Metal material high-energy-beam additive/subtractive material and on-line laser ultrasonic detection composite processing method

A technology of laser ultrasonic and metal materials, which is applied in the analysis of materials, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the material analysis using sonic/ultrasonic/infrasonic waves, etc. It can solve the problems that additive manufacturing parts cannot be detected and removed online, etc. Achieve the effect of reducing product defect rate, fast detection speed and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

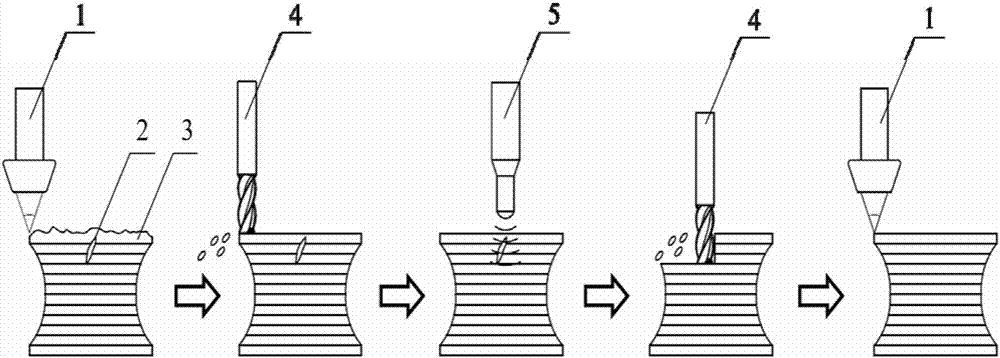

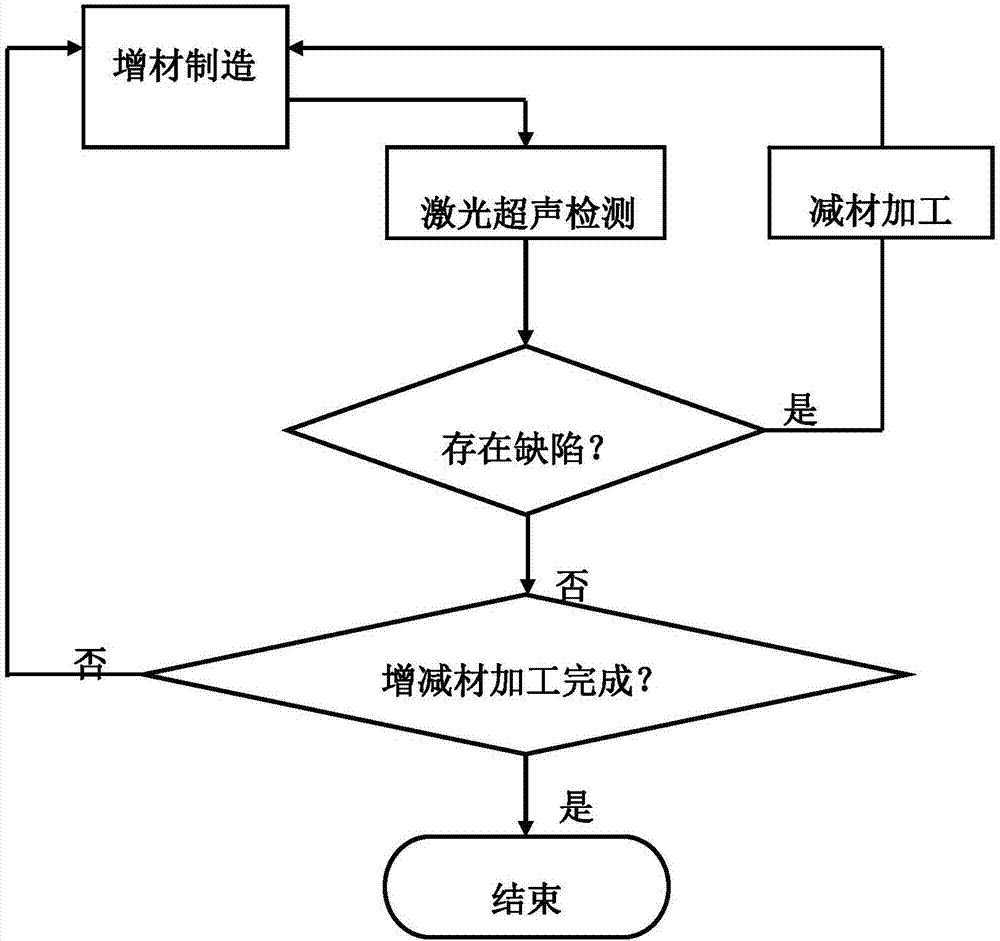

[0047] Such as figure 1 As shown, a metal material high-energy beam addition and subtraction-on-line laser ultrasonic detection composite processing method, the specific operation includes the following steps:

[0048] The high-energy beam spray head 1 forms a deposited workpiece 3 with a certain number of layers according to the preset planned layered cross-section high-energy beam scanning path;

[0049] According to the specific process parameter settings, the material reduction tool 4 performs necessary material reduction processing on the deposited workpiece 3, removes the step effect and processes the surface detection plane;

[0050] Planar scanning of the newly deposited material after material reduction is carried out by the laser ultrasonic probe 5, and the laser ultrasonic signal is used to determine whether there is a subsurface defect 2 on the surface or inside of the material and determine its position;

[0051] If an intolerable subsurface defect 2 is detected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com