Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Low cold brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

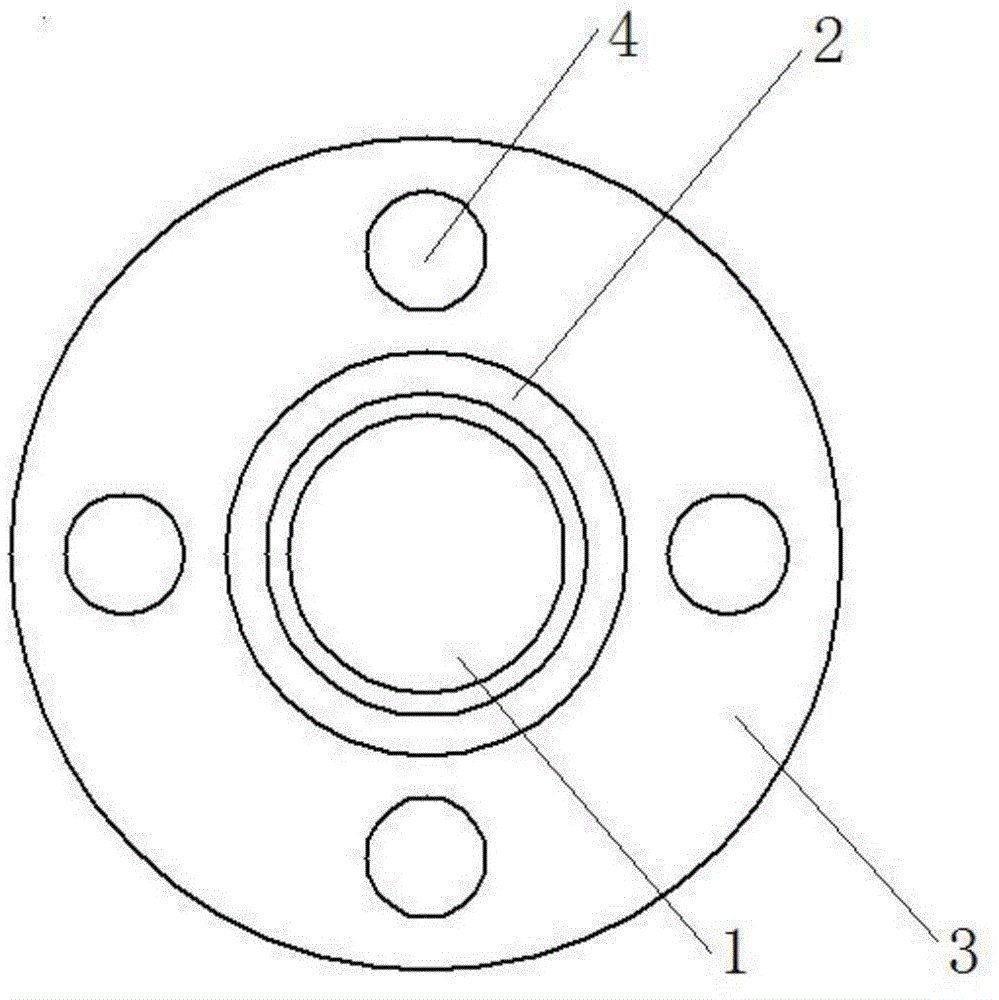

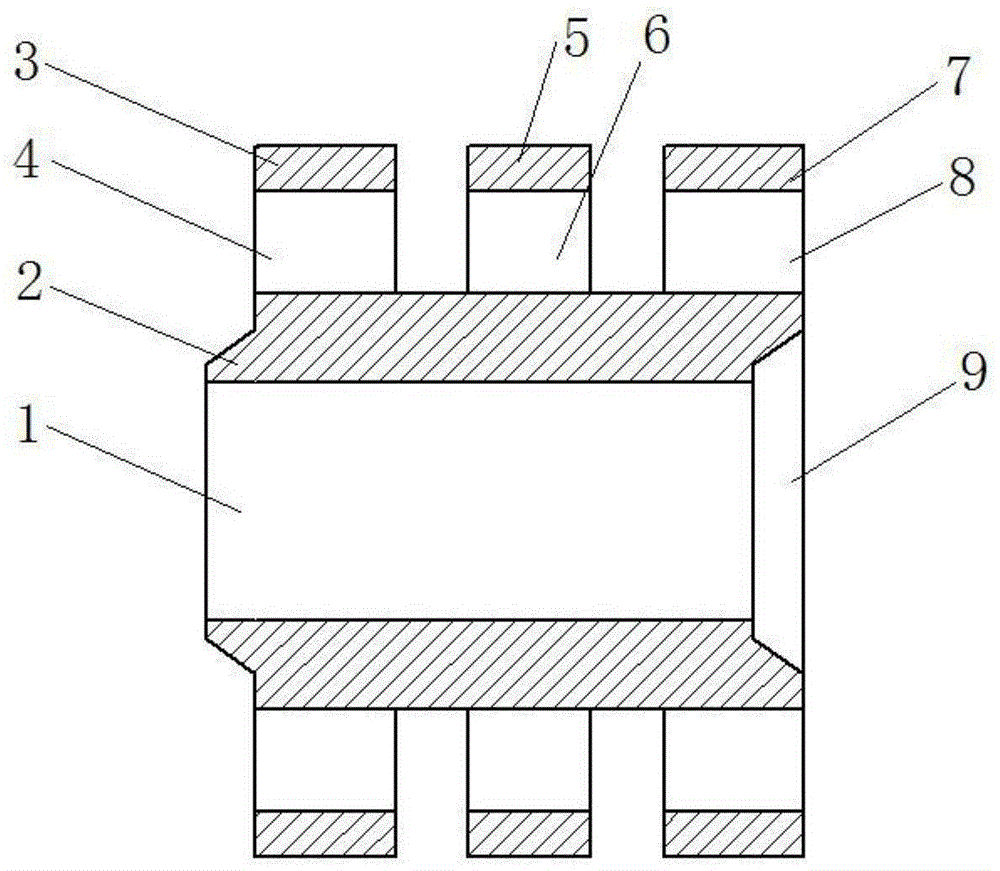

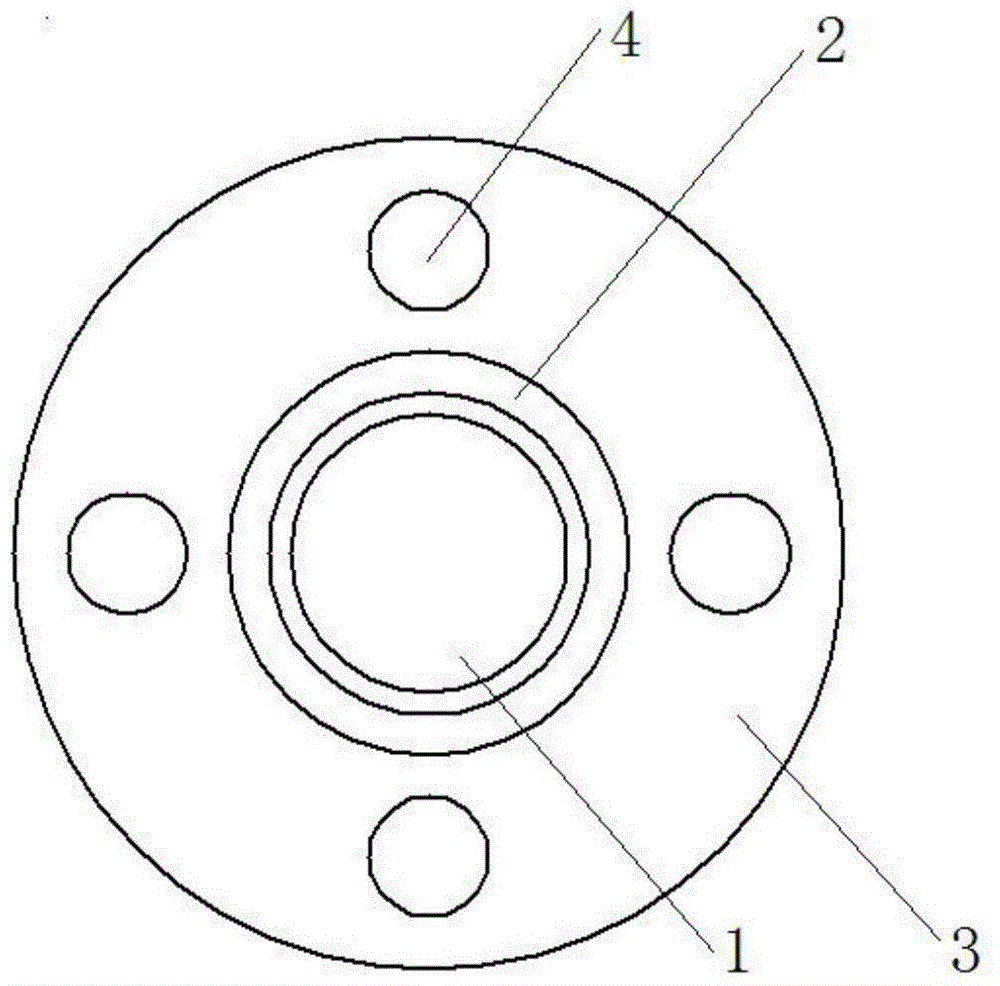

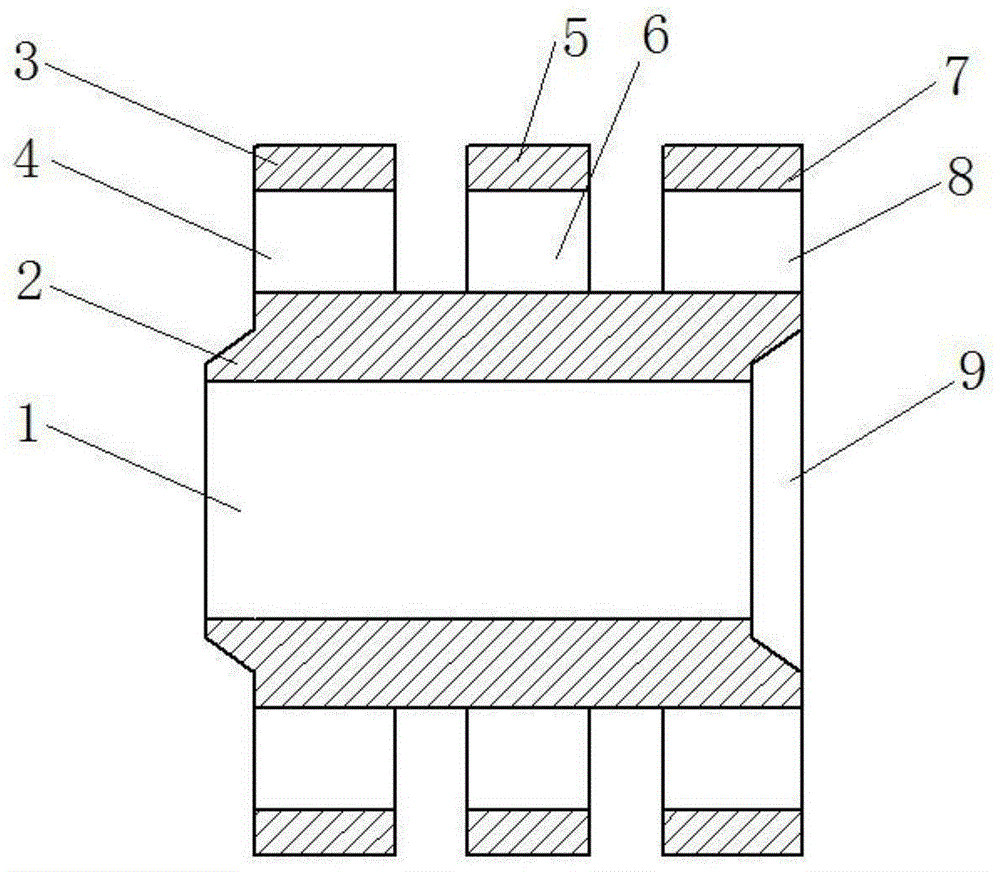

F304/F304L double-standard stainless steel flange and production process thereof

ActiveCN104791562AReasonable structureExquisite designFlanged jointsCircular discSS - Stainless steel

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

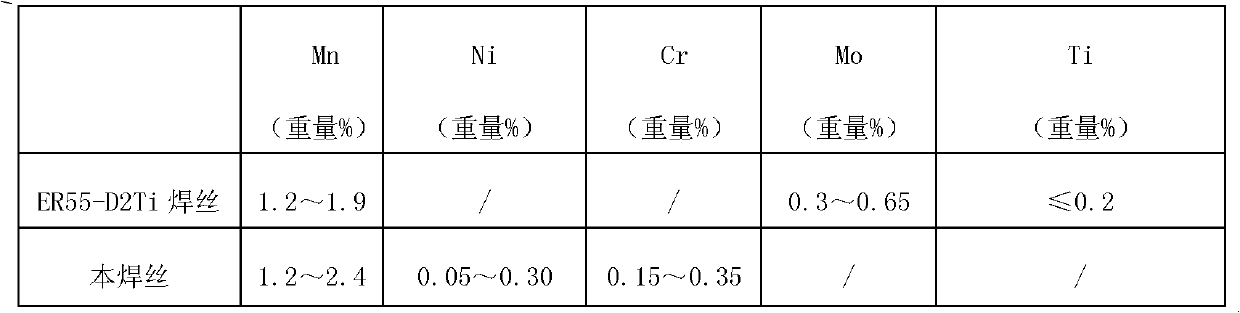

Solid welding wire for high-toughness structural steel

ActiveCN101905393AIncrease contentMeet welding requirementsArc welding apparatusWelding/cutting media/materialsChemical compositionSheet steel

The invention provides a solid welding wire for high-toughness structural steel, which comprises the following chemical components by weight percent: C: 0.06-0.12, Si: 0.4-0.8, Mn: 1.2-2.4, Ni: 0.05-0.30, Cr: 0.15-0.30, S: not more than 0.015, P: not more than 0.020 and the balance of Fe and other unavoidable impurities. As for the solid welding wire for the high-toughness structural steel provided by the invention, yield strength for deposited metal is more than 500MPa and tensile strength is more than 600MPa; after welding, welding seams have beautiful shaping, little splash and low crack sensitivity, thus meeting the welding requirement for a low-alloy high strength steel plate; and relative to an ER55-D2Ti welding wire or a 60kg of welding wire containing Ni-Mo system, the solid welding wire of the invention lowers production cost and use cost on the premise of guaranteeing intensity and impact toughness, thus being suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

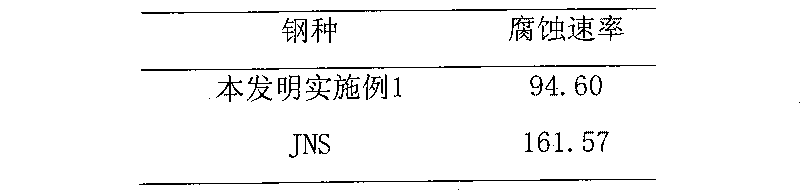

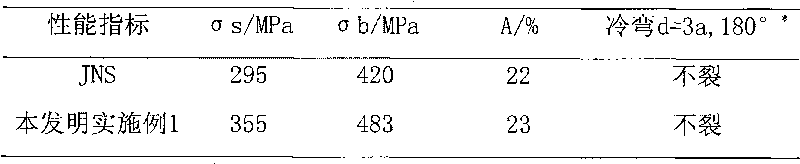

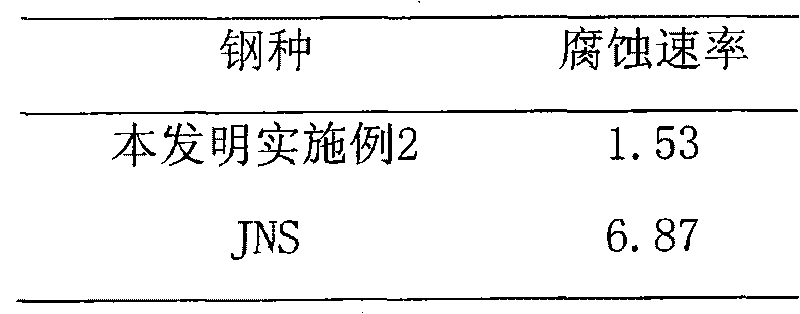

High-strength low-alloy steel resistant to sulfuric acid dew point corrosion

InactiveCN101705441AGood mechanical propertiesImproved resistance to sulfuric acid dew point corrosionCorrosionDew point

The invention provides high-strength low-alloy steel resistant to sulfuric acid dew point corrosion, which is characterized in that the steel contains the following components (in percentage by weight): 0.01 to 0.10 percent of C, 0.20 to 0.40 percent of Si, 0.35 to 1.0 percent of Mn, 0.01 to 0 .05 percent of S, 0.3 to 0.6 percent of Ni, 0.5 to 1.0 percent of Cr, 0.3 to 0.5 percent of Cu, 0.01 to 0.15 