Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

512 results about "Abrasive agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing slurry for silicon oxide, additive liquid and polishing method

InactiveUS20070175104A1Increase speedInhibit progressPigmenting treatmentOther chemical processesPolyethylene glycolSlurry

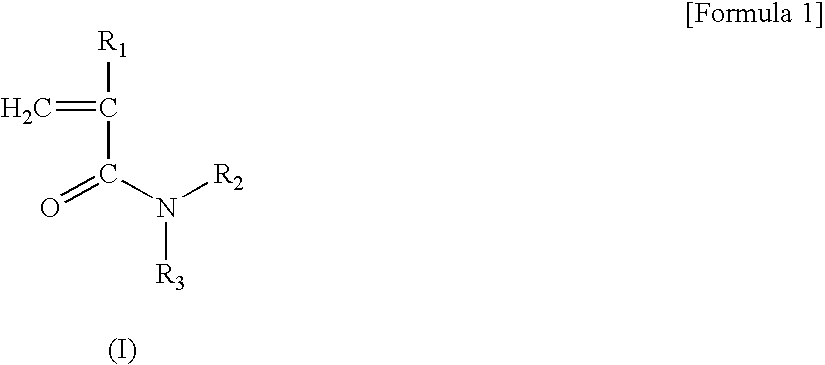

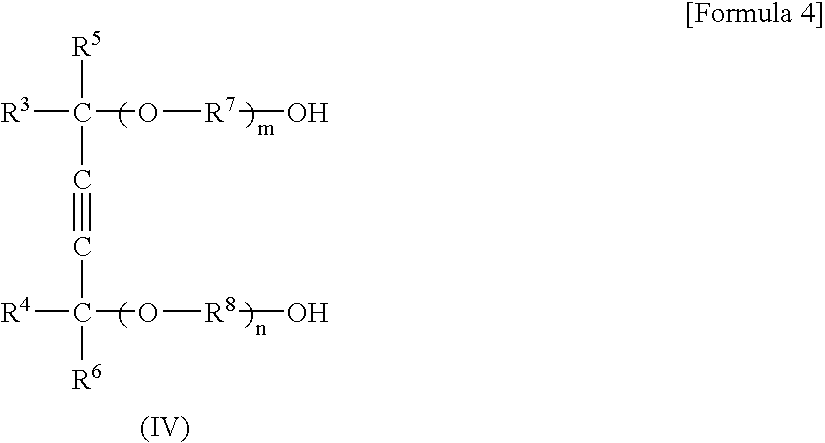

The polishing slurry of the invention is a polishing slurry for polishing a silicon oxide film on polysilicon, which contains an abrasive, polysilicon polishing inhibitor, and water. As the polishing inhibitor, it is preferable to use (1) a water-soluble polymer having a N-monosubstituted or N,N-disubstituted skeleton substituted by any member selected from the group consisting of acrylamide, methacrylamide, and α-substituted derivatives thereof, (2) polyethylene glycol, (3) an oxyethylene adduct of an acetylene-based diol, (4) a water-soluble organic compound having an acetylene bond, (5) an alkoxylated linear aliphatic alcohol, or (6) a copolymer containing polyvinyl pyrrolidone or vinyl pyrrolidone. There is provided a polishing method which is capable of polishing a silicon oxide film on a polysilicon film at a high speed, and inhibiting the progress of polishing of a polysilicon film in exposed parts in the manufacturing method for a semiconductor.

Owner:HITACHI CHEM CO LTD

Tooth whitening compositions and delivery systems therefor

InactiveUS20060024244A1Sufficient amountCosmetic preparationsContainers for annular articlesPolyphosphateSilicon dioxide

Stain-removing oral compositions, such as gum compositions are herein provided. The compositions include an orally acceptable carrier and a stain-removing anionic surfactant. The surfactant includes a fatty acid salt having at least one hydroxyl functionality. The fatty acid salt may be a salt of ricinoleic acid, and may be combined with a chelating agent and / or an abrasive. The chelating agent may be a polyphosphate and the abrasive may be a silica abrasive.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Methods of cleaning and cutting using jetted fluids

InactiveUS20050183741A1Inorganic/elemental detergent compounding agentsDetergent mixture composition preparationAbrasive agentLiquid based

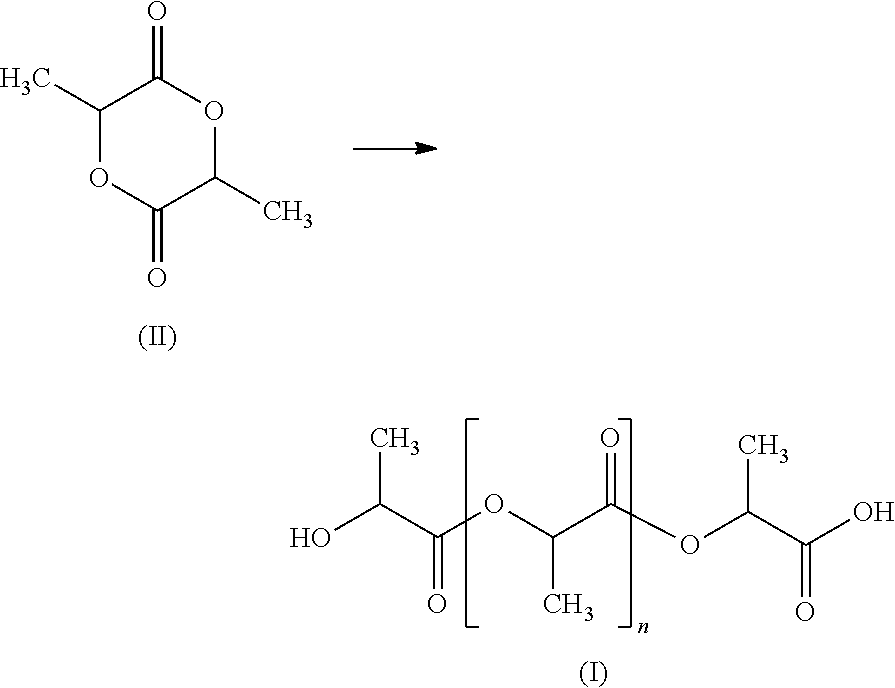

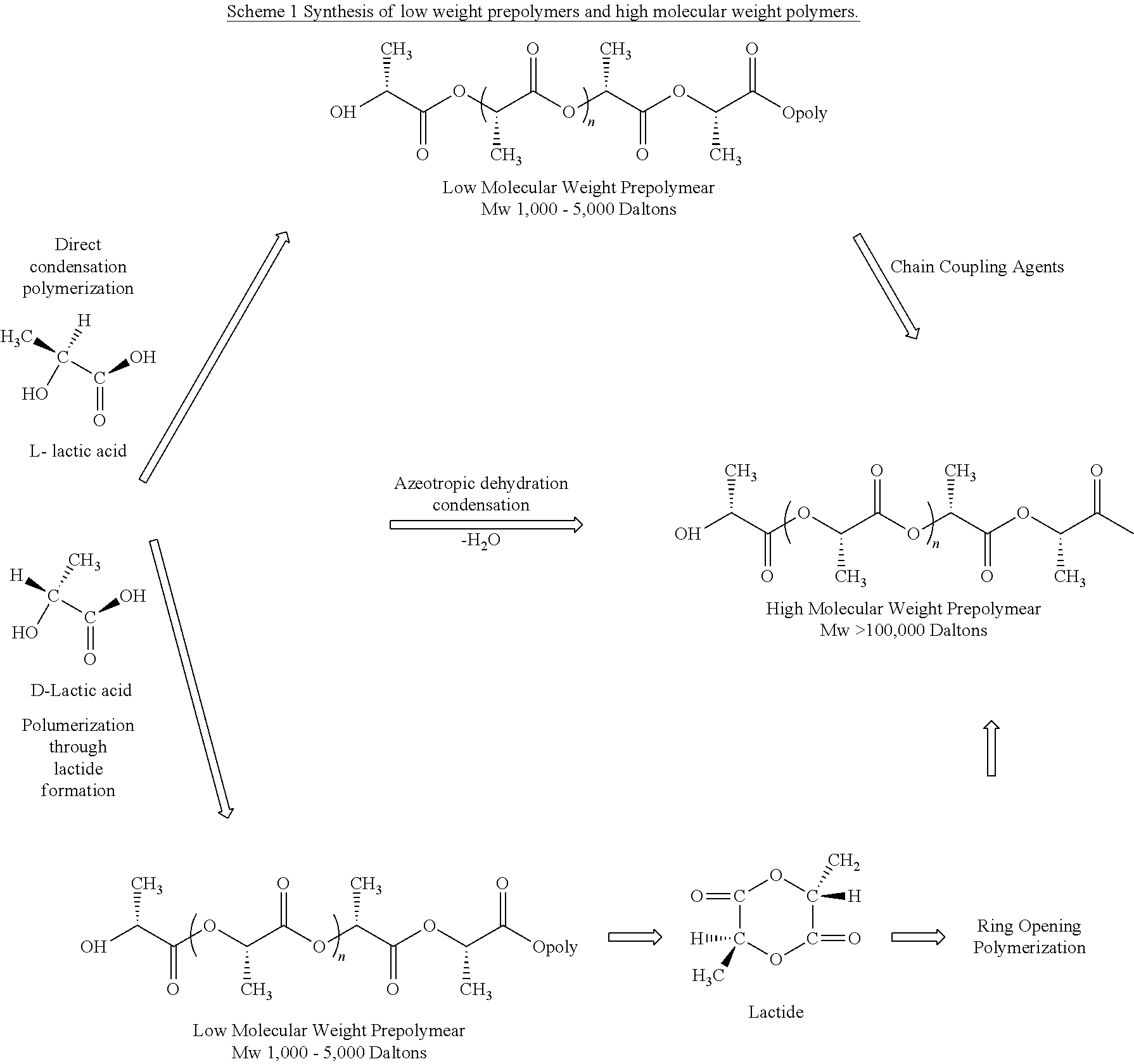

Methods of cleaning a surface comprising the step of jetting against a surface to be cleaned, a cleaning fluid comprising a liquid base fluid and degradable particles wherein the degradable particles act as an abrasive agent.

Owner:HALLIBURTON ENERGY SERVICES INC

Liquid cleaning and/or cleansing composition comprising a polylactic acid biodegradable abrasive

InactiveUS8440603B2Improve performanceImprove securityInorganic/elemental detergent compounding agentsCosmetic preparationsAbrasive agentPolymer chemistry

The present invention relates to a liquid, cleaning and / or cleansing composition comprising biodegradable abrasive cleaning particles.

