Preparation method for preparing compact small-grain BaFe12O19 ferrite ceramic by three-step sintering method

A bafe12o19, bafe19o12 technology, applied in the field of magnetoplumbite-type ferrite materials, can solve the problems of low saturation magnetization, reduced ceramics, limited density contribution, etc. The effect of world migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

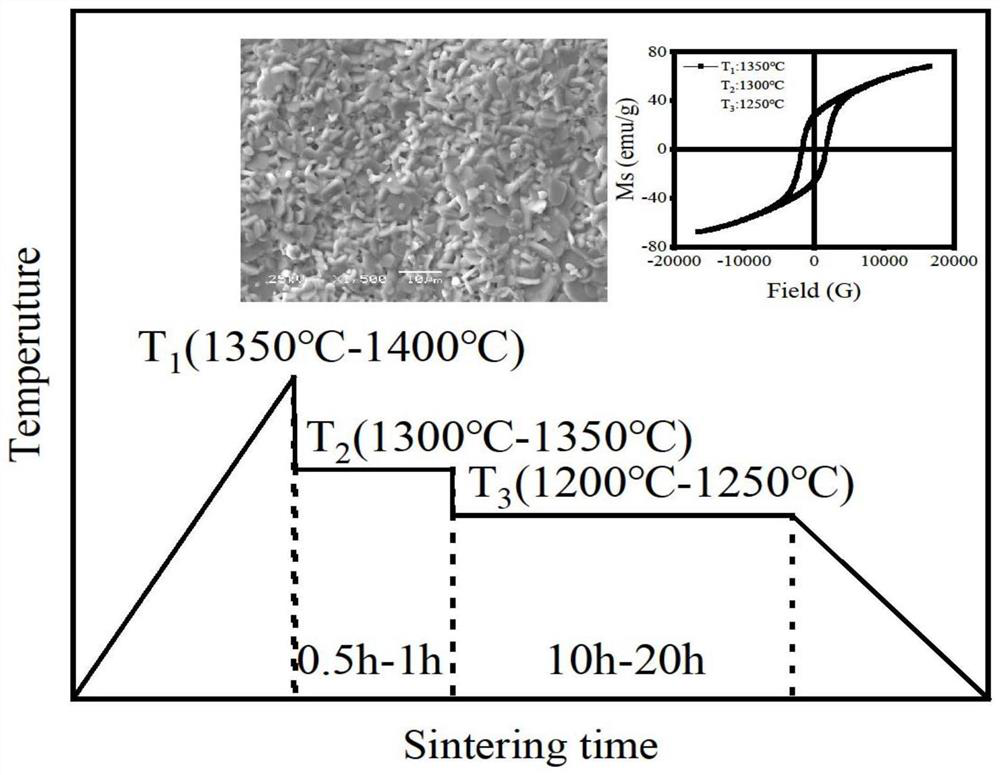

[0026] The invention discloses a three-step sintering method for preparing dense small grain BaFe 12 o 19 The preparation method of ferrite ceramics comprises the following steps:

[0027] Preparation of precursor solution: ferric nitrate (Fe(NO 3 ) 3 ) and barium nitrate (Ba(NO 3 ) 2 ) powder is dissolved in deionized water after being weighed according to the molar ratio of 12:1 to obtain a clear solution, then add citric acid with the same amount of nitrate ion in ferric nitrate and barium nitrate, fully stir, and allow citric acid to completely Dissolving to obtain a precursor solution;

[0028] Adjust the pH value: continue to stir, and slowly add ammonia water to the precursor solution until the pH value of the solution is 6-7, forming a light green transparent sol;

[0029] Gel formation: put the sol in a water bath, heat the water bath to form a wet gel, put the wet gel into an electric blast drying oven, and keep it warm for 36 hours to obtain a loose dry gel; ...

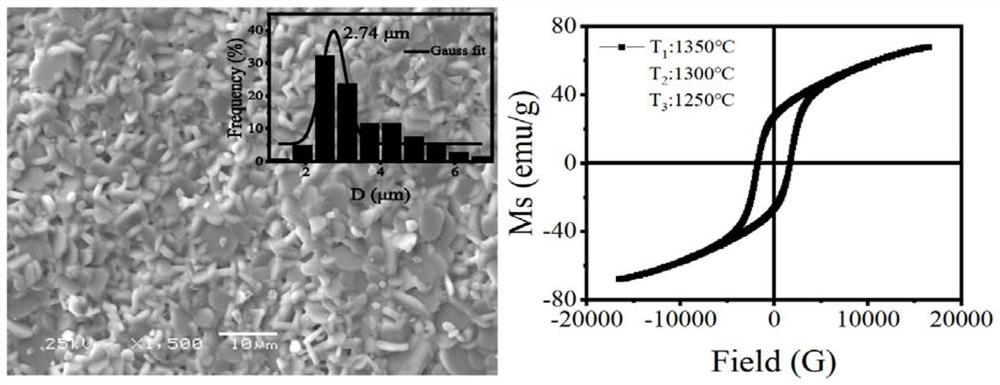

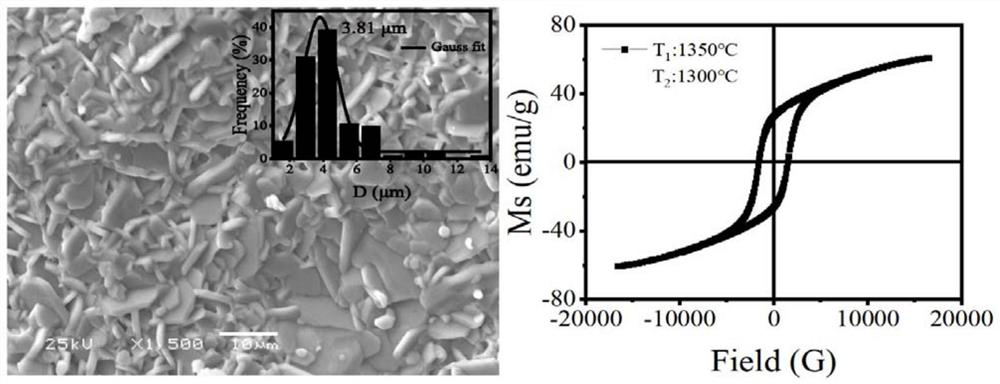

Embodiment 1

[0041] A dense small grain BaFe 19 o 12 The preparation method of ceramics comprises the following steps:

[0042] Preparation of precursor solution: ferric nitrate (Fe(NO 3 ) 3 ) and barium nitrate (Ba(NO 3 ) 2 ) powder is dissolved in deionized water after being weighed according to the molar ratio of 12:1 to obtain a clear solution, then add citric acid with the same amount of nitrate ion in ferric nitrate and barium nitrate, fully stir, and allow citric acid to completely Dissolving to obtain a precursor solution;

[0043] Adjust the pH value: continue to stir, and slowly add ammonia water to the precursor solution until the pH value of the solution is 6-7, forming a light green transparent sol;

[0044] Gel formation: put the sol in a water bath, heat the water bath to form a wet gel, put the wet gel into an electric blast drying oven, and keep it warm for 36 hours to obtain a loose dry gel;

[0045] Pre-calcination: Grind the dry gel into powder, put the powder in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com