Grinding system of intelligent numerical control platform

A technology of numerical control platform and intelligent control module, which is applied to the parts of grinding machine tools, grinding/polishing equipment, and automatic grinding control devices, etc., which can solve problems affecting machining accuracy, unskilled, loose parts, etc., and achieve saving cost, increased accuracy, and the effect of improved processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

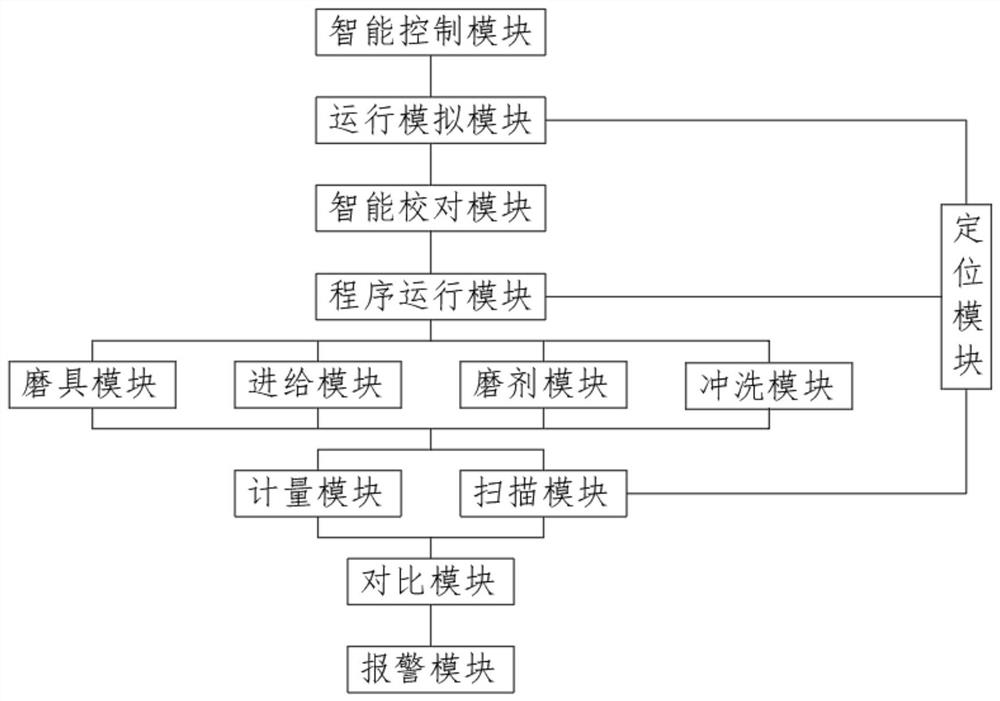

[0050] see Figure 1-2 , a grinding system of an intelligent numerical control platform, an intelligent control module, an operation simulation module, an intelligent proofreading module, a program operation module, an abrasive tool module, a feed module, an abrasive module, a flushing module, a metering module, a scanning module, and a positioning module , comparison module, alarm module;

[0051] The intelligent control module is used for the import and editing of NC programs or models, and the overall module control of the NC platform;

[0052] The running simulation module is used for simulating the running of the NC program, judging the implementability of the program, whether the position and model of each module are wrong, and can detect the errors and failures of the equipment in time;

[0053] Intelligent proofreading module, used for proofreading and adjusting the errors, omissions and faults of the abrasive tool module, feed module, abrasive module, and flushing mo...