percent of Sb, 0.01 to 0 .10 percent of Re, 0.01 to 0 .10 percent of Mo, 0.01 to 0 .10 percent of Nb, 0.01 to 0 .10 percent of Ti, 0.01 to 0 .10 percent of V, and the balance of Fe and inevitable impurities, wherein the total content of alloying elements is less than or equal to 3. The invention has a plurality of alloying elements added at the same time, so that the effects of high strength and corrosion resistance are achieved through the small-amount multi-component effect of the alloying elements.

Owner:SHANGHAI GENFU METALLURGICAL SCI & TECH

Supporting hanger for grooved cable bridge and preparation process of supporting hanger

ActiveCN104862608AHigh elastic limitIncrease yield pointSolid state diffusion coatingCable trayElectric cables

The invention discloses a supporting hanger for a grooved cable bridge. The supporting hanger comprises the following constituents: C, Cr, B, Ni, N, Mo, Cu, Al, V, W, Si, Mn, Nb, Ti, S, P, and the balance of Fe and inevitable impurities. The invention further provides a preparation process of the supporting hanger for the grooved cable bridge. The preparation process is simple and feasible, low in manufacture cost and pollution-free in the manufacture process, and the prepared supporting hanger is abrasion-proof, corrosion resistant, high in strength and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Explosion-proof type fixed ammonia gas detection probe and manufacturing method thereof

InactiveCN105039787AHigh elastic limitIncrease yield pointMaterial analysisRare-earth elementPhysical chemistry

The invention discloses an explosion-proof type fixed ammonia gas detection probe used on an ammonia gas detector. The explosion-proof type fixed ammonia gas detection probe comprises a displayer and a probe tube extending out of the displayer. The probe tube comprises the following components of C, Mn, P, S, Mo, Ni, Cu, Si, Ti, Cr, Mn, Fe, Pb, Nb, V, rare earth elements and the balance Al. The rare earth elements comprise La, Y, Sc, Gd, Sm, Ho, Tb and the balance lanthanide. The invention further provides a manufacturing method for the explosion-proof type fixed ammonia gas detection probe. The manufacturing method is simple and easy to implement, manufacturing cost is low, pollutants cannot be generated in the manufacturing process, the corrosion resistance of the manufactured fixed ammonia gas detection probe is good, the explosion-proof performance is good, service life is prolonged, and cost is reduced.