Owner:THE PROCTER & GAMBLE COMPANY

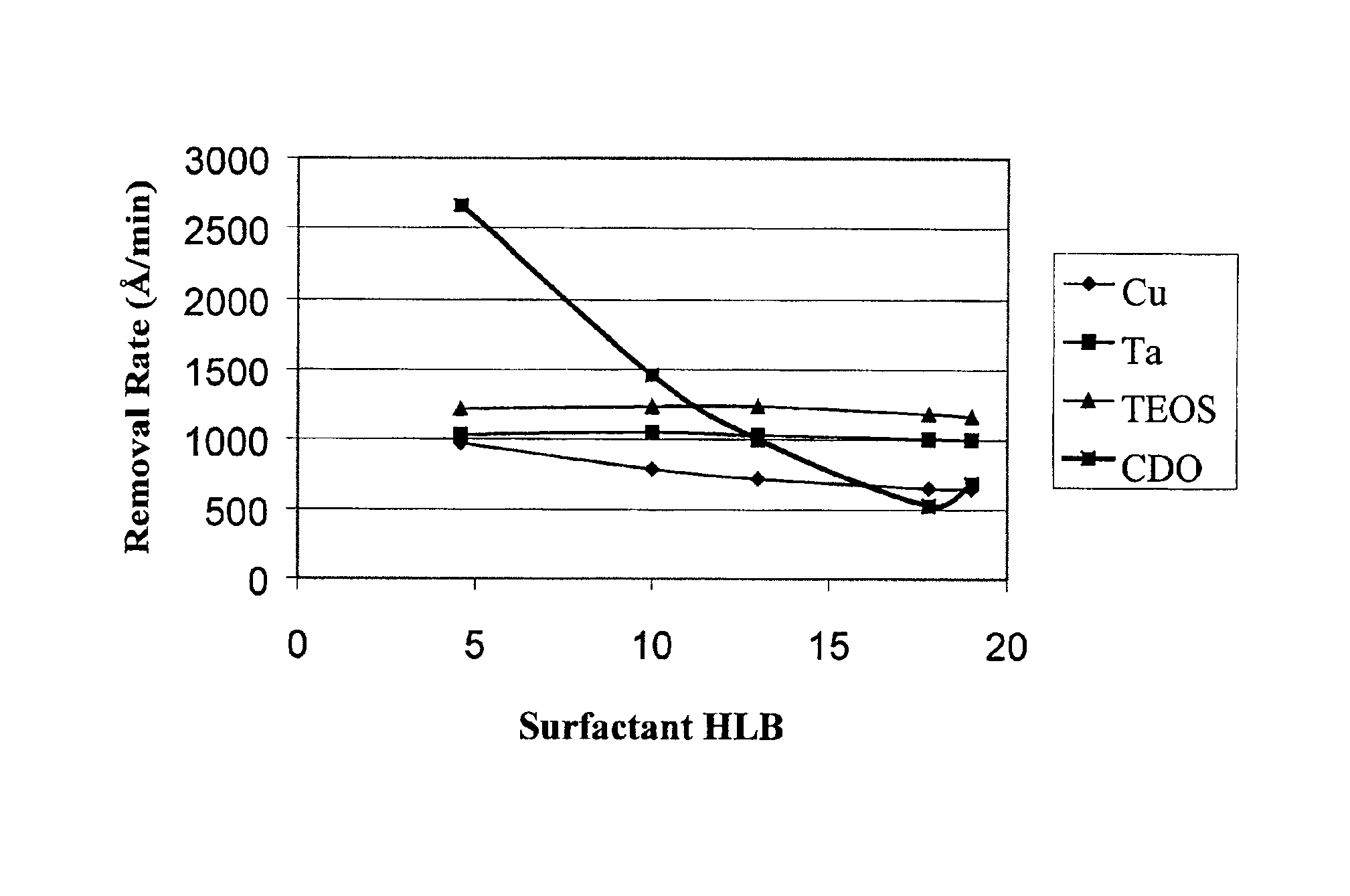

CMP compositions for low-k dielectric materials

InactiveUS6974777B2Non-ionic surface-active compoundsOther chemical processesLow-k dielectricNonionic surfactant

The invention provides a method of polishing a substrate containing a low-k dielectric layer comprising (i) contacting the substrate with a chemical-mechanical polishing system comprising (a) an abrasive, a polishing pad, or a combination thereof, (b) an amphiphilic nonionic surfactant, and (c) a liquid carrier, and (ii) abrading at least a portion of the substrate to polish the substrate.

Owner:CMC MATERIALS INC

Polyurethane foam products with controlled release of agents and additives

InactiveUS6706775B2High densityLow densityPowder deliveryBiocideSuperabsorbent polymerIndividual animal

Owner:H H BROWN SHOE TECH

Surface modified colloidal abrasives, including stable bimetallic surface coated silica sols for chemical mechanical planarization

A composition and an associated method for chemical mechanical planarization (or other polishing) are described. The composition includes a surface-modified abrasive modified with at least one stabilizer and at least one catalyst differing from the at least one stabilizer. The composition can further include a medium containing the abrasive and an oxidizing agent (e.g., hydrogen peroxide), wherein the at least one catalyst is adapted to catalyze oxidation of a substrate by the oxidizing agent. Preferably, the abrasive is alumina, titania, zirconia, germania, silica, ceria and / or mixtures thereof, the stabilizer is B, W and / or Al, and the catalyst is Cu, Fe, Mn, Ti, W and / or V. Both the stabilizer and the catalyst are immobilized on the abrasive surface. The method includes applying the composition to a substrate to be polished, such as substrates containing W, Cu and / or dielectrics.