Embodiment 2

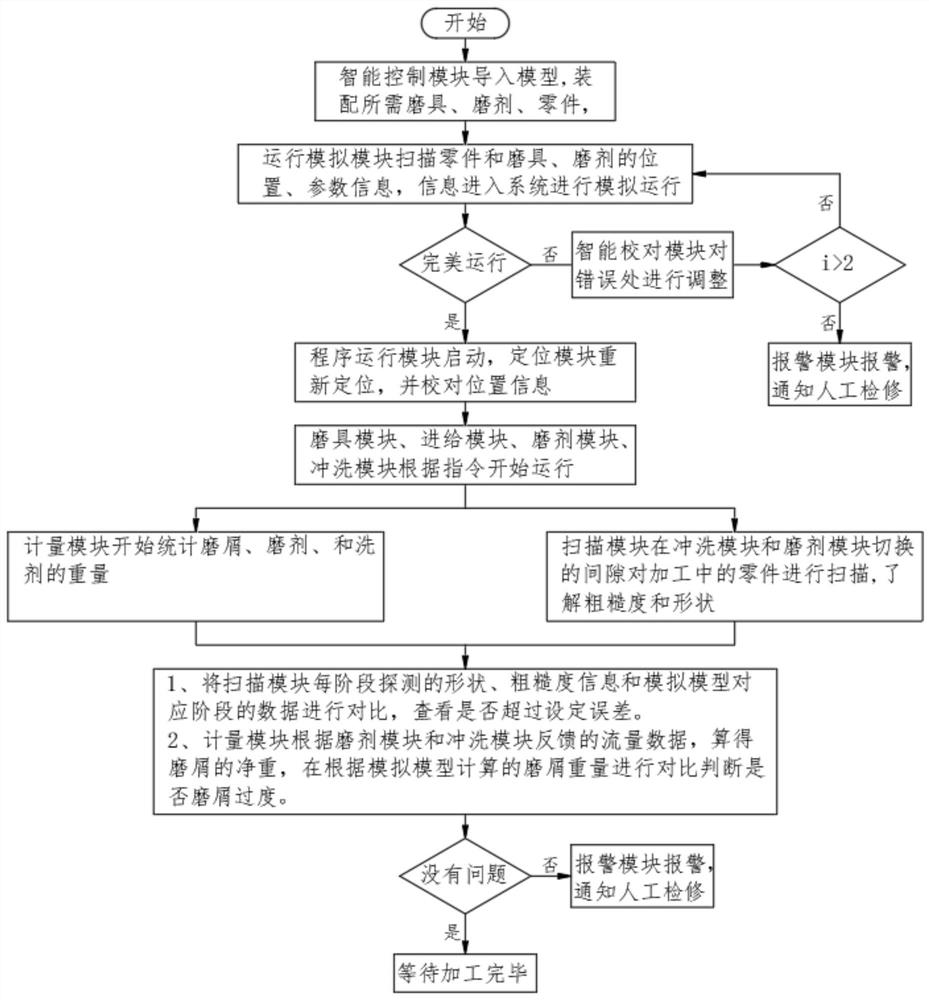

[0068] see Figure 1-3 , a grinding system of an intelligent numerical control platform, an intelligent control module, an operation simulation module, an intelligent proofreading module, a program operation module, an abrasive tool module, a feed module, an abrasive module, a flushing module, a metering module, a scanning module, and a positioning module , comparison module, alarm module;

[0069] The intelligent control module is used for the import and editing of NC programs or models, and the overall module control of the NC platform;

[0070] The grinding tool module is used to install the grinding tools required for the grinding process and identify the grinding tool model;

[0071] Feed module, used to control the movement of the grinding tool;

[0072] Abrasive agent module, used for spraying the abrasive agent for grinding auxiliary abrasive tools, and identifying the type of abrasive agent;

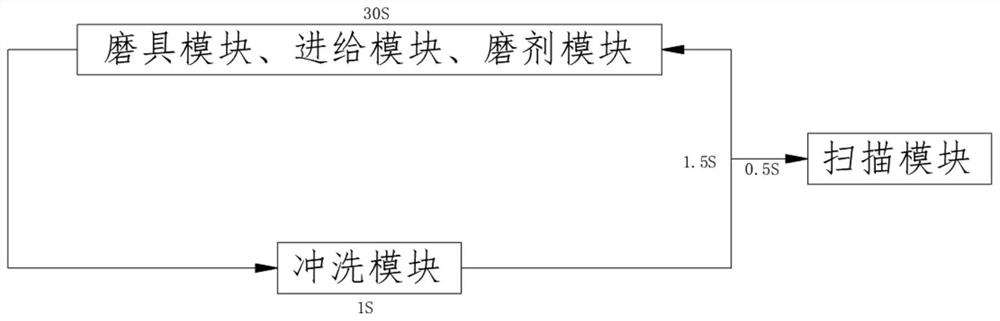

[0073] The flushing module is used to flush off the abrasive and debris ...

Embodiment 3

[0084] see Figure 1-4 , a grinding system of an intelligent numerical control platform, an intelligent control module, an operation simulation module, an intelligent proofreading module, a program operation module, an abrasive tool module, a feed module, an abrasive module, a flushing module, a metering module, a scanning module, and a positioning module , comparison module, alarm module;

[0085] The intelligent control module is used for the import and editing of NC programs or models, and the overall module control of the NC platform;

[0086] The running simulation module is used for simulating the running of the NC program, judging the implementability of the program, whether the position and model of each module are wrong, and can detect the errors and failures of the equipment in time;

[0087] The grinding tool module is used to install the grinding tools required for the grinding process and identify the grinding tool model;

[0088] Feed module, used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com