Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Grain boundary migration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deforming magnesium alloy and preparation method thereof

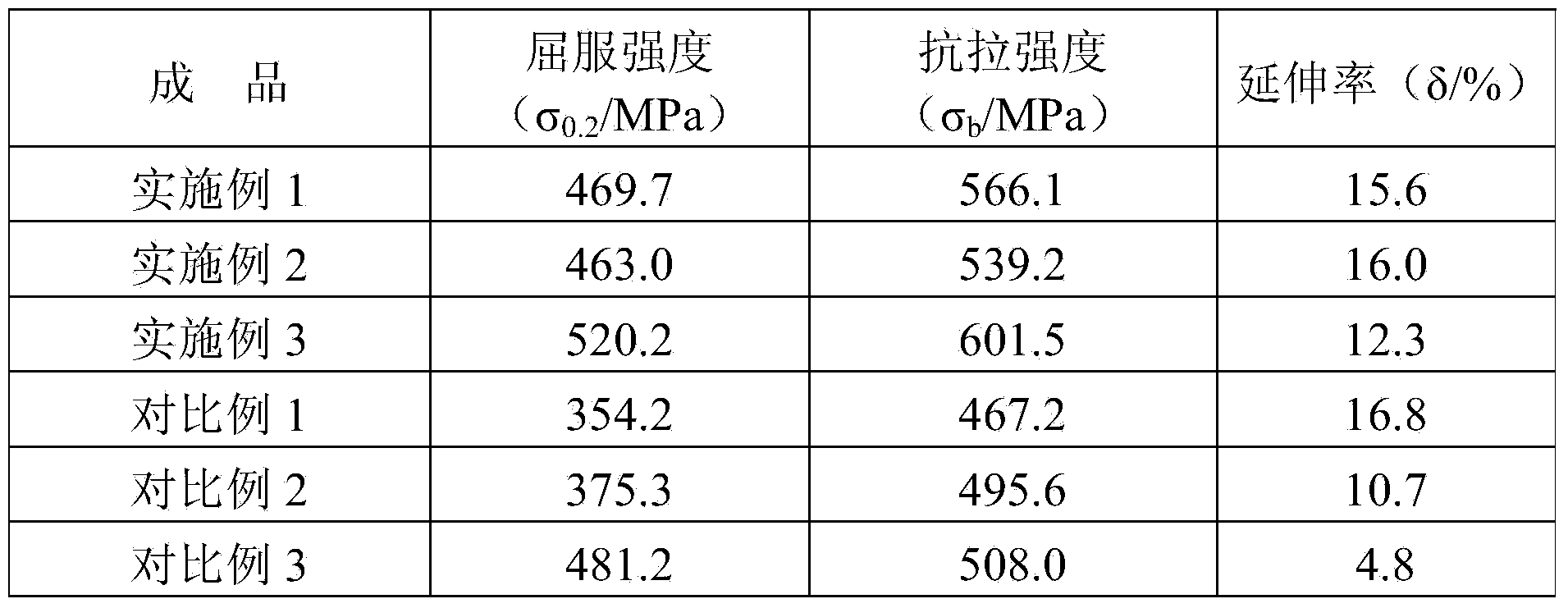

ActiveCN102828094AImprove high temperature stabilityImprove mechanical propertiesRare-earth elementYttrium

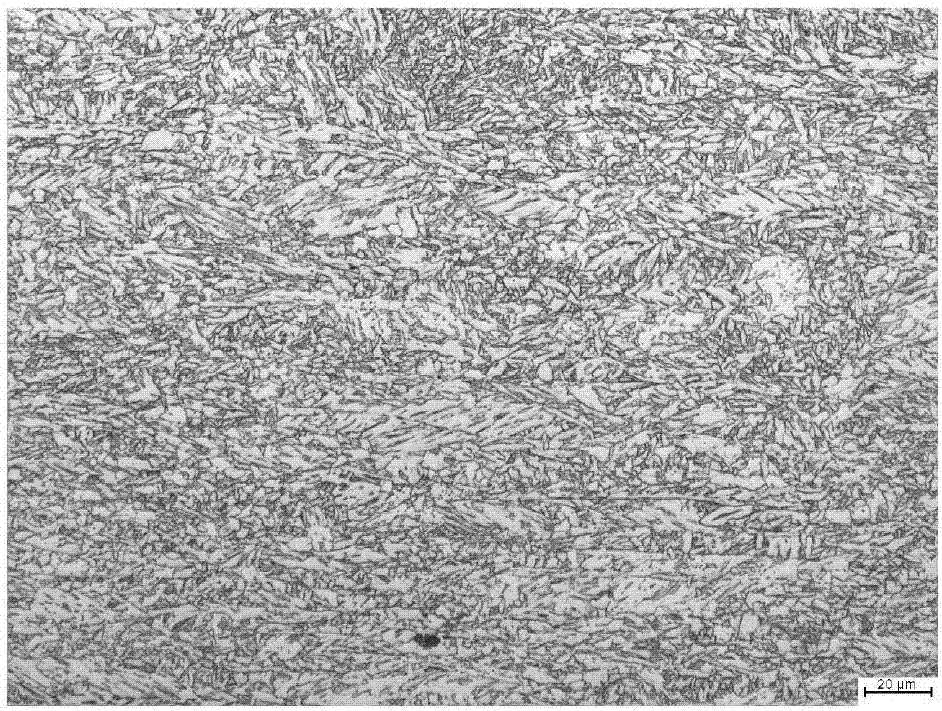

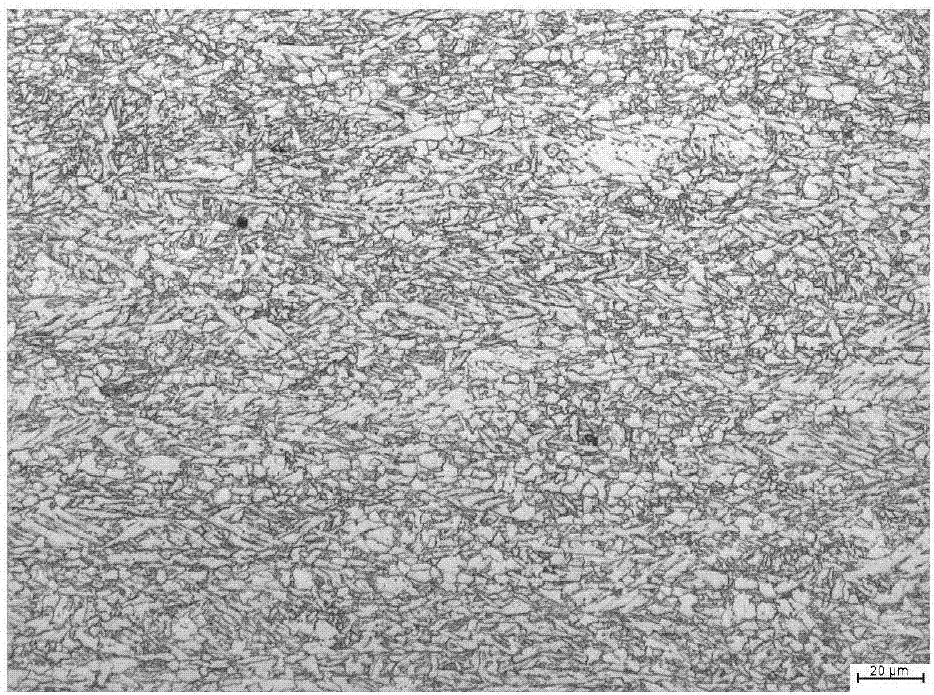

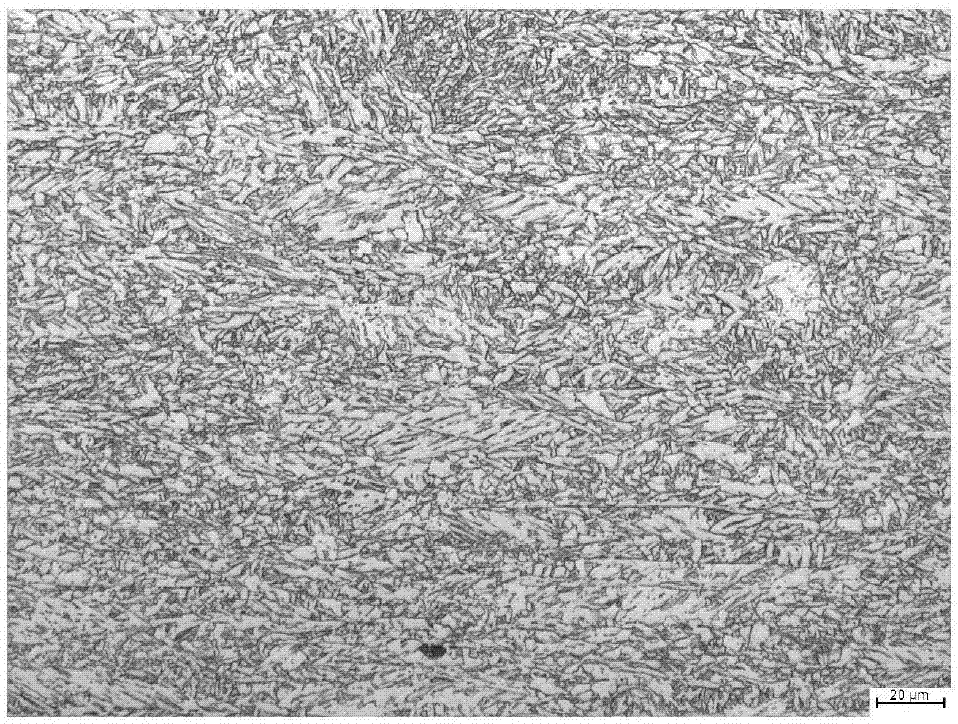

The invention provides a deforming magnesium alloy and a preparation method thereof. The deforming magnesium alloy comprises the following components in percentage by mass: 0.1-10% of neodymium, 10-12% of gadolinium, 3-5% of yttrium, 0.5-2% of zinc, 0.3-0.8% of zirconium, and the balance of magnesium and inevitable impurities. Compared with WE54 in the prior art, the invention is characterized in that rare-earth elements neodymium, gadolinium and yttrium are added into the Mg-Zn-Zr magnesium alloy. Firstly, after adding zinc, abundant strip Mg12YZn precipitated phases are formed at the alloy grain boundary to prevent grain boundary migration at high temperature and enhance the high-temperature stability of the alloy, and the precipitated phases are uniformly arranged in the extrusion direction to prevent basal dislocation migration and enhance the mechanical properties of the alloy; and secondly, the three rare-earth elements gadolinium, yttrium and neodymium are added, so the interactions among the rare-earth elements can be utilized to lower the solid solubility of the gadolinium, yttrium and neodymium in the magnesium base, thereby promoting the formation of the precipitated phases and enhancing the mechanical properties of the alloy.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Hot treatment process for remarkably improving comprehensive performance of aluminum alloy

ActiveCN103882354AMeet the requirements of large structural partsPractical application value of large industryAtomic clusterGrain structure

The invention relates to a hot treatment process for remarkably improving the comprehensive performance of aluminum alloy. According the hot treatment process, aluminum-copper-magnesium alloy in a solid solution state undergoes pre-aging treatment, asymmetric rolling deformation and secondary aging treatment; one part of atoms are segregated through pre-aging to form nanometer scale atomic clusters which block dislocation movement during subsequent deformation to form meshy dislocation cells or sub-boundary to refine grains; the other part of undecomposed solute atoms obtain vacancy / atomic cluster complex, G.P. zone, microtexture and special shearing texture under the strain action of subsequent deformation high shear stress; one part of fine grains grow with the aid of grain boundary migration due to the interaction of the compound textures during secondary aging to form a dual grain structure, so that the strength-plasticity coordination of the alloy is improved, and the toughness of the alloy is improved. The hot treatment process is simple, safely operated and conveniently, easily industrialized, and is a novel hot treatment technology with great application prospect; the comprehensive performance of the alloy is effectively improved through improving the microtexture of alloy according to the hot treatment process.

Owner:CENT SOUTH UNIV +1

Thick-wall large-diameter high-grade pipeline steel for increasing low-temperature toughness and manufacturing method thereof

The invention relates to a manufacturing method of thick-wall large-diameter high-grade pipeline steel for increasing the low-temperature toughness. A section casting blank of which the thickness is 320 mm is adopted, the blank heating is reasonably improved, the rolling schedule is optimized, and the laminar cooling process is improved, so that different deformation storage energy and grain boundary mobility are guaranteed, the tissue grain size is effectively refined so as to obtain bainite and acicular ferrite with uniform tissues, the stable tissues and performance are guaranteed, the performance requirement of the wide thick high-grade pipeline steel is satisfied, and economic benefits are obvious.

Owner:NANJING IRON & STEEL CO LTD

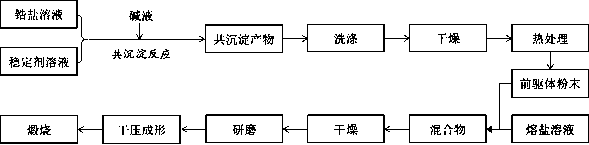

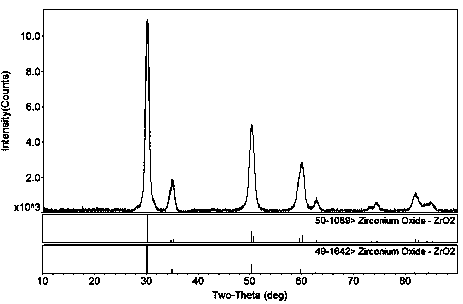

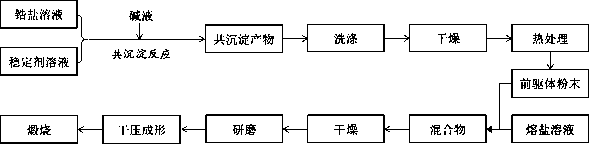

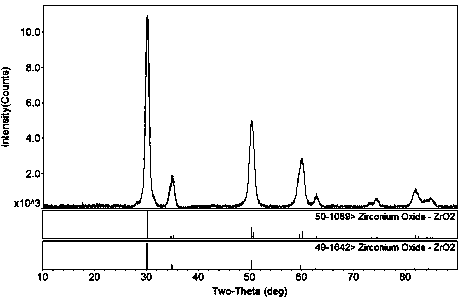

Method for rapidly sintering fully stabilized zirconia powder under low temperature and normal pressure

The invention discloses a method for rapidly sintering fully stabilized zirconia powder under low temperature and normal pressure, which belongs to the field of fine chemical engineering. The method includes the steps of zirconium salt and stabilizer mixing, coprecipitation, washing, drying, heat treatment, mixing with molten salt solution, drying, grinding, dry pressing, calcination and the like. By introducing trace molten salt into the fully stabilized zirconia powder and utilizing the molten salt to form liquid phase under low temperature, while promoting the grain boundary diffusion of the powder, the method inhibits the grain boundary migration of the powder, consequently, the contradiction between densification and grain coarsening in the process of sintering the fully stabilized zirconia powder is solved, and the normal-pressure rapid sintering of the fully stabilized zirconia powder under low temperature is realized; in addition, cations in the molten salt get into the ZrO2 crystal lattice by doping, consequently, the ZrO2 crystal form is further stabilized, and the properties of the material are further improved; the average bending strength of the obtained sintered body is greater than 450Mpa, the theoretical density is greater than 93 percent, and the grain size is between 425nm and 520nm.

Owner:JIANGXI UNIV OF SCI & TECH

Manufacturing method of thick-wall and large-caliber high-grade pipeline steel

The invention discloses a manufacturing method of thick-wall and large-caliber high-grade pipeline steel. The purity of molten steel is improved through calcium treatment process improvement, five-hole water port use and middle ladle sampling position optimization; the macrostructure of a casting blank is improved through low-temperature and constant-pulling-speed casting; the heating temperature of the casting blank is reasonably selected to set open rolling temperatures in the first phase and the second phase; the reasonable final rolling temperature guarantees different deformation storage energy and grain boundary migration rates; organization grains are effectively refined through the final rolling temperature; the water feeding temperature, the final cooling temperature and the cooling speed are reasonably matched to guarantee fine ferrite structures and to guarantee strength and toughness of steel plates; and a reasonable reduction schedule guarantees the stability of structures and performances to satisfy the performance requirements of the thick-wall and large-caliber pipeline steel.

