Corrosion-resistant and weather-resistant gear ring for gear box coupling and preparation method of corrosion-resistant and weather-resistant gear ring

A coupling, corrosion-resistant technology, used in belts/chains/gears, manufacturing tools, mechanical equipment, etc., can solve the problems of reduced service life of the ring gear, poor corrosion resistance and weather resistance, and achieve increased service life and enhanced Strength, the effect of improving fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

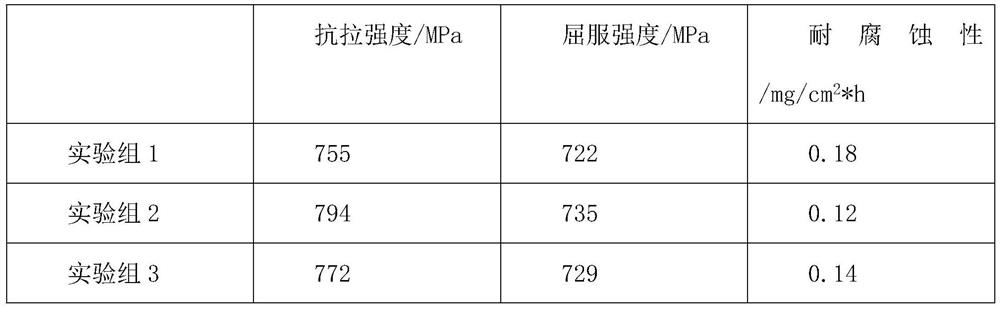

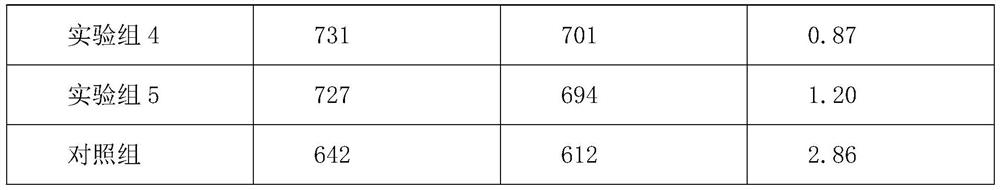

Embodiment 1

[0026] The invention provides a corrosion-resistant and weather-resistant ring gear for a gearbox coupling, which comprises the following raw materials in weight percentage: 0.1% carbon, 1.5% silicon, 0.5% nickel, 0.005% phosphorus, 0.5% titanium, 12% chromium, 0.1% vanadium, 0.3% lanthanum, 0.1% tungsten, 0.1% molybdenum, 0.2% rhenium, the balance is iron and unavoidable impurities.

[0027] In a preferred embodiment, the content of said unavoidable impurities is less than 0.005%.

[0028] The present invention also provides a method for preparing a corrosion-resistant and weather-resistant ring gear for a gearbox coupling, and the specific preparation steps are as follows:

[0029] Step 1: Weigh each raw material according to the above weight percentage, import the weighed scrap iron, scrap steel and scrap alloy steel into the intermediate frequency furnace, then pass a low current to the intermediate frequency furnace, and raise the temperature to 1150°C at a heating rate o...

Embodiment 2

[0041] The difference from Example 1 is that a corrosion-resistant and weather-resistant ring gear for a gearbox coupling includes the following raw materials in weight percentages: 0.18% carbon, 2.3% silicon, 0.8% nickel, 0.015% phosphorus, 0.1% titanium, Chromium 15%, vanadium 0.4%, lanthanum 0.5%, tungsten 0.2%, molybdenum 0.2%, rhenium 0.5%, and the balance is iron and unavoidable impurities.

Embodiment 3

[0043] The difference from Examples 1-2 is that a corrosion-resistant and weather-resistant ring gear for a gearbox coupling includes the following raw materials in weight percentages: 0.25% carbon, 3% silicon, 1% nickel, 0.025% phosphorus, titanium 1.5%, chromium 18%, vanadium 0.7%, lanthanum 0.8%, tungsten 0.3%, molybdenum 0.3%, rhenium 0.8%, and the balance is iron and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com