Combined photovoltaic module aluminium frame and production process thereof

A photovoltaic module and production process technology, applied in the field of frame, can solve the problems of poor connection, poor sealing, inconvenient installation, etc., and achieve the effect of reducing tension, grinding workload, and residual lye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

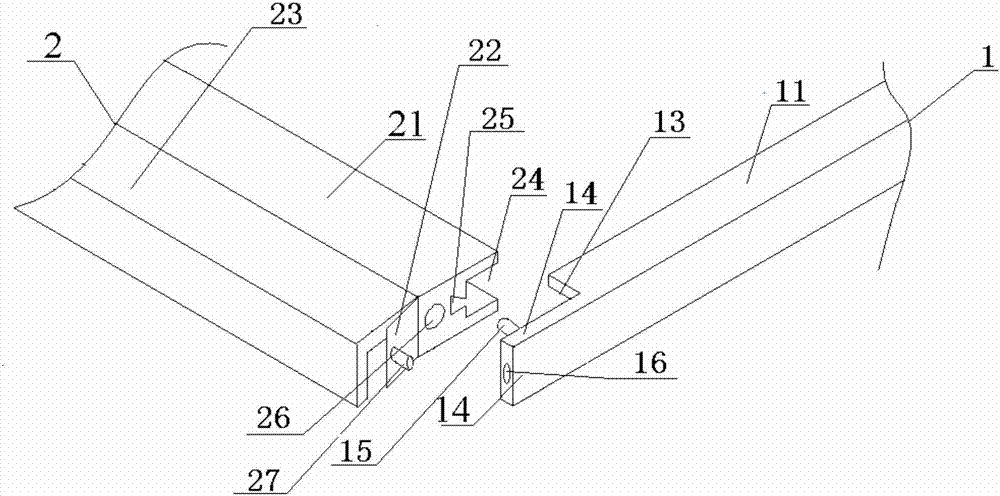

[0048] The aluminum frame of a combined solar photovoltaic module provided in this embodiment has a structure such as figure 1 As shown, including the main frame, the main frame is composed of the matching long frame 1, short frame 2 and U-shaped fixing block, wherein:

[0049] The short frame 2 is composed of a first concave profile 21, a fixed side 22 and a first connecting block 23, the fixed side 22 is arranged at both ends of the first concave profile 21, and the fixed side 22 is hinged on the first concave profile 21 , the first connection block 23 is formed by extending from one side of the first concave profile 21, and the notch of the first concave profile 21 is also provided with a first groove 24 and a glue injection groove 25, and the first groove 24 and the injection The glue groove 25 is connected, the first groove 24 and the glue injection groove 25 both penetrate the two ends of the first concave profile 21, and the glue injection groove 25 is formed by extendi...

Embodiment 2

[0053] This embodiment provides the production process of the aluminum frame of the combined solar photovoltaic module in the embodiment, which specifically includes the following steps:

[0054] (1) According to the shape of the frame of the combined solar photovoltaic module, mold sand and core sand are used as molding materials to make corresponding casting molds. Before making molds, first place the molding sand in the molding materials in an oven for drying, and Use a brush to clean the surface of the prepared mold to remove sand, and apply a layer of paint inside the mold, and let it dry naturally for use;

[0055] (2) Add the components of the profile raw material of the frame into the resistance furnace for melting, the melting temperature is 700°C, until all the components of the profile raw material are melted, and then add them to the LF refining furnace for refining and degassing. Ethyl chloride is degassed, the refining temperature is 750°C, and the refining time ...

Embodiment 3

[0070] This embodiment provides the production process of the aluminum frame of the combined solar photovoltaic module in the embodiment, which specifically includes the following steps:

[0071] (1) According to the shape of the frame of the combined solar photovoltaic module, mold sand and core sand are used as molding materials to make corresponding casting molds. Before making molds, first place the molding sand in the molding materials in an oven for drying, and Use a brush to clean the surface of the prepared mold to remove sand, and apply a layer of paint inside the mold, and let it dry naturally for use;

[0072] (2) Put the various components of the profile raw material of the frame into the resistance furnace for melting, the melting temperature is 750°C, until all the components of the profile raw material are melted, and then add the LF refining furnace for refining and degassing work, using six Ethyl chloride is degassed, the refining temperature is 780°C, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com