Owner:NANJING IRON & STEEL CO LTD

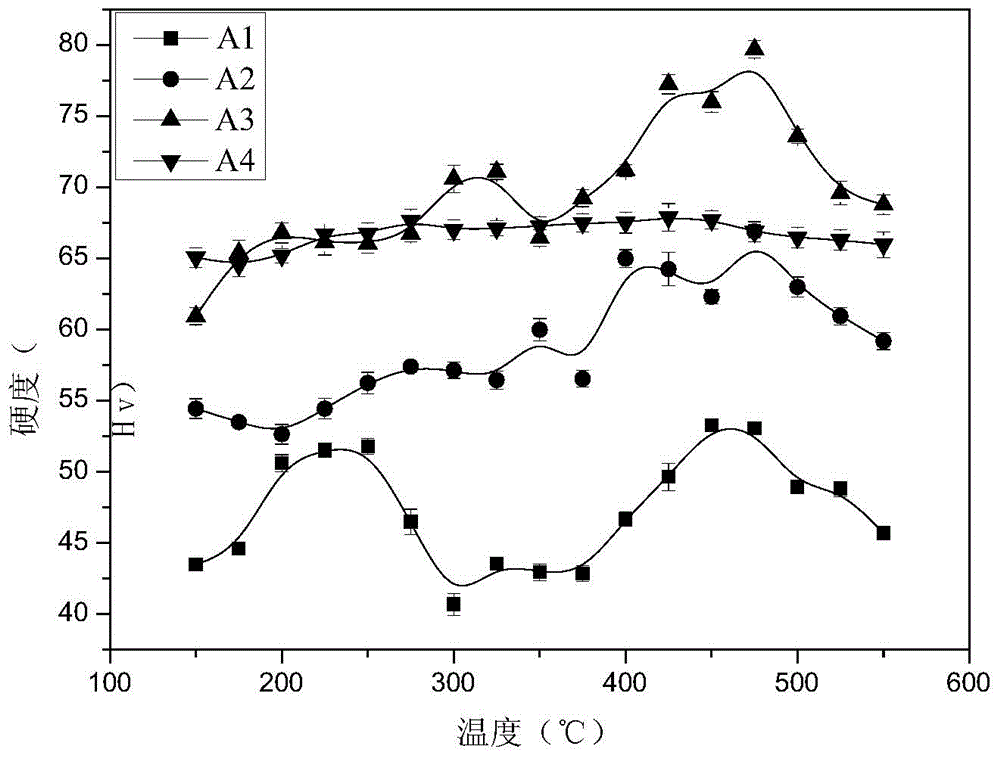

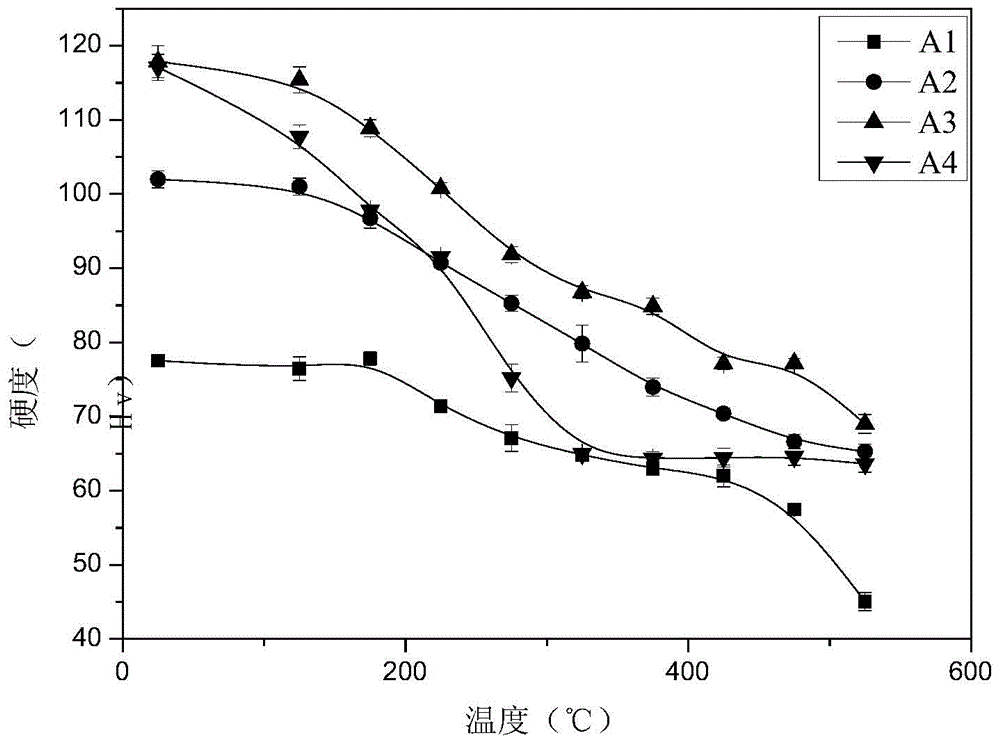

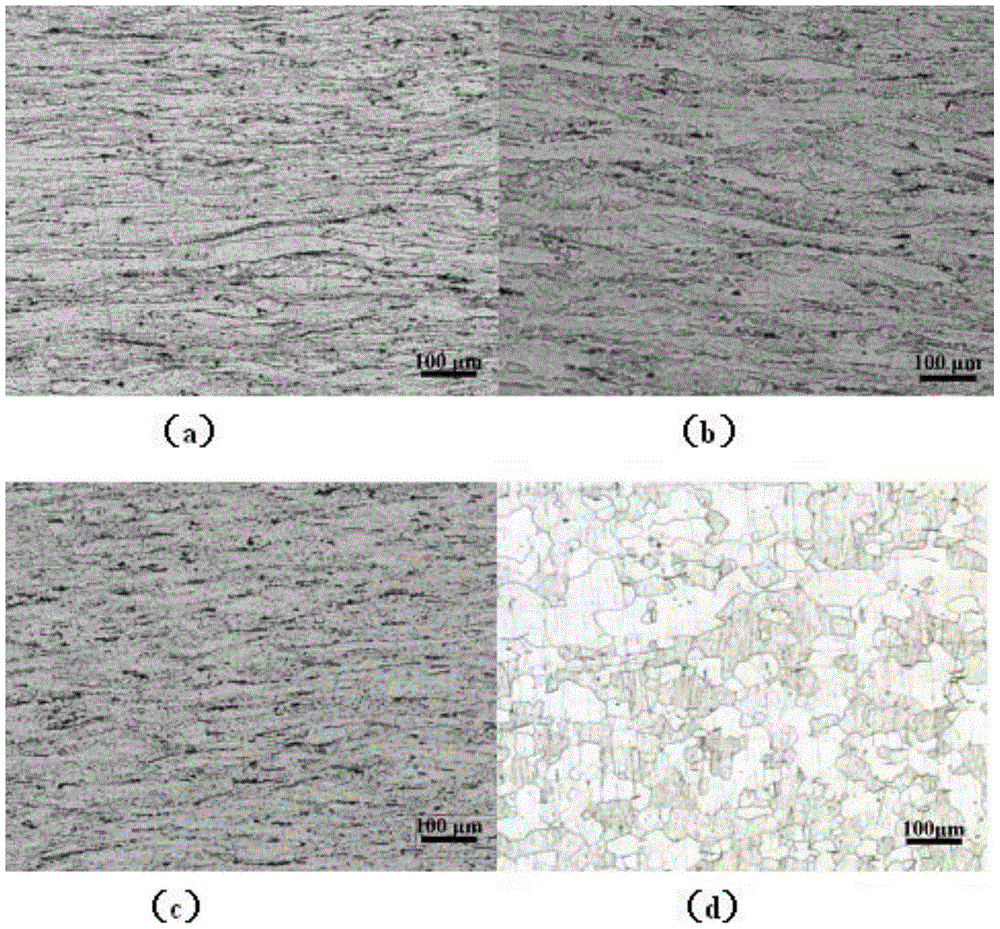

A kind of al-mg-er-zr heat-resistant aluminum alloy and its preparation process

ActiveCN104498785BImprove the strengthening effectRaise the recrystallization temperatureGrain boundary migrationAluminium matrix

Al-Mg-Er-Zr heat-resistant aluminum alloy and its preparation technology belong to the technical field of alloy. The alloy is obtained by adding 1.1-5.1 wt% of Mg, 0.25-0.35 wt% of Er and 0.25-0.3 wt% of Zr into an aluminium matrix. The percentage is weight percentage of each component in the Al-Mg-Er-Zr heat-resistant aluminum alloy. The preparation technology comprises the following steps: smelting Al-Mg-Er-Zr alloy at 760-780 DEG C, stirring after each alloy element is smelted, casting to obtain as-cast alloy, isochronally annealing the alloy every 25 DEG C between 150-475 DEG C for 3 hours, and carrying out cold rolling on the annealed alloy by a cold-rolling mill. Total deformation of cold rolling is 60-80%. A lot of Al3 (Er,Zr) strengthening phase particles are separated out, and the hardening effect is remarkable during the annealing process. When an alloy cold-rolled sheet is used at high temperature, the strengthening phase particles can impede alloy dislocation and grain and sub-grain boundary migration and merging and inhibit recrystallization process of the alloy. Recrystallization temperature of the alloy is raised.

Owner:BEIJING UNIV OF TECH

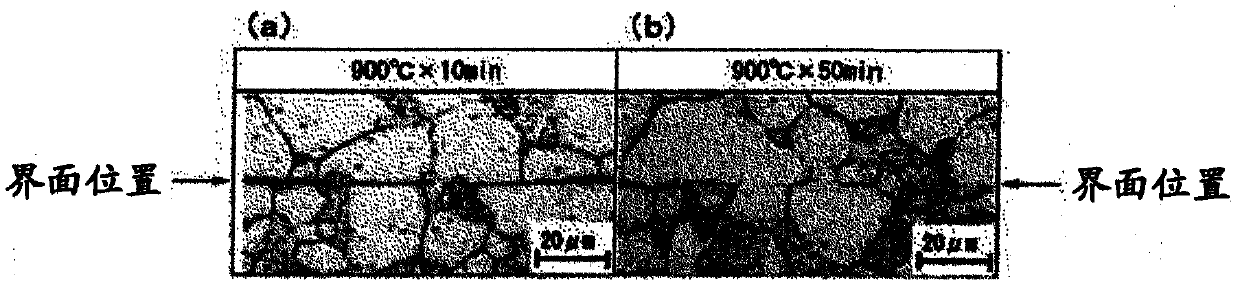

Process for producing stainless steel diffusion-joined product

ActiveCN105517748AImprove reliabilityHigh bonding strengthFurnace typesWelding/cutting media/materialsGrain boundary migrationAustenite

A process for producing a stainless steel diffusion-joined product is disclosed for the purpose of providing a stainless steel diffusion-joined product having excellent reliability of a joint by a "direct process" which can be carried out at a workload equivalent to that of a conventional insertion process using an insert material. This process includes bringing stainless steel materials into direct contact with each other and unifying the materials through diffusion joining, wherein: at least one of the stainless steel materials which are to be brought into contact with each other is a duplex stainless steel which has an austenization initiation temperature at heating, namely Ac1, of 650 to 950 DEG C and an austenite / ferrite two-phase temperature region falling within a range of 880oC or higher; and the diffusion joining is made to proceed under the conditions of contact surface pressure of 1.0MPa or less and heating temperature of 880 to 1080 DEG C, while being accompanied with grain boundary migration occurring during the ferrite-to-austenite transformation of the duplex stainless steel.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Lead zirconate titanate piezoelectric ceramic and preparation method thereof

The invention discloses a lead zirconate titanate piezoelectric ceramic. The lead zirconate titanate piezoelectric ceramic is prepared from the following raw materials in parts by weight: 55 to 75 parts of lead tetroxide, 0 to 6 parts of barium sulfate, 0.2 to 8 parts of strontium carbonate, 0.1 to 0.9 part of niobium pentoxide, 0.2 to 1 part of antimony pentoxide, 15 to 25 parts of zirconium dioxide and 8 to 15 parts of titanium dioxide. According to the lead zirconate titanate piezoelectric ceramic disclosed by the invention, an excellent lead zirconate titanate piezoelectric ceramic material is prepared by adopting a two-step sintering solid-phase synthesis preparation method, so that the high-temperature sintering time is effectively shortened, and the energy, the time and the production cost are saved to a certain extent. According to the two-step sintering method, by controlling the temperature change, grain boundary migration can be restrained, grain boundary diffusion can be kept in an active state, and therefore the purpose of completing sintering on the premise that grains do not grow up is achieved.

Owner:GUANGZHOU KAILITECH ELECTRONICS

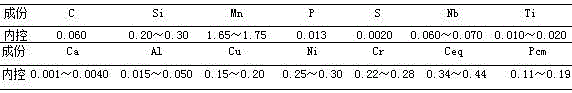

Thick X80 hot rolled coil for phi 1422mm ultra large diameter spiral submerged arc welded pipe and manufacturing method of thick X80 hot rolled coil

ActiveCN108411197AMeet performance requirementsImprove tensile propertiesGrain boundary migrationAlloy

The invention discloses a thick X80 hot rolled coil for a phi 1422mm ultra large diameter spiral submerged arc welded pipe and a manufacturing method of the thick X80 hot rolled coil. The X80 hot rolled coil defines the weight percentage cold cracking sensitivity Pcm of various components to be smaller than or equal to 0.20 percent. The X80 hot rolled coil provided by the invention is less in addition amounts of precious metals such as Nb, Mo and Ni and low in alloy cost; a preparation technology optimizes the pressing rate in each pass and a distribution rule thereof of rough rolling and finish rolling; particularly, by performing 3+3 passes of austenite recrystallization rolling, rough rolling is less in pass and large in pass pressing rate, can increase a gamma recrystallization amountto the maximum, prevents strain-induced grain boundary migration to refine grains, is low in investment cost of production equipment and has good tensile property and low-temperature toughness.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

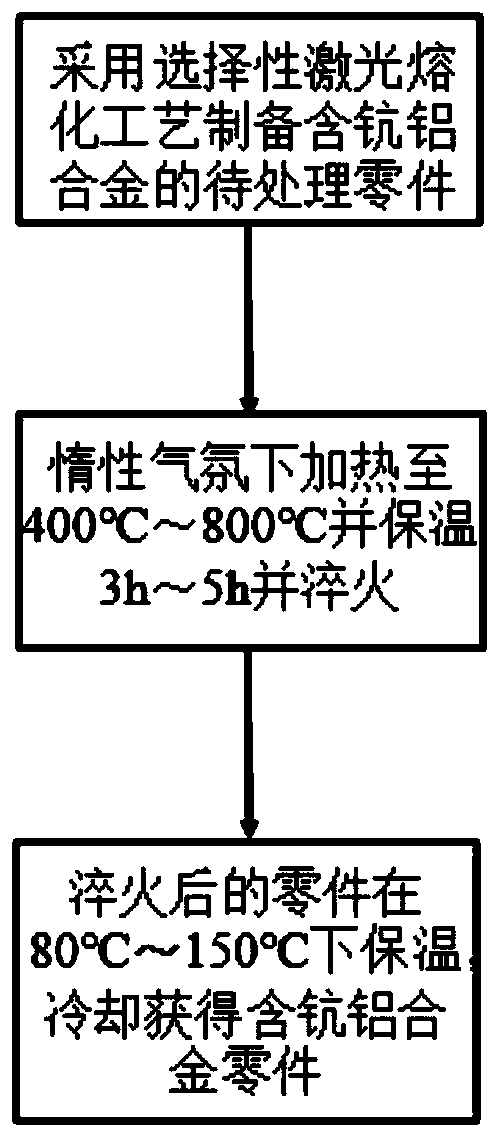

Method for preparing scandium-containing aluminum alloy part by 3D printing and product thereof

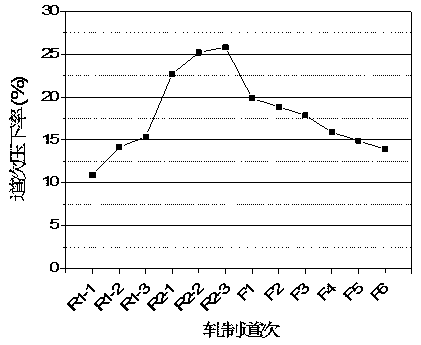

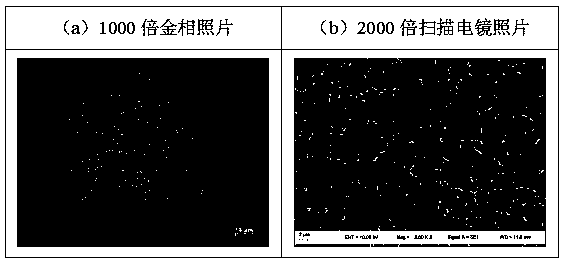

ActiveCN110899696AHigh strengthStrong pinningAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingGrain boundary migration

The invention belongs to the field of alloy forming manufacturing, and particularly discloses a method for preparing a scandium-containing aluminum alloy part by 3D printing and a product thereof. Themethod comprises the following steps that a scandium-containing aluminum alloy part to be treated is prepared by adopting a selective laser melting process; the part is heated to 400 DEG C-800 DEG Cunder an inert atmosphere and subjected to heat preservation for 3h-5h, and then the part is transferred to water for quenching; and the quenched part is subjected to heat preservation at 80 DEG C-150DEG C for a preset time, and cooling is conducted to room temperature to obtain the scandium-containing aluminum alloy part. According to the method, a large amount of fine Al3Sc and Al3Zr particlesdiffused in the part to be treated have a coherent relationship with a matrix of the alloy, the relatively small mismatching degree and the higher thermal stability are achieved, moreover, dislocationand crystal can be strongly pinned, dislocation motion and grain boundary migration are prevented, the solid solution in the alloy is precipitated in the crystal, the crystal boundary is a crystal precipitation phase of intermittent distribution, and the strength of the scandium-containing aluminum alloy part is remarkably improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

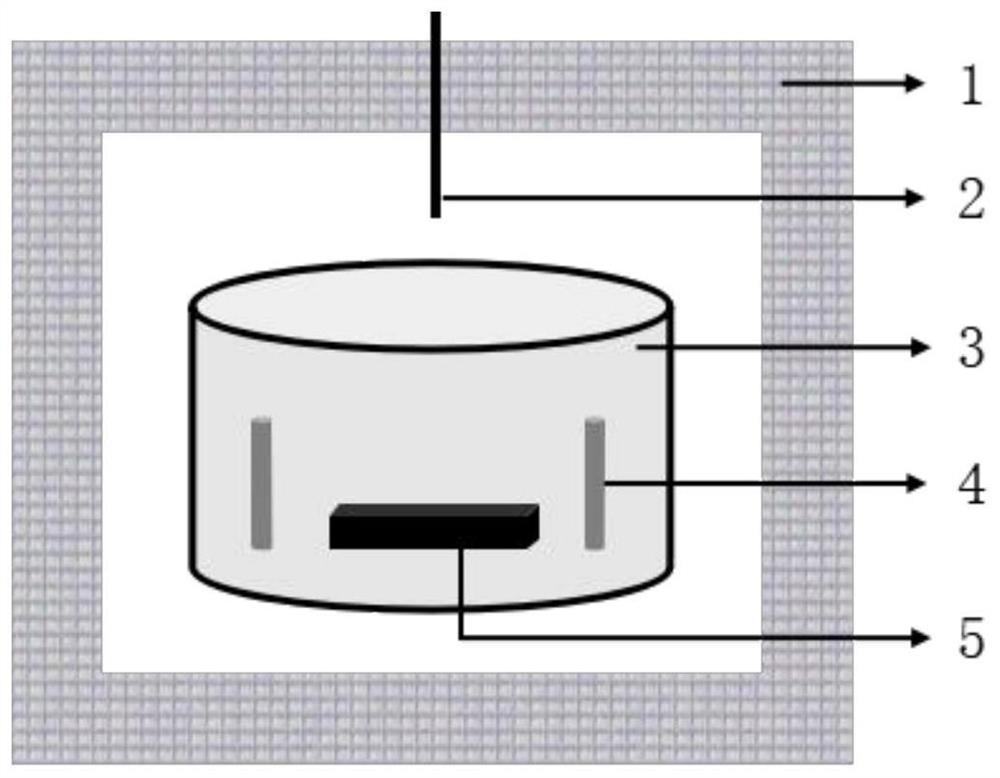

Method for realizing secondary sintering preparation of artificial bone by utilizing selective laser and temperature control furnace

InactiveCN103420681AImprove efficiencySmall heating areaProsthesisTemperature controlGrain boundary migration

The invention discloses a molding method for realizing secondary sintering preparation of a high-toughness three-dimensional nano ceramic artificial bone by utilizing a selective laser and a temperature control furnace. In the first sintering, the selective laser is utilized for layer-by-layer scanning of a biological ceramic powder according to artificial bone model information, and layers are superposed to obtain a nano artificial bone initial green body having a complex geometric profile and controllable interconnected micropores; and in the second sintering, the laser molded piece is subjected to long-time heat preservation at a relatively low sintering temperature in the temperature control furnace, grain boundary migration is inhibited in the heat preservation stage, grain boundary diffusion is maintained, thus grain growth is under control, and a densification process can be still carried out until the artificial bone is fully densified. The molded artificial bone not only has the profile consistent with an implantation site and has the interconnected and controllable pore space structure, but also is a nano biological ceramic artificial bone scaffold having good mechanical properties.