Owner:JIANGSU JINDI ELECTRONICS TECH

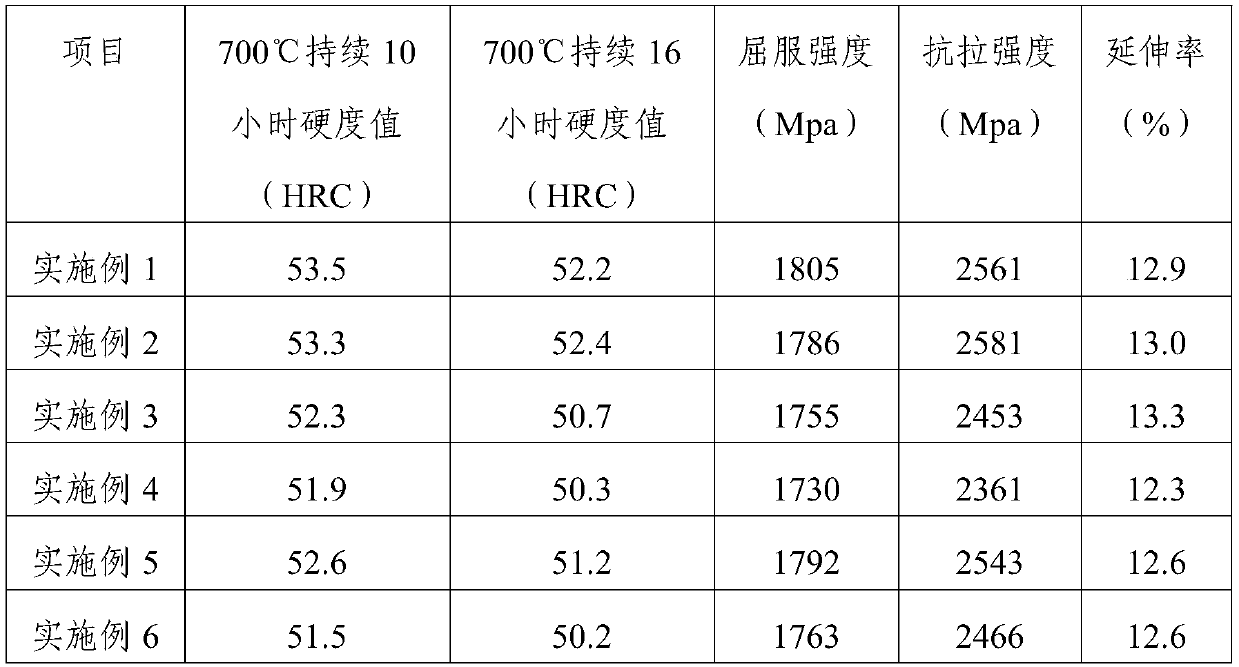

Manufacturing process of hot work die steel for high performance die-casting die

InactiveCN111057933ATissue uniform refinementHigh strengthSolid state diffusion coatingFurnace typesTemperingManufacturing technology

The invention provides a manufacturing process of hot work die steel for a high performance die-casting die and relates to the technical field of die steel. The manufacturing process of the hot work die steel comprises the following steps of (1) smelting; (2) high-temperature homogenization treatment; (3) forging; (4) annealing treatment; (5) quenching and tempering treatment; (6) nitriding treatment; and (7) tempering treatment. The hot work die steel is prepared from the following components in percent by weight: 0.33-0.46% of C, 1.5-2.3% of Si, 0.32-0.45% of Mn, 1.6-2.3% of Mo, 2.6-3.6% ofW, 0.16-0.27% of Nb, 2.8-3.7% of Cr, 0.21-0.53% of Sr, 0.16-0.31% of Ti, 0.05-0.09% of Ce, less than or equal to 0.003% of S, less than or equal to 0.03% of P and the balance Fe. The hot work die steel prepared by the manufacturing process has relatively high surface hardness and wear resistance, relatively good impact toughness and excellent fatigue resistance and strength, so that the service life of the hot work die steel for the die-casting die is prolonged effectively.

Owner:宁波海琰伟业金属制品有限公司

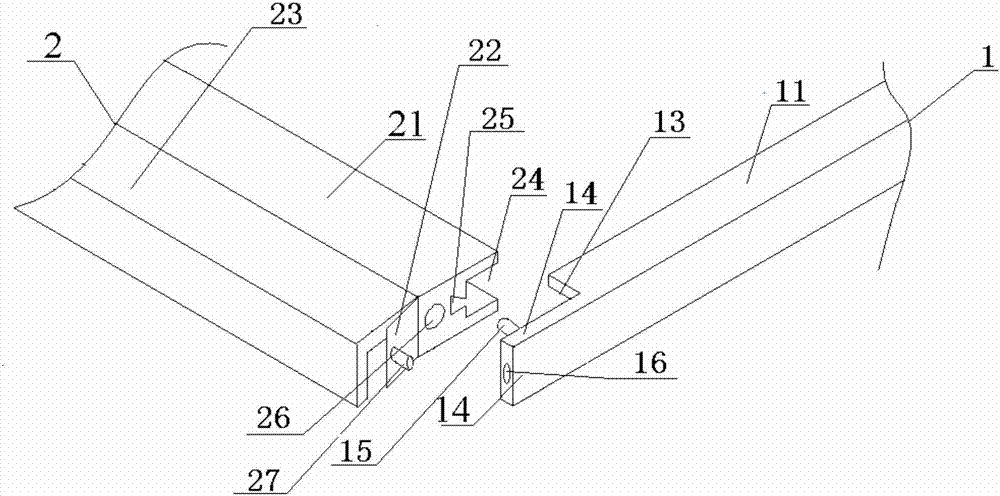

Combined photovoltaic module aluminium frame and production process thereof

PendingCN107196591AImprove performancePlay the effect of purifying castingsPhotovoltaicsPhotovoltaic energy generationEngineeringPhotovoltaics

The invention discloses a combined solar photovoltaic module frame. The combined solar photovoltaic module frame comprises a main body frame; the main body frame is composed of a long frame, a short frame and a U-shaped fixing block; the long frame and the short frame are matched; the short frame is composed of a first concave profile, fixing edges and a first connection block; the fixing edges are arranged at two ends of the first concave profile; the first connection block is formed by extension from one side of the first concave profile; a first groove and a glue injecting groove are also arranged at the notch of the first concave profile; locating holes are also arranged at two ends of the first concave profile; a fixing block is also arranged on the fixing edge; the long frame mainly comprises a second concave profile; a second groove is arranged at the notch of the second concave profile; extension plates extend from two ends of the second concave profile; a locating column is arranged on the extension plate; and a fixing hole is also formed on the side surface of the extension plate. The invention further designs a production process of the combined solar photovoltaic module frame. The aluminium frame is simple in structure, good in protection performance, low in cost and convenient to disassemble and install; furthermore, the aluminium frame can be individually used; and furthermore, multiple aluminium frames can be used in a combined manner.

Owner:镇江神飞新能源科技有限公司

Tungsten carbide coating cutter and preparation technology thereof

PendingCN112403637AHigh strengthImprove wear resistanceOther manufacturing equipments/toolsGrain treatmentsTitaniumSpot welding

The invention discloses a tungsten carbide coating cutter and a preparation technology thereof. The tungsten carbide coating cutter comprises a blade; a cutting edge is formed in the blade; the cutting edge is coated with a tungsten carbide coating; the blade is made of a titanium-cobalt alloy steel material; the surface of the cutting edge is completely coated with a tungsten carbide medium; andcomprehensive spot welding is conducted under spot welding equipment. According to the tungsten carbide coating cutter and the preparation technology, titanium-cobalt alloy steel is used as materialsof the blade and the cutting edge, combination of the tungsten carbide medium and the cutting edge is achieved in a spot welding mode, operation is easy, the requirement for the equipment is not high,the tungsten carbide coating is formed on the surface of the cutting edge, the strength and the abrasion resistance of the cutter can be greatly improved, and the service life of the cutter can be prolonged by five times or above; the titanium element and the cobalt element in the material of the cutting edge can be combined with tungsten carbide, the fragile characteristic of tungsten carbide can be overcome, the brittleness of the tungsten carbide coating can be reduced, the tungsten carbide coating is not prone to falling off, and compared with a common tungsten carbide coating, the cutterhas the advantages that the service life can be greatly prolonged, and the stability can be greatly improved.

