Liquid fermentation method for producing pectinase

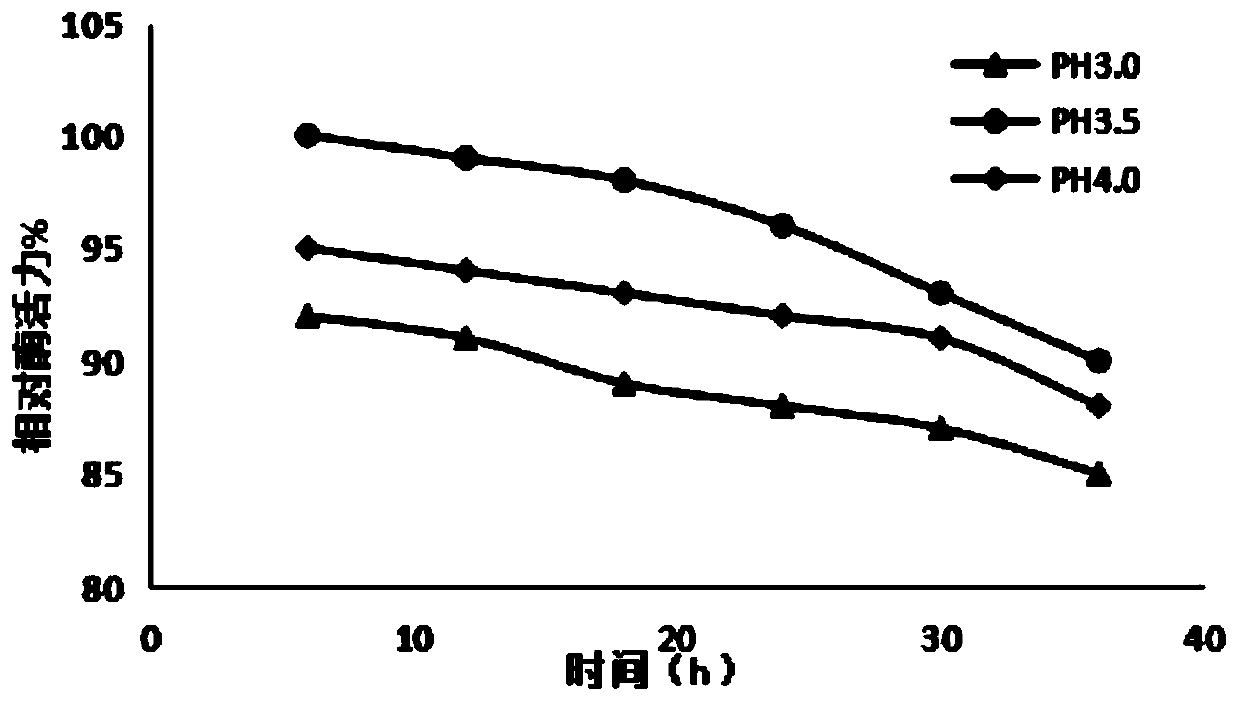

A liquid fermentation and pectinase technology, applied in the field of bioengineering, can solve the problems of limited wide application, high production cost, low enzyme activity, etc., and achieve the effects of increasing fermentation capacity, reducing fermentation cost, and significantly acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Aspergillus niger LD-092 fermentation enzyme production and the extraction method of pectinase produced

[0035] The fermentative enzyme production method of Aspergillus niger LD-092 mainly comprises the following steps:

[0036] Slant culture: Pick a ring of Aspergillus niger LD-092 and inoculate it on a solid slant medium, and culture at a constant temperature of 30°C for 36 hours to obtain first-class seeds;

[0037] Shake flask culture: Take a ring of the first-class seeds and insert them into the seed medium, and cultivate them for 48 hours at a constant temperature of 30°C and a shaker speed of 200r / min to obtain the second-class seed liquid;

[0038] Seed tank culture: put the secondary seed solution into the seed tank culture medium at a ratio of 15% (v / v) of the inoculation amount, and cultivate for 45 hours at a constant temperature of 30°C and a rotational speed of 200r / min;

[0039] Fermentation tank culture: the seed liquid in the seed tank is co...

Embodiment 2

[0050] Embodiment 2 Aspergillus niger LD-092 fermentation performance verification

[0051] Carry out 50L fermenter verification experiment according to the fermentative enzyme production method of embodiment 1 Aspergillus niger LD-092, fermentation cycle 155h, its 7 batches of fermentative enzyme production situation, the pectinase average enzyme activity in the fermented liquid is 82882U / mL, table 1 shows that the strain not only produces high-yield pectinase, but also has remarkable stability in its fermentation performance and the enzymatic activity of pectinase produced by it.

[0052] Table 1 Enzyme production by fermentation of 7 batches of high pectinase-producing strains

[0053]

Embodiment 3

[0054] Embodiment 3 pectinase activity assay method

[0055] (1) Preparation of enzyme liquid: the fermentation liquid was centrifuged at 6000 r / min for 15 min, and the supernatant was collected to be the crude enzyme liquid.

[0056] (2) Determination method: 3,5-dinitrosalicylic acid method (DNS method) is adopted. Take 0.5ml of appropriately diluted crude enzyme solution in a 25mL colorimetric tube, add 2.0ml of 0.4% pectin solution (pH4.0) as a substrate solution, react in a water bath at 45°C for 30min, add DNS solution and boil for 5min, cool down, and constant volume To 25ml, measure the absorbance at 520nm.

[0057] (3) Definition of enzyme activity: under certain conditions, the amount of enzyme needed to decompose pectin to generate 1 μmol galacturonic acid per minute is an enzyme activity unit (U).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com