Owner:CENT SOUTH UNIV

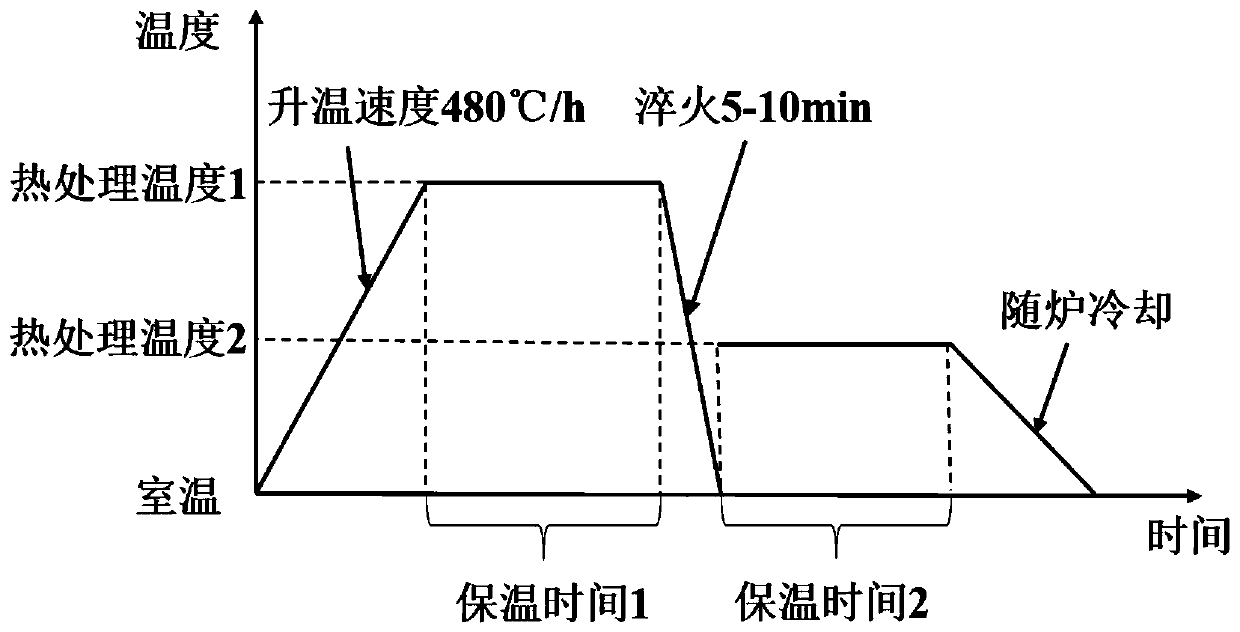

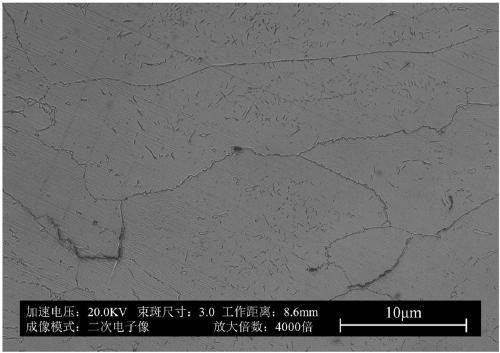

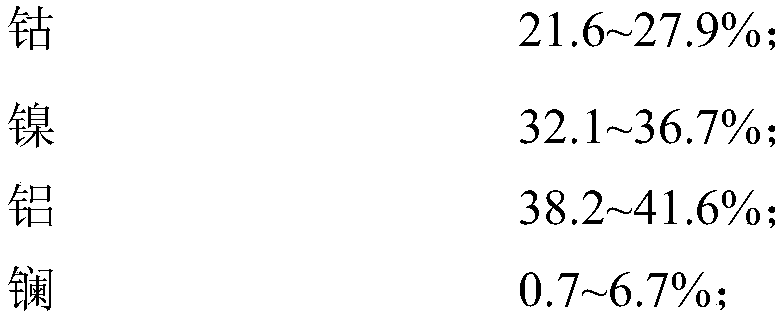

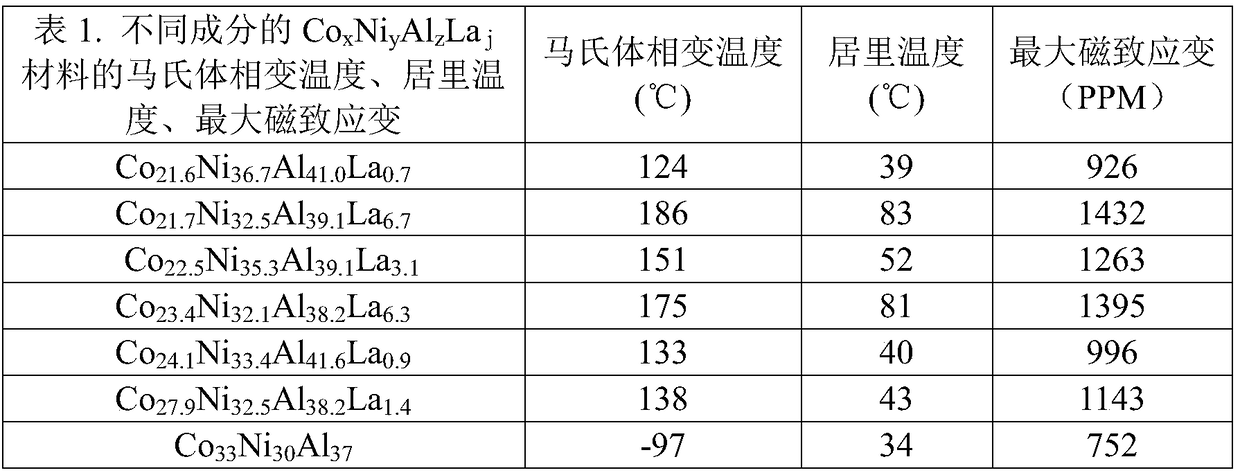

Magnetic memory alloy with large strain and preparation method thereof

ActiveCN109097610AImprove mechanical propertiesExcellent large magnetic strainInductances/transformers/magnets manufactureMagnetic materialsGrain boundary migrationMagnetic memory

The invention provides a magnetic memory alloy with large strain and a preparation method thereof and belongs to the field of shape memory alloys. The alloy has the capacity of generating high magnetic strain under control of an external magnetic field at the room temperature condition, and is a magnetic control shape memory alloy capable of driving martensite twin grain boundary migration and reverse migration through changes of the external magnetic field so as to generate recoverable strain at the room temperature condition. The chemical formula of the alloy is CoxNiyAlzLaj, wherein x is larger than or equal to 21.6 and smaller than or equal to 27.9, y is larger than or equal to 32.1 and smaller than or equal to 36.7, z is larger than or equal to 38.2 and smaller than or equal to 54.6,j is larger than or equal to 0.7 and smaller than or equal to 6.7, the sum of x, y, z and j is 100, and x, y, z and j represent Mole percentages. Compared with an existing material, by forming an ultrafine Al3La metal intermediate phase in a matrix of the memory alloy, the alloy has a wide magnetic strain temperature range, high magnetic strain capacity and good mechanical properties, and has important application to the field of high-precision drivers, actuators and the like used at the room temperature condition.

Owner:HOHAI UNIV +1

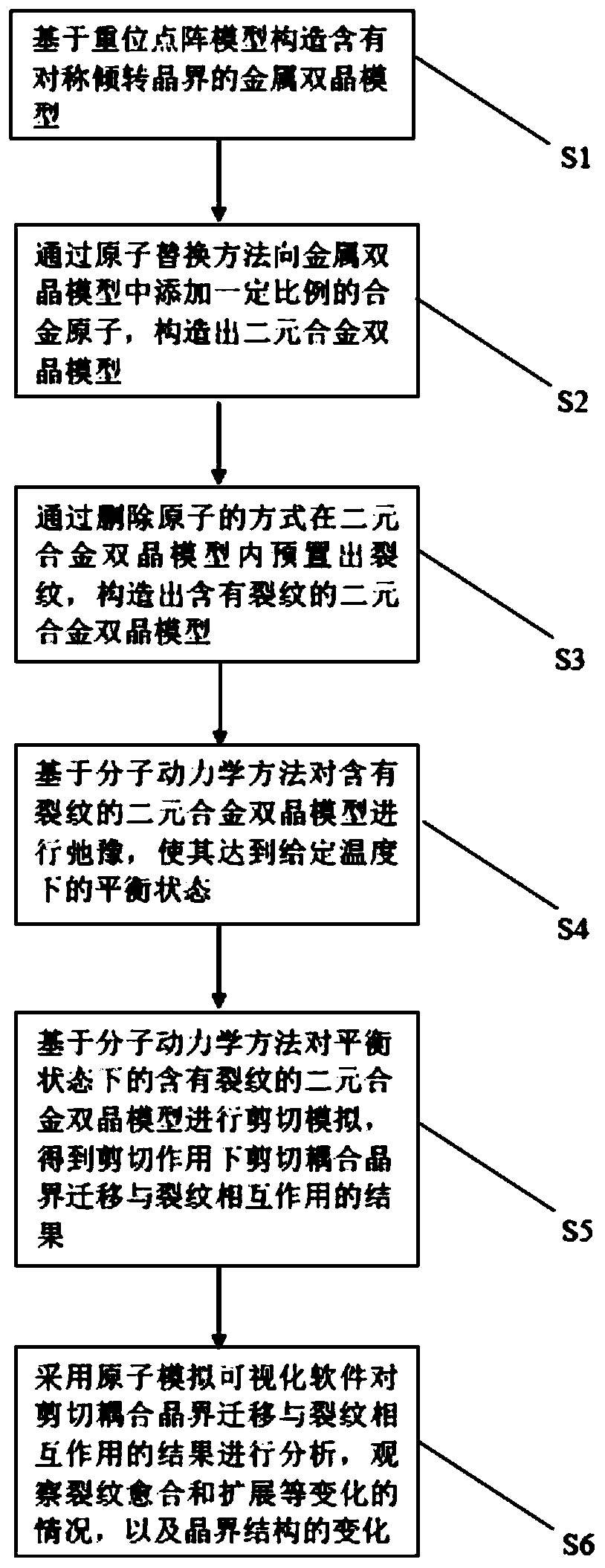

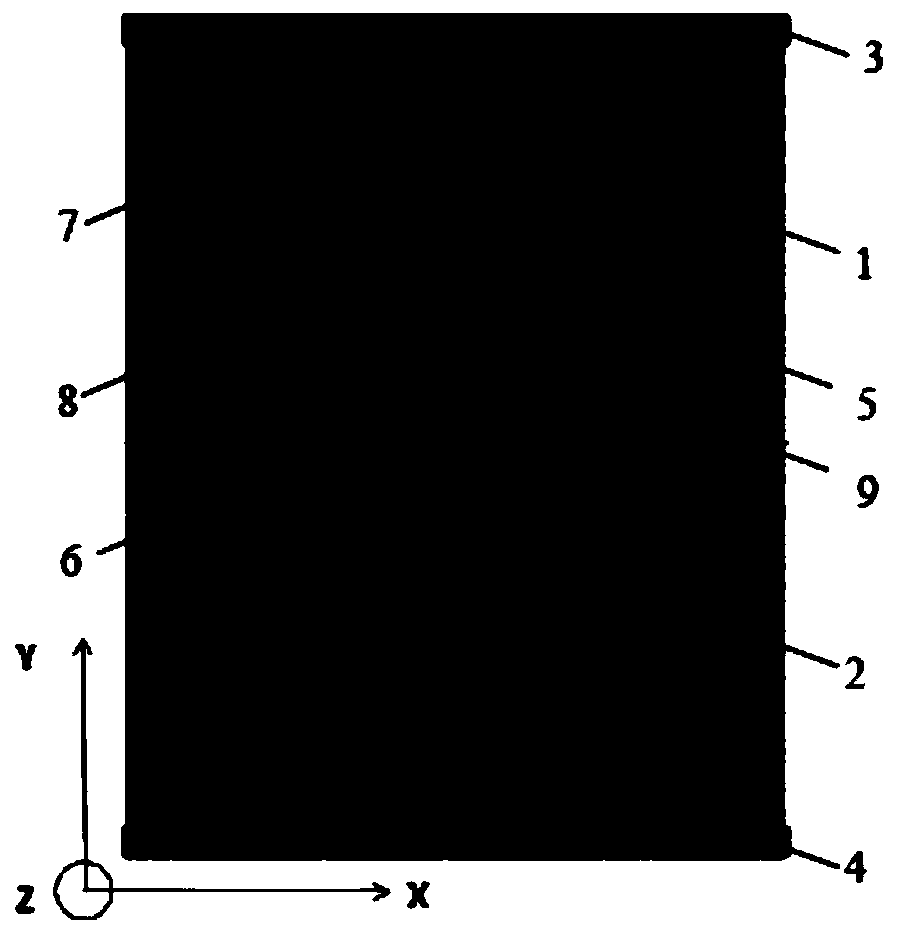

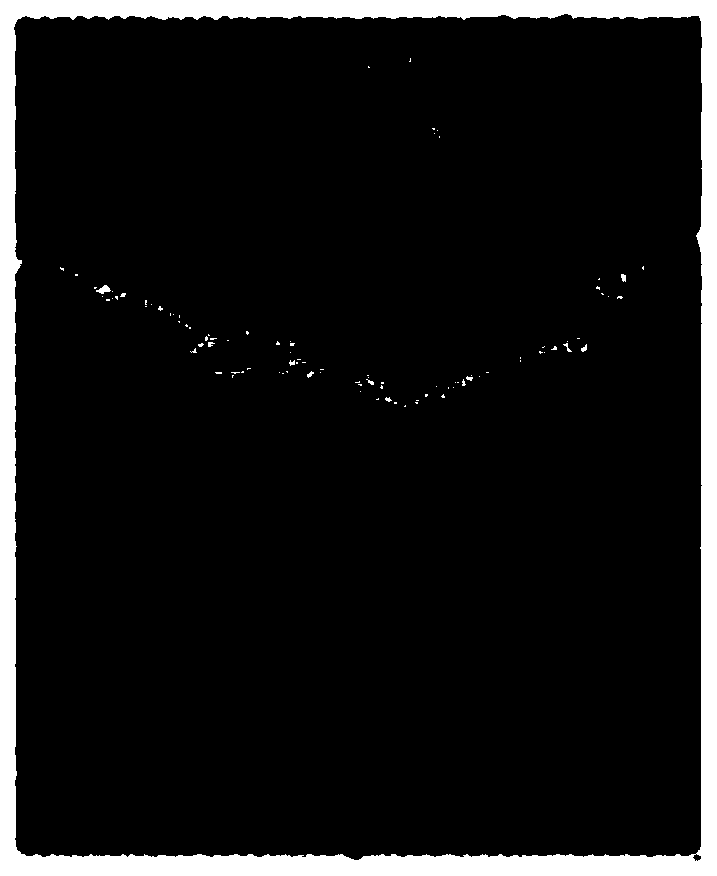

Shear coupling grain boundary migration and crack interaction simulation method in binary alloy

InactiveCN109800490AExtended service lifeAny componentSpecial data processing applicationsBinary alloyGrain boundary migration

The invention belongs to the field of material simulation, and particularly relates to a shear coupling grain boundary migration and crack interaction simulation method in binary alloy. The method comprises the following steps: S1, constructing a pure metal bicrystal model based on a heavy dot matrix model; S2, adding a certain proportion of alloy atoms into the pure metal bicrystal model throughan atom replacement method to construct a binary alloy bicrystal model; S3, presetting cracks in the binary alloy bicrystal model by deleting atoms, and constructing a binary alloy bicrystal model containing the cracks; S4, conducting relaxation on the binary alloy bicrystal model containing the cracks based on a molecular dynamics method; And S5, based on a molecular dynamics method, carrying outshear simulation on the binary alloy bicrystal model containing the cracks in a balanced state to obtain a result of shear coupling grain boundary migration and crack interaction in the binary alloy.According to the invention, a binary alloy system is constructed by randomly replacing atoms, and a binary alloy model with any components and any concentration can be established.

