A kind of welding material and its production device

A technology for production equipment and welding materials, applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve problems such as reducing welding integrity, avoid high temperature plastic loss cracks, refine grains, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A welding material, comprising a welding rod, the welding rod is composed of a welding core and a coating, and the welding core is composed of 8-15 parts by weight of carbon, 18-25 parts of manganese, 6-10 parts of silicon, and 20-30 parts of chromium , 35-42 parts of nickel, 10-15 parts of titanium, 8-12 parts of molybdenum, 6-15 parts of niobium; composition of the skin by weight: 14-22 parts of potassium water glass, 8-14 parts of ilmenite, carbonic acid 2-8 parts of salt, 9-13 parts of ferrosilicon, 10-15 parts of nickel powder, 5-9 parts of mica.

[0033] The electrode can be replaced by a wire, and the core is covered by a coating.

[0034] The potassium water glass can be used as arc stabilizer and adhesive.

Embodiment 2

[0036] A welding material, comprising a welding rod, the welding rod is composed of a welding core and a coating, and the welding core is composed of 6-10 parts by weight of carbon, 20-22 parts of manganese, 8-9 parts of silicon, and 25-28 parts of chromium , 36-40 parts of nickel, 11-13 parts of titanium, 9-10 parts of molybdenum, 8-10 parts of niobium; the composition of the drug skin by weight: 16-20 parts of potassium water glass, 10-14 parts of ilmenite, carbonic acid 2-4 parts of salt, 10-11 parts of ferrosilicon, 11-13 parts of nickel powder, 6-7 parts of mica.

[0037] The electrode can be replaced by a wire, and the core is covered by a coating.

[0038] The potassium water glass can be used as arc stabilizer and adhesive.