Owner:金湖双洋机械有限公司

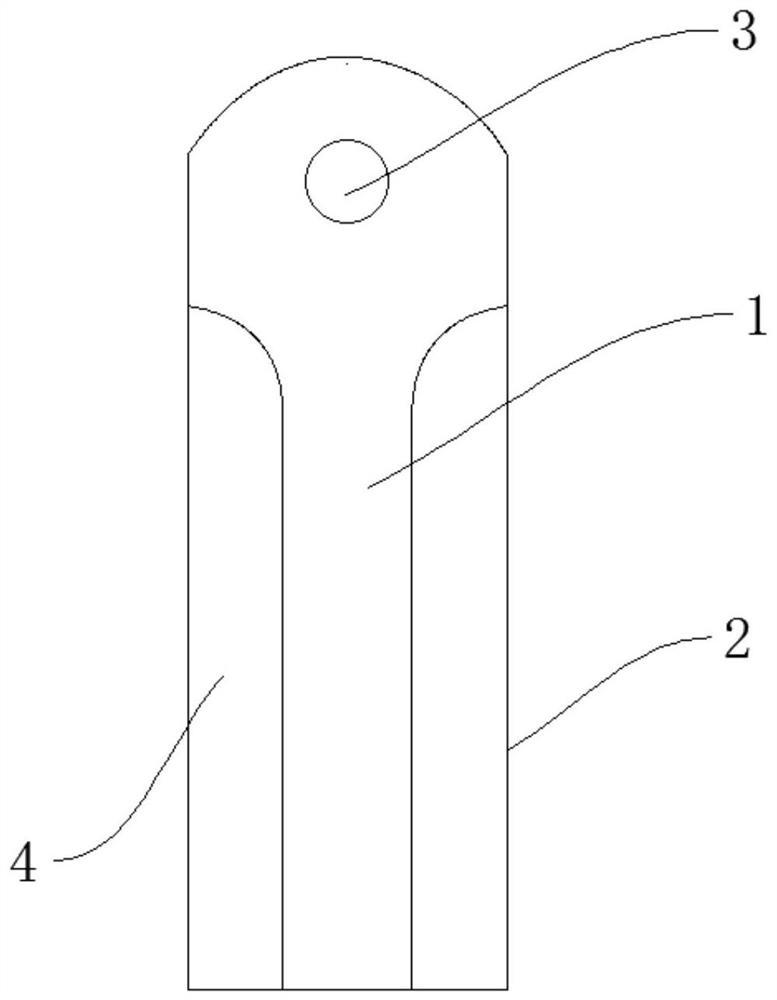

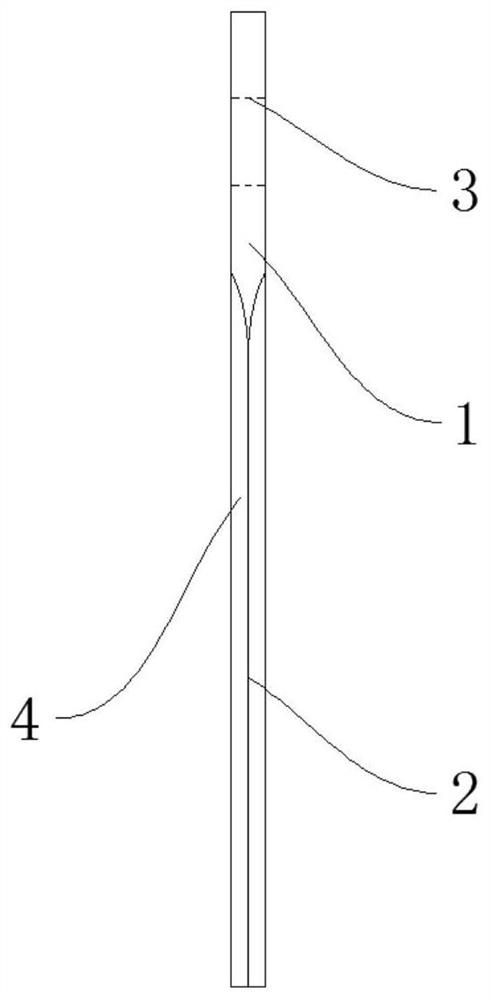

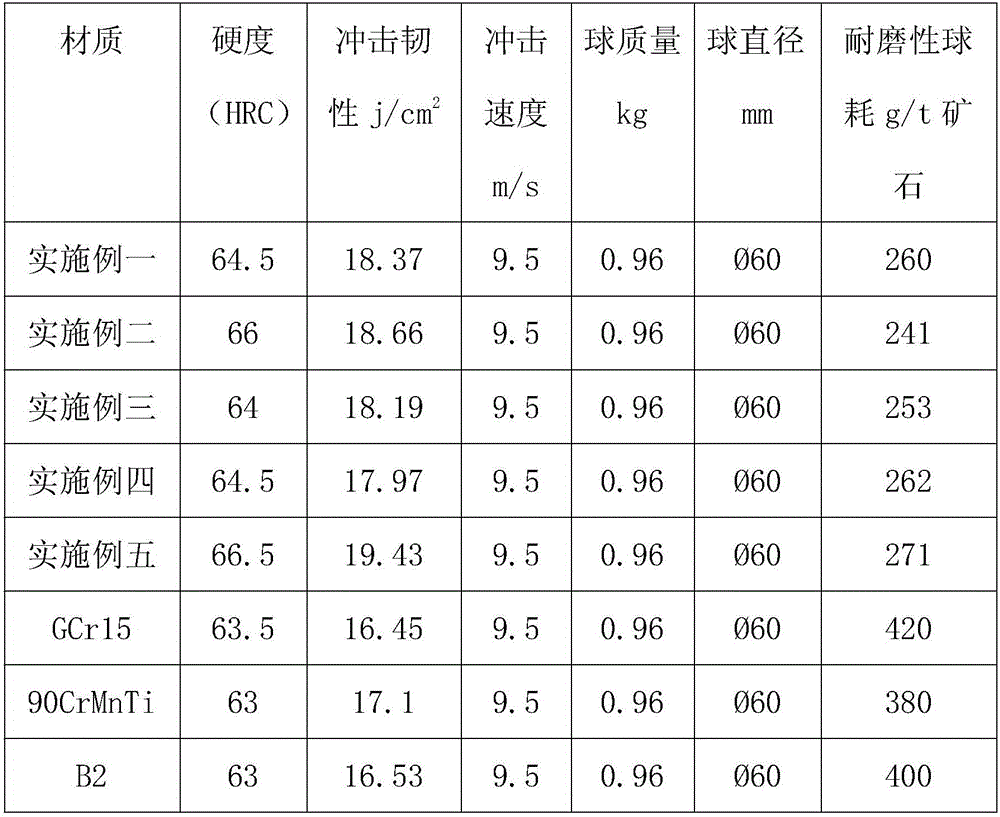

Steel for high-strength wear-resisting type ball grinder steel balls and preparation method thereof

The invention discloses steel for high-strength wear-resisting type ball grinder steel balls. The steel comprises, by weight, 0.9%-1.0% of C, 0.2%-0.4% of Si, 0.8%-1.2% of Mn, 1.0%-1.3% of Cr, 0.15%-0.23% of W, 0.04%-0.10% of Ti, 0-0.03% of P, 0-0.03% of S, and the balance Fe and a small number of impurities. The preparation method includes the steps that S1, smelting is performed, the W, Fe, Cr and Ti are smelted at first, and smelted molten steel is obtained; S2, refining is conducted, the smelted molten steel is transferred into a refining furnace, the C, Si, Mn, P and S and a refining agent are added for primary refining, and then the vacuum degassing and desulfuration procedures are carried out, so that refined liquid is obtained; and S3, the refined liquid is placed into a continuous casting machine, a casting blank is obtained by forming, cooling and cutting, and then the casting blank is subjected to rough rolling and finish rolling procedures so that the steel for the high-strength wear-resisting type ball grinder steel balls can be obtained. According to the steel, strength and hardness are high, the wear-resisting property is also high, and the service life is long; and purity is high, the degassing and desulfuration speed is also high, and the effect is good.