Owner:NANJING UNIV OF SCI & TECH

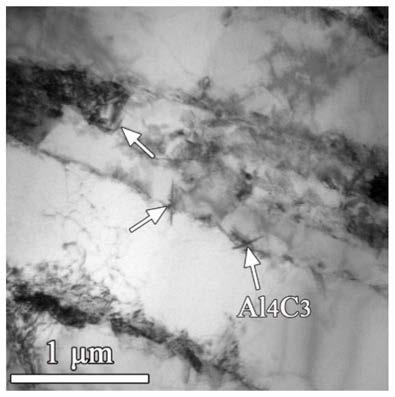

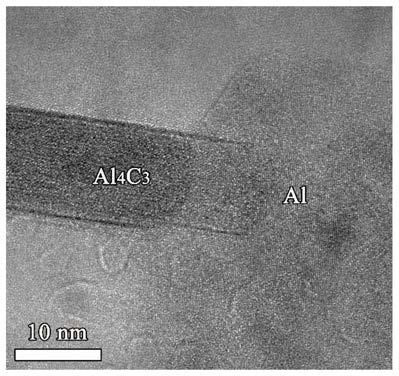

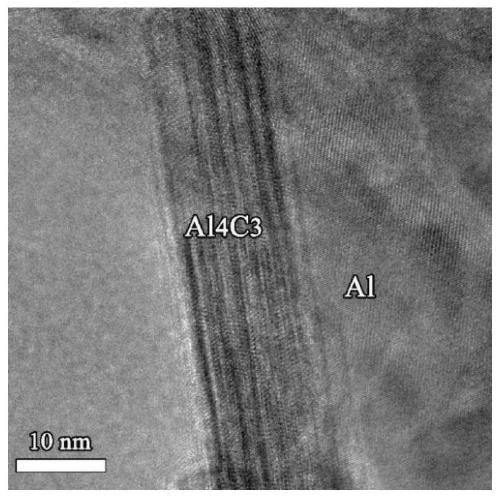

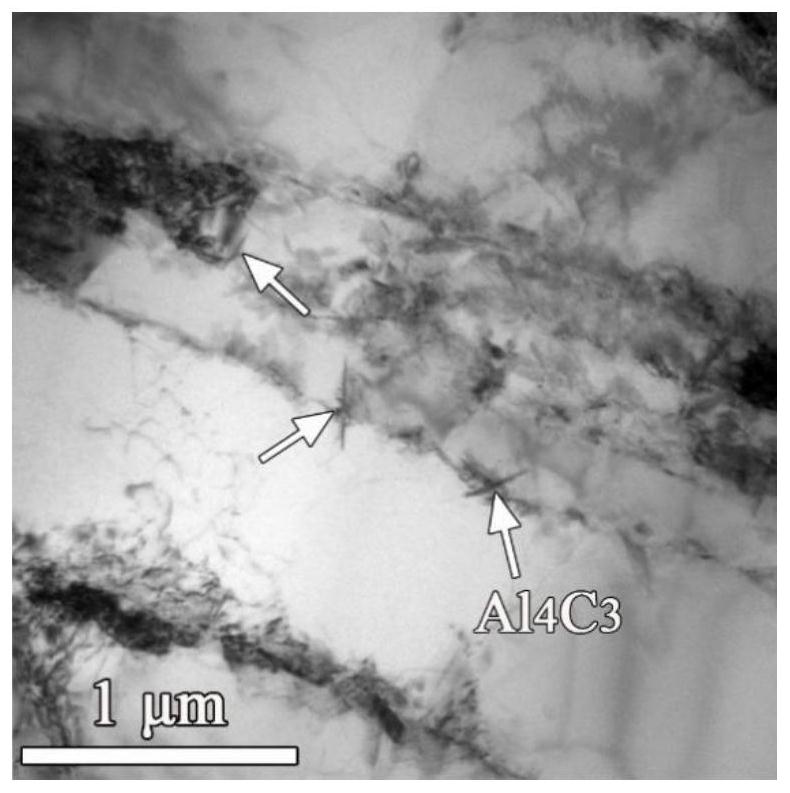

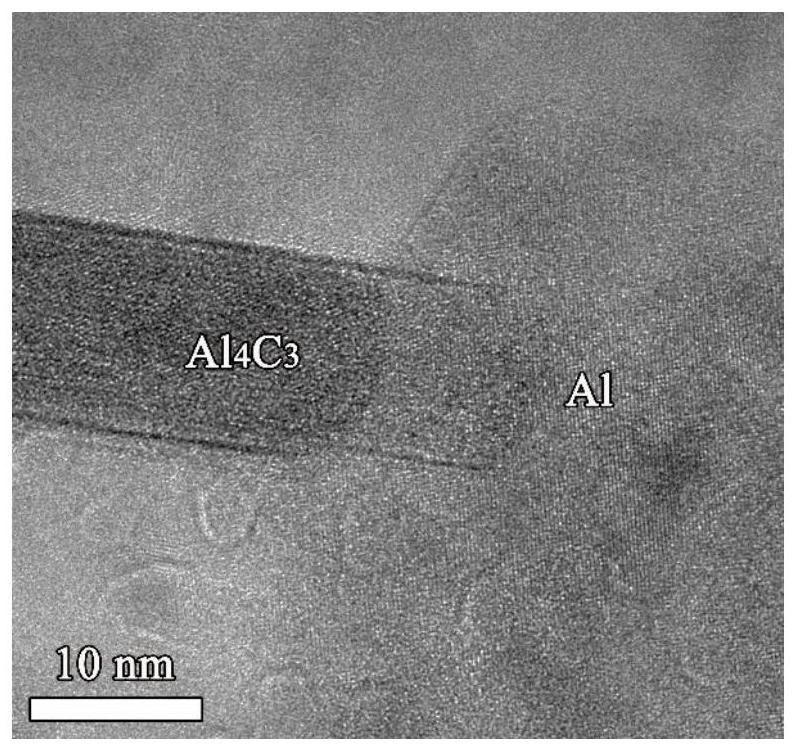

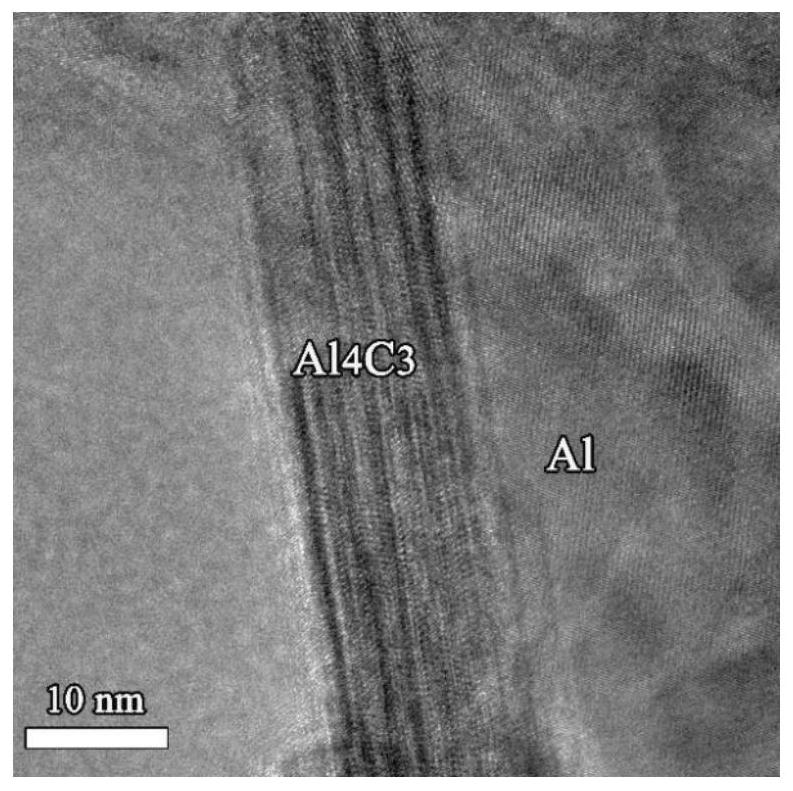

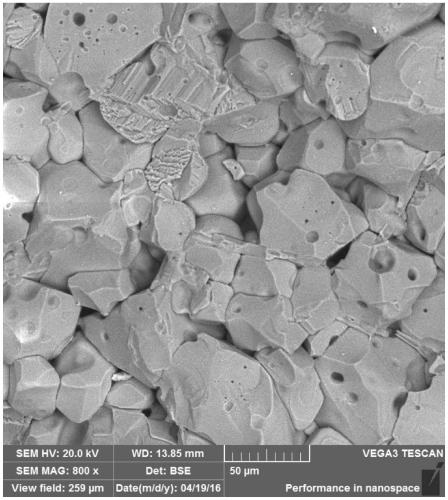

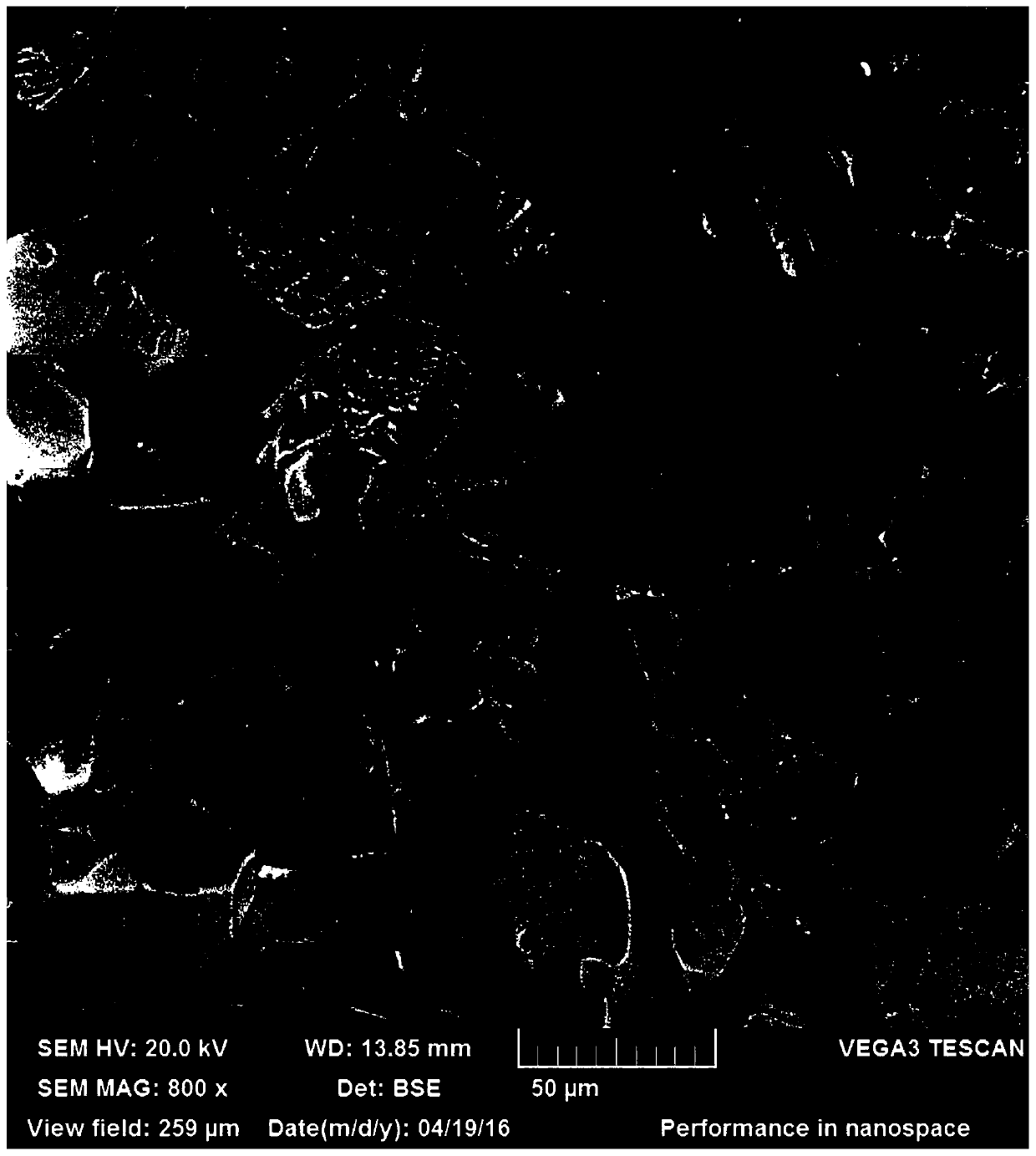

In-situ synthesized aluminum carbide reinforced aluminum matrix composite material and preparation method thereof

The invention provides an in-situ synthesized aluminum carbide reinforced aluminum matrix composite material and a preparation method thereof. The composite material comprises aluminum powder and graphene powder, the aluminum powder and the graphene powder generate dispersedly-distributed nano-scale Al4C3 through in-situ reaction, and the nano-scale Al4C3 is distributed in the composite material in two forms. In one form, the two ends of the nano-scale Al4C3 in a rod-shaped form grow into two aluminum crystal grains and pin two adjacent aluminum crystal grains; and in the other form, the nano-scale Al4C3 is arranged along the grain boundary in the rod-shaped length direction, and dislocations and grain boundary migration can be effectively prevented. On one hand, the nano-scale Al4C3 effectively pins the grain boundary migration of a Al matrix, the strength of the Al matrix is kept, meanwhile, the Al4C3 serves as a hard reinforcing phase, the composite material has high room temperature strength and high-temperature mechanical properties due to stress bearing and the Orowan effect, and the composite material has wide application prospects in the fields of high service temperature conditions such as aerospace and the like.

Owner:SHANGHAI JIAO TONG UNIV

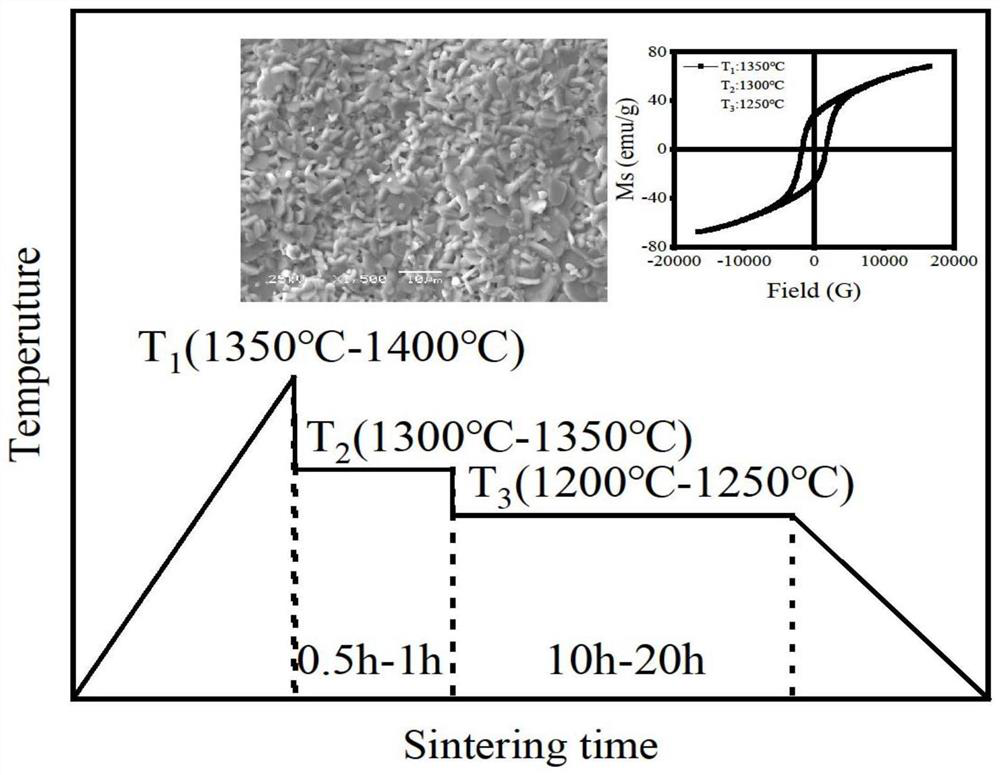

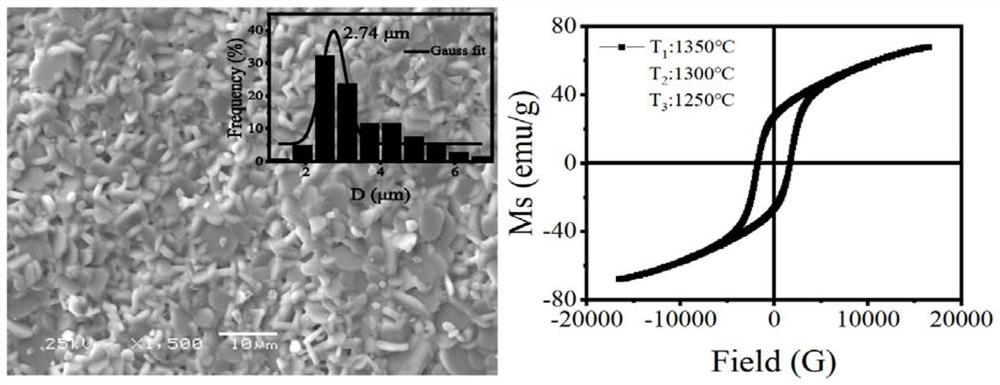

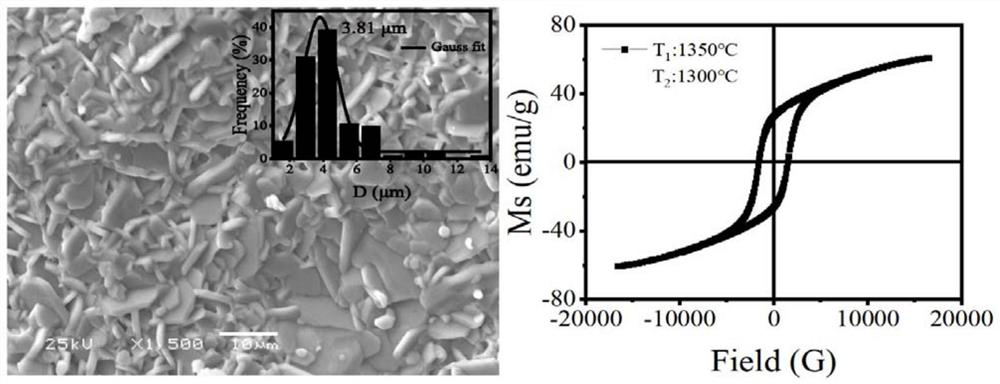

Preparation method for preparing compact small-grain BaFe12O19 ferrite ceramic by three-step sintering method

The invention discloses a preparation method for preparing compact small-grain BaFe12O19 ferrite ceramic by a three-step sintering method. BaFe19O12 powder formed by a sol-gel method is small in particle size and excellent in magnetic property, and the size uniformity of the used BaFe19O12 powder particles is realized by granulating and sieving. In the sintering process, the temperature is rapidly increased to a large value (T1), then the temperature is rapidly reduced to a low value (T2), heat preservation is conducted for a short time, then the temperature is continuously and rapidly reduced to a lower value (T3), heat preservation is conducted for a long time, BaFe19O12 ceramic grain boundary migration is inhibited in the process, and meanwhile BaFe19O12 ceramic grain boundary diffusion activity is kept; and the preparation of the compact small-grain BaFe19O12 ceramic is realized. The product synthesized by the method is small in grain size and high in purity; the prepared BaFe12O19 ceramic has obviously better parameters such as compactness, grain size, saturation magnetization and the like than the BaFe12O19 ceramic prepared by the traditional method, and can meet higher application requirements.

