C for 1 h, the residual enzyme activity is 89.5%, and after heat preservation is conducted at 80 DEG C for 2h, the residual enzyme activity is 58.9%, so that the lactase has good heat resistance, and can be widely applied to industrial production.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

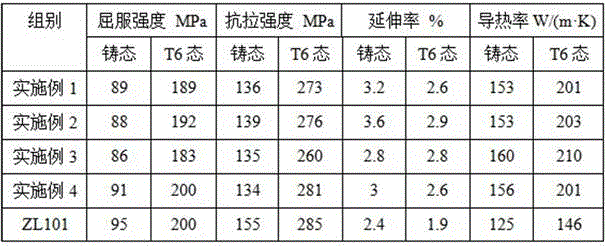

Cast aluminum alloy with high thermal conductivity and preparation method thereof

InactiveCN103526082BExpand the range of industrial applicationsImprove thermal conductivityTitanium zirconiumManganese

The invention discloses a casting aluminum alloy with high thermal conductivity and a preparation method thereof. The composition of the casting aluminum alloy includes 5.0-7.5% of silicon, 0.25-0.5% of magnesium, 0.01-0.06% of boron, and 0.005-0.02% of titanium. Zirconium is 0.005-0.02%, iron is less than 0.2%, copper is less than 0.2%, manganese is less than 0.1%, zinc is less than 0.1%, the sum of other impurities is not more than 0.3%, and the balance is aluminum. In the preparation process, boron oxide is used as a modifier, combined with the addition of titanium and zirconium elements, a cast aluminum alloy with a thermal conductivity of 210W / (m·K) can be obtained. The invention realizes that on the basis of existing good casting performance, mechanical performance and heat treatment performance, the thermal conductivity of Al7SiMg cast aluminum alloy is significantly improved, and its industrial application range is expanded.

Owner:GUANGZHOU KINBON NON FERROUS ALLOY METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com