Owner:DENGFENG RONGTAI MACHINERY PARTS CO LTD

Tube shell type slide oil fresh water cooler for ship and manufacturing technology of tube shell type slide oil fresh water cooler

The invention discloses a tube shell type slide oil fresh water cooler for a ship. The tube shell type slide oil fresh water cooler comprises, by mass percentage, 0.18% to 0.20% of C, 0.84% to 0.88% of Mn, 0.13% to 0.17% of Si, 0.002% to 0.003% of P, 0.001% to 0.0015% of S, 0.09% to 0.11% of Nb, 0.02% to 0.04% of W, 0.21% to 0.23% of Ti, 0.45% to 0.65% of Al, 0.96% to 0.98% of Cu, 0.75% to 0.79% of Cr, 0.06% to 0.08% of Mo, 0.71% to 0.73% of rare earth elements, and the balanced Fe and inevitable impurities. The invention further discloses the tube shell type slide oil fresh water cooler for the ship and a manufacturing method of the tube shell type slide oil fresh water cooler. The tube shell type slide oil fresh water cooler is resistant to high temperature and acid and alkali corrosion, not prone to rusting and aging, and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Impact-resisting high-strength alloy material for partition wall of bearing warehouse and processing technique of alloy material

The invention discloses an impact-resisting high-strength alloy material for a partition wall of a bearing warehouse. The alloy material comprises the following components in percentage by mass: 0.31-0.43 percent of C, 0.29-0.35 percent of Mn, 0.11-0.13 percent of Si, 0.15-0.21 percent of Nb, 0.01-0.03 percent of W, 0.18-0.36 percent of V, 0.54-0.56 percent of Ti, 0.031-0.043 percent of Y, 2.17-3.19 percent of Al, 0.08-0.12 percent of Cu, 0.28-0.32 percent of Ni, 0.18-0.22 percent of Nb, 0.85-0.95 percent of Cr, 0.17-0.25 percent of Mo, 0.25-0.32 percent of rare-earth trace elements and the balance of Fe and unavoidable impurities, wherein the total content of the impurities is smaller than or equal to 0.2%; the content of P is smaller than or equal to 0.004%; the content of S is smaller than or equal to 0.006%; the content of H is smaller than or equal to 0.004%; the content of N is smaller than or equal to 0.006%; the content of O is smaller than or equal to 35ppm; the mass percentage of chemical components of the rear-earth trace elements is as follows: 2-4 percent of Nd, 4-8 percent of Ce, 2-6 percent of Pr, 1-4 percent of Pm, 0-5 percent of Dy and the balance of La. The invention also discloses a processing technique of the impact-resisting high-strength alloy material for the partition wall of the bearing warehouse. The alloy material disclosed by the invention is high in strength, high in toughness, excellent in processability, resistant to high temperature, resistant to corrosion, unlikely to abrade and long in service life.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Corrosion-resistant alloy steel material for roller of wire processing machine and preparing method of corrosion-resistant alloy steel material

A corrosion-resistant alloy steel material for a roller of a wire processing machine contains the following chemical elements by mass: 0.8-0.9 of carbon, 2.5-3 of tungsten, 1.0-1.3 of molybdenum, 1.5-2.5 of vanadium, 5.5-6.5 of chromium, 0.05-0.10 of niobium, 0.05-0.10 of holmium, 0.04-0.08 of Sn, 1.3-1.5 of Mn, not more than 0.030 of P, not more than 0.030 of S and the rest of Fe. Various alloy elements, such as the holmium, the niobium and the tungsten are added on the basis of high-carbon steel and are secondarily refined, the temperature of thermal treatment after casting is reasonably controlled, and the raw materials are fed in batches, so that the alloy steel has the properties of high-speed steel, such as high-temperature resistance, high-hardness maintenance and great rigidity and toughness fitting. The surface of the corrosion-resistant alloy steel material has great wear resistance, great peeling resistance and low cold brittleness and is resistant to cold and hot alternate corrosion. The corrosion-resistant alloy steel material is suitable for being used for the roller of the wire processing machine. The cost is low due to the low alloy element content.

Owner:马鞍山市方圆材料工程股份有限公司

High-strength alloy material for goods shelf bearing gird and processing process for high-strength alloy material

The invention discloses a high-strength alloy material for a goods shelf bearing grid. The alloy material is prepared from the following components in percentage by mass: 0.21-0.23% of C, 0.19-0.25% of Mn, 0.11-0.13% of Si, 0.003-0.005% of P, 0.001-0.003% of S, 0.045-0.047% of Nb, 0.01-0.03% of W, 0.54-0.56% of Ti, 0.011-0.013% of Sr, 0.17-0.19% of Al, 0.08-0.12% of Cu, 0.08-0.12% of Nb, 0.85-0.95% of Cr, 0.07-0.13% of Mo, 0.08-0.10% of lanthanum, 0.05-0.07% of neodymium, 0.01-0.03% of cerium and the balance of Fe and inevitable impurities. The invention further discloses a processing process for the high-strength alloy material for the goods shelf bearing grid. The high-strength alloy material is high in product strength, strong in toughness, excellent in processing performance, high-temperature-resistant, corrosion-resistant, less in abrasion possibility and long in service life.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Corrosion-resisting and high-strength aluminum alloy outer cover material used for air purifier

The invention discloses a corrosion-resisting and high-strength aluminum alloy outer cover material used for an air purifier. The corrosion-resisting and high-strength aluminum alloy outer cover material is characterized by comprising the following raw materials including, by weight, 1.25-1.29 parts of silicon, 1.76-1.78 parts of zinc, 1.42-1.46 parts of magnesium, 0.56-0.58 part of germanium, 0.14-0.16 part of chromium, 0.66-0.68 part of iron, 3.58-3.78 parts of titanium, 1.06-1.08 parts of nickel, 0.87-0.89 part of antimony, 3.87-3.97 parts of a rare earth mixture and 45-50 parts of aluminum. The corrosion-resisting and high-strength aluminum outer cover material used for the air purifier is high in strength, good in corrosion resistance, small in mass, not likely to age and deform, not likely to change colors and resistant to corrosion. Meanwhile, the invention provides a preparing method for the corrosion-resisting and high-strength aluminum alloy outer cover material used for the air purifier, the material cost is low, raw materials are easy to obtain, the technology is simple, and high practical value and good application prospects are achieved.