Owner:VERSUM MATERIALS US LLC

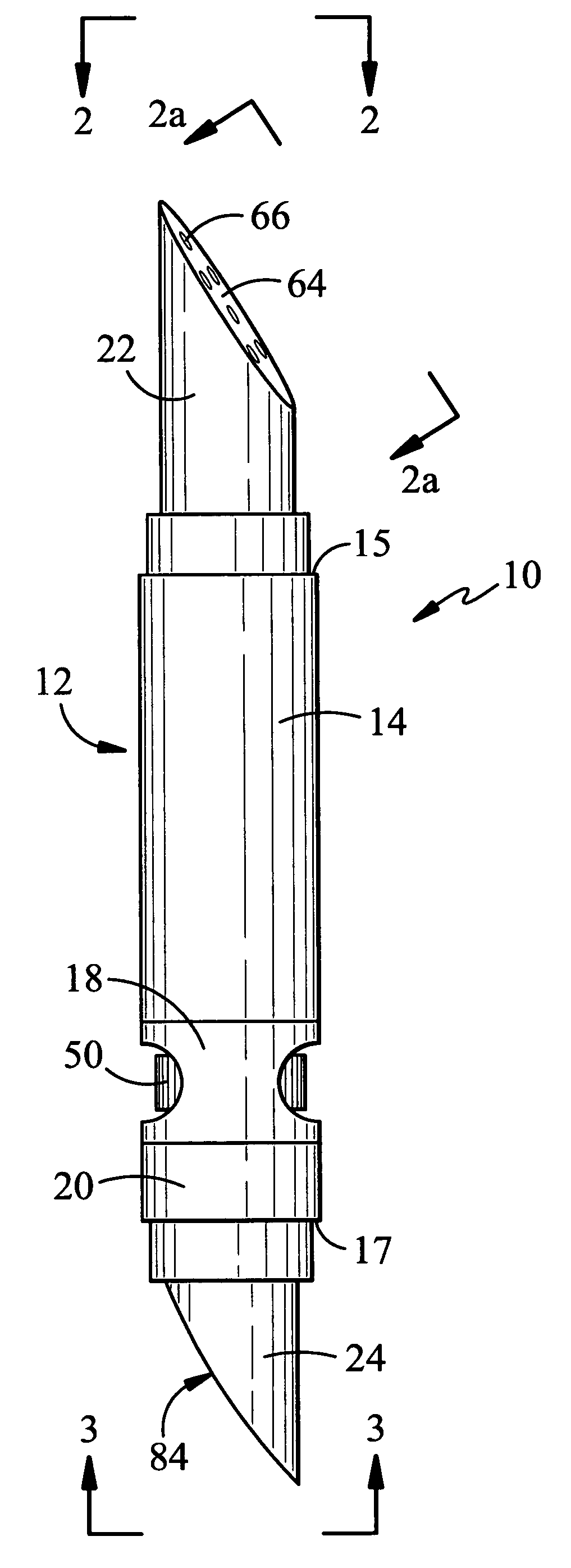

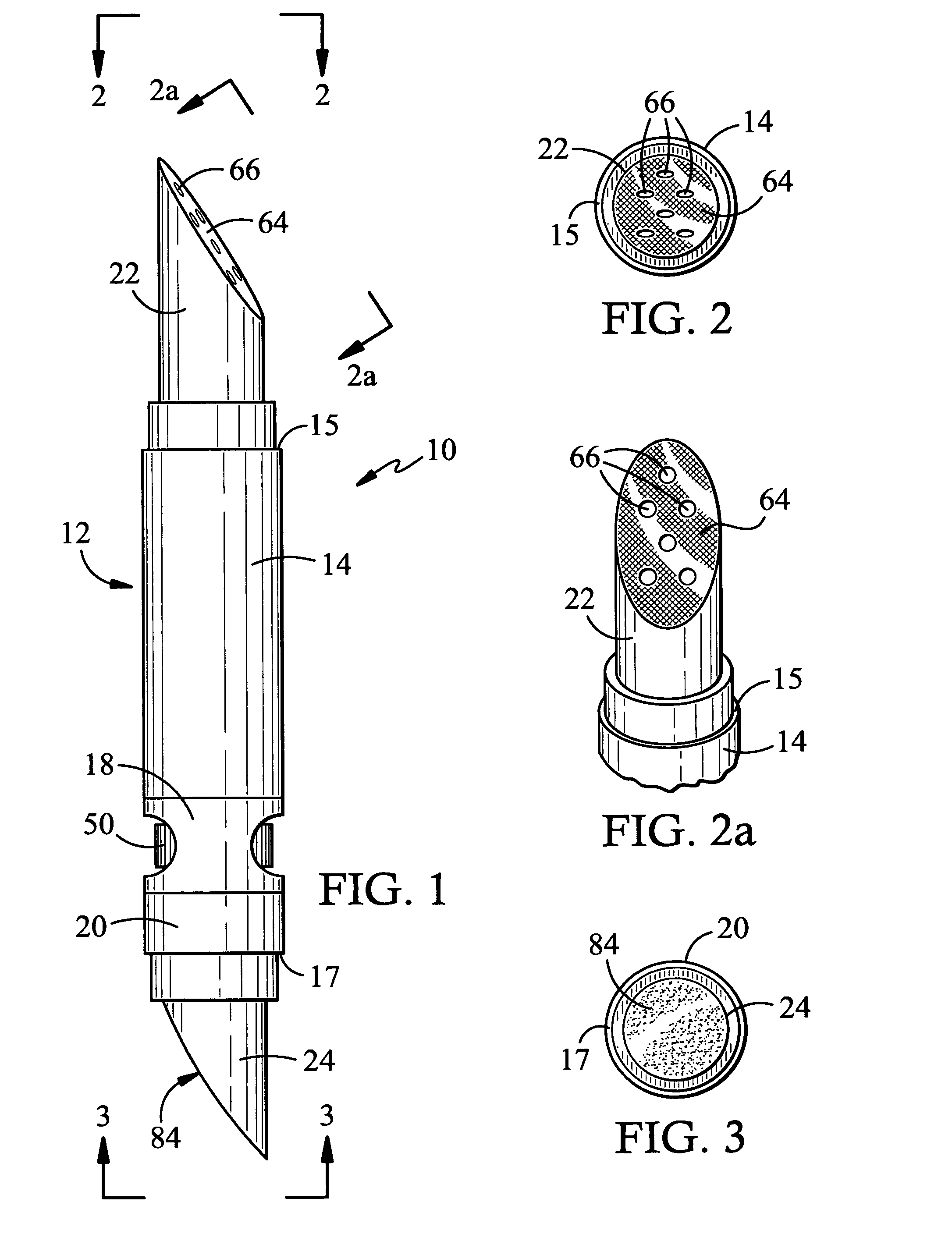

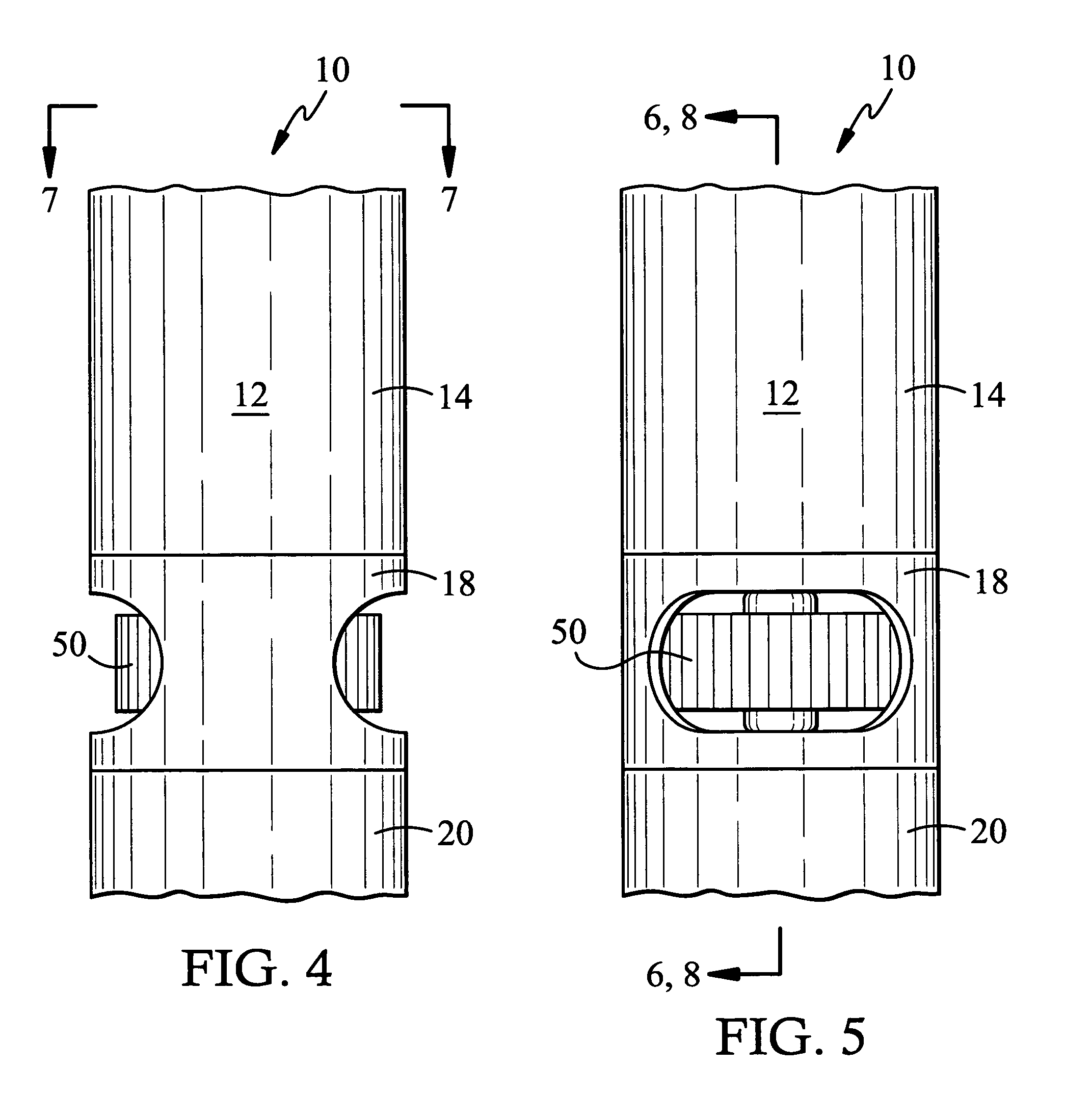

Cosmetic applicator device

InactiveUS7785026B2Easy accessEasy to useLiquid surface applicatorsCleaning machinesDead cellAbrasive agent

Owner:TOPLINE PROD

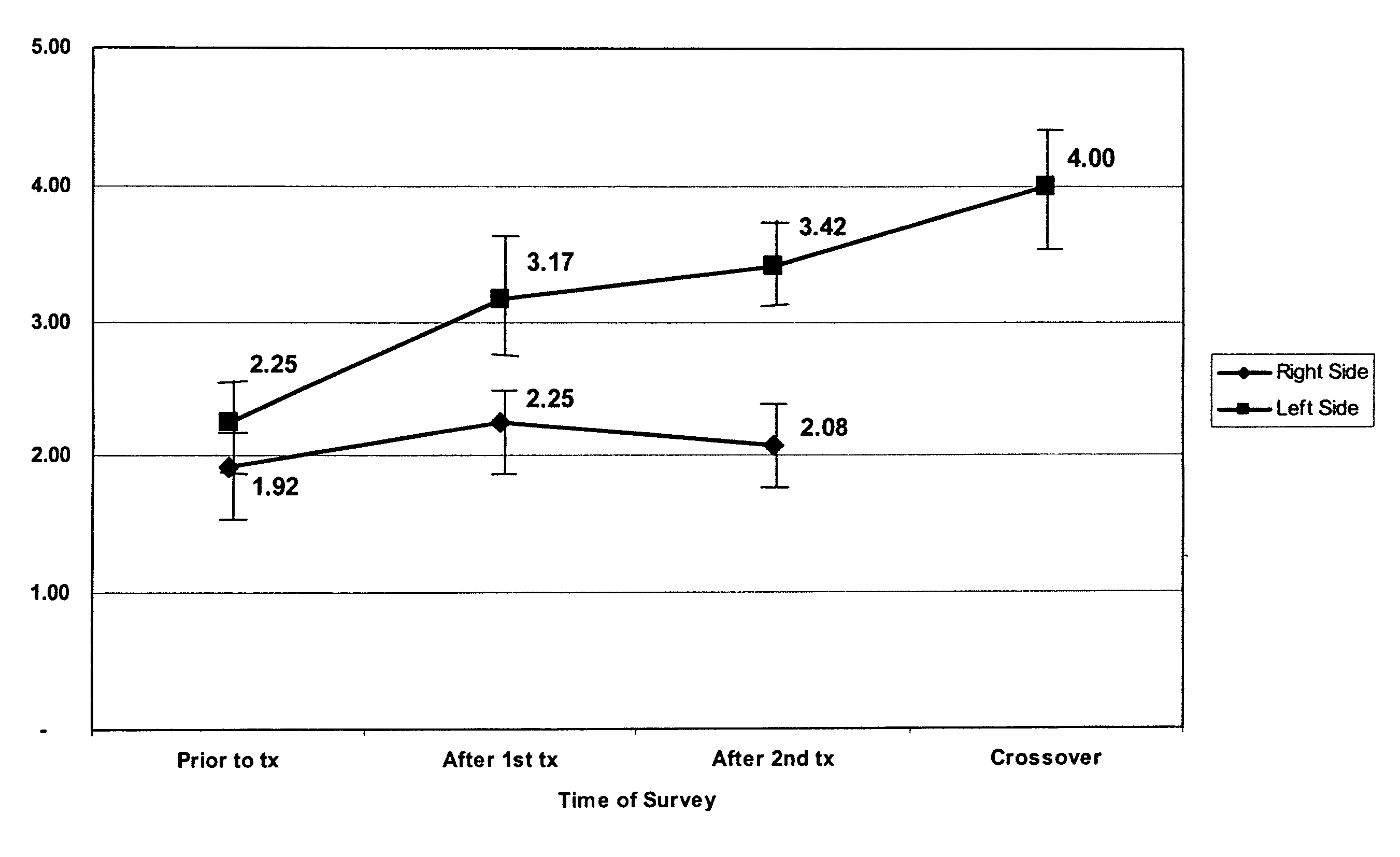

Methods and compositions for treating skin lines and wrinkles and improving skin quality

InactiveUS20070065515A1Improve skin textureImprove skin qualityPowder deliveryCosmetic preparationsWrinkle skinDermabrasion

Methods and compositions for improving skin quality are disclosed. The methods include applying a solution of about 20-30% pre-wetting agent, such as hyaluronic acid, to a skin surface with concurrent dermabrasion treatment. These methods lead to significant improvement in the treatment of skin aging. Compositions for improving skin quality are also disclosed. These compositions comprise a pre-wetting agent and an abrasive agent.

Owner:KEY DOUGLAS J

Toothpaste containing notoginseng extract and preparing method

ActiveCN101023914AAvoid bleedingPrevent Mouth UlcersCosmetic preparationsToilet preparationsDiseaseFoaming agent

The present invention relates to a toothpaste containing notoginseng extract and its preparation method. Its composition includes (by wt%) 0.07%-1.2% of notoginseng extract, 30%-55% of abrasive agent, 15%-30% of moistening agent, 0.6%-1.5% of binder and 2%-2.7% of foaming agent. Said toothpaste containing notoginseng extract has the health-care functions of preventing and curing the diseases of peridentitis, gingivitis, gingival bleeding and stomatocace, etc.

Owner:昆明牙膏有限责任公司

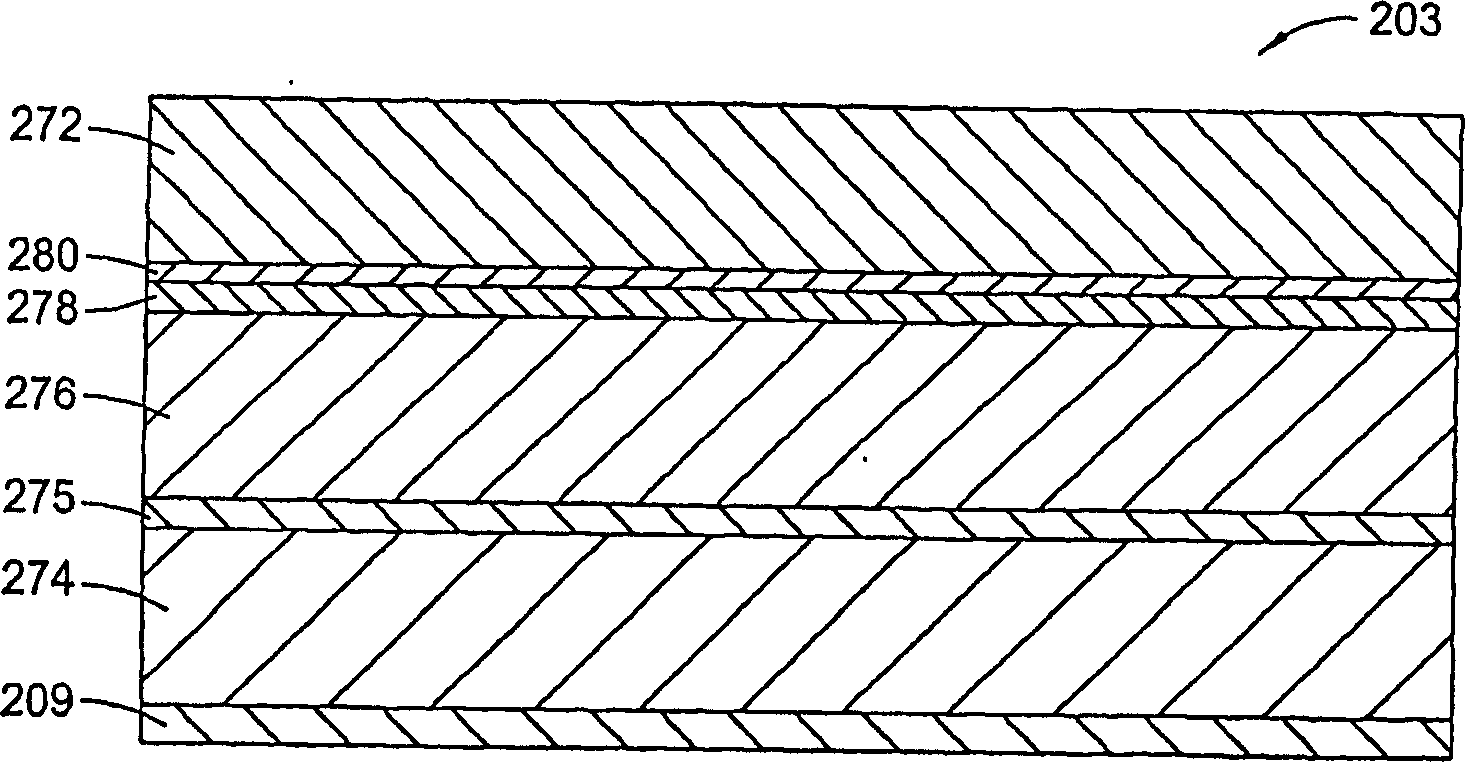

Method of polishing a multi-layer substrate

InactiveUS6852632B2Increase rate increaseOther chemical processesAbrasion apparatusThiocarboxylic acidNitroso

The invention provides a method for polishing one or more layers of a multi-layer substrate that includes a first metal layer and a second layer comprising (i) contacting the first metal layer with a polishing system comprising a liquid carrier, at least one oxidizing agent, at least one polishing additive that increases the rate at which the system polishes at least one layer of the substrate, wherein the polishing additive is selected from the group consisting of pyrophosphates, condensed phosphates, phosphonic acids and salts thereof, amines, amino alcohols, amides, imines, imino acids, nitriles, nitros, thiols thioesters, thioethers, carbothiolic acids, carbothionic acids, thiocarboxylic acids, thiosalicylic acids, and mixtures thereof, and a polishing pad and / or an abrasive, and (ii) polishing the first metal layer with the system until at least a portion of the first metal layer is removed from the substrate.