Owner:HANGZHOU DIANZI UNIV

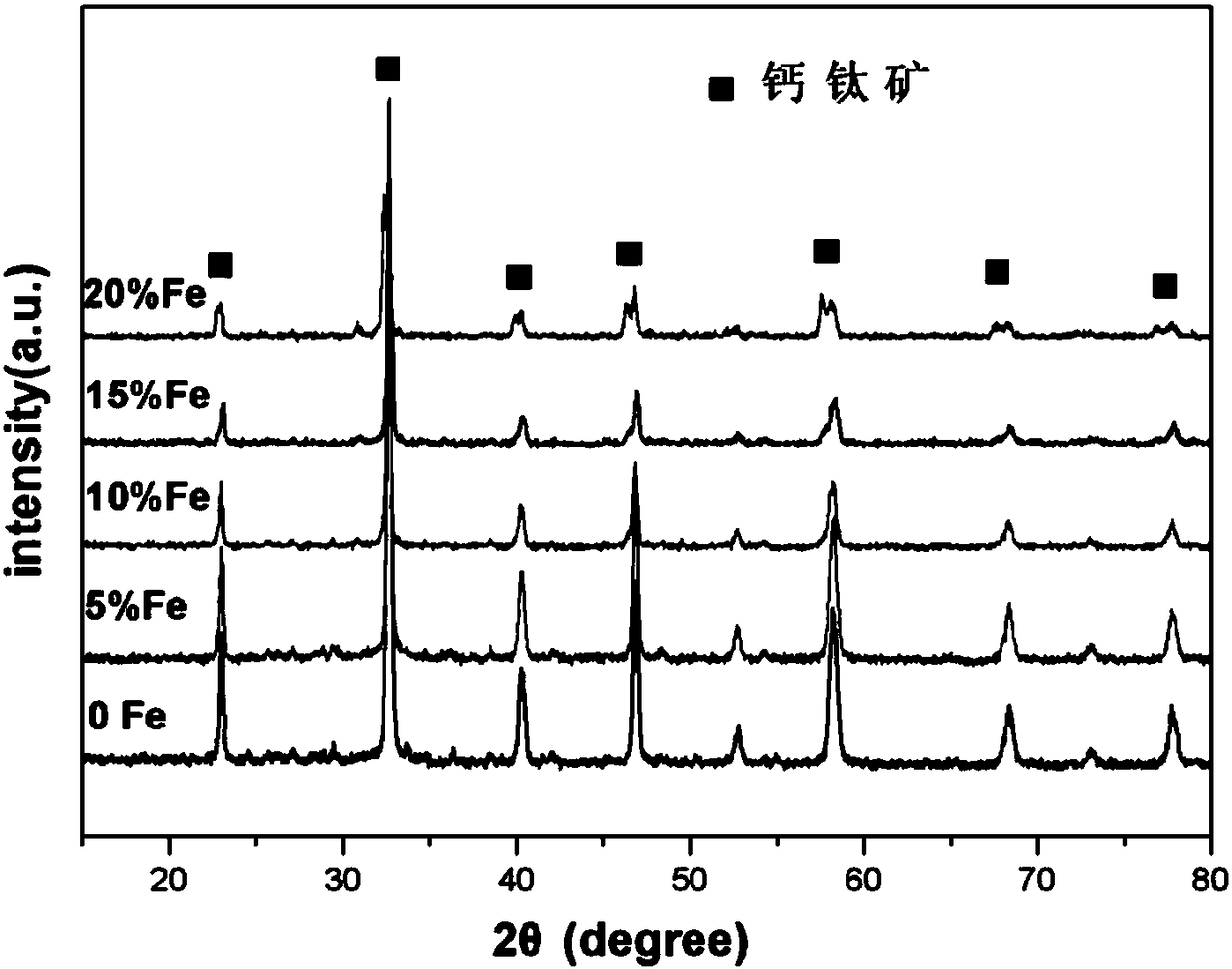

Iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material and preparation thereof

ActiveCN108585854AUniform particle sizeImprove ball milling activityGrain boundary migrationNegative temperature

The invention provides a preparation method of an iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material. The method comprises the following steps: weighing rawmaterials according to a La-Cr-Fe atomic percent of 30-55 to 10-65 to 5-35), and performing wet grinding to obtain slurry; drying the slurry, and grinding to obtain a powder; calcining to obtain a perovskite phase (LaCrFe)2O3 powder; preparing a bulk material from the powder, adopting a two-step sintering method, and performing furnace cooling, so as to obtain the iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material. According to the preparation method disclosed by the invention, the two-step sintering method is adopted, grain boundary diffusion is positioned in an active state while inhibiting grain boundary migration, and the aim of completing sintering on premise of not growing grains is achieved; the finally prepared ceramic material is smallin grain size, uniform in distribution, high in resistance, wide in adjustable range, small in value B change, high in stability and excellent in consistency.

Owner:UNIV OF JINAN

A method for rapid sintering of fully stabilized zirconia powder at low temperature and atmospheric pressure

The invention discloses a method for rapidly sintering fully stabilized zirconia powder under low temperature and normal pressure, which belongs to the field of fine chemical engineering. The method includes the steps of zirconium salt and stabilizer mixing, coprecipitation, washing, drying, heat treatment, mixing with molten salt solution, drying, grinding, dry pressing, calcination and the like. By introducing trace molten salt into the fully stabilized zirconia powder and utilizing the molten salt to form liquid phase under low temperature, while promoting the grain boundary diffusion of the powder, the method inhibits the grain boundary migration of the powder, consequently, the contradiction between densification and grain coarsening in the process of sintering the fully stabilized zirconia powder is solved, and the normal-pressure rapid sintering of the fully stabilized zirconia powder under low temperature is realized; in addition, cations in the molten salt get into the ZrO2 crystal lattice by doping, consequently, the ZrO2 crystal form is further stabilized, and the properties of the material are further improved; the average bending strength of the obtained sintered body is greater than 450Mpa, the theoretical density is greater than 93 percent, and the grain size is between 425nm and 520nm.

Owner:JIANGXI UNIV OF SCI & TECH

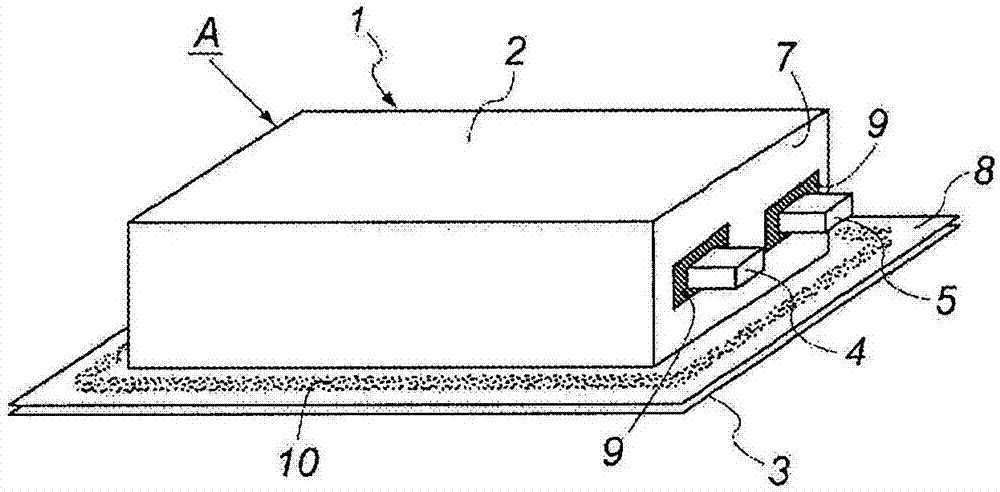

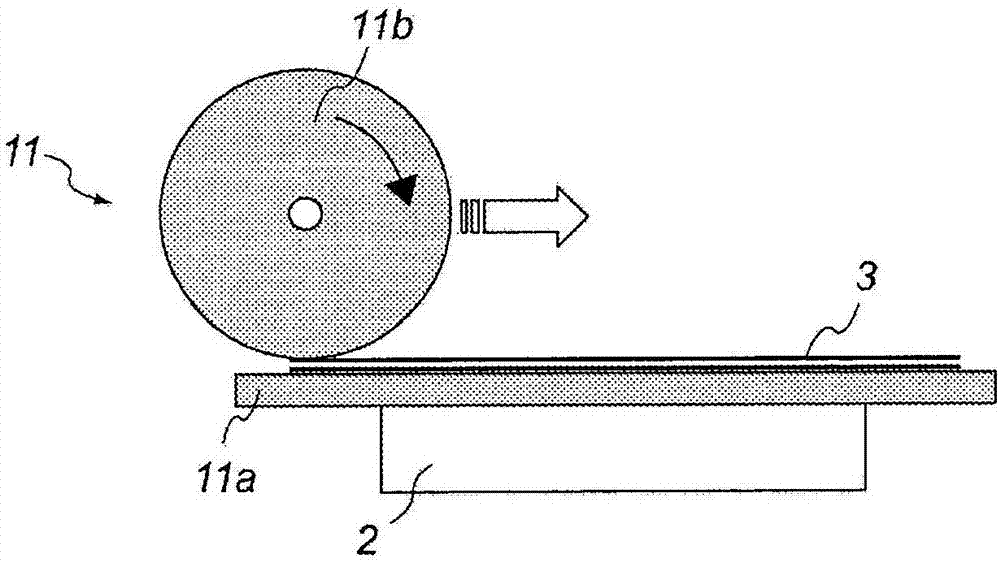

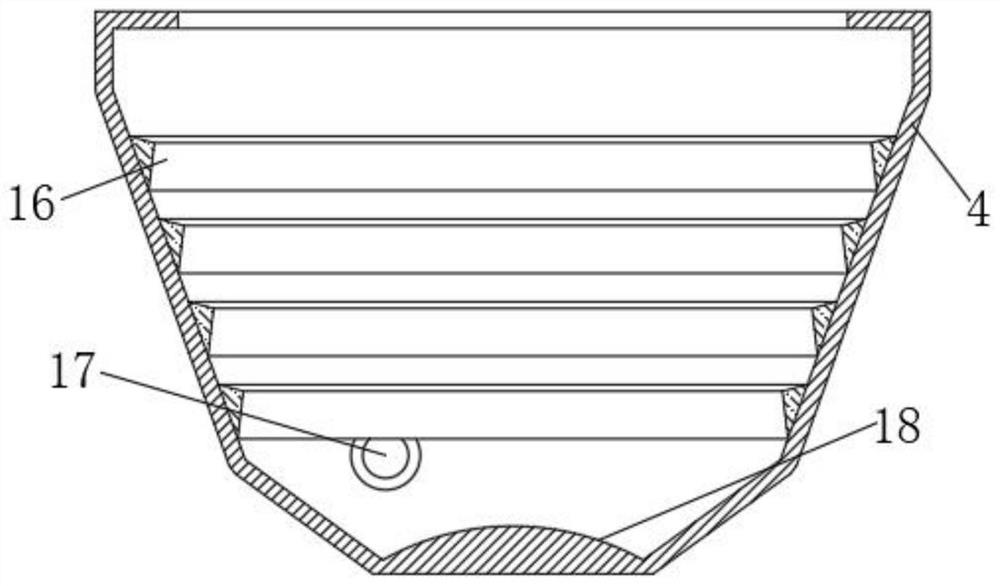

Lithium-ion secondary-battery case and manufacturing method therefor

InactiveCN107078230ADifficulty deformingHigh strengthFinal product manufactureSecondary cellsLithiumGrain boundary migration

This invention provides a lithium-ion secondary-battery case, and a manufacturing method therefor, that can be joined with no weld spatter and is strong with respect to external forces acting on said case. Said case is characterized in that: a cup component (2) comprises an austenite stainless-steel foil; a cap component (3) comprises a two-phase stainless steel that exhibits an austenite start temperature Ac1 between 650 DEG C and 950 DEG C during a temperature-raising process and has an austenite-ferrite two-phase temperature region starting at 880 DEG C; said components are placed in direct contact with each other; and in a heating-temperature range of 880-1080 DEG C, diffusion bonding is performed, accompanied by grain-boundary migration as the ferrite phase of the two-phase steel transforms into an austenite phase.

Owner:NISSHIN STEEL CO LTD

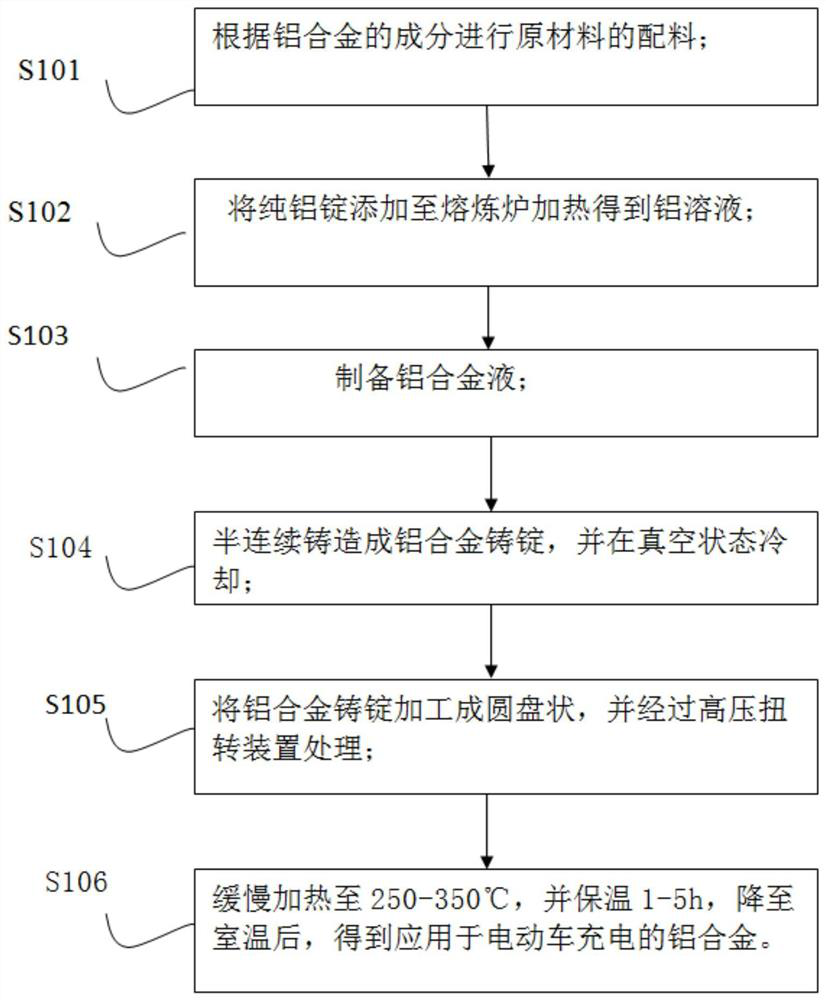

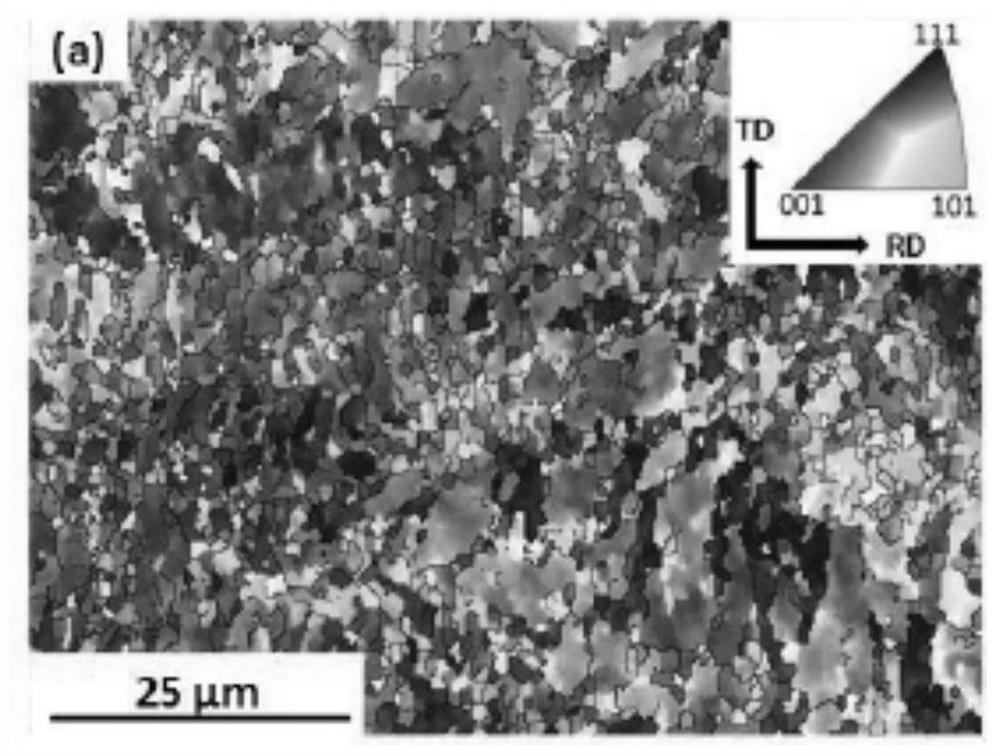

Aluminum alloy applied to electric vehicle charging and preparation method thereof

InactiveCN111850359AImprove refinementHomogeneous nanocrystalline structureFiberGrain boundary migration

The invention provides aluminum alloy applied to electric vehicle charging and a preparation method thereof. Through optimizing the composition of the aluminum alloy and adding a certain proportion oftrace elements, after an aluminum alloy ingot is treated through high-pressure torsion, and heating and insulation treatment is carried out, grain refinement can be significantly promoted, a uniformnanocrystalline structure is formed through twist deformation, fiber distribution presents, and at the same time, a large-angle grain boundary greater than 15 degrees migrates to a smaller-angle grainboundary, and the average grain size dTEM of the obtained aluminum alloy is 40-60 nm, while the hardness of the aluminum alloy is ensured, the plasticity and heat resistance of the use of the aluminum alloy can be ensured, and the yield of products is improved; and on the whole, the problem that during the aluminum alloy processing, fine and uniform crystal aluminum alloy cannot be obtained, resulting in poor plasticity and heat resistance of prepared aluminum alloy materials in plastic use is solved.