Owner:合肥市淑芹美装饰工程有限公司

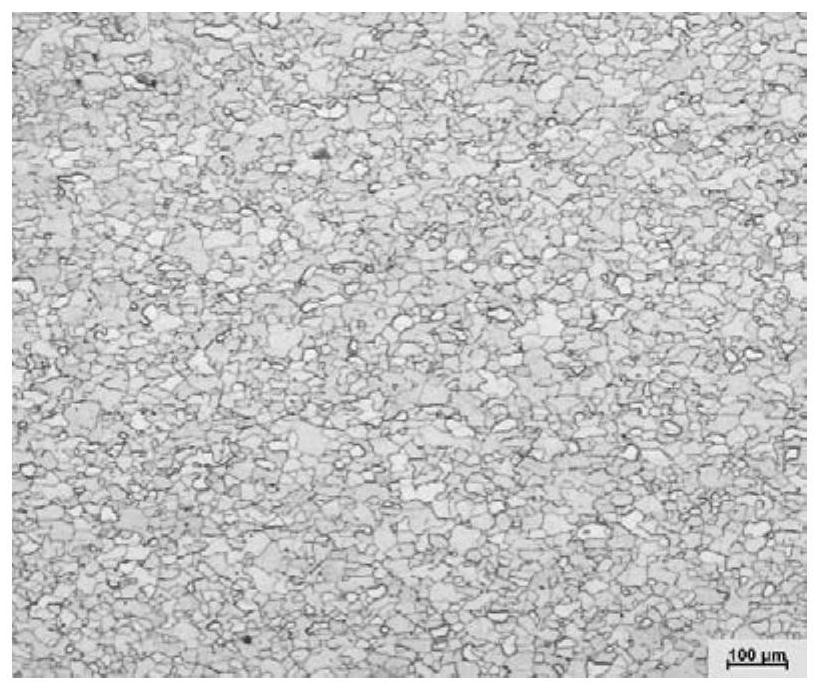

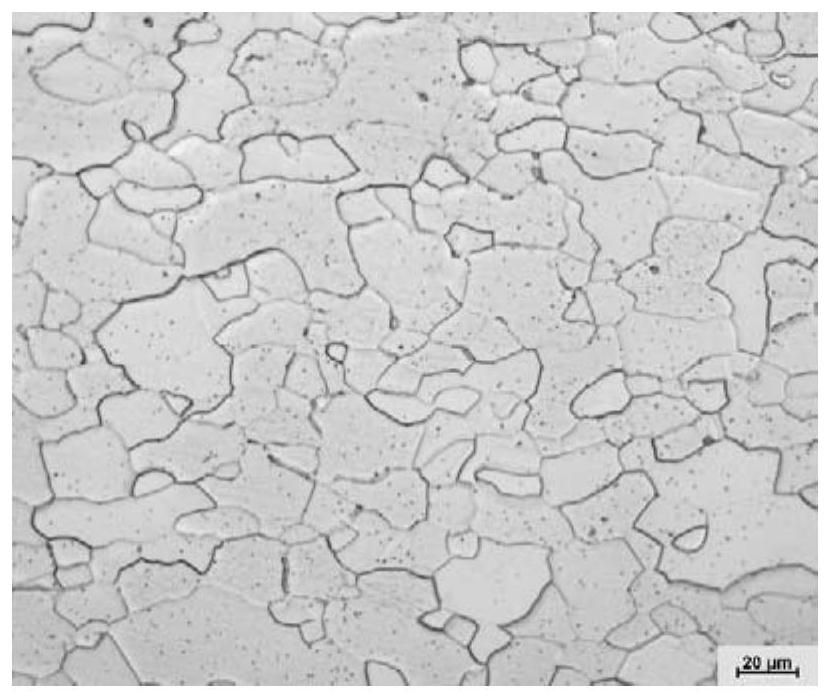

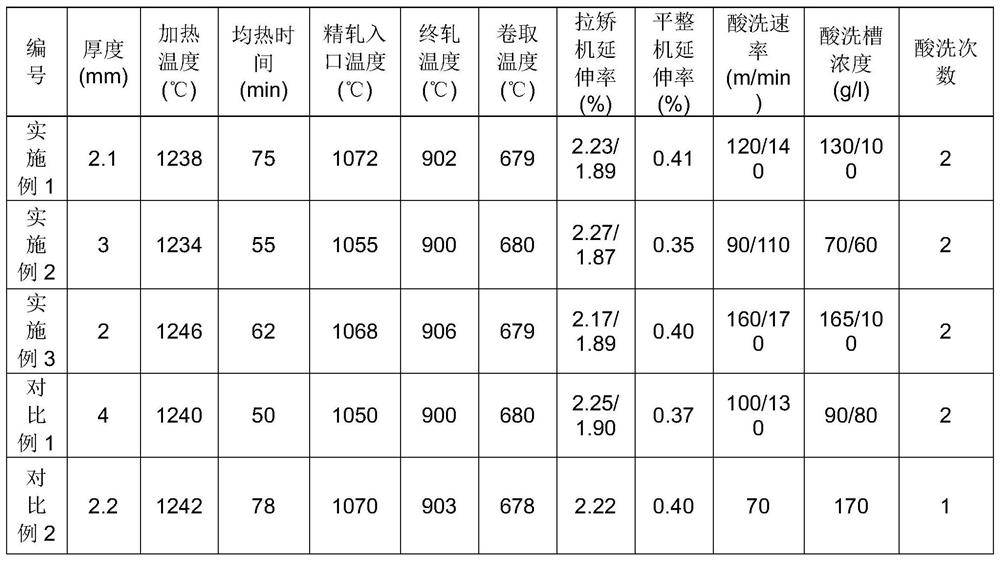

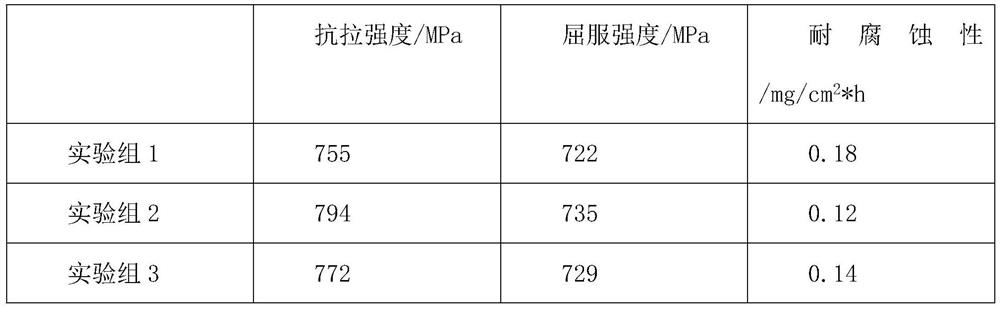

DDQ-grade hot-rolled pickling cold-formed steel and manufacturing method thereof

The invention discloses DDQ-grade hot-rolled pickling cold-formed steel and a manufacturing method thereof, and belongs to the technical field of hot-rolled pickling cold-formed steel. The steel comprises the following chemical components including, by weight percent, smaller than or equal to 0.0020% of C, smaller than or equal to 0.03% of Si, 0.08%-0.25% of Mn, 0.005%-0.015% of P, 0.05%-0.015% ofS, 0.025%-0.045% of Als, smaller than or equal to 0.0040% of N, 0.030%-0.050% of Ti, 0.015%-0.030% of Nb, and the balance Fe and inevitable impurities. According to the steel, multiple elements are added on the basis of traditional hot-rolled cold-formed steel, the content of each element is reasonably adjusted, so that the yield strength and the tensile strength of the steel are improved to a certain extent, the ductility of the steel is well improved, meanwhile, the thickness of a steel plate meets the use requirement, and a cold-rolled steel plate is effectively replaced. According to themanufacturing method of the steel, the components, the component content and the specific production process of the steel plate are optimally designed, the yield strength and the elongation of the obtained steel plate are guaranteed, and meanwhile, the surface characteristics of the steel plate are improved through secondary pickling, so that the steel plate has high-grade roughness and surface gloss comparable with surface gloss of a cold-rolled plate.

Owner:MAANSHAN IRON & STEEL CO LTD

Step type vertical convex bending through bridge frame and preparation method thereof

The invention discloses a step type vertical convex bending through bridge frame. The step type vertical convex bending through bridge frame comprises symmetrically arranged groove frames and a transverse support arranged between the groove frames. The groove frames and the transverse support of the step type vertical convex bending through bridge frame are made of the same material. The material comprises the following components: C, Si, Mn, Ni, Mo, Cr, N, Cu, Al, Ti, S, P, Nb, V and a rare earth element, the balance being Fe and unavoidable impurities. The rare earth element comprises the following components: lanthanum, cerium, praseodymium, dysprosium, holmium, gadolinium and yttrium, the balance being lanthanide-series rare earth. The invention also provides a preparation method of the step type vertical convex bending through bridge frame. The preparation method is simple and easily implemented, the preparation cost is low, pollutants are not generated in a production technical process, and the prepared step type vertical convex bending through bridge frame is good in processing performance and high in strength and is highly guaranteed in quality.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Corrosion-resistant cast steel material for automobile parts

The invention discloses a corrosion-resistant cast steel material for auto parts, which is made of the following raw materials in parts by weight: steel scrap (iron content not less than 98%) 95-98, Z18 pig iron 2-3, crystalline silicon 0.7-0.75, Carbon 0.3-0.35, niobium 0.04-0.05, titanium 0.4-0.5, manganese 1.2-1.3, chromium 0.04-0.05, calcium silicide 0.8-0.86, gelatin 0.2-0.23, lime powder 0.2-0.24, calcium fluoride 0.3-0.4, heavy Crystal 0.5-0.55, impurity ≤ 0.01. The invention can improve the intergranular corrosion and improve the corrosion resistance of the cast steel material by rationally configuring the ratio of element components and the production process, and adding elements such as titanium and niobium; The auto parts produced are corrosion-resistant, low-temperature resistant, and have a long service life.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Corrosion-resistant and weather-resistant gear ring for gear box coupling and preparation method of corrosion-resistant and weather-resistant gear ring

InactiveCN113444983AImprove corrosion resistanceHigh strengthMolten spray coatingPortable liftingRheniumLanthanum

The invention discloses a corrosion-resistant and weather-resistant gear ring for a gearbox coupling, and particularly relates to the technical field of coupling gear rings. The corrosion-resistant and weather-resistant gear ring comprises the following raw materials: carbon, silicon, nickel, phosphorus, titanium, chromium, vanadium, lanthanum, tungsten, molybdenum, rhenium and the balance of iron and inevitable impurities. The titanium, the chromium, the vanadium, the lanthanum, the tungsten, the molybdenum and the rhenium are added, the added titanium can form stable, dispersed, high-melting-point and high-hardness carbide with carbon in the gear ring material, the intergranular corrosion tendency in the gear ring material is eliminated, and therefore the corrosion resistance of the gear ring is improved. Meanwhile, the content of the chromium in the gear ring material is 12-18%, the strength and corrosion resistance of the gear ring can be better due to the high-content chromium element, and by adding vanadium, tungsten and molybdenum, deterioration can be purified, grains can be refined, and the wear resistance and strength of the composite plate can be improved. The produced coupling gear ring has high corrosion resistance and weather resistance, and the service life is greatly prolonged.

Owner:江阴市万众精密机械有限公司

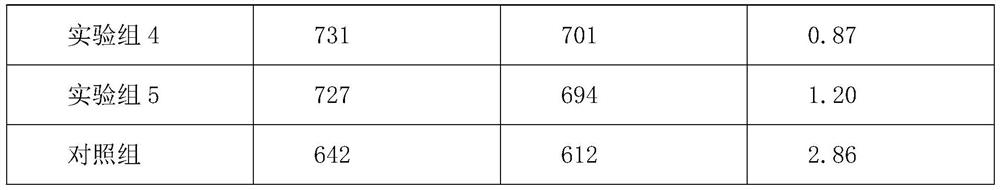

Reinforcing bar for ultralow temperature environments

InactiveCN105543668AReduce toughnessReduced soldering performanceBuilding reinforcementsChemical compositionRebar

Owner:广西丛欣实业有限公司

Closed circulation water cooler and manufacturing process thereof

The present invention discloses a closed circulation water cooler, wherein the raw materials comprise, by mass, 0.102-0.104% of C, 0.053-0.055% of B, 0.001-0.003% of N, 0.34-0.36% of Mn, 0.087-0.089% of Si, 0.065-0.067% of Nb, 2.23-2.25% of Cr, 0.075-0.079% of Mo, 0.041-0.045% of W, 0.012-0.014% of V, 0.504-0.508% of Ti, 1.32-1.34% of Al, 0.41-0.43% of Cu, 0.423-0.425% of composite rare earth, and the balance of Fe and unavoidable impurities. The product of the present invention has characteristics of high temperature resistance, low temperature resistance, corrosion resistance under acid and alkali environments, rust resistance, aging resistance, and long service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

Alloy steel material for low temperature resistant pump valve and preparation method thereof

The invention relates to a low-temperature-resistant alloy steel material for pump valves, which contains the following chemical components in percentage by mass: 0.2-0.4% of carbon, 1.3-1.5% of silicon, 3.2-3.4% of manganese, 0.3-0.4% of vanadium, 0.12-0.24% of niobium, 1.0-1.1% of titanium, 0.04-0.07% of Mg, at most 0.04% of S, at most 0.04% of P and the balance of iron. The titanium, manganese, niobium and other elements are added on the basis of medium / low-carbon steel, so the cold brittleness of the alloy is greatly lowered, and the alloy can resist low temperature. The material has the characteristics of excellent wear resistance, higher hardness and favorable plasticity. Part of scrap iron is used as the raw material, and secondary refining is performed, so that the product quality is more stable and uniform. When the refining agent is used for casting production, the porosity in the casting is lowered by 1-2 degrees, and the oxide inclusions are in the second grade or so. The alloy steel is used for pump valves, impellers and delivery pipelines operating in a low-temperature environment, can not be easily damaged, and has long service life.