Owner:CABOT MICROELECTRONICS CORP

Polishing film and method for making same

ActiveCN101225281AUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventRoller Coating Method

The invention discloses a polishing film and the preparation method, which adopts the ultrafine micro mist as the grinding material and prepares in flow-casting coating method, namely the powdered or granular resin is dissolved into the organic solvent and then added in functional additive to make the resin adhesive, then the abrasive of surface-modified ultrafine micro mist is added into the resin adhesive and the spread coating liquid can be obtained after fully mixing, finally the paint is painted on the surface of soft base in flow-casting coating method and the polishing film can be obtained after drying and curing. The preparation method of the polishing film has the advantages of small equipment investment, simple operation, high productivity and automation level, steady craft, even film performance and low manufacturing cost. The polishing film can adjust the craft parameters of the flow-casting craft conveniently according to the different quality requirement and standards of the products, and can achieve production in multi-specification and small lot production and overcomes the problems that the rapid transformation of the product specification is difficult due to the limit of the equipment structure in roller coating method.

Owner:HENAN UNION ABRASIVES

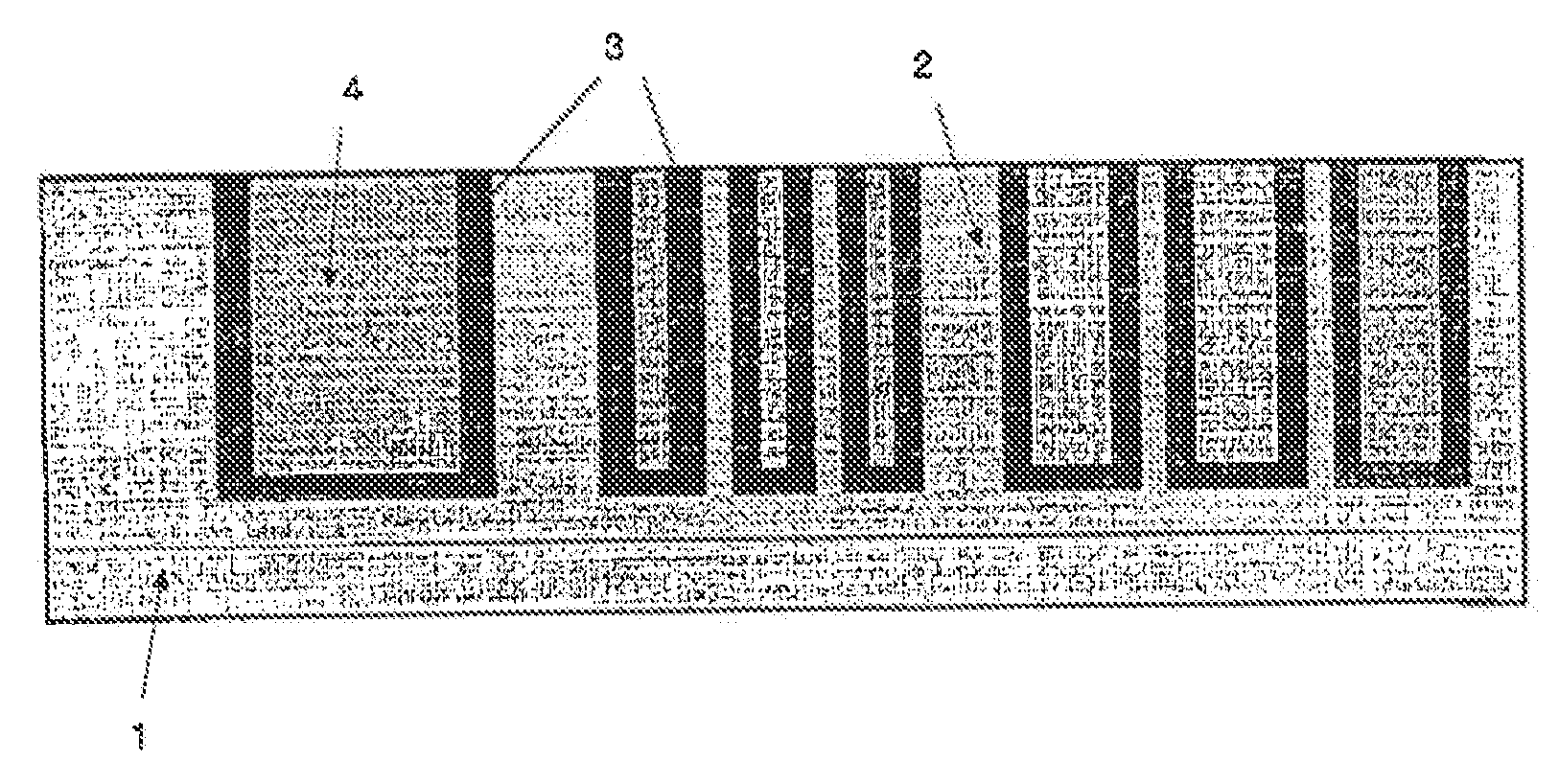

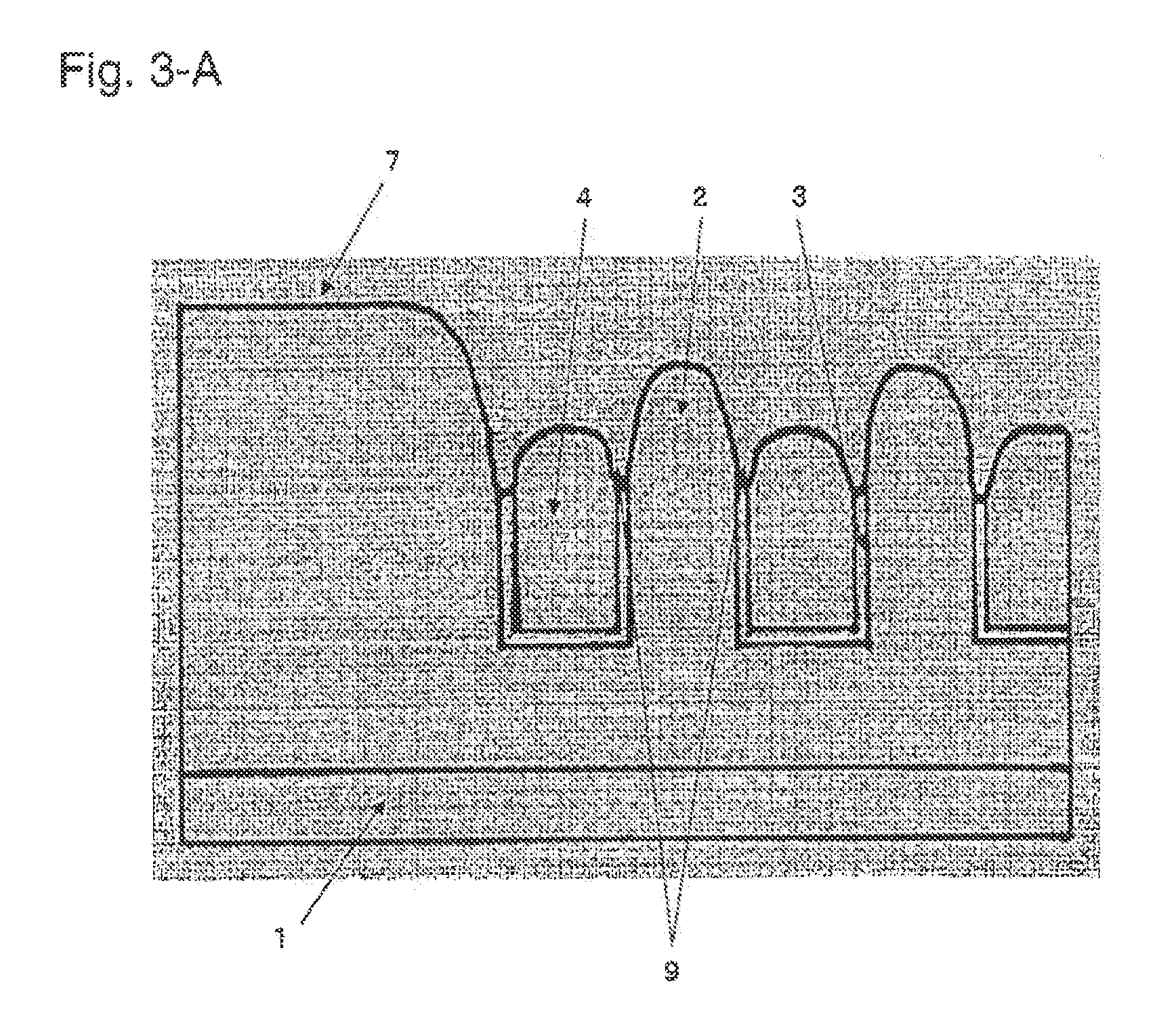

Method for grinding soft crisp functional crystal

InactiveCN101376228AAvoid scratchesPrevent embeddingSupport wheelsAqueous dispersionsHigh surfaceGrinding wheel

A soft brittle functional crystal grinding and machining method belongs to the technical field of soft brittle functional crystal machining, and particularly relates to a soft brittle functional crystal ultra-precision grinding and machining method for a semiconductor and a photoelectric crystal. The method is characterized in that a micro-powder diamond segmental variable speed feed and a soft abrasion grinding wheel chemical mechanical grinding method are adopted to machine the soft brittle function crystal. During the crude grinding period and the accurate grinding period, the feeding speed of the grinding wheel is firstly high and then low. A grinding fluid is de-ionized water. A soft abrasive agent grinding wheel is adopted to conduct the chemical mechanical grinding. The soft abrasive agent is a macromolecule polymer or waterproof resin. A filler is NaHCO3 or a refined naphthalene foaming agent. The chemical and mechanical grinding fluid is adopted as a reaction fluid and a cooling fluid. The grinding fluid mainly contains lactic acid, acetic acid and de-ionized water. The pH value of the grinding fluid is 2-4. The invention has the advantages of high grinding and machining efficiency, low machining cost and high surface precision. In addition, no surface / sub-surface damage is caused to the surface of a workpiece, such as small scratches, embedment of free abrasive agent, plastic deformation, residual stress, and the like.

Owner:DALIAN UNIV OF TECH

Process and slurry for chemical mechanical polishing

InactiveUS20050009714A1Semiconductor/solid-state device manufacturingLiquid carbonaceous fuelsCompound (substance)Abrasive agent

The invention provides a chemical-mechanical polishing process for polishing the surface of a semiconductor wafer, which comprises the steps of separately preparing a chemical agent and an abrasive agent, combining them into an abrasive slurry at the beginning of the polishing procedure or at the platen end, and polishing the metal layer on the surface of the semiconductor wafer with said admixed abrasive slurry. The invention further provides a chemical-mechanical polishing slurry for polishing the surface of a semiconductor wafer, characterized by being prepared by the steps of separately preparing a chemical agent and an abrasive agent and then combining them at the beginning of the polishing procedure or at the platen end, wherein said chemical agent comprises an aqueous medium, a corrosion inhibitor, and an ionic surfactant, and said abrasive agent comprises abrasive particles and deionized water.

