Cellulose acetate filter membrane and preparation method thereof

A technology of cellulose acetate and filter membrane, which is applied in the field of filter membrane, which can solve the problems of affecting the enhancement effect, agglomeration, and inability to directly and evenly disperse, so as to achieve the effects of improving filtration performance, reducing adsorption, and broadening the scope of industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

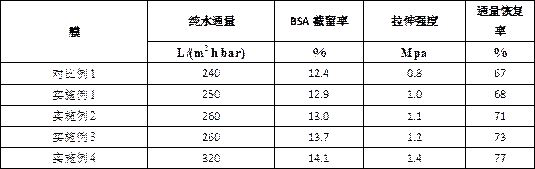

Examples

Embodiment 1

[0019] (1) Weigh 3 g of CNCs and add it into 300 mL of deionized water, and treat it with an ultrasonic device with a power of 200 W for 30 min to obtain an aqueous dispersion of CNCs. Ammonia water was added dropwise to adjust the pH value of the aqueous dispersion of CNCs to 8.5, then 0.15 g DA (accounting for 5 wt% of the dry weight of CNCs) was added, and the reaction was stirred at room temperature for 12 h. Finally, dilute acid solution was added to stop the reaction, vacuum filtration and thorough washing were performed, and the obtained brown product was polydopamine-coated cellulose nanocrystals (PDA@CNCs). 20gCA and 0.6gPVP were added to 79.4gDMAc, and magnetically stirred at room temperature for 48h. After CA and PVP were completely dissolved, a 20wt% transparent CA solution was obtained. 0.2 g of PDA@CNCs was dispersed in 99.8 g of DMAc to obtain a 0.2 wt% PDA@CNCs dispersion.

[0020] (2) The CA solution and the PDA@CNCs dispersion were mixed at a weight ratio of...

Embodiment 2

[0024] (1) Weigh 3 g of CNCs and add it into 300 mL of deionized water, and treat it with an ultrasonic device with a power of 200 W for 30 min to obtain an aqueous dispersion of CNCs. Ammonia water was added dropwise to adjust the pH value of the CNCs aqueous dispersion to 8.5, then 0.30 g DA (accounting for 10 wt% of the dry weight of CNCs) was added, and the reaction was stirred at room temperature for 12 h. Finally, dilute acid solution was added to stop the reaction, vacuum filtration and thorough washing were performed, and the obtained brown product was polydopamine-coated cellulose nanocrystals (PDA@CNCs). 20gCA and 0.6gPVP were added to 79.4gDMAc, and magnetically stirred at room temperature for 48h. After CA and PVP were completely dissolved, a 20wt% transparent CA solution was obtained. 0.4 g of PDA@CNCs was dispersed in 99.6 g of DMAc to obtain a 0.4 wt% PDA@CNCs dispersion.

[0025] (2) The CA solution and the PDA@CNCs dispersion were mixed at a weight ratio of 1...

Embodiment 3

[0029] (1) Weigh 3 g of CNCs and add it into 300 mL of deionized water, and treat it with an ultrasonic device with a power of 200 W for 30 min to obtain an aqueous dispersion of CNCs. Ammonia water was added dropwise to adjust the pH value of the aqueous dispersion of CNCs to 8.5, then 0.45 g DA (accounting for 15 wt% of the dry weight of CNCs) was added, and the reaction was stirred at room temperature for 12 h. Finally, dilute acid solution was added to stop the reaction, vacuum filtration and thorough washing were performed, and the obtained brown product was polydopamine-coated cellulose nanocrystals (PDA@CNCs). 20gCA and 0.6gPVP were added to 79.4gDMAc, and magnetically stirred at room temperature for 48h. After CA and PVP were completely dissolved, a 20wt% transparent CA solution was obtained. 0.6 g of PDA@CNCs was dispersed in 99.4 g of DMAc to obtain a 0.6 wt% PDA@CNCs dispersion.

[0030] (2) The CA solution and the PDA@CNCs dispersion were mixed at a weight ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com