High-strength low-alloy steel resistant to sulfuric acid dew point corrosion

A dew point corrosion, low alloy steel technology, applied in the field of low alloy steel, can solve the problems of sulfuric acid dew point corrosion resistance can not meet the actual production requirements, low strength, fracture damage of bearing parts, etc., to achieve sulfuric acid dew point corrosion resistance performance improvement, mechanical Excellent performance and the effect of reducing the total cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: adopt open hearth furnace and electric furnace smelting, rare earth is added in the steel ladle in the tapping process or after tapping, and can be made into plate, pipe, section bar etc. after continuous casting and rolling, and its chemical composition is as follows (weight %): C: 0.07, Si: 0.34, Mn: 0.52, P: 0.011, S: 0.015, Ni: 0.45, Cr: 0.73, Cu: 0.38, Sb: 0.09, Re: 0.10, Mo: 0.06, Nb: 0.04, Ti; 0.07, V: 0.03, Fe: Yu.

[0021] On the steel plate of this embodiment, a sample of 40 × 40 × 4 mm was cut, soaked in 50% sulfuric acid aqueous solution at 70 ° C for 4 hours, and carried out with reference to the standard of GB10124-88 "Metal Material Laboratory Uniform Corrosion Full Immersion Test Method" Sulfuric acid immersion test, the test results are shown in Table 1. The comparison of mechanical properties is shown in Table 2.

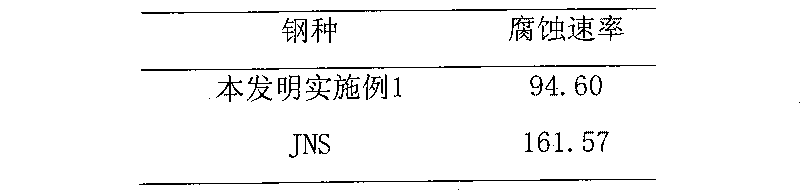

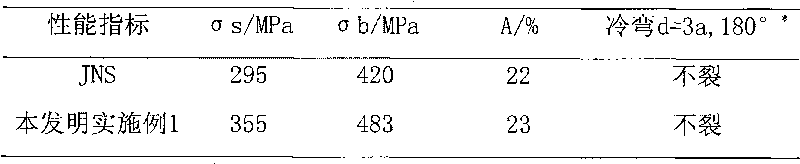

[0022] Table 1 Comparison of sulfuric acid dew point corrosion rates of different steels (mm y -1 )

[0023]

[0024] ...

Embodiment 2

[0027] Embodiment 2: the present embodiment is basically the same as the embodiment 1, the difference lies in the composition, the chemical composition of the present embodiment is (% by weight): C: 0.06, Si: 0.38, Mn: 0.57, P: 0.016, S: 0.013 , Ni: 0.54, Cr: 0.84, Cu: 0.41, Sb: 0.11, Re: 0.05, Mo: 0.07, Nb: 0.05, Ti; 0.06, V: 0.02, Fe: Yu.

[0028] On the steel plate of this embodiment, a sample of 40 × 40 × 4mm was intercepted, soaked in 20% sulfuric acid aqueous solution at 30°C for 24 hours, and carried out with reference to the standard of GB10124-88 "Metal Material Laboratory Uniform Corrosion Full Immersion Test Method" Sulfuric acid immersion test, the test results are shown in Table 3, and the comparison of mechanical properties is shown in Table 4.

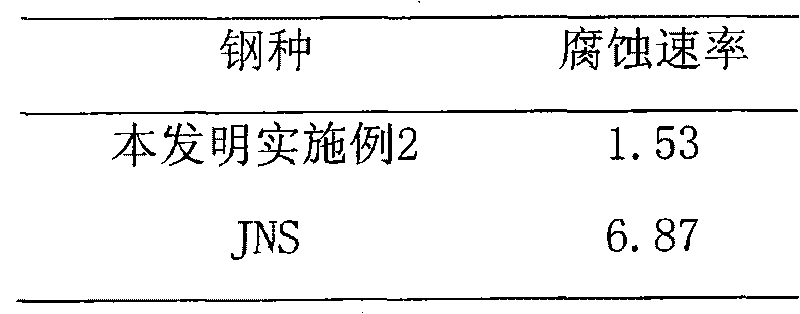

[0029] Table 3 Comparison of sulfuric acid dew point corrosion rates of different steels (mm y -1 )

[0030]

[0031] Table 4 Comparison of mechanical properties of different steels

[0032]

[0033] *d bend cen...

Embodiment 3

[0034] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference lies in the composition, the chemical composition of this embodiment is (% by weight): C: 0.10, Si: 0.40, Mn: 1.0, S: 0.05, Ni: 0.6 , Cr: 1.0, Cu: 0.5, Sb: 0.15, Re: 0.10, Mo: 0.10, Nb: 0.10, Ti: 0.10, V: 0.10, and the rest are Fe and inevitable inclusions.

[0035] On the steel plate of this embodiment, a sample of 40 × 40 × 4mm was intercepted, soaked in 20% sulfuric acid aqueous solution at 30°C for 24 hours, and carried out with reference to the standard of GB10124-88 "Metal Material Laboratory Uniform Corrosion Full Immersion Test Method" Sulfuric acid immersion test, the test results are shown in Table 5, and the comparison of mechanical properties is shown in Table 6.

[0036] Table 5 Comparison of sulfuric acid dew point corrosion rates of different steels (mm y -1 )

[0037]

[0038] Table 6 Comparison of mechanical properties of different steels

[0039]

[0040]*d ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com