Owner:佛山金兰铝厂有限公司

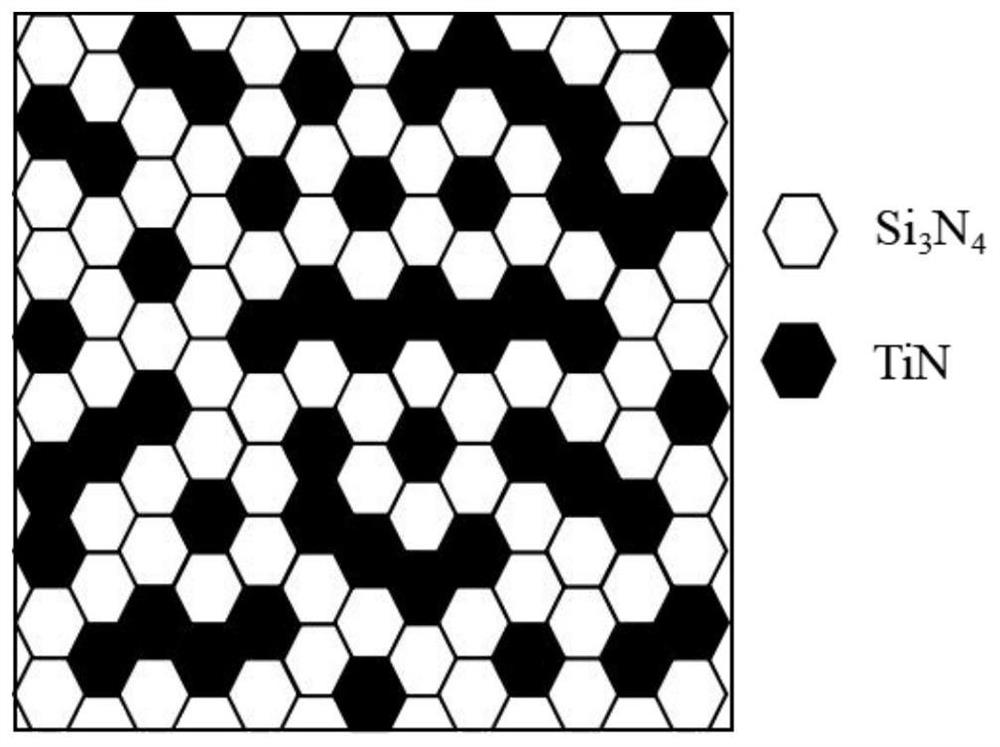

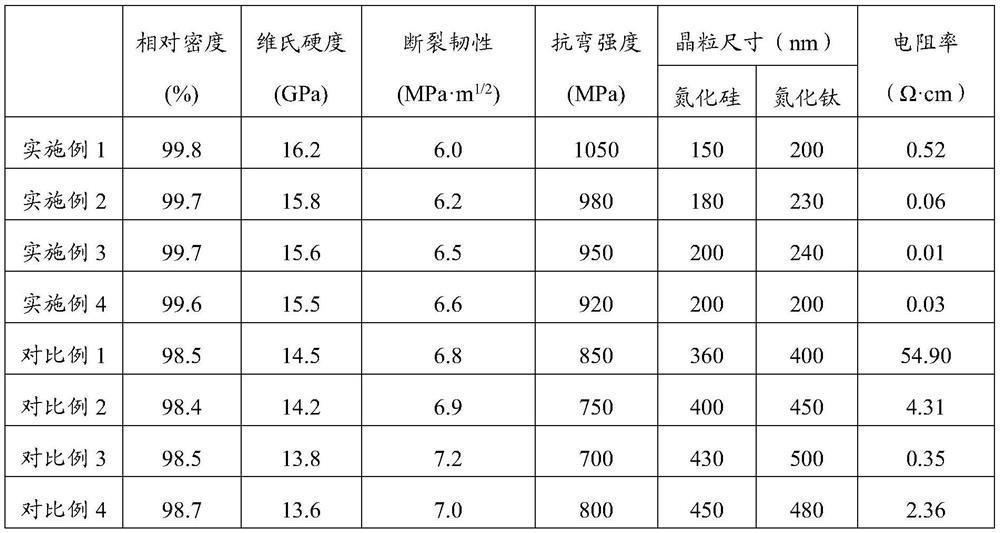

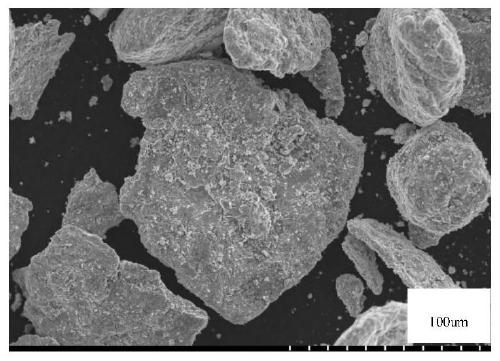

Preparation method of silicon nitride-based multiphase conductive ceramic

ActiveCN112851365AFine and uniform grainHigh densityGrain boundary migrationUltimate tensile strength

The invention provides a preparation method of silicon nitride-based multiphase conductive ceramic. According to the invention, silicon nitride is taken as a matrix, a conductive phase and a sintering aid are added, and a two-step microwave sintering method is adopted, so that the prepared silicon nitride-based multiphase conductive ceramic is fine and uniform in grain and high in density, and the mechanical properties such as strength and hardness are also remarkably improved. A two-step microwave sintering method is adopted, grain boundary migration can be inhibited, and densification is achieved through grain boundary diffusion. Therefore, the method not only can inhibit the growth of crystal grains in the later stage of sintering, but also does not affect the densification. The result of the embodiment shows that the relative density of the silicon nitride-based multiphase conductive ceramic provided by the invention is greater than 99%, the Vickers hardness is greater than 15 GPa, the fracture toughness is greater than 6 MPa.m<1 / 2>, the bending strength is greater than 900 MPa, and the resistivity is less than 1 [omega].cm.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD

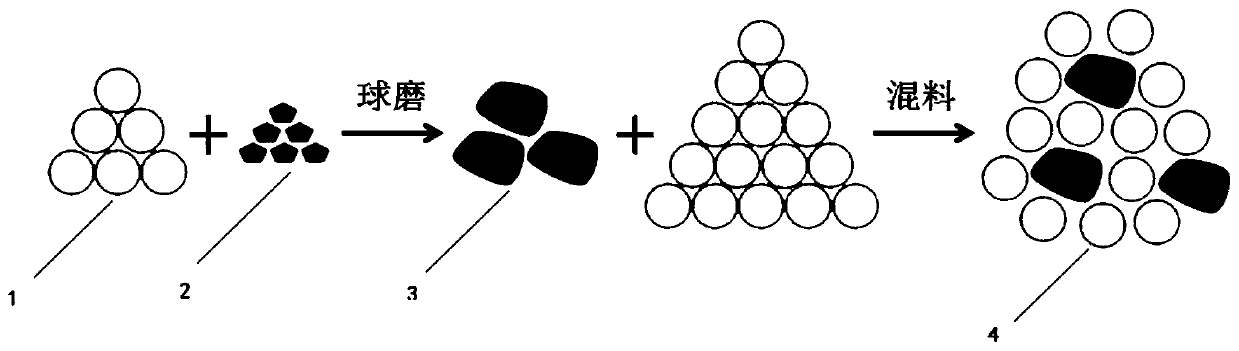

A kind of high-entropy alloy reinforced by ceramic particles and its preparation method

ActiveCN109338199BReduce decreaseImprove mechanical propertiesGrain boundary migrationHigh entropy alloys

The invention discloses a preparation method of a ceramic particle reinforced high-entropy alloy. The preparation method comprises the following steps that (1), ceramic particles and a high-entropy alloy are weighed, wherein the ceramic particles account for 0.1-0.5 wt.% of the sum of weights of high-entropy alloy powder and the ceramic particles, and the ceramic particles serve as alloy elementsto conduct ball milling with a first part of the high-entropy alloy to obtain high-entropy-ceramic alloy powder, wherein the first part of the high-entropy alloy accounts for 5-10% of the total weight; (2) the high-entropy-ceramic alloy powder and remaining high-entropy alloy powder are mixed; (3) the mixed powder is cold-pressed to be formed, and a pre-pressed part is obtained; and (4) the pre-pressed part is sintered at a high temperature, the grain boundary of the high-entropy alloy is migrated, thus the ceramic particles are wrapped, and natural cooling is conducted after sintering. The preparation method is less in consumed time and low in cost, the ceramic particles in the grain boundary of the high-entropy alloy are reduced, and thus the possibility of brittle fracture is decreased.According to the ceramic particle reinforced high-entropy alloy, the comprehensive mechanical properties of the high-entropy alloy are improved.

