Friction stir welding method based on hawk energy and mixed surface nanocrystallization technology

A technology of friction stir welding and nanotechnology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems that affect the comprehensive performance of welded joints and large surface roughness, and achieve convenient manufacturing and maintenance, simple replacement, The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

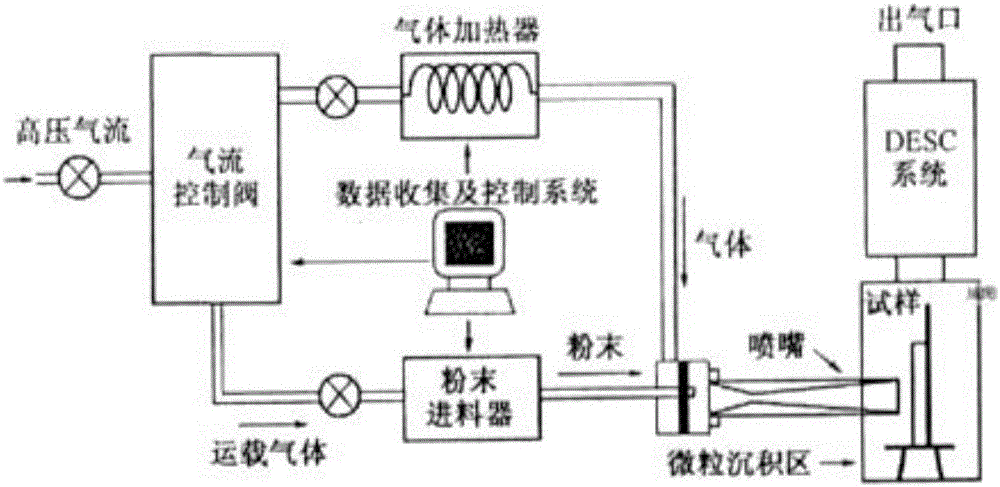

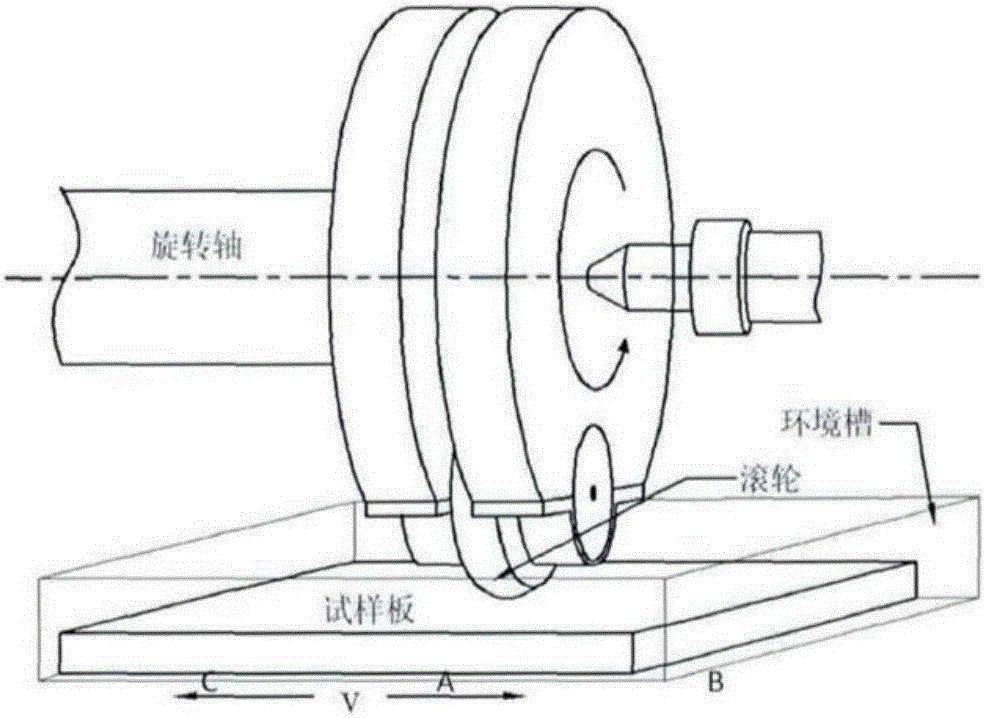

[0030] The invention belongs to the field of friction stir welding of metal materials, and specifically relates to a method for welding the base material to be welded by adopting friction stir welding technology after the surface of the metal base material to be welded is subjected to mixed surface nanometer treatment. The present invention first adopts the supersonic particle bombardment technology, and uses the high-pressure gas generated by the high-pressure gas generating device to carry hard spherical particles to continuously bombard the surface of the metal substrate to be welded at a speed of 340-1200m / s, so that a nano-layer of a certain thickness is formed on the surface , on this basis, the surface of the base material to be welded continues to be processed by sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com