Owner:ETERNAL MATERIALS CO LTD

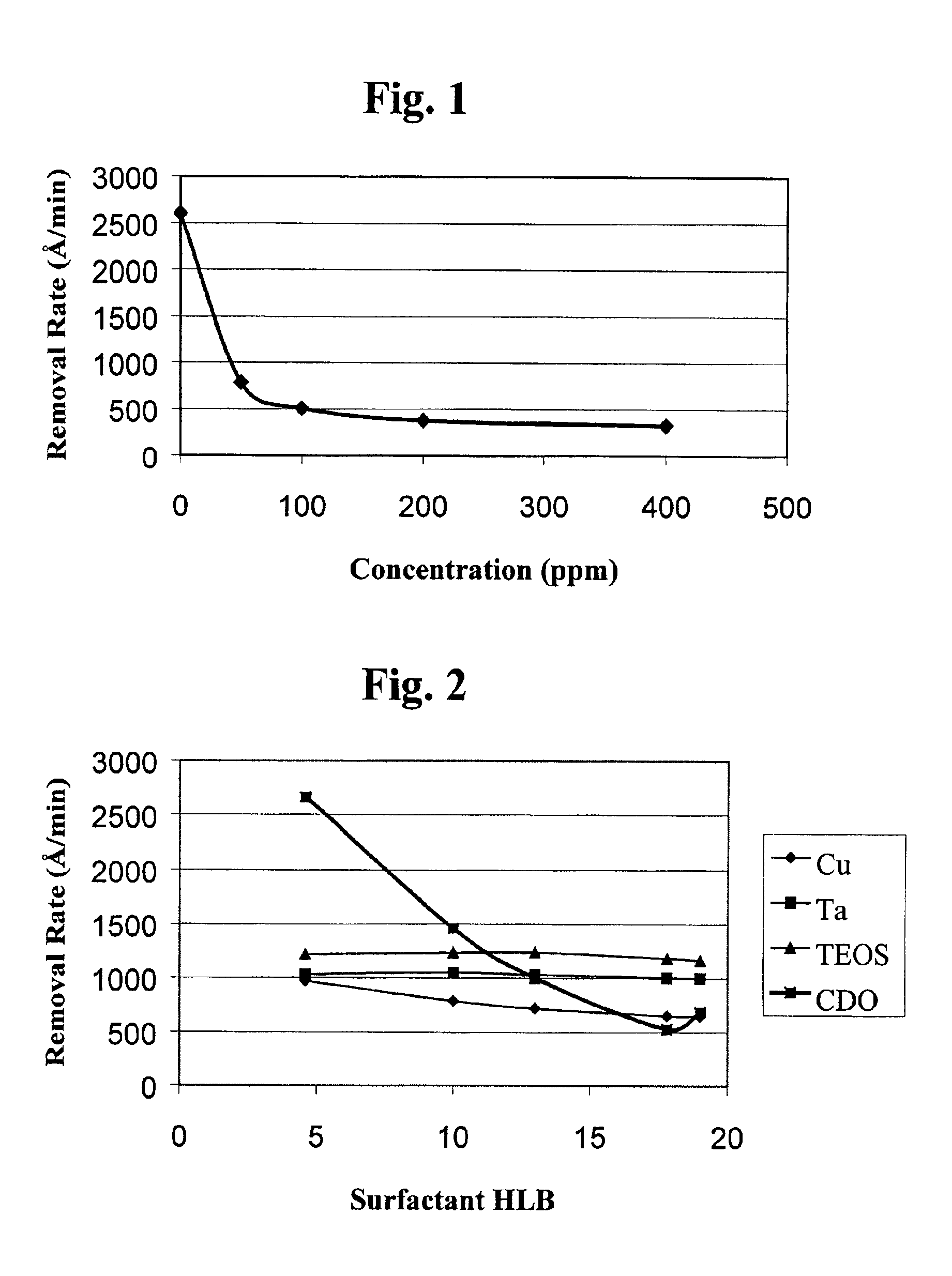

Anionic abrasive particles treated with positively charged polyelectrolytes for cmp

InactiveCN1630697AIncrease speedIdeal planarization efficiencyOther chemical processesSemiconductor/solid-state device manufacturingPolyelectrolytePolymer science

The invention provides chemical-mechanical polishing systems, and methods of polishing a substrate using the polishing systems, comprising (a) an abrasive, (b) a liquid carrier, and (c) a positively charged polyelectrolyte with a molecular weight of about 15,000 or more, wherein the abrasive comprises particles that are electrostatically associated with the positively charged polyelectrolyte.

Owner:CMC MATERIALS INC

Polishing agent and method for polishing substrate using the polishing agent

ActiveCN102017091AHigh speed and low grinding damageOther chemical processesSemiconductor/solid-state device manufacturingAbrasive agentSilicon oxide

Disclosed is a polishing agent comprising water, particles of a tetravalent metal hydroxide, and an additive. The additive contains at least one of a cationic polymer and a polysaccharide. In a CMP technique for flattening an insulating film, the polishing agent can polish the insulating film at a high speed without causing significant polishing flaws and has a high polishing speed ratio between a silicon oxide film and a stopper film. Also disclosed are a polishing agent set for storing the polishing agent and a method for polishing a substrate using the polishing agent.

Owner:株式会社力森诺科

Sprayable liquid abrasive cleanser with polyethylene glycol

InactiveUS20120258903A1Readily and reliable sprayableEasy to cleanNon-ionic surface-active compoundsSoap detergents with inorganic compounding agentsCleansers skinHard-surface cleaner

Liquid abrasive cleanser compositions sprayable through conventional manual trigger sprayers comprise a polyalkylene glycol, a nonionic surfactant, a pH adjusting agent, an abrasive, and water, wherein sprayability is made possible by the addition of the polyalkylene glycol. The compositions that are sprayable and acceptable as hard surface cleaners comprise polyethylene glycol as the polyalkylene glycol. The addition of polyethylene glycol having molecular weight of from about 4,000 to about 1,000,000 dramatically increases the sprayer output volume of liquid abrasive compositions having greater than or equal to 10 wt. % calcium carbonate. Addition of polyethylene glycol of molecular weight of from about 4,000 to about 100,000 converts otherwise non-sprayable liquid abrasive compositions into reliably sprayable compositions.

Owner:DIAL CORPORATION

Polishing composition and method for polishing a conductive material

InactiveCN1842577AReduce concentrationLow pHOther chemical processesSemiconductor/solid-state device manufacturingParticulatesPhosphoric acid

A method of processing a substrate having a conductive material layer disposed thereon is provided which includes positioning the substrate in a process apparatus and supplying a first polishing composition between to the substrate. The polishing composition comprises phosphoric acid, at least one chelating agent, a corrosion inhibitor, a salt, an oxidizer, abrasive particulates, at least one pH adjusting agent to provide a pH from about 4 to about 7 and a solvent. The method further includes forming a passivation layer on the conductive material layer, removing the passivation layer to expose a portion of the conductive material layer, applying a first bias to the substrate, and removing at least about 50% of the conductive material layer. The method further includes separating the substrate from the first polishing composition, exposing the substrate to a second polishing composition and a second bias, and continuing to remove the conductive material layer.