Owner:XI AN JIAOTONG UNIV

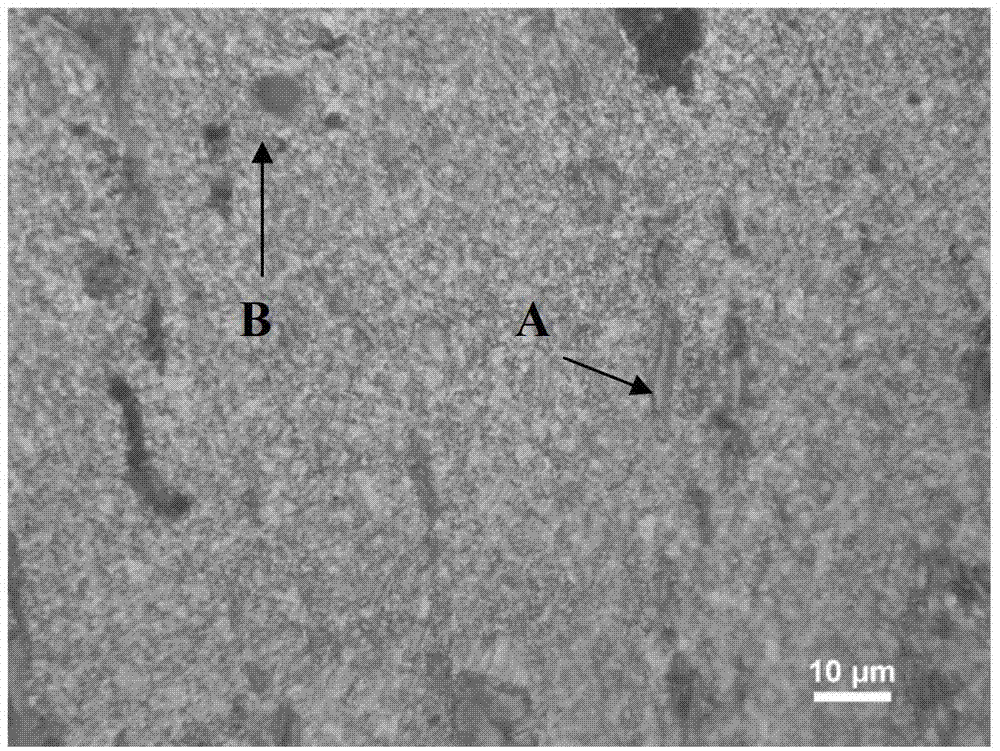

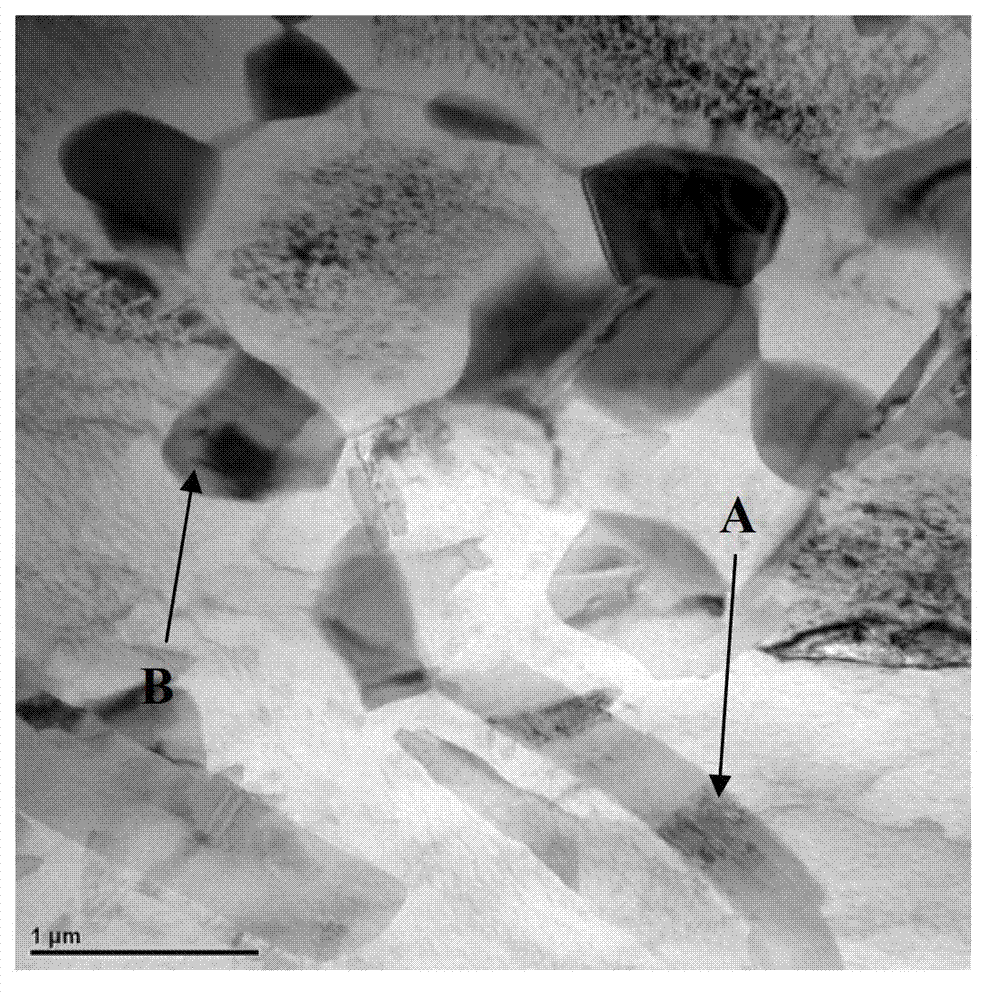

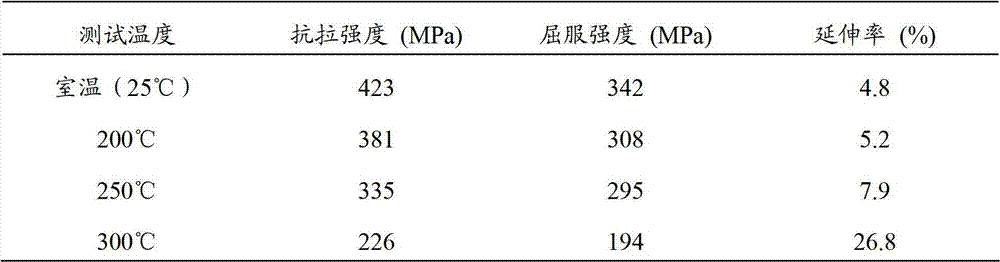

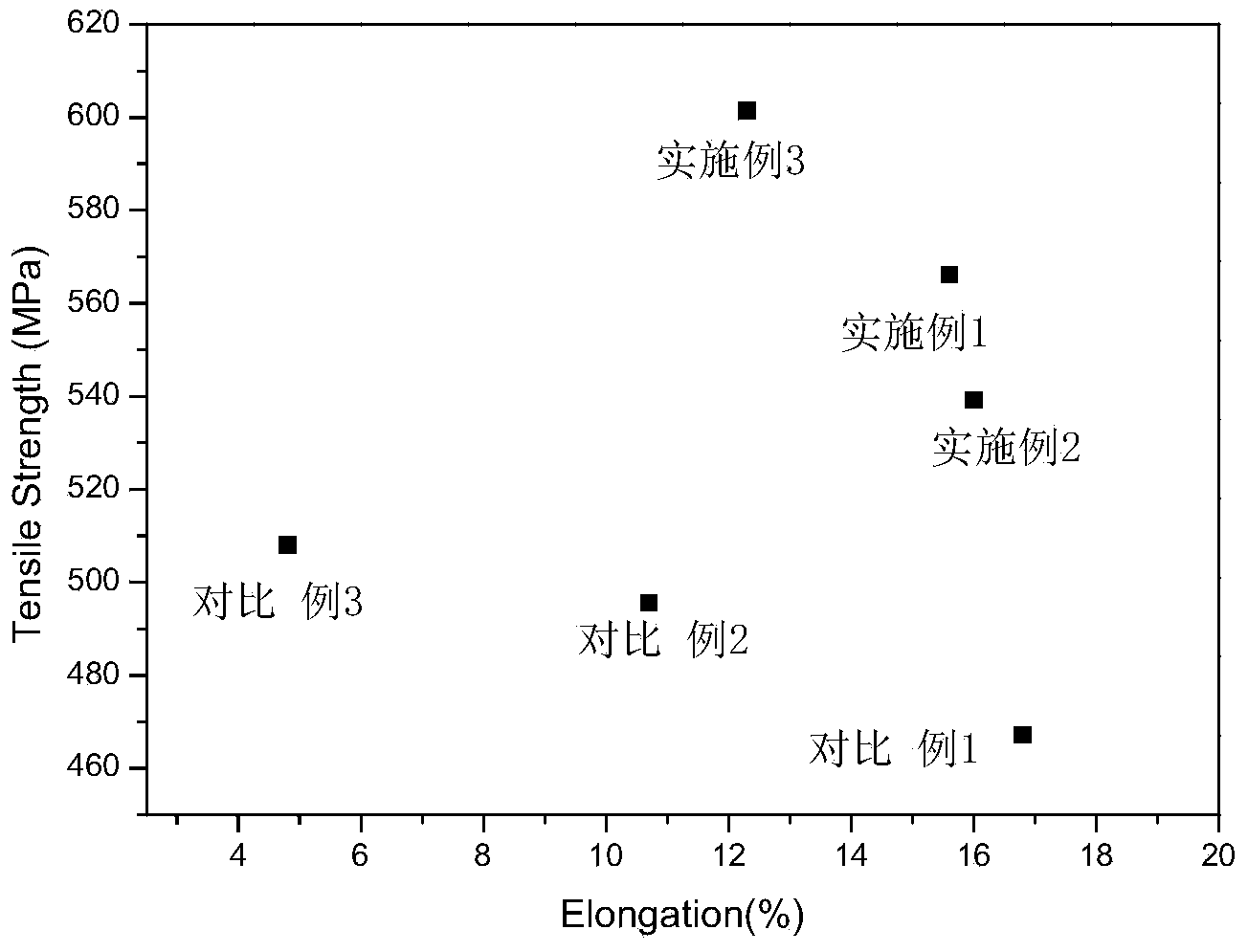

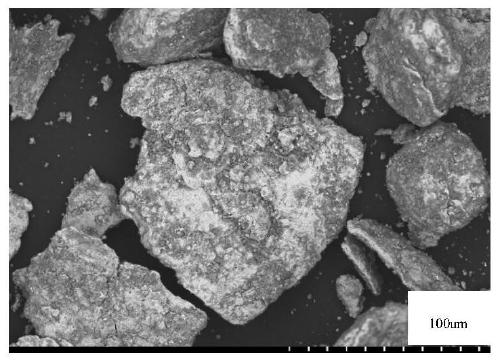

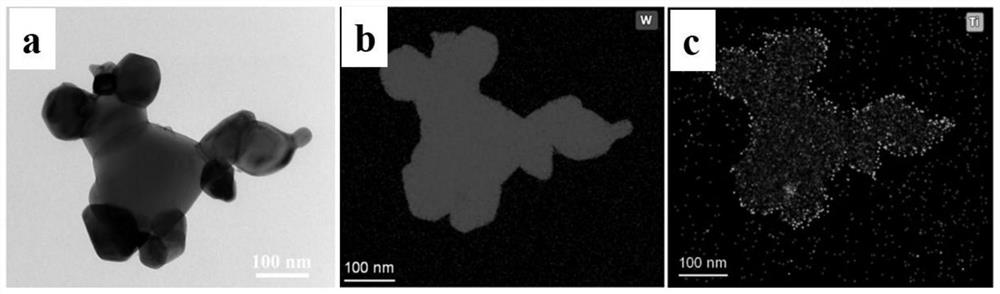

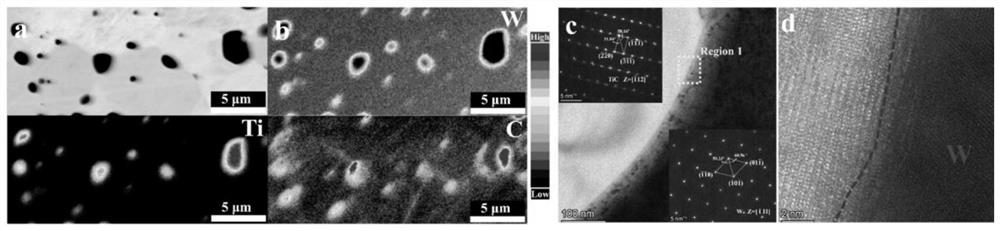

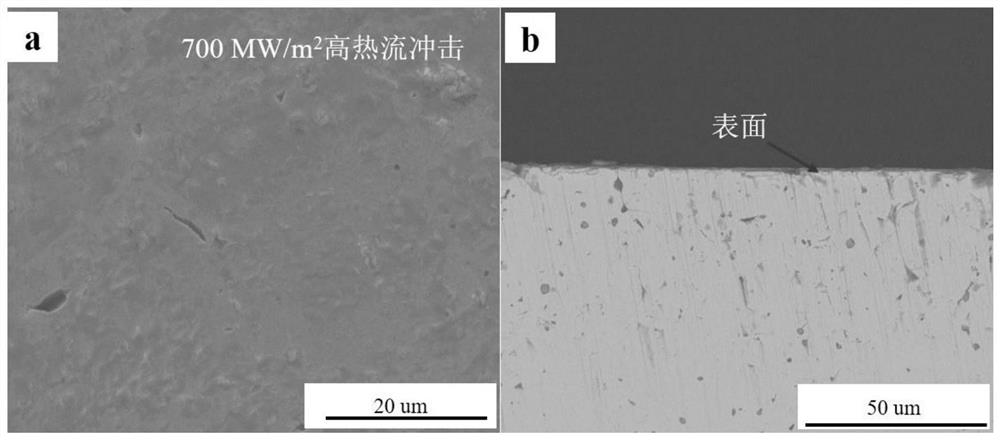

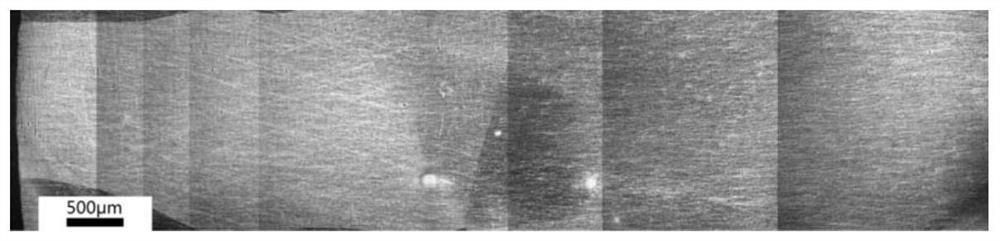

High-heat load impact resistant high-toughness fine-grain W-based composite material and preparation method thereof

The invention provides a fine grain W-based composite material with high thermal load impact resistance and high toughness and a preparation method thereof. The composite material is composed of a composite reinforcement phase, wherein the composite reinforcement phase is composed of nanoscale ultra-high-temperature ceramic carbide (TiC or ZrC), Ti and Zr alloying elements and a refractory metal W matrix; alloying elements are distributed on the surface of a W matrix, and an enrichment area is formed at nano ultra-high-temperature carbide particles, so that an interface structure of an ultra-high-temperature carbide ceramic phase and a W matrix phase is effectively improved, W grain boundary migration and partial formation of semi-coherence are hindered, and fine grains and interface strengthening and toughening are realized; the preparation method comprises the following steps: sol spray drying, reduction, high-energy activation treatment and low-temperature reinforced sintering. The grain size of the composite material is 1-2 [mu] m, the tensile strength at room temperature reaches 450-600 MPa, the ductility is 5%-8%, no crack damage is formed on the surface under the impact of a transient electron beam high heat load of 700 MW / m < 2 >, and the high heat load impact resistance of the W composite material is remarkably improved.

Owner:CENT SOUTH UNIV +1

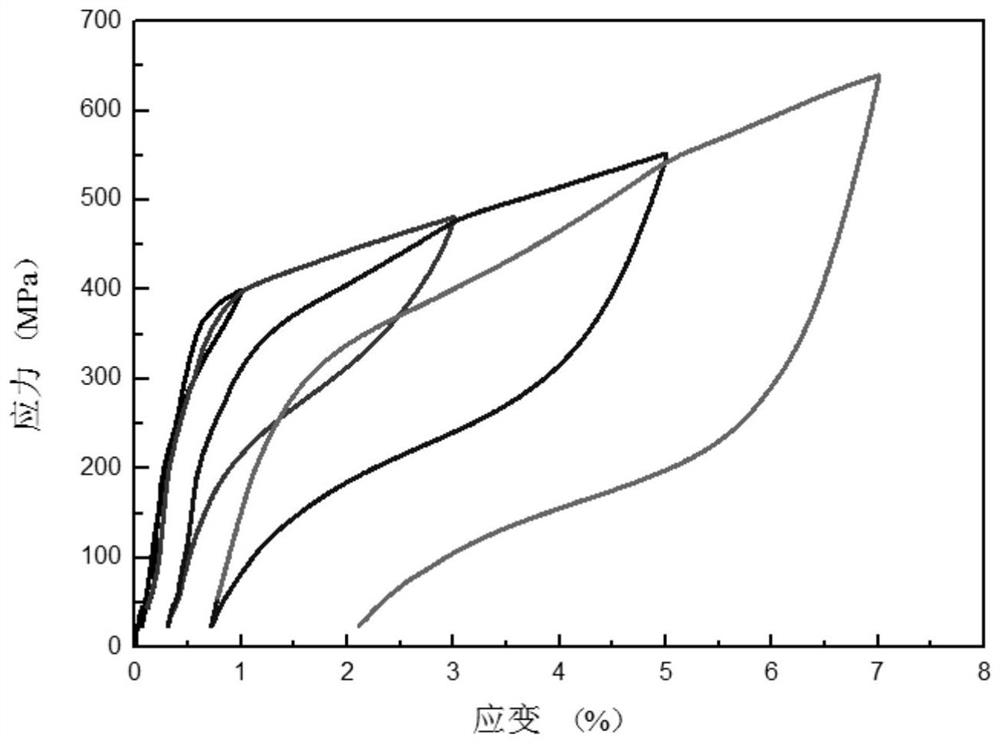

A kind of cualmn shape memory alloy and preparation method thereof

ActiveCN109112349BPromote growthDirectional annealing process is simpleAbnormal grain growthGrain boundary migration

The invention provides CuAlMn shape memory alloy and a preparation method thereof. The alloy is prepared from the following component by mass percentage: 12.0-20.0% of Al, 7.0-15.0% of Mn and the balance of Cu; the preparation method of the alloy comprises the following steps: (1) selecting Cu, Al and Mn and proportioning according to the alloy composition, and then smelting in a crucible to obtain an alloy ingot; (2) deforming the alloy ingot to obtain a sample to be used; (3) enabling the sample to be used to be subjected to regional heating, arranging a temperature field having a temperature gradient near a heating region, and enabling the sample to be subjected to directional annealing after passing through the heating region and the temperature field; (4) then, adopting a cyclic heattreatment method, an orientation annealing method or a cyclic heat treatment and orientation annealing combined method to obtain the CuAlMn shape memory alloy having a single crystal or a columnar crystal structure. The method provided by the invention uses the directional annealing to realize directional grain boundary migration of the CuAlMn shape memory alloy in an abnormal grain growth process, thus being beneficial to the directional growth of crystals; the method is simple in directional annealing process, is not limited by the sizes and shapes of products, and can be used for efficiently preparing the large-size single-crystal CuAlMn shape memory alloy.

Owner:HARBIN ENG UNIV

A kind of high-temperature embrittlement-resistant free-cutting aluminum alloy and preparation method thereof

The invention provides a high-temperature-embrittlement-resistant free-cutting aluminum alloy and a preparation method thereof. The aluminum alloy is composed of the following components of, by mass,1.0-1.2% of Mg, 0.6-0.9% of Si, 0.3-0.5% of Mn, 0.15-0.2% of Cu, 0.15-0.2% of Fe, 0.1-0.15% of Cr, 0.04-0.05% of Sr, 0.03-0.04% of Ti, 0.006-0.008% of B, 0.4-0.6% of Sn, 0.3-0.5% of Bi and the balanceAl and unavoidable impurity elements. By optimizing and designing the composition and preparation process of the alloy, a continuous network Sn-Bi low-melting-point eutectic structure on the grain boundary is transformed into a discontinuous network, coarse needle-like Fe-rich phases and excess Si phases are transformed into fine grains which are dispersed in an aluminum matrix, grain boundary migration and dislocation motion are inhibited, the recrystallization temperature and high temperature stability of the free-cutting aluminum alloy are improved, and the problem of high temperature embrittlement of the free-cutting aluminum alloy is solved. The aluminum alloy has excellent cutting performance and high temperature resistance, does not contain heavy metal elements such as lead and cadmium, and belongs to environmental-friendly free-cutting aluminum alloys.

Owner:GUANGDONG INST OF NEW MATERIALS

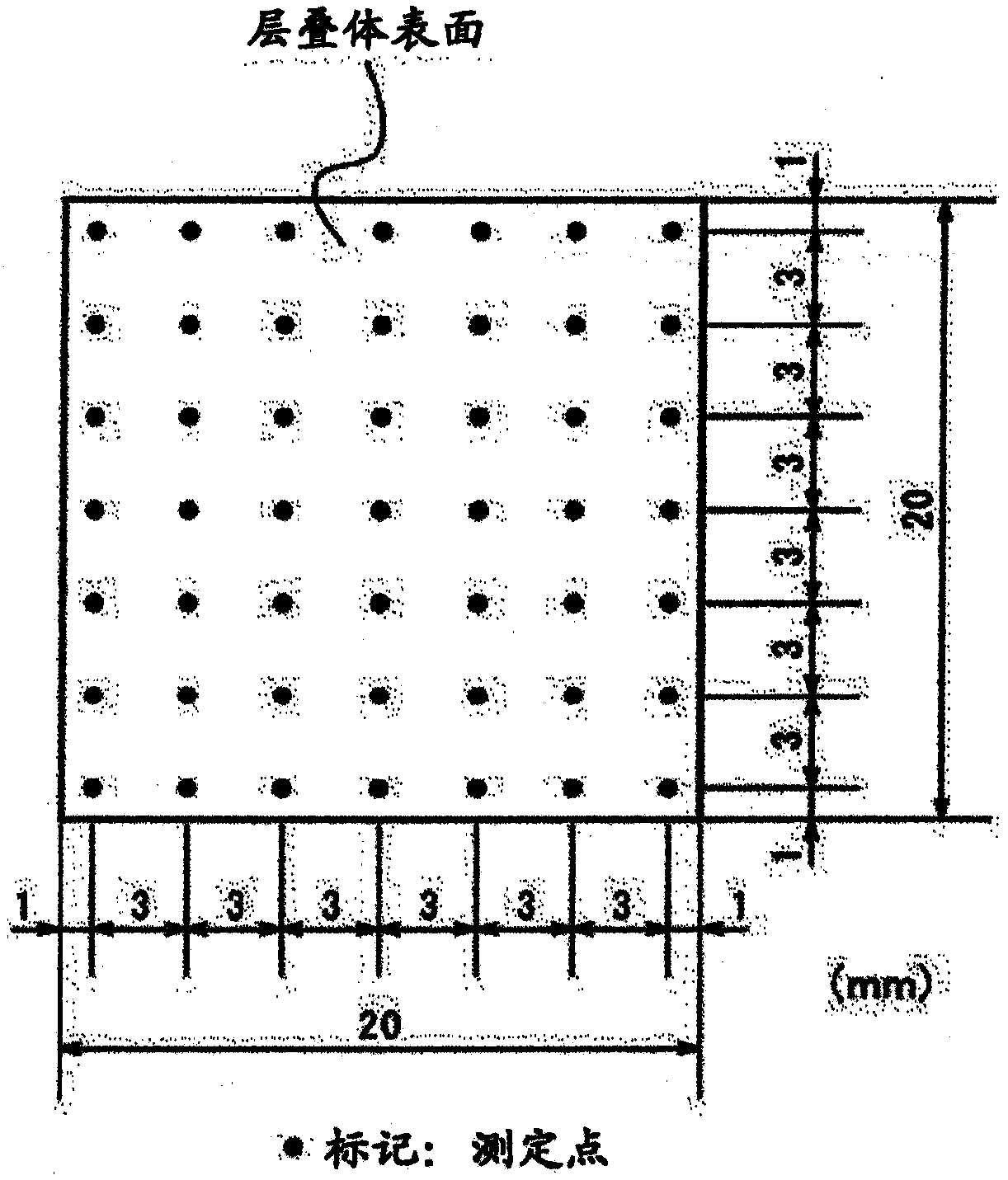

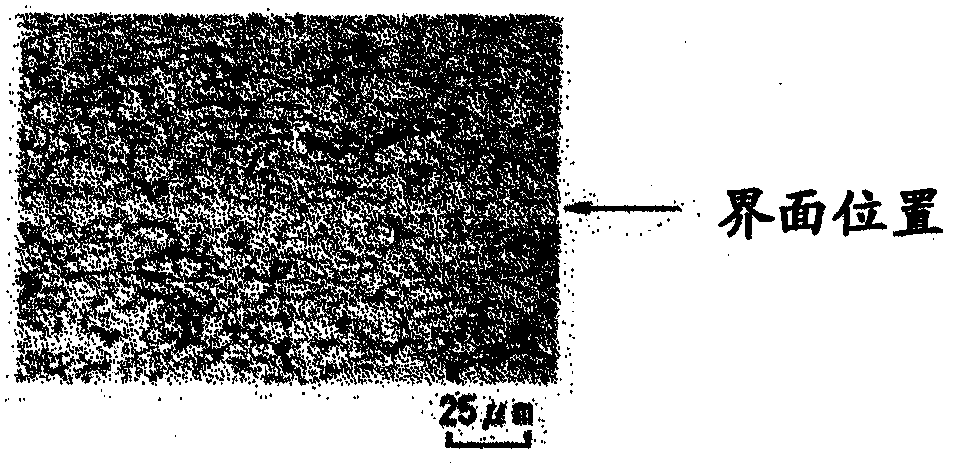

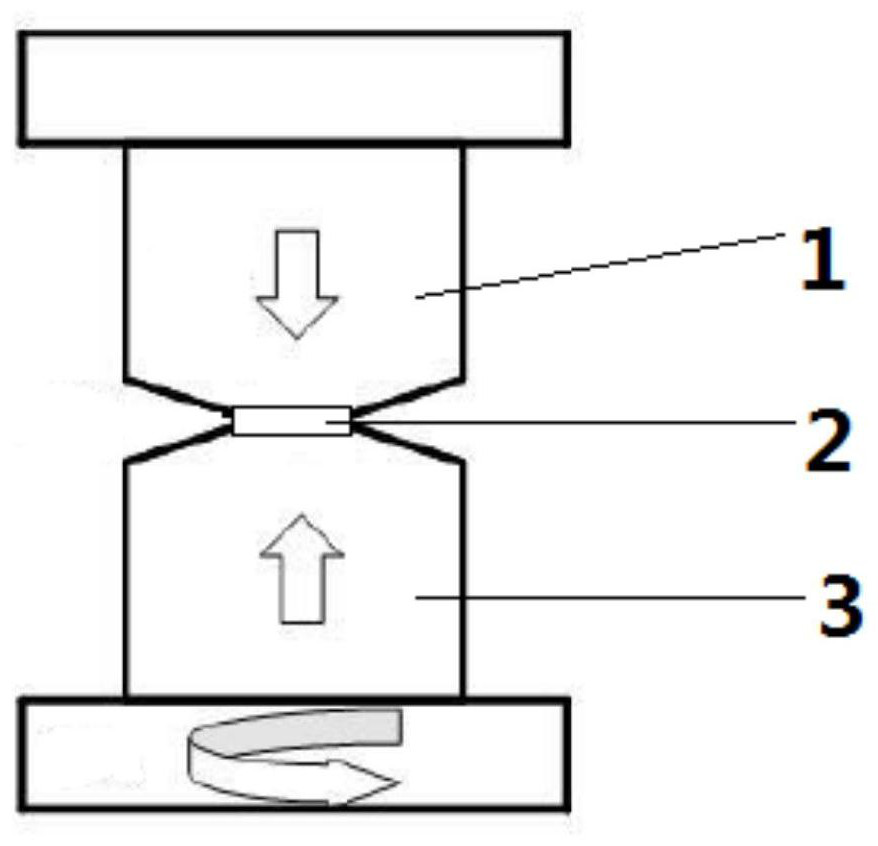

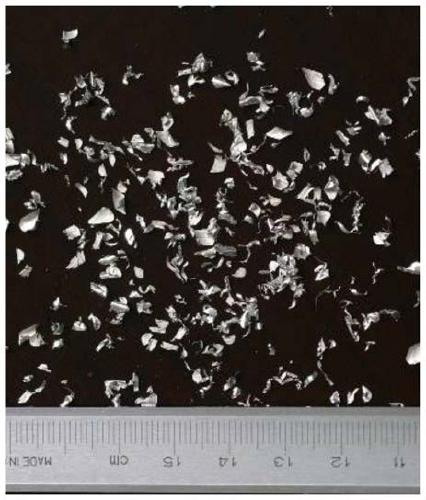

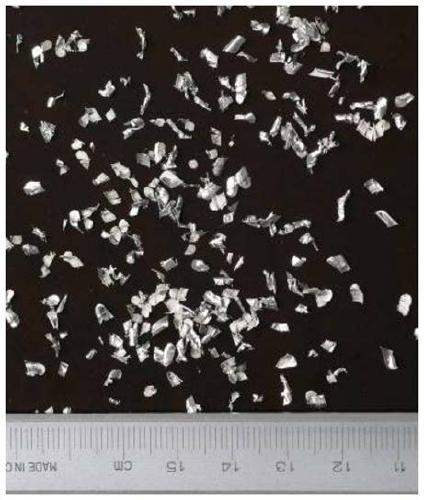

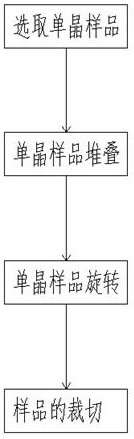

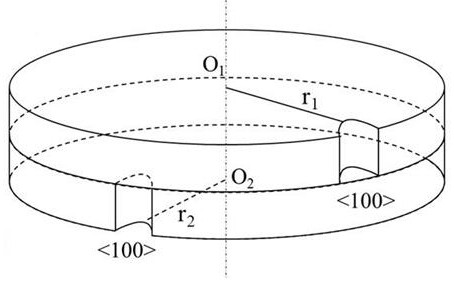

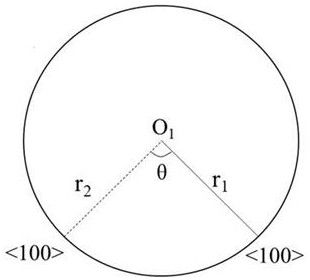

Experimental method for simulating grain boundary migration

PendingCN114112892AReduce the likelihood of migrationHigh migration energy barrierMaterial analysis using wave/particle radiationUsing mechanical meansGrain boundary migrationExperimental methods

The invention relates to an experimental method for simulating grain boundary migration. The experimental method is characterized by comprising the following specific steps: S1, selecting a single crystal sample; s2, stacking the single crystal samples; s3, rotating the single crystal sample; s4, cutting the sample; the method comprises the following steps of: constructing a real polycrystalline system under a large-volume sample by taking laminated single-crystal high-purity metal as an object, and screening out grain boundary characteristic information capable of migrating under the action of shear stress on the basis of adopting a high-pressure torsion process; the characteristic information makes research on a common crystal boundary migration mechanism of shear coupling possible.

