Method for grinding soft crisp functional crystal

A grinding and functional technology, applied in machine tools, metal processing equipment, grinding/polishing equipment, etc. suitable for grinding workpiece planes, which can solve the residual stress of plastic deformation, micro-scratch, surface soft and brittle functional crystal embedding, etc. problem to avoid scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

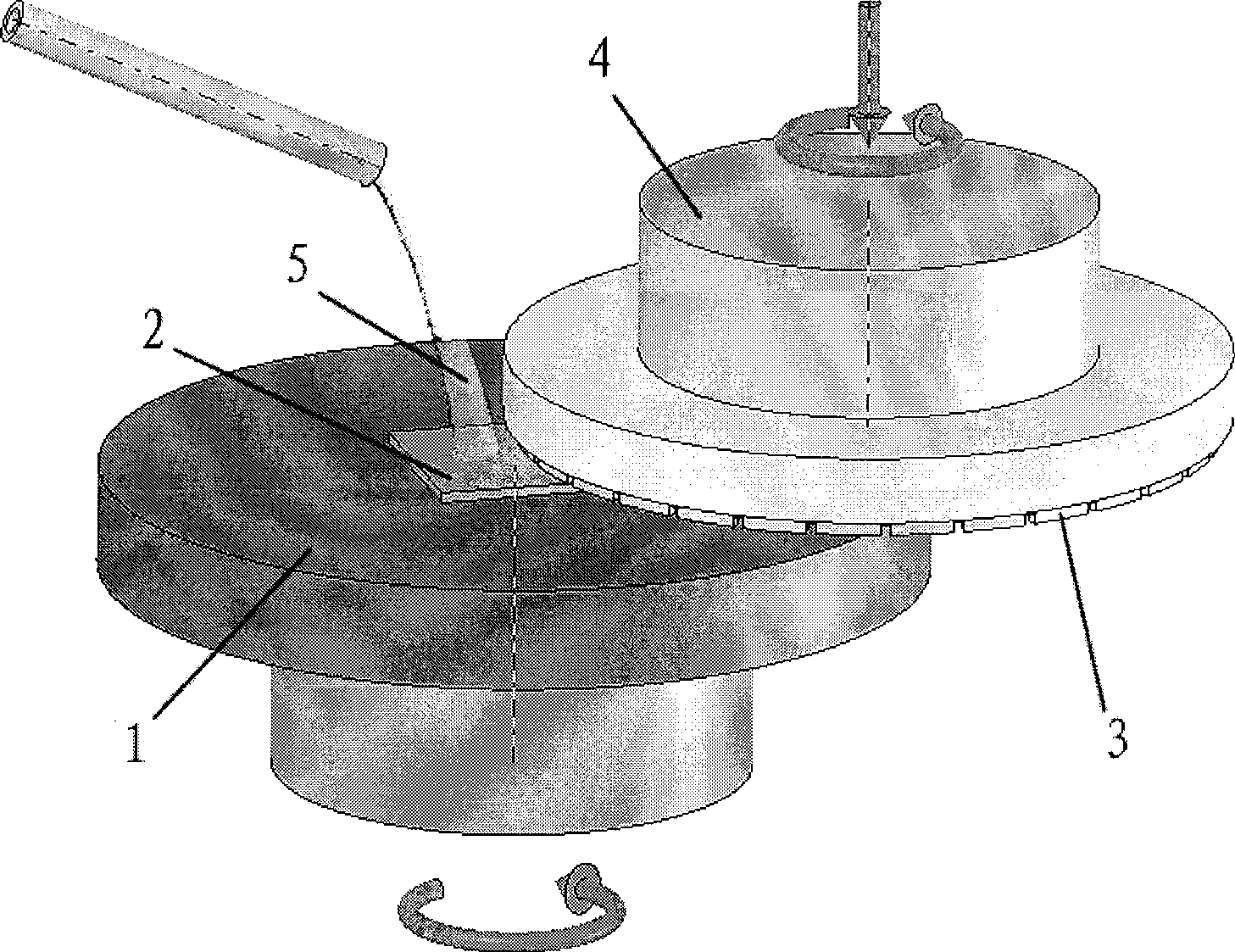

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0012] Adopt VG401MKII end face ultra-precision grinding machine. with Cd 0.96 Zn 0.04 Te(110) is used as a soft and brittle functional crystal sample, the sample size is 10mm×10mm×1.5mm, and the infrared light transmittance is >60%. The workpiece is fixed with a vacuum ceramic suction cup, and the diameter of the small hole of the vacuum suction cup is 0.2mm. First, use #3000 diamond grinding wheel for rough grinding, the grinding wheel spindle speed is 2000r / min, the grinding feed rate is 15μm / min, the workpiece speed is 200r / min, the flow rate of deionized water is 300ml / min, and the duration is 10min. Subsurface damaged layer. Then carry out precision grinding, the grinding wheel spindle speed is 1500r / min, the grinding feed speed is 5μm / min, the workpiece speed is 150r / min, the deionized water flow rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com