Tungsten carbide coating cutter and preparation technology thereof

A technology of tungsten carbide coating and preparation process, applied in other manufacturing equipment/tools, manufacturing tools, grain processing, etc. , The effect of low equipment requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

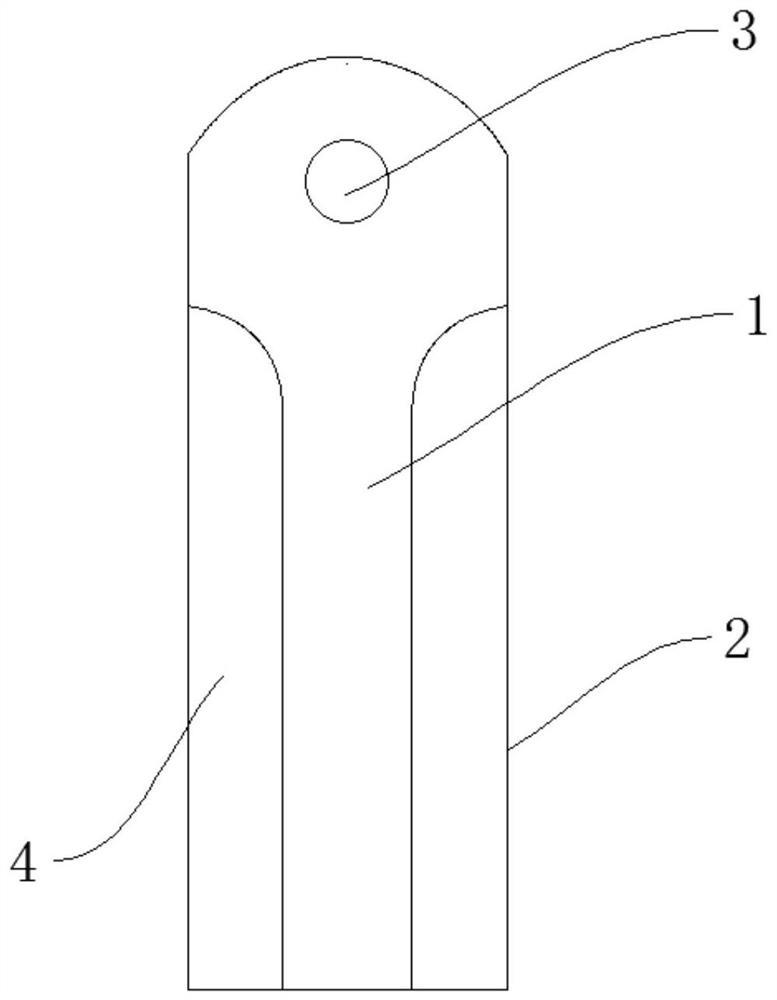

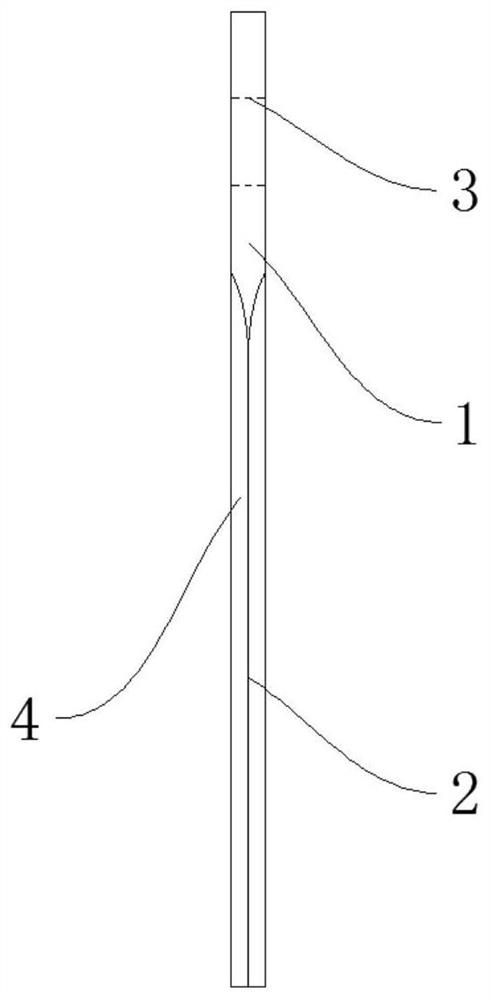

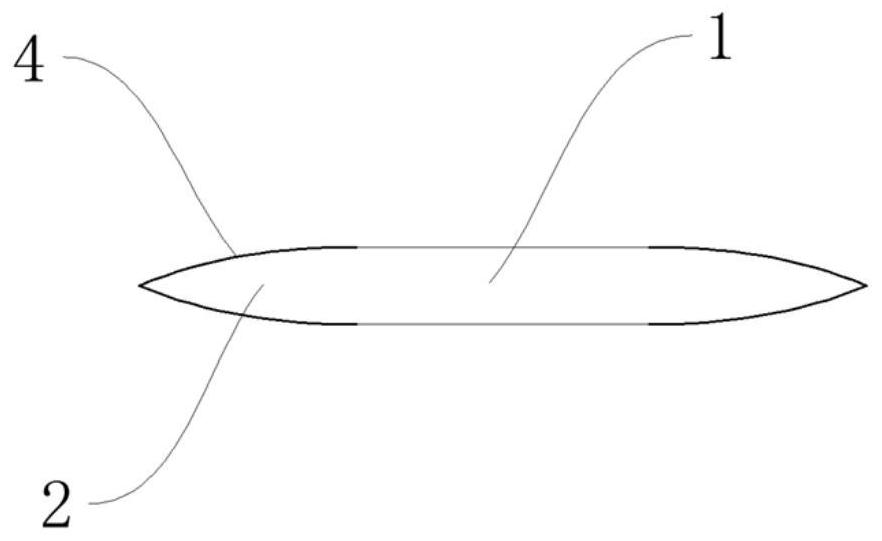

[0031] ginseng Figure 1 ~ Figure 3 As shown, a tungsten carbide coated knife includes a blade 1, the blade 1 is made of titanium-cobalt alloy steel, and the raw material of the titanium-cobalt alloy steel material includes titanium element with a mass fraction of 2-4% and a mass fraction of 0.5-1.5% The cobalt element specifically includes titanium element with a mass fraction of 2% and cobalt element with a mass fraction of 0.5%.

[0032] The blade 1 is provided with a fixing hole 3, which is used to fix the blade 1 in the pulverizer. The blade 1 is provided with a blade 2. The length and position of the blade 2 can be determined according to the actual situation. The blade 2 is coated with There is a tungsten carbide coating 4, the thickness of the tungsten carbide coating 4 is 0.015-0.035 mm, specifically, the thickness of the tungsten carbide coating 4 is 0.015 mm.

[0033] A preparation process for a tungsten carbide coated knife, comprising the following steps:

[003...

Embodiment 2

[0040] ginseng Figure 1 ~ Figure 3 As shown, a tungsten carbide coated knife includes a blade 1, the blade 1 is made of titanium-cobalt alloy steel, and the raw material of the titanium-cobalt alloy steel material includes titanium element with a mass fraction of 2-4% and a mass fraction of 0.5-1.5% The cobalt element specifically includes titanium element with a mass fraction of 4% and cobalt element with a mass fraction of 1.5%.