Owner:NANTONG L S LIGHT METAL FORMING

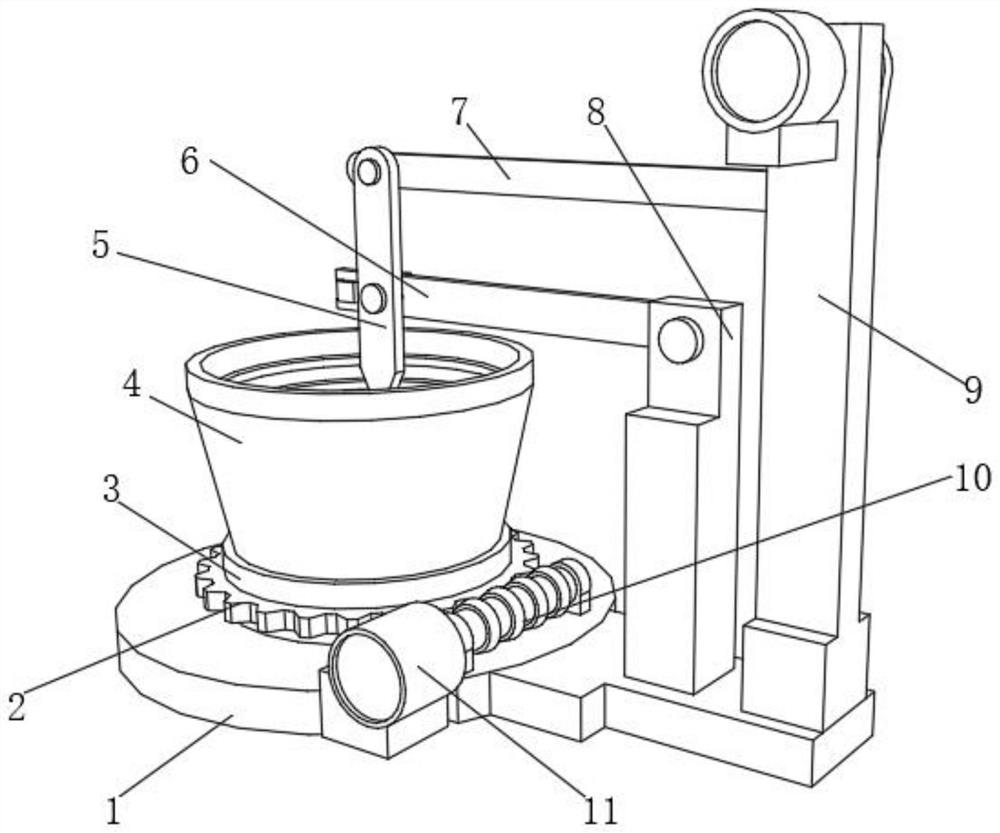

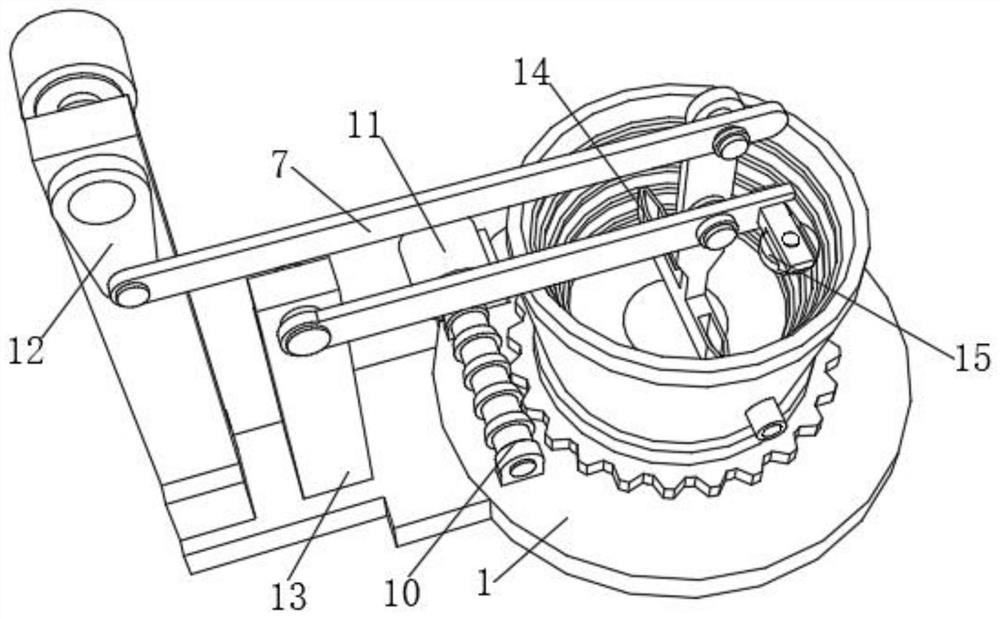

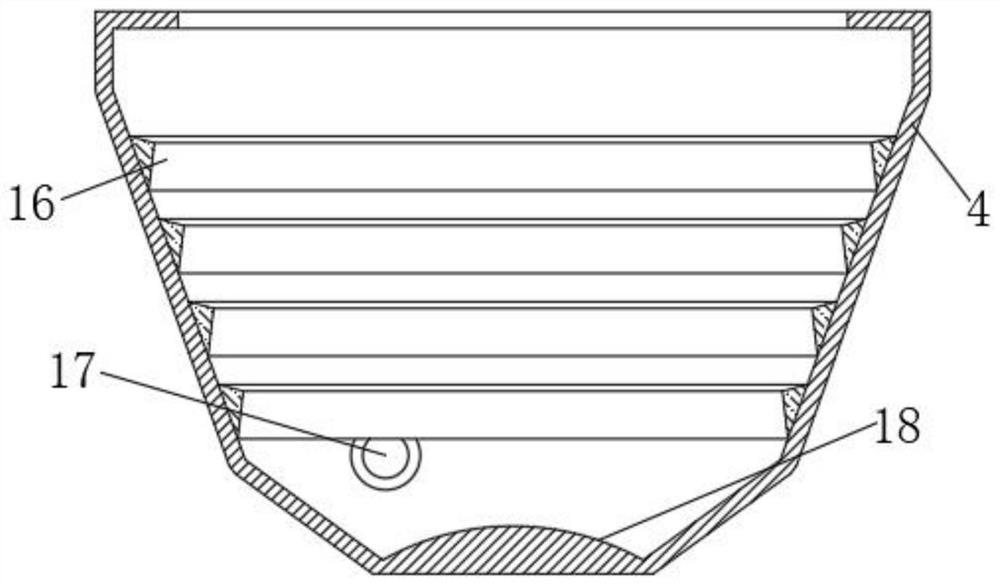

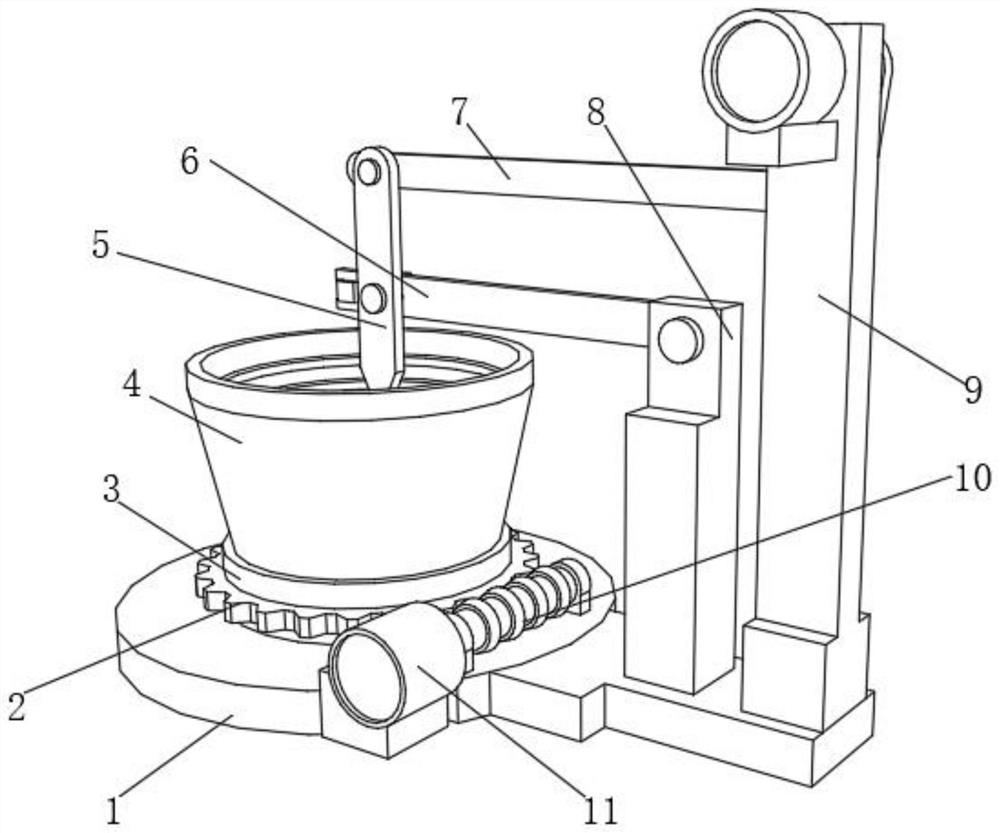

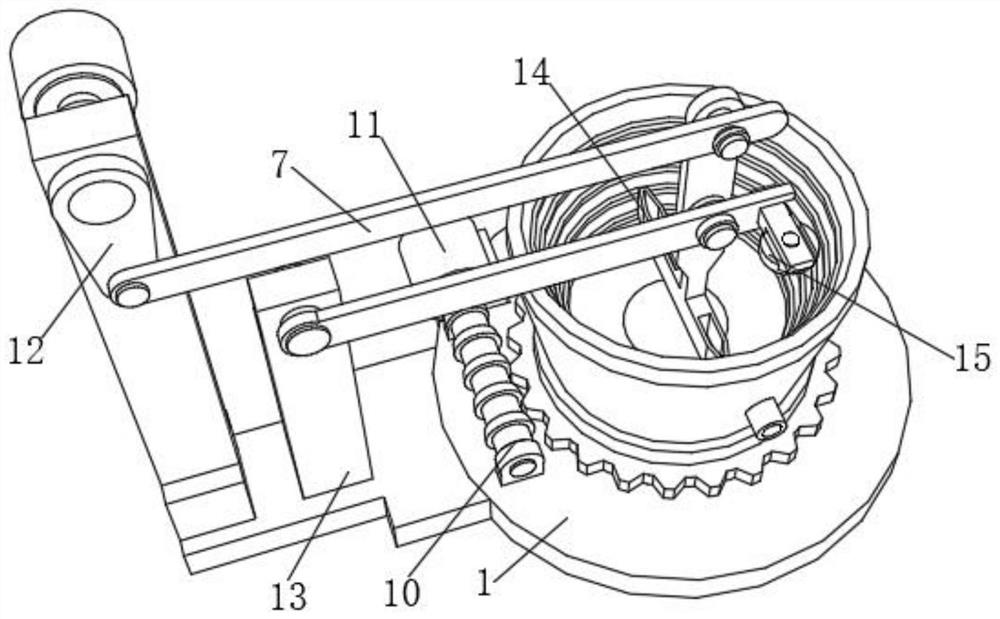

Welding material and production device thereof

ActiveCN112276415AImprove arc striking effectWell formed weldRotating receptacle mixersTransportation and packagingGrain Boundary SlidingGrain boundary migration

The invention discloses a welding material and a production device thereof, relates to the technical field of welding materials, and aims to solve the problem of high-temperature plastic loss cracks.The production device specifically comprises a base, a mounting groove is formed in the outer wall of one side of the top of the base, a first motor is fixed to the inner wall of one side of the mounting groove through a supporting plate, a worm is fixed to the output end of the first motor through a coupler, the two ends of the worm are fixed to the top of the base through bearing pedestals correspondingly, a driving gear is fixed to the outer wall of the top circle center of the base through a supporting shaft and engaged with the worm, a first mounting base and a second mounting base are fixed to the outer wall of one side of the base through bolts, a second motor is fixed to the outer wall of one side of the second mounting base through a supporting plate, and a mounting plate is fixedto the outer wall of the top of the driving gear through threads. Gathering of lattice defects can be blocked, grain boundary sliding and grain boundary migration are prevented from occurring at thesame time and meeting, and then high-temperature plastic loss cracks are avoided.

Owner:东安县双龙焊剂新材料有限公司

A kind of welding material and its production device

ActiveCN112276415BAvoid formingAvoid accumulationRotating receptacle mixersTransportation and packagingGrain Boundary SlidingGrain boundary migration

The invention discloses a welding material and a production device thereof, and relates to the technical field of welding materials; in order to solve the problem of high-temperature plastic loss cracks; it specifically includes a base, the outer wall of the top side of the base is provided with a mounting groove, and one of the mounting grooves is The side inner wall is fixed with the first motor through the support plate, the output end of the first motor is fixed with the worm through the coupling, and the two ends of the worm are respectively fixed with the top of the base through the bearing seat, and the outer wall of the top circle center of the base is fixed with the support shaft There are driving teeth, and the driving teeth and the worm mesh with each other. The outer wall on one side of the base is fixed with the first mounting seat and the second mounting seat by bolts, and the second motor is fixed on the outer wall of the second mounting seat through a support plate. The driving gear The top outer wall is screwed with a mounting plate. The invention can block the accumulation of lattice defects, prevent grain boundary sliding and grain boundary migration from occurring and meeting at the same time, thereby avoiding the formation of high-temperature plastic loss cracks.

Owner:东安县双龙焊剂新材料有限公司

A kind of in-situ synthesis aluminum carbide reinforced aluminum matrix composite material and preparation method thereof

ActiveCN111235436BHigh strengthImprove mechanical propertiesGrain boundary migrationAluminium powder

Owner:SHANGHAI JIAOTONG UNIV

Method for preparing artificial bone by secondary sintering using selective laser and temperature-controlled furnace

InactiveCN103420681BImprove efficiencySmall heating areaProsthesisTemperature controlSelective laser sintering

The invention discloses a molding method for realizing secondary sintering preparation of a high-toughness three-dimensional nano ceramic artificial bone by utilizing a selective laser and a temperature control furnace. In the first sintering, the selective laser is utilized for layer-by-layer scanning of a biological ceramic powder according to artificial bone model information, and layers are superposed to obtain a nano artificial bone initial green body having a complex geometric profile and controllable interconnected micropores; and in the second sintering, the laser molded piece is subjected to long-time heat preservation at a relatively low sintering temperature in the temperature control furnace, grain boundary migration is inhibited in the heat preservation stage, grain boundary diffusion is maintained, thus grain growth is under control, and a densification process can be still carried out until the artificial bone is fully densified. The molded artificial bone not only has the profile consistent with an implantation site and has the interconnected and controllable pore space structure, but also is a nano biological ceramic artificial bone scaffold having good mechanical properties.

Owner:CENT SOUTH UNIV

A process for increasing the volume density of tabular alumina

ActiveCN108191414BImproved grain boundary propertiesFacilitate solid phase reactionGrain boundary migrationLanthanum

The invention discloses a technology for increasing the volume density of tabular corundum. The technology comprises the steps that gamma-aluminum oxide and lanthanum oxide are mixed and ground, and ground powder is put into a ball forming machine, subjected to ball forming, dried and sintered to obtain tabular corundum, wherein the mass fraction of lanthanum oxide in the ground powder is 0.01-0.05%. According to the technology for increasing the volume density of tabular corundum, aiming at the characteristic that grain boundary migration influences crystal growth in solid-phase sintering inthe production process of tabular corundum, a small amount of lanthanum oxide is added to fine powder to improve the grain boundary characteristic, so that the aim of promoting sintering is achieved,the sintered product is high in volume density and good in crystal development, the liquid phase does not exist, and the sintering technology is easy to control.

Owner:山东恒嘉高纯铝业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com