Owner:ANHUI RONGDA VALVE

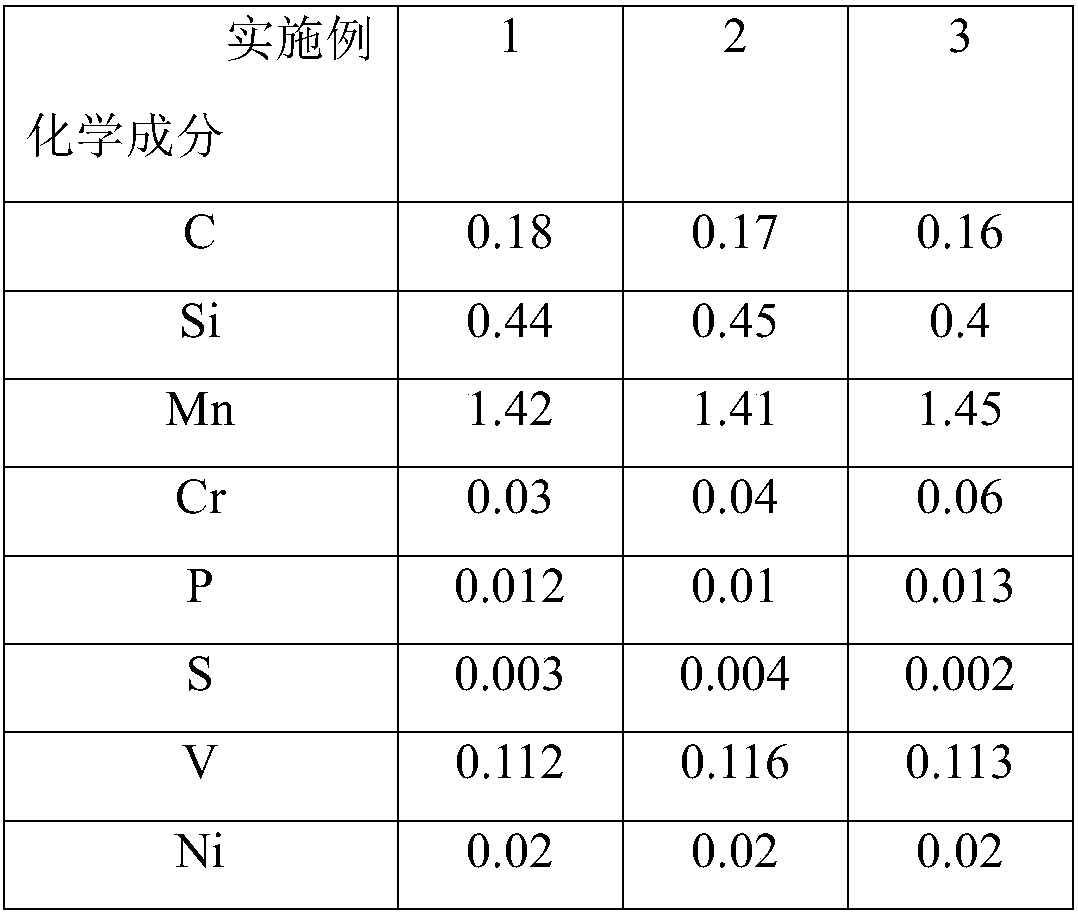

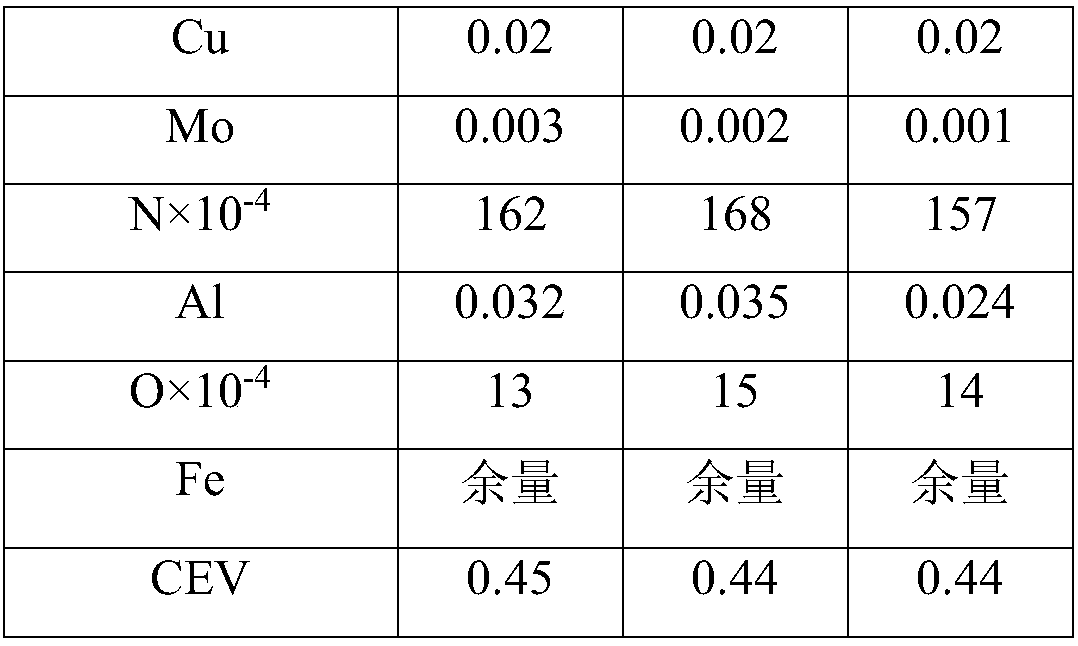

Steel for axle head and preparation method thereof

ActiveCN106399847BLow carbon equivalentGood welding performanceChemical compositionMechanical property

The invention discloses steel for an axle head and a preparation method thereof. The steel is prepared from the following chemical components in mass percent: 0.16 to 0.18% of C, 0.40 to 0.50% of Si, 1.40 to 1.45% of Mn, less than or equal to 0.10% of Cr, less than or equal to 0.020% of P, less than or equal to 0.008% of S, 0.11 to 0.12% of V, less than or equal to 0.10% of Ni, less than or equal to 0.10% of Cu, less than or equal to 0.10% of Mo, 0.015 to 0.017% of N, 0.025 to 0.045% of Al, less than or equal to 15ppm of [O], the balance of Fe and inevitable impurities and less than or equal to 0.47% of CEV. The preparation method of the steel for the axle head comprises the steps of smelting, pouring, rolling, scaling and inspecting. The steel for the axle head has the advantages of low carbon equivalent and good welding performance and mechanical properties.

Owner:SHANDONG IRON & STEEL CO LTD

A kind of high toughness alloy steel material and preparation method thereof

InactiveCN103789704BLow cold brittlenessStable and uniform qualityRecovering materialsPorosityChemical element

The invention provides a high-toughness alloy steel material. The material comprises the following chemical elements by mass percent: 0.02%-0.05% of carbon, 6.0%-6.3% of manganese, 0.45%-0.75% of silicon, 3.3%-2.5% of nickel, 0.04%-0.05% of chromium, 0.005%-0.008% of molybdenum, 0.02%-0.05% of vanadium, 0.3%-0.5% of copper, not more than 0.030% of P, not more than 0.030% of S and the balance being iron. The material has the beneficial effects that by combining the raw materials such as nickel, molybdenum and vanadium and reasonably setting the ratio, the production process and the putting order, the formed alloy material has excellent toughness and plasticity, high strength and wear resistance and low aging sensitivity and cold brittleness; part of scrap iron is used as the raw material, thus improving the stability and uniformity of alloy quality; the material has good processability and is suitable for various parts subjected to forging, stretching processing and the like; the porosity is reduced by 1-2 degrees by adding a refining agent.

Owner:安徽省临泉县智创精机有限公司

Corrosion-resistant steel tube for conveying industry fuel gas and preparation technology thereof

PendingCN108692112AReduce rustImprove rust resistanceCorrosion preventionAnti-corrosive paintsDiethylenetriamineFumed silica

The invention relates to the technical field of steel tubes, in particular to a corrosion-resistant steel tube for conveying industry fuel gas and a preparation technology thereof. Vinylidene chloridecomposite high polymer emulsion, ethylene diamine tetra (methylene phosphonic acid) sodium, diethylenetriamine pentacarboxylic acid salt and gallic acid in an outer coating are matched with one another to undergo not only a complex reaction with rust but also a high polymer reaction, so that speed of further corrosion of the outside of an steel tube is slowed down, and anti-rust effect of the steel tube is enhanced. Coated metal in an electroplated layer is Zn and Sn, which are electroplated on the surface of a tube blank, so that speed of corrosion of the surface of the tube blank by moisture can be reduced. Nb, V and Cu in the tube blank are mutually cooperated with one another to significantly improve abilities of atmospheric corrosion resistance and anti-hydrogen, anti-nitrogen and anti-ammonia corrosion at high temperature of the steel tube. Use of fumed silica in an inner coating enhances the ability of gas barrier of the inner coating, speed of corrosion of inner wall of the tube blank by moisture in fuel gas is slowed down, and the service life of the tube blank is prolonged.