Owner:APPLIED MATERIALS INC

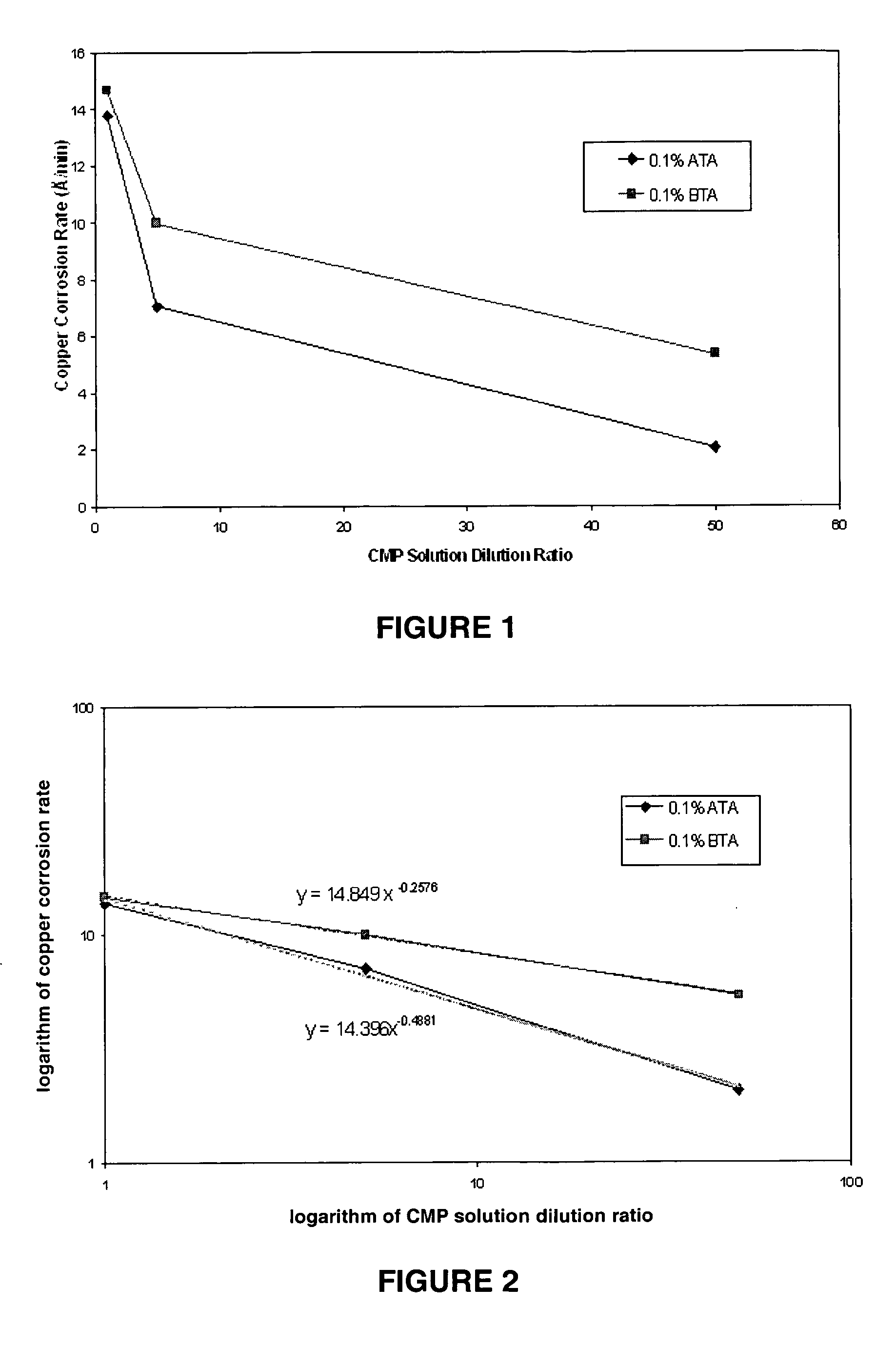

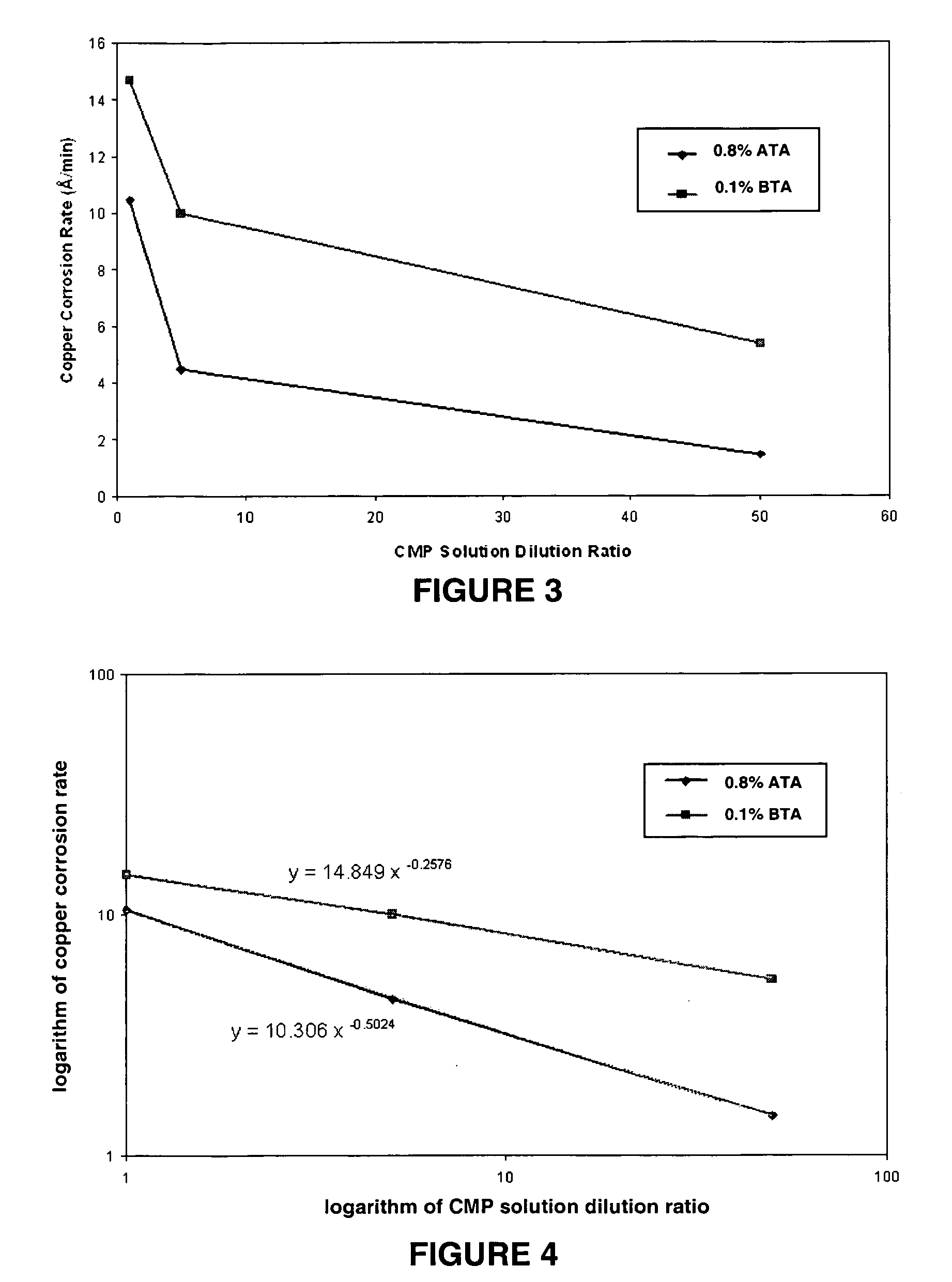

Passivative chemical mechanical polishing composition for copper film planarization

InactiveUS20050255693A1Semiconductor/solid-state device manufacturingPolishing compositions with abrasivesPhysical chemistryCompound (substance)

A CMP composition containing 5-aminotetrazole, e.g., in combination with oxidizing agent, chelating agent, abrasive and solvent and a method of use. Such CMP composition may be diluted during the CMP polish to minimize the occurrence of dishing or other adverse planarization deficiencies in the polished copper, even in the presence of substantial levels of copper ions in the CMP composition and at the copper / CMP composition interface during CMP processing.

Owner:ENTEGRIS INC

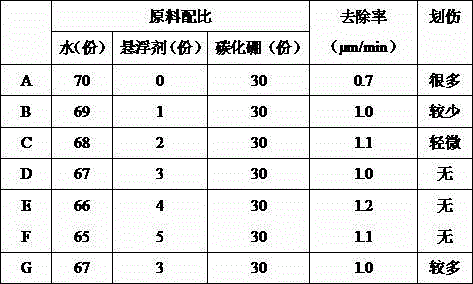

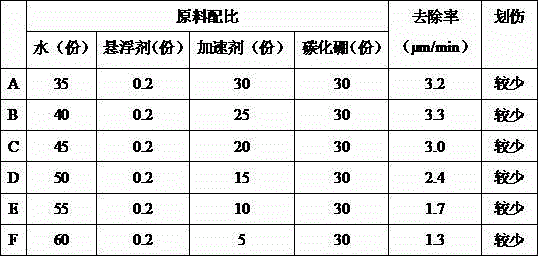

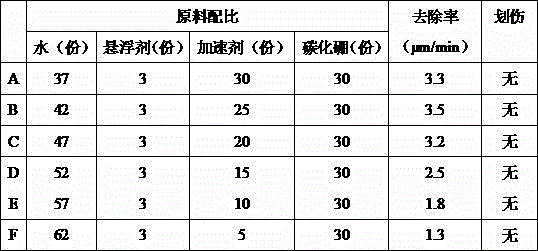

High-performance sapphire grinding fluid and preparation method thereof

ActiveCN104592898AEvenly dispersed and stableSimple preparation processPolishing compositions with abrasivesAbrasive agentSapphire

The invention discloses a high-performance sapphire grinding fluid and a preparation method thereof. The grinding fluid is prepared from the following components in parts by weight: 3-60 parts of abrasive agent, 0.2-5 parts of suspending agent, 5-30 parts of accelerant and 12-70 parts of water; the pH value of the grinding fluid ranges from 7 to 13. The preparation method comprises the following steps: (1) weighing the abrasive agent, the suspending agent, the accelerant and the water according to the weight proportions; (2) dissolving the suspending agent into the water thoroughly and stirring evenly; (3) dispersing the abrasive agent in the liquid of the step (2) to form a suspension; (4) adding the accelerant to the suspension and stirring evenly; (5) regulating the pH value to the range of 7-13. The high-performance sapphire grinding fluid is good in suspension property, not easy to precipitate, high in removal rate and long in cyclic service life; the grinding processing efficiency can be greatly improved and the cost can be reduced.

Owner:JIANGSU SINO KRYSTALS OPTROINCS

Polishing compound, method for polishing surface to be polished, and process for producing semiconductor integrated circuit device

InactiveUS20080200033A1High removal rateSuppress polishingPigmenting treatmentOther chemical processesO-Phosphoric AcidTetrazole

To provide a polishing compound which is capable of polishing SiC at a high removal rate, or capable of suppressing polishing of silicon dioxide in an insulating layer on the other hand, while polishing SiC at a high removal rate, in production of a semiconductor integrated circuit device, whereby it is possible to obtain a semiconductor integrated circuit device having a planarized multiplayer structure.The present polishing compound comprising abrasive particles (A), an adjusting agent of removal rate (B) which is at least one selected from the group consisting of a benzotriazole, a 1H-tetrazole, a benzene sulfonic acid, phosphoric acid or organic phosphonic acid, an organic solvent (C) having a relative permittivity of from 15 to 80, a boiling point of from 60 to 250° C. and a viscosity of from 0.5 to 60 mPa·S at 25° C., and water (D).

