F304/F304L double-standard stainless steel flange and production process thereof

A production process, stainless steel technology, applied in flange connection, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of intergranular corrosion resistance not as good as F304L material, high temperature and pressure of process system, and achieve good sealing effect, The effect of uniform distribution and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

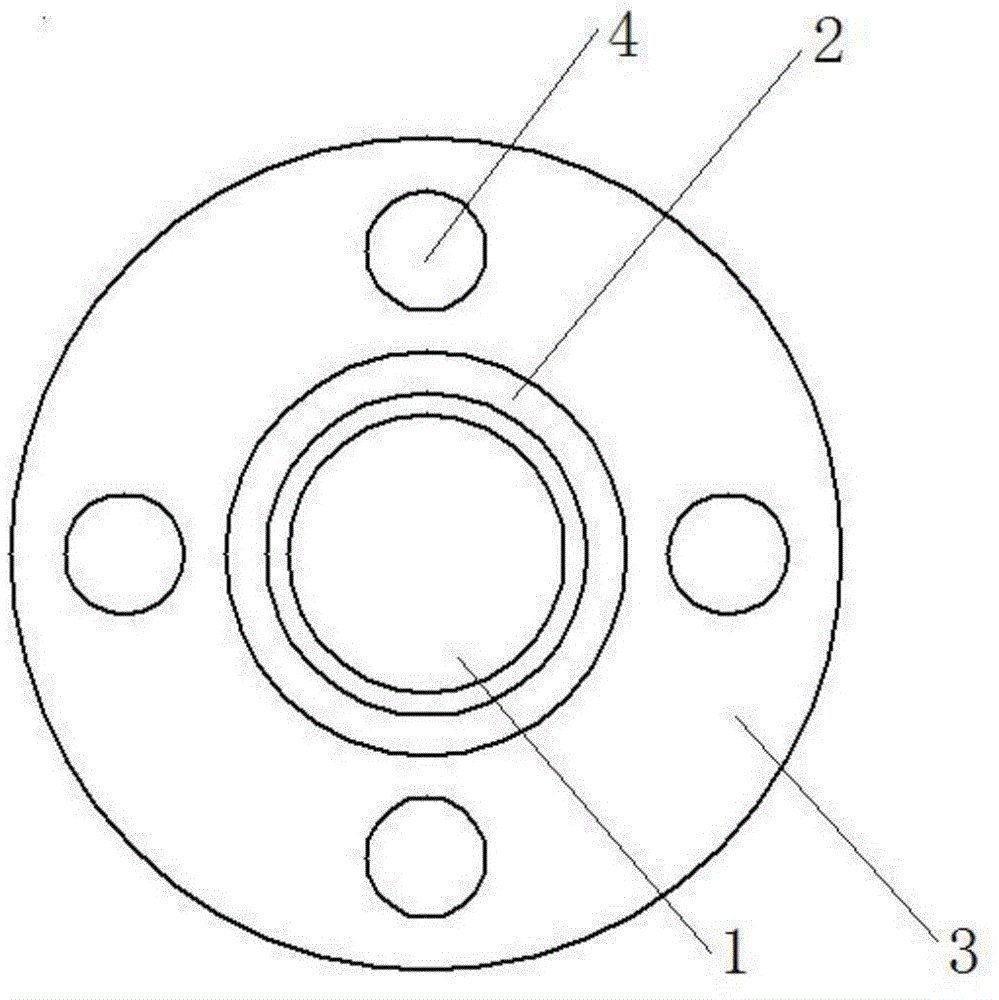