Owner:梅州中燃城市燃气发展有限公司

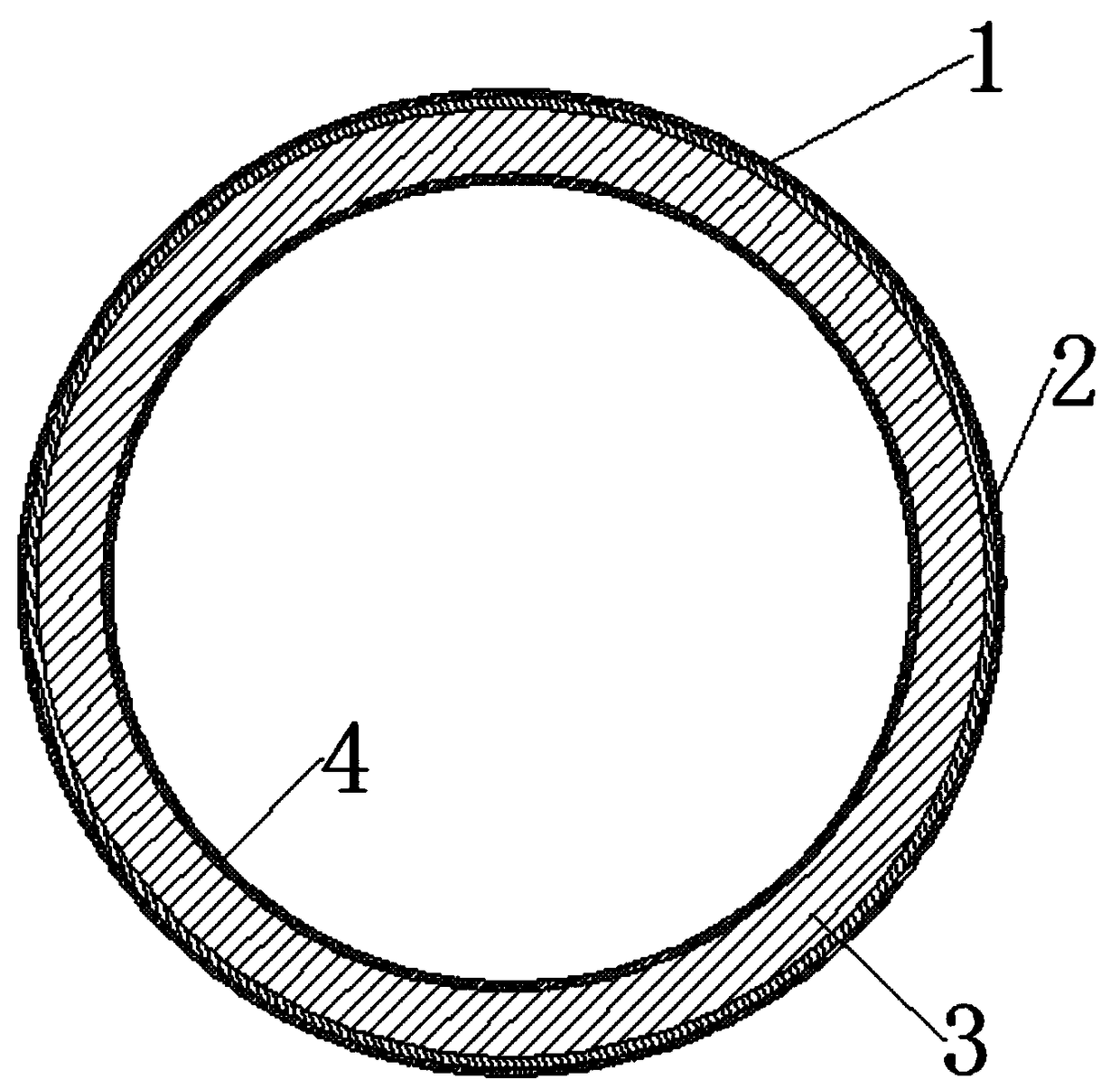

f304/f304l double-standard stainless steel flange and its production process

ActiveCN104791562BHigh strengthGood atmospheric corrosion resistanceFlanged jointsAgricultural engineeringUltimate tensile strength

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

Boron-contained alloy steel material for roller and preparation method thereof

InactiveCN103741043AIncrease stiffnessImprove toughnessProcess efficiency improvementNiobiumChromium

The invention relates to a boron-contained alloy steel material for a roller. The boron-contained alloy steel material contains the chemical elemental ingredients in percentage by mass: 0.8-0.9% of carbon, 2.5-3% of tungsten, 0.5-1.0% of molybdenum, 1.5-2.5% of vanadium, 2.5-3.0% of chromium, 0.05-0.10% of niobium, 0.1-0.15% of dysprosium, 0.2-0.5% of titanium, 0.1-0.15% of aluminum, 0.07-0.09% of copper, 0.15-0.19% of boron, not higher than 0.030% of P, not higher than 0.030% of S and the balance of iron. According to the boron-contained alloy steel material, through adding a variety of alloy elements, such as boron, niobium, tungsten and the like, based on high-carbon steel, carrying out secondary refining, reasonably controlling post-casting heat treatment temperature and dosing raw materials in batches, the alloy steel material has the characteristics of high-speed steel, is resistant to high temperature, is high in red hardness and good in rigidity and toughness matching, has the characteristics of good surface abrasion resistance, good spalling resistance and low cold brittleness, is applicable to rollers of wire machines, and is relatively low in cost due to relatively low alloy element content.

Owner:马鞍山市方圆材料工程股份有限公司

A kind of prestressed reinforcement with yield platform and its prestressed member construction method

ActiveCN103643154BImprove atomic activityStrong interactionBuilding material handlingPre stressClassical mechanics

Owner:江苏森林建筑新材料股份有限公司

Alloy steel material for boron-containing roll and preparation method thereof

InactiveCN103741043BIncrease stiffnessImprove toughnessProcess efficiency improvementNiobiumMaterials science

The invention relates to a boron-contained alloy steel material for a roller. The boron-contained alloy steel material contains the chemical elemental ingredients in percentage by mass: 0.8-0.9% of carbon, 2.5-3% of tungsten, 0.5-1.0% of molybdenum, 1.5-2.5% of vanadium, 2.5-3.0% of chromium, 0.05-0.10% of niobium, 0.1-0.15% of dysprosium, 0.2-0.5% of titanium, 0.1-0.15% of aluminum, 0.07-0.09% of copper, 0.15-0.19% of boron, not higher than 0.030% of P, not higher than 0.030% of S and the balance of iron. According to the boron-contained alloy steel material, through adding a variety of alloy elements, such as boron, niobium, tungsten and the like, based on high-carbon steel, carrying out secondary refining, reasonably controlling post-casting heat treatment temperature and dosing raw materials in batches, the alloy steel material has the characteristics of high-speed steel, is resistant to high temperature, is high in red hardness and good in rigidity and toughness matching, has the characteristics of good surface abrasion resistance, good spalling resistance and low cold brittleness, is applicable to rollers of wire machines, and is relatively low in cost due to relatively low alloy element content.

Owner:马鞍山市方圆材料工程股份有限公司

A stepped vertical convex curved bridge frame and its preparation method

The invention discloses a step type vertical convex bending through bridge frame. The step type vertical convex bending through bridge frame comprises symmetrically arranged groove frames and a transverse support arranged between the groove frames. The groove frames and the transverse support of the step type vertical convex bending through bridge frame are made of the same material. The material comprises the following components: C, Si, Mn, Ni, Mo, Cr, N, Cu, Al, Ti, S, P, Nb, V and a rare earth element, the balance being Fe and unavoidable impurities. The rare earth element comprises the following components: lanthanum, cerium, praseodymium, dysprosium, holmium, gadolinium and yttrium, the balance being lanthanide-series rare earth. The invention also provides a preparation method of the step type vertical convex bending through bridge frame. The preparation method is simple and easily implemented, the preparation cost is low, pollutants are not generated in a production technical process, and the prepared step type vertical convex bending through bridge frame is good in processing performance and high in strength and is highly guaranteed in quality.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

A kind of low temperature resistant corrosion resistant alloy steel material and preparation method thereof

The invention relates to a low-temperature-resistant corrosion-resistant alloy steel material which contains the following chemical components in percentage by mass: 0.2-0.4% of carbon, 0.2-0.4% of silicon, 0.2-0.4% of manganese, 3.3-2.5% of chromium, 0.7-0.9% of titanium, 1.2-1.5% of aluminum, 4.6-5.1% of cobalt, 0.006-0.009% of niobium, 0.04-0.07% of W, 21.0-22.5% of Ni, 0.07-0.09% of V, at most 0.030% of P, at most 0.030% of S and the balance of iron. By using the raw material combination of the titanium and the like, the proportion, production technique and feed sequence are reasonably arranged, so that the formed alloy material has favorable comprehensive mechanical properties and especially has the characteristics of low cold brittleness. The alloy material is suitable to be used in various environments, and is especially suitable for ultralow-temperature-resistant environments. The refining agent is added to lower the porosity by 1-2 degrees.

Owner:SICHUAN ZIGONG IND PUMP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com