Owner:ASAHI GLASS CO LTD

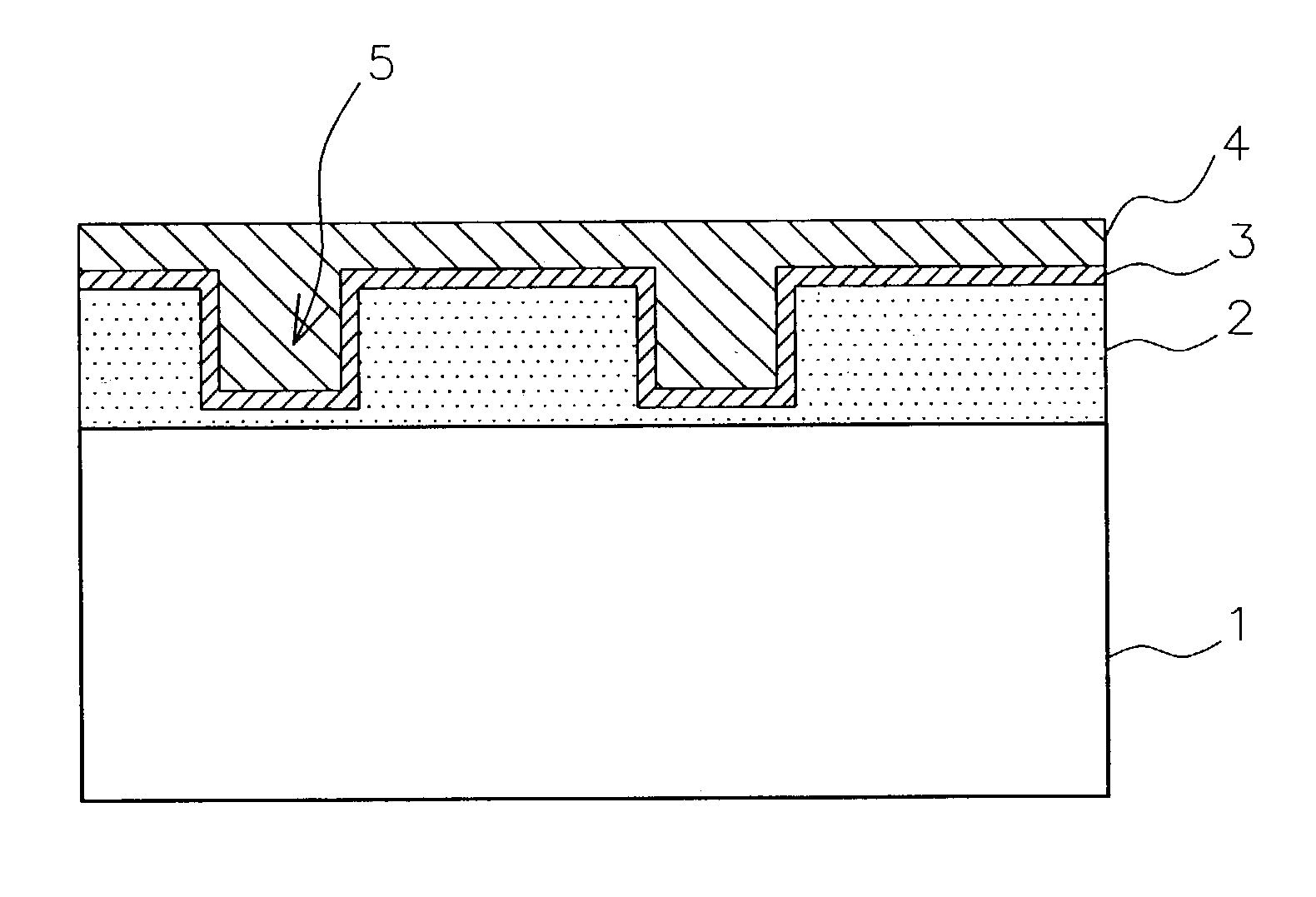

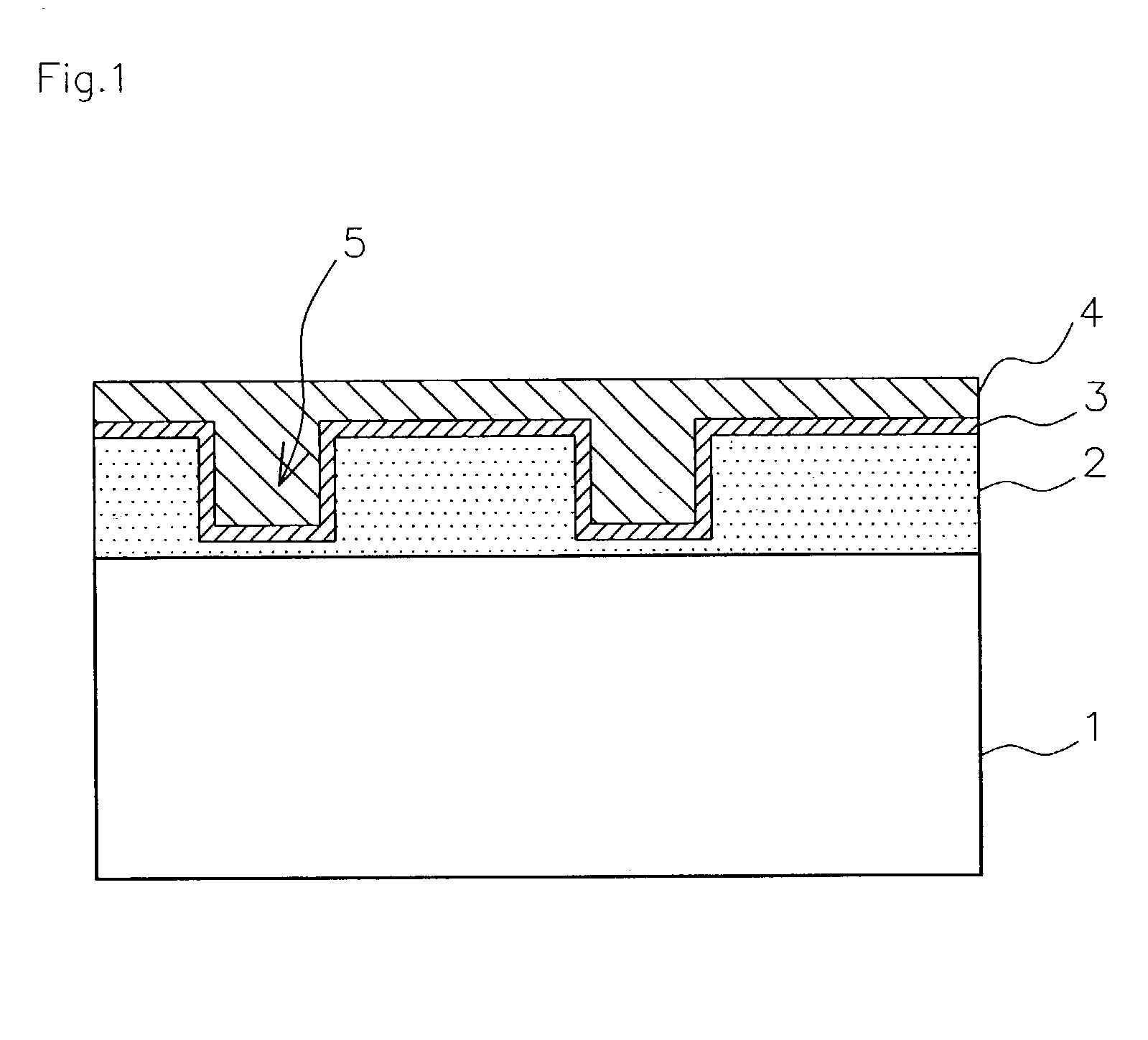

Process for chemical mechanical polishing of semiconductor substrate and aqueous dispersion for chemical mechanical polishing

InactiveUS7183211B2Reduce generationHigh removal rateOther chemical processesSemiconductor/solid-state device manufacturingDevice materialCarboxylic acid

The object of the present invention is to provide a process for chemical mechanical polishing of semiconductor substrate that is particularly useful for chemical mechanical polishing a wafer having a wiring pattern and an insulating layer having a low dielectric constant is formed between wiring patterns, interlayers in the case of a multi-layer wiring and the like in the process of producing a semiconductor device, and an aqueous dispersion for chemical mechanical polishing which is used in this process. The process for chemical mechanical polishing of a semiconductor substrate of the present invention is that a surface to be polished of the semiconductor substrate is polished under conditions of a rotation speed of a polishing table fixing a polishing pad at the range from 50 to 200 rpm and a pressing pressure of the semiconductor substrate fixed to a polishing head against a polishing pad at the range from 700 to 18,000 Pa, by using an aqueous dispersion for chemical mechanical polishing comprising an abrasive and at least one compound selected from the group consisting of polycarboxylic acid having a heterocycle and anhydride thereof, and the polishing pad.

Owner:JSR CORPORATIOON

High-precision compound polishing solution and preparation method thereof

InactiveCN106479371APolished lowReduce ratePolishing compositions with abrasivesSuspending AgentsSolvent

The invention provides a high-precision compound polishing solution. The high-precision compound polishing solution is prepared from components in percentage by weight as follows: 0.1%-50% of an abrasive, 0.01%-20% of a dispersant, 0.01%-15% of a suspending agent, 0.1%-5% of a corrosion inhibitor and the balance of a deionized water solvent. The polishing solution mainly adopts mechanical removal and can realize high-speed polishing of base materials; the preparation method has the advantages that the production efficiency is high, the continuity is high, the cost is low, the product fineness is high and the like and has no requirement for the particle size distribution and uniformity of raw materials for the abrasive, the selection range of the raw materials for the abrasive is broadened, and all powder materials meeting the average particle size requirement can be applied.

Owner:惠州市米特仑科技有限公司

Alkaline computer hard disk polishing liquid and producing method thereof

InactiveCN101016438AImprove polishing efficiencyPolishing machinesPolishing compositions with abrasivesAbrasive agentChemical preparation

The invention discloses a preparing method of alkality computer hard disk polishing liquid in chemical preparation domain, which comprises the following steps: setting pH value of polishing liquid at 7-10; making the mass percent of oxidant, organic complexing agent and grinding agent at 0.1%-5%, 0.1%-5% and 0.5%-20% separately; composing ingredient A with diamond pyramid hardness bigger than 7 and ingredient B with diamond pyramid hardness bigger than 5; getting grinding agent; forming oxidant, organic metal chelating agent, high hardness and low hardness rubbing agent in neutral and alkality agent; adopting soft and hard merging multiple polished rubbing particle method; decreasing grievous fish tail caused by big particle boule aluminum oxide; increasing graduation efficiency; This invention adopts alkality polishing agent, which decreases the polishing loss of hard disk edge.