[0041] The blade 1 is provided with a fixing hole 3, which is used to fix the blade 1 in the pulverizer. The blade 1 is provided with a blade 2. The length and position of the blade 2 can be determined according to the actual situation. The blade 2 is coated with There is a tungsten carbide coating 4, the thickness of the tungsten carbide coating 4 is 0.015-0.035 mm, specifically, the thickness of the tungsten carbide coating 4 is 0.035 mm.

[0042] A preparation process for a tungsten carbide coated knife, comprising the following steps:

[004...

Embodiment 3

[0049] ginseng Figure 1 ~ Figure 3 As shown, a tungsten carbide coated knife includes a blade 1, the blade 1 is made of titanium-cobalt alloy steel, and the raw material of the titanium-cobalt alloy steel material includes titanium element with a mass fraction of 2-4% and a mass fraction of 0.5-1.5% The cobalt element specifically includes titanium element with a mass fraction of 3% and cobalt element with a mass fraction of 1%.

[0050] The blade 1 is provided with a fixing hole 3, which is used to fix the blade 1 in the pulverizer. The blade 1 is provided with a blade 2. The length and position of the blade 2 can be determined according to the actual situation. The blade 2 is coated with There is a tungsten carbide coating 4, the thickness of the tungsten carbide coating 4 is 0.015-0.035 mm, specifically, the thickness of the tungsten carbide coating 4 is 0.025 mm.

[0051] A preparation process for a tungsten carbide coated knife, comprising the following steps:

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com