Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

A low thermal expansion coefficient, thermoplastic resin technology, applied in the field of low thermal expansion coefficient thermoplastic resin composition, can solve the problems of linear expansion coefficient gap, increased weight of parts, poor toughness, etc., and achieve high flexural modulus, low linear expansion coefficient , good impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take raw material (weight part) according to following weight:

[0038] PC 540 copies,

[0039] Toughening agent MBS 55 parts,

[0040] Lubricant pentaerythritol stearate 2 parts,

[0041] Antioxidant 1076 1 part,

[0042] Antioxidant 168 2 parts,

[0043] 400 parts of continuous carbon fiber (single filament diameter: 30um);

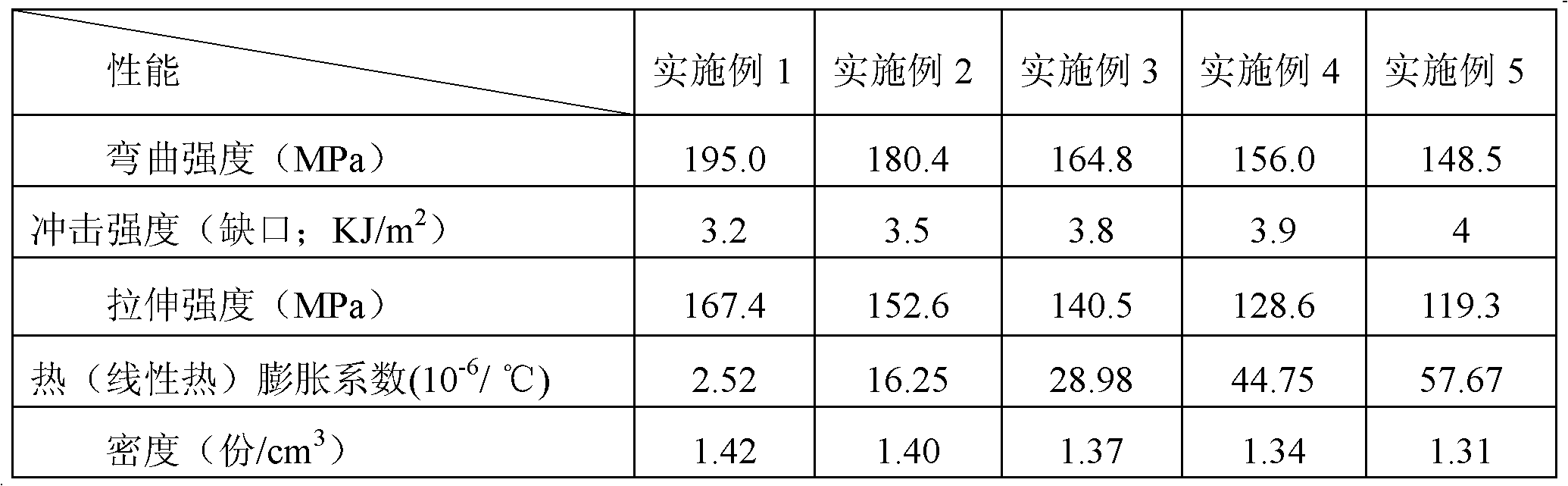

[0044] Put the above raw materials except carbon fiber into the high-speed mixer and mix for 5 minutes, then take it out and add it to the twin-screw extruder; After melt blending, extrusion, traction, and granulation in a separate twin-screw extruder; pelletize the extruded material and dry it at 120°C for 4 hours; use an injection molding machine to inject the obtained pellets to obtain ASTM standard mechanical test specimens are used to test product-related properties, see Table 1.

[0045] The barrel temperatures of the twin-screw extruder are 210°C, 245°C, 280°C, 285°C, and 280°C; the injection molding temperatures are 220°C, 255°C, 28...

Embodiment 2

[0047] Take raw material (weight part) according to following weight:

[0048] PC 590 copies,

[0049] Toughening agent butyl acrylate-methyl methacrylate copolymer 55 parts,

[0050] Lubricant solid paraffin wax 2 parts,

[0051] Antioxidant 1076 1 part,

[0052] Antioxidant 168 2 parts,

[0053] Continuous carbon fiber (monofilament diameter is 50um) 350 parts;

[0054] Put the above raw materials except carbon fiber into the high-speed mixer and mix for 10 minutes, then take it out and add it to the twin-screw extruder; After melt blending, extrusion, traction, and granulation in a separate twin-screw extruder; pelletize the extruded material and dry it at 120°C for 4 hours; use an injection molding machine to inject the obtained pellets to obtain ASTM standard mechanical test specimens are used to test product-related properties, see Table 1.

[0055] The barrel temperatures of the twin-screw extruder are 210°C, 245°C, 280°C, 285°C, and 280°C; the injection molding tem...

Embodiment 3

[0057] Take raw material (weight part) according to following weight:

[0058] PC 640 copies,

[0059] Toughening agent ethylene-methyl methacrylate copolymer 55 parts,

[0060] Lubricant pentaerythritol stearate 2 parts,

[0061] Antioxidant 1076 1 part,

[0062] Antioxidant 168 2 parts,

[0063] Chopped carbon fiber (single filament diameter is 1um) 300 parts;

[0064] First put the above raw materials except carbon fiber into the high-speed mixer and mix for 30 minutes, then take it out and add it to the twin-screw extruder; After melt blending, extrusion, traction, and granulation in a separate twin-screw extruder; pelletize the extruded material and dry it at 120°C for 4 hours; use an injection molding machine to inject the obtained pellets to obtain ASTM standard mechanical test specimens are used to test product-related properties, see Table 1.

[0065] The barrel temperatures of the twin-screw extruder are 210°C, 245°C, 280°C, 285°C, and 280°C; the injection mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com