Owner:孙韬

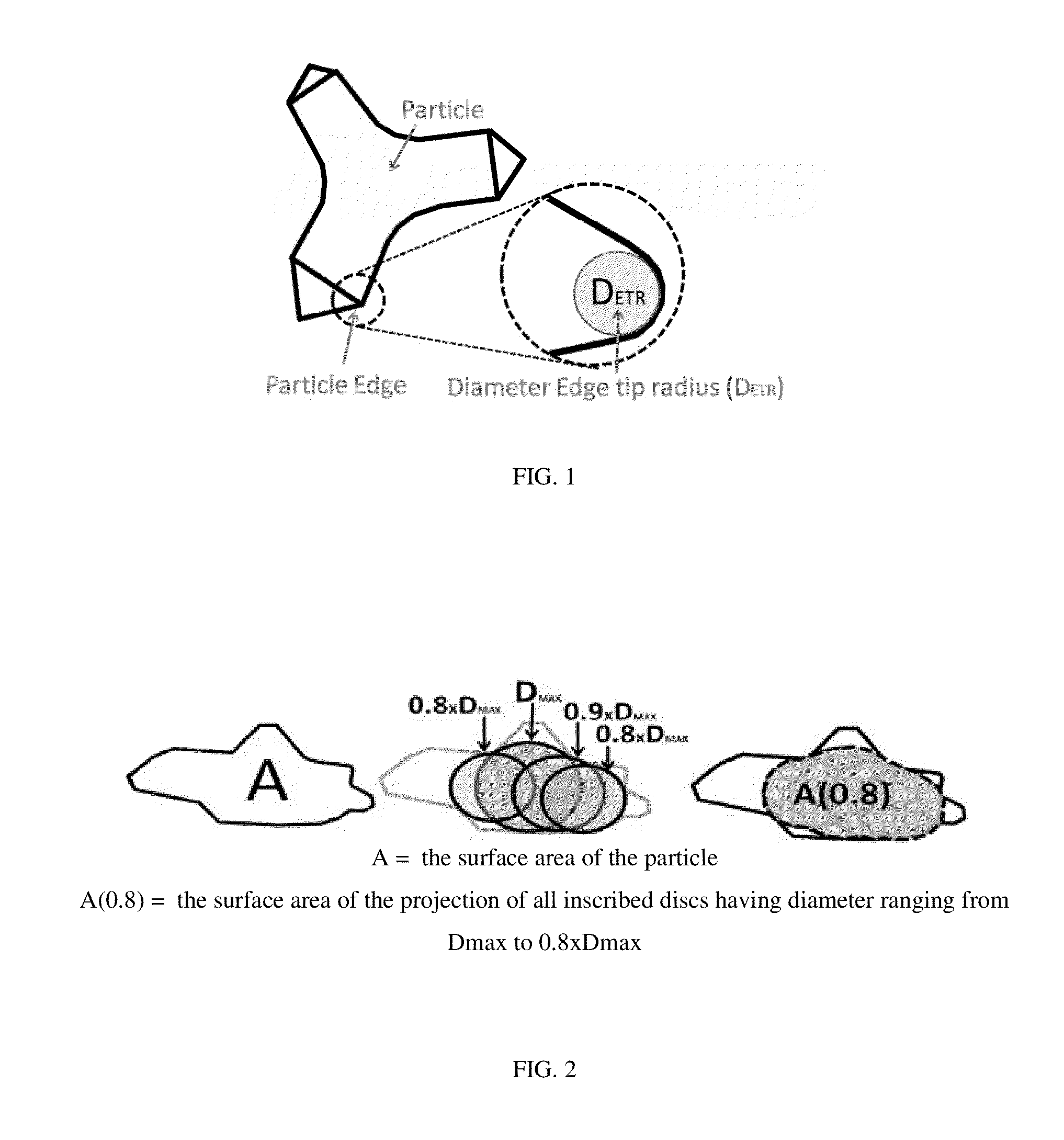

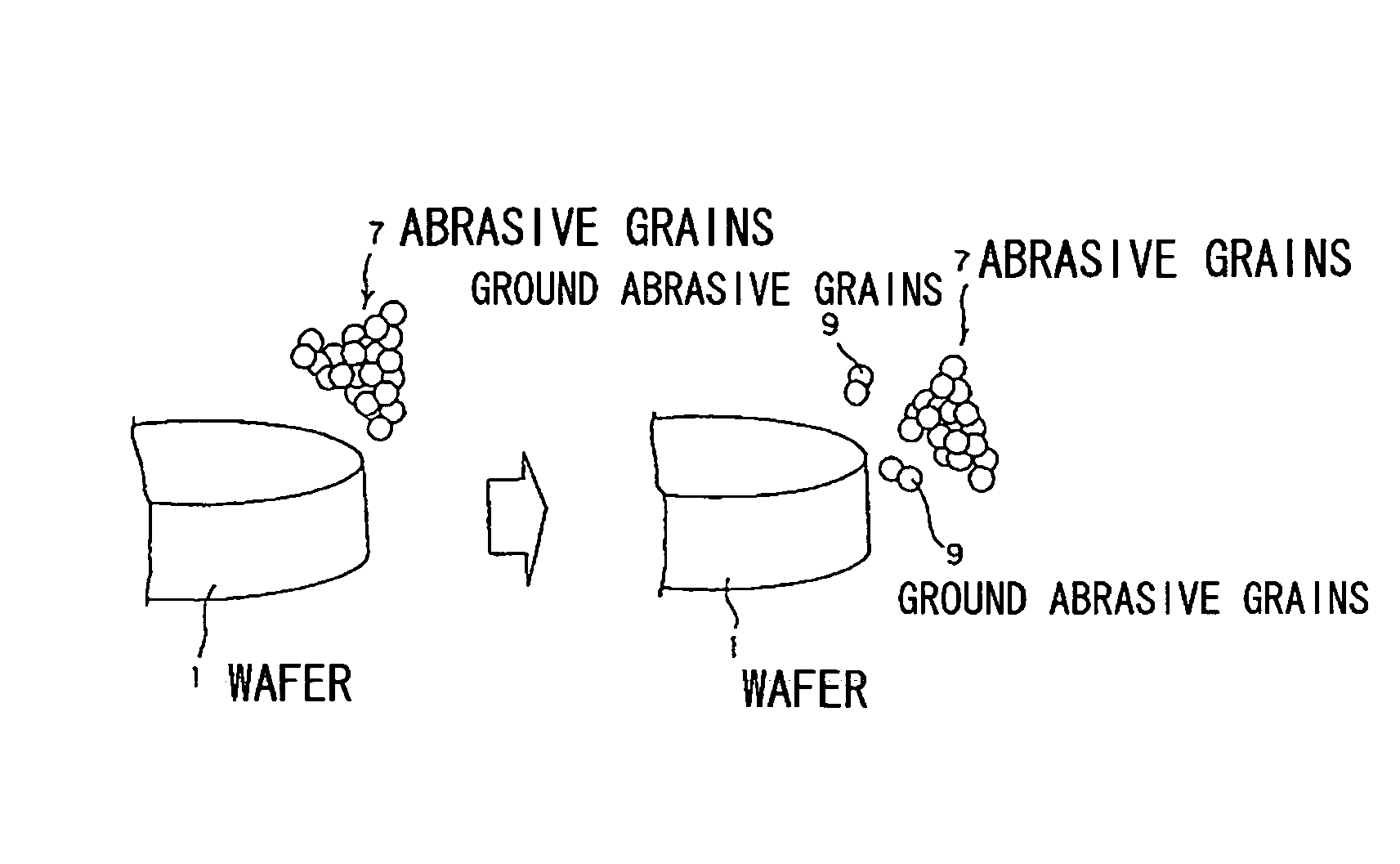

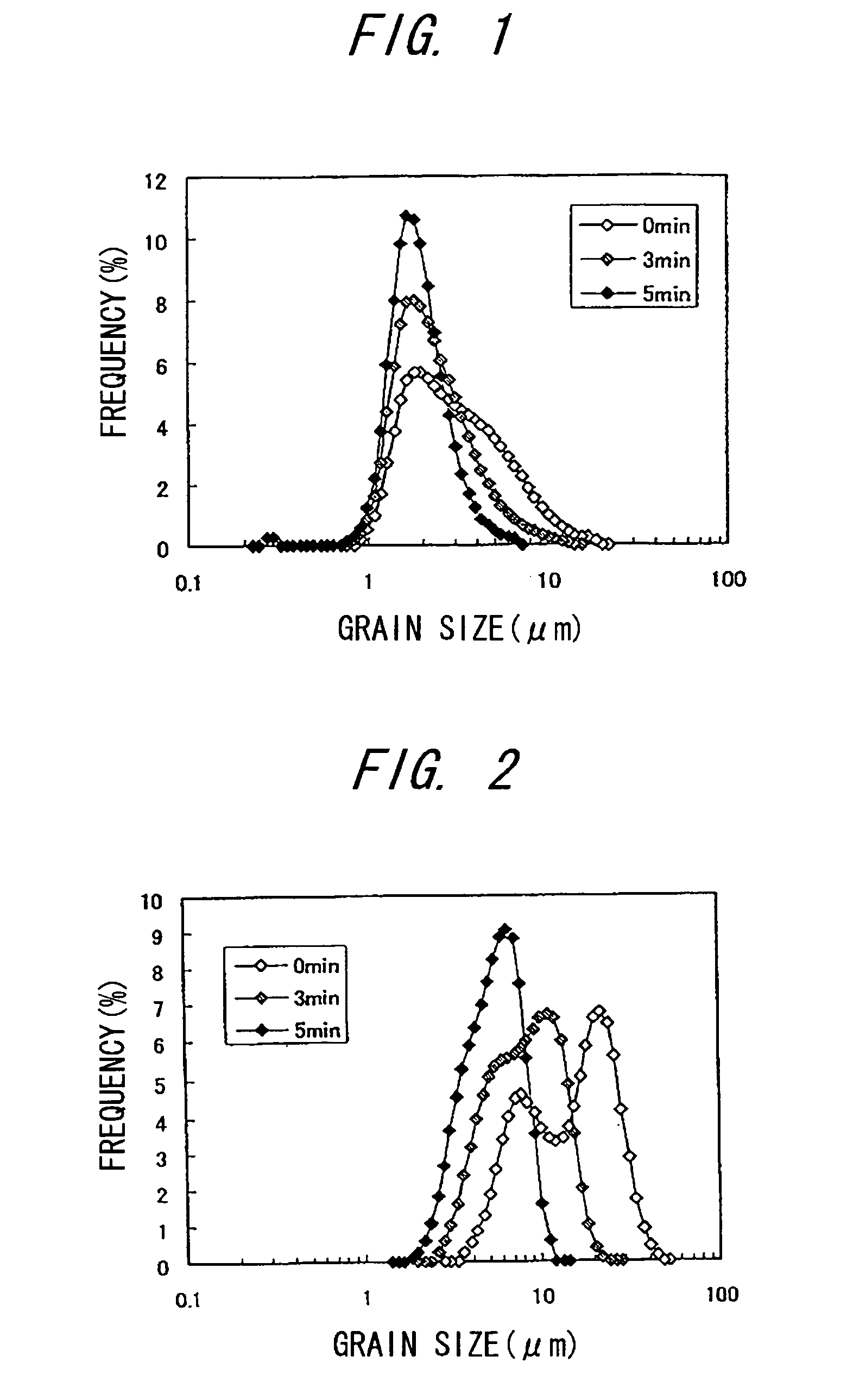

Grinding abrasive grains, abrasive, abrasive solution, abrasive solution preparation method, grinding method, and semiconductor device fabrication method

ActiveUS7267604B2High speed grindingLow mechanical strengthPigmenting treatmentOther chemical processesAbrasive agentSemiconductor

Abrasive grains have mainly grains with a roundness of 0.50 or more and 0.75 or less, where the roundness is defined as the ratio of the circumference of a circle having the same area as that of a grain to the perimeter of that grain. An abrasive has the abrasive grains and at least one of an oxidizer, an oxide solution, an abrasive grain dispersion agent and a basic compound. An abrasive solution has the abrasive grains and water or hydrophilic substance.

Owner:SUMITOMO CHEM CO LTD

Low oil mist gear grinding oil composition

ActiveCN101701163AHigh viscosity indexExcellent antioxidant stabilityAdditivesBase-materialsGear grindingEcological environment

The invention discloses a low oil mist gear grinding oil composition, belonging to the field of metalworking liquid. The composition according to the invention is composed of the following components by weight percent: 70-81% of refined mineral oil, 10-20% of synthesized fatty acid ester oiliness agent, 5-10% of sulfulrized fatty acid ester, 0-3% of phosphate, 0.3-1.0% of oil mist inhibitor and 0.01-0.1% of antifoaming agent; in the composition, the polymer of oil mist inhibitor is innovatively introduced by means of the coordinate proportioning of the refined mineral oil and the fatty acid ester oiliness agent as main component, thus enhancing lubricity, quickening the sedimentation of the oil mist and effectively reducing the concentration of the oil mist in the operating environment, and in addition, lubricating agent and anti-abrasive agent are scientifically proportioned and used, so the composition contains no chlorine which does harm to ecological environment and human body, has strong universality, can be used for processing black and non-ferrous metals and is non-corrosive to copper, therefore, the composition according to the invention not only imparts excellent processing performance to gear grinding oil, but also effectually improves oil mist environment, which is favorable for environmental protection and body health of operating staff.

Owner:BOER TECH WUHAN

Insulator electrified cleaning agent

InactiveCN105296244AImprove insulation performanceHigh insulation valueSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsStain

An insulator electrified cleaning agent is composed of, by weight, 60-90 parts of a solvent dimethyl carbonate, 15-30 parts of a cosolvent ethylene glycol derivative, 5-10 parts of a nonionic surfactant, 2-5 parts of an abrasive agent nanocrystalline metal oxide, 1-5 parts of a diffusant dichloromethane, 0.5-2 parts of a washing aid N-alkyl pyrrolidone, 0.2-1 part of a stabilizing agent cocomut oil die thanolamide and 1-3 parts of polymethyl siloxane. The cleaning agent can effectively remove stains on the surface of an insulator anti-pollution flashover coating in a high saline and sodic environment with high industrial pollution and recover excellent hydrophobicity and hydrophobic migration of the insulator surface. Thus, the cleaning agent has the capability of effectively guaranteeing safe operation of electrical equipment.

Owner:杨超

Method of forming particles for use in chemical-mechanical polishing slurries and the particles formed by the process

InactiveUS6596042B1Low efficiencyPrevent and delay aqueous decompositionMaterial nanotechnologyPigmenting treatmentAbrasive agentCerium

The present invention provides a process for producing particles suitable for use as abrasives in chemical-mechanical polishing slurries. The process according to the invention includes adding a crystallization promoter such as Ti[OCH(CH3)2)]4 to an aqueous cerium salt solution, adjusting the pH of the solution to higher than 7.0 using one or more bases, and subjecting the solution to hydrothermal treatment at a temperature of from about 90° C. to about 500° C. to produce the particles.

Owner:FERRO CORP

CMP Abrasive Slurry for Polishing Insulation Film, Polishing Method, and Semiconductor Electronic Part Polished by the Polishing Method

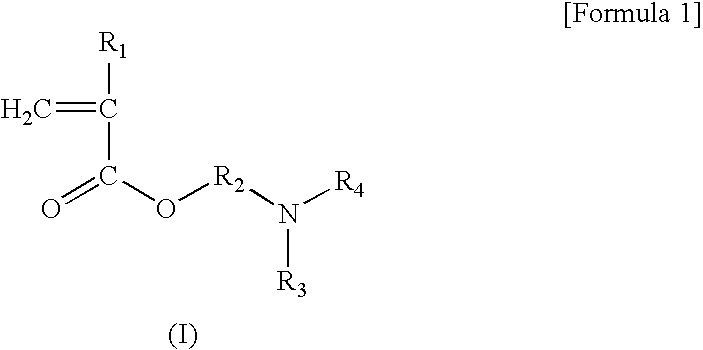

ActiveUS20090047786A1High-throughput and cost-effective polishingEfficient and high-speed polishingOther chemical processesSemiconductor/solid-state device manufacturingSide chainAbrasive agent

The present invention provides a CMP abrasive slurry for polishing insulation film, that allow efficiently and high-speed polishing of insulation films such as SiO2 film and SiOC film in the CMP method of flattening an interlayer insulation film, a BPSG film, an insulation film for shallow trench isolation, or a wiring-insulating film layer, a polishing method by using the abrasive slurry, and a semiconductor electronic part polished by the polishing method. A CMP abrasive slurry for polishing insulation film containing cerium oxide particles, a dispersant, a water-soluble polymer having amino groups on the side chains and water, a polishing method by using the CMP abrasive slurry, and a semiconductor electronic part polished by the polishing method.

Owner:RESONAC CORP

Foaming clean and polish emulsions comprising bisquaternary organomodified silicone

ActiveUS20050187121A1Inorganic/elemental detergent compounding agentsCationic surface-active compoundsAntioxidantNon ionic

This invention provides for, inter alia, a cleaning and polishing oil-in-water emulsion which comprises: A. about 0.1 to about 25% of at least one silicone oil with a viscosity ranging between about 20 and about 100,000 mPas.; B. about 0.5 to about 25% of at least one bisquaternary organomodified silicone of the formula: [Z-M-(R′R″)SiO—[(R′R″)SiO]n—Si(R′R″)-M-Z]2+2X− (I) whereby Z is a quaternary nitrogen radical, R′ and R″ are independently from each other an alkyl or an aryl radical, M is a divalent hydrocarbon radical having at least 4 carbon atoms which optionally contain at least one hydroxyl group and which may be interrupted by one or more oxygen atoms and / or groups of the type —C(O)—, —C(O)O— or —C(O)N—, n is a number between 1 and 200, X− is a inorganic or organic anion, C. about 0.1 to about 15.0% of at least one nonionic or amphoteric surfactant which has an alkyl chain length between 6 and 14 carbon atoms; D. about 1 to about 40% of at least one oil selected from the group of mineral oils, paraffin oils, petroleum distillates, hydrocarbon solvents, ester oils, triglycerides and cyclic silicone oils; E. about 0.1 to about 15% of at least one emulsifier; F. about 20 to about 99% water; and optionally one or more auxiliaries selected from the group consisting of consistency enhancers, thickeners, stabilizers, fragrances, preservatives, antioxidants, dyes, abrasives, glycol ethers, alcohols, and builders. The inventive oil-in-water emulsion, when used in a non-pressurized foam dispenser, dispenses as a foam that is stable and dense. The inventive oil-in water emulsions may be used in cleaning and polishing surfaces.

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com