Embodiment 3

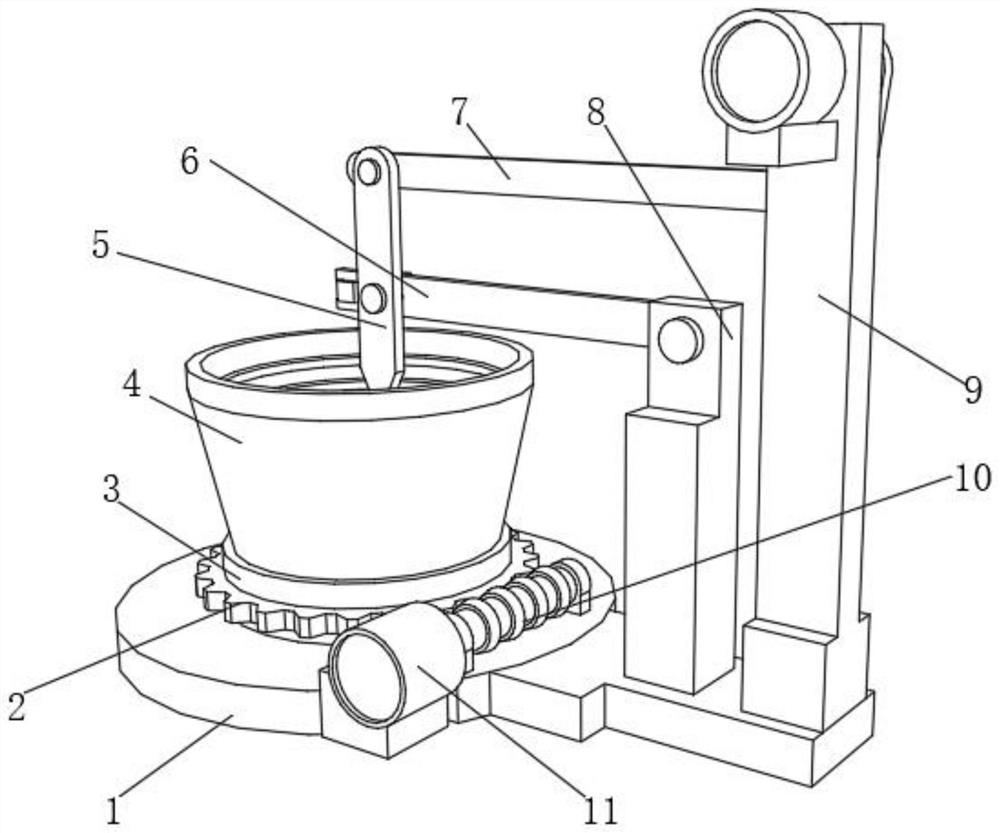

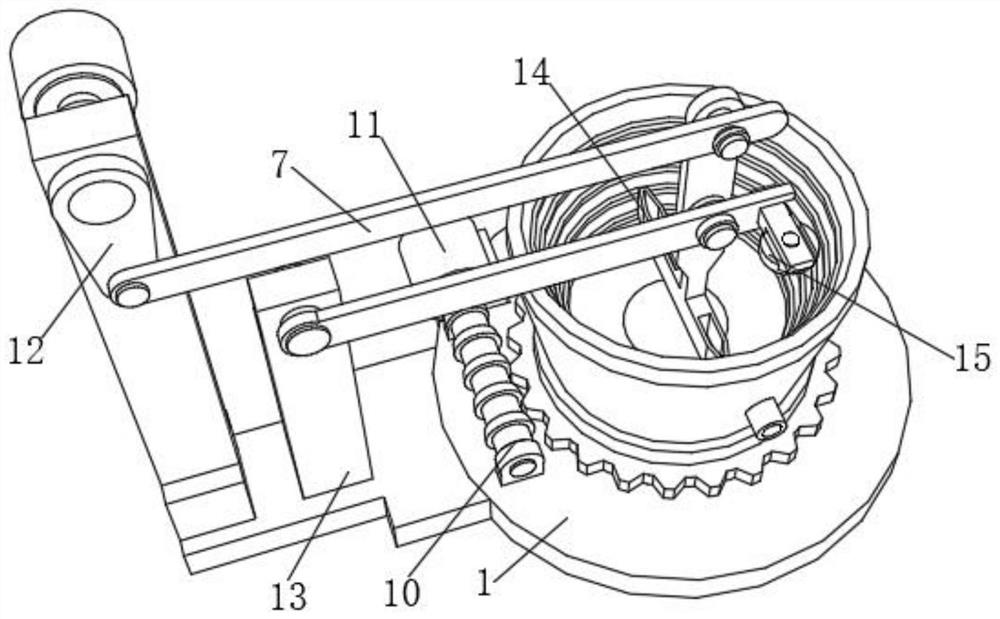

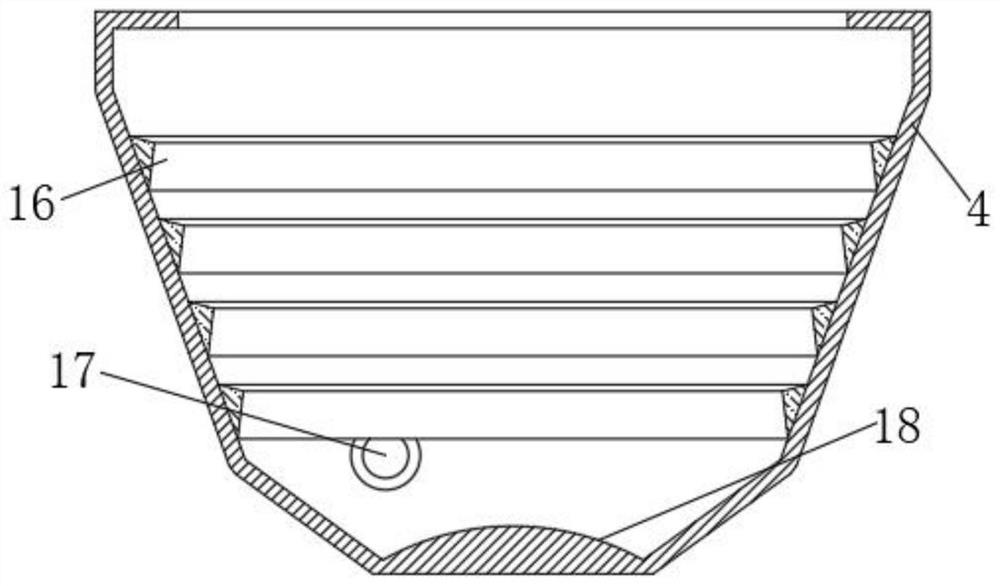

[0040] A production device for welding materials, such as Figure 1-4As shown, this embodiment also uses a welding rod production device on the basis of Embodiment 1, including a base 1, the outer wall of one side of the top of the base 1 is provided with a mounting groove, and the inner wall of one side of the mounting groove is fixed by a support plate. The first motor 11, the output end of the first motor 11 is fixed with a worm 10 through a coupling, and the two ends of the worm 10 are respectively fixed with the top of the base 1 through a bearing seat, and the outer wall of the top of the base 1 is fixed with a support shaft. The driving tooth 2, and the driving tooth 2 and the worm 10 are engaged with each other, the first mounting seat 8 and the second mounting seat 9 are fixed on one side of the outer wall of the base 1 by bolts, and the one side outer wall of the second mounting seat 9 is fixed with a supporting plate. For the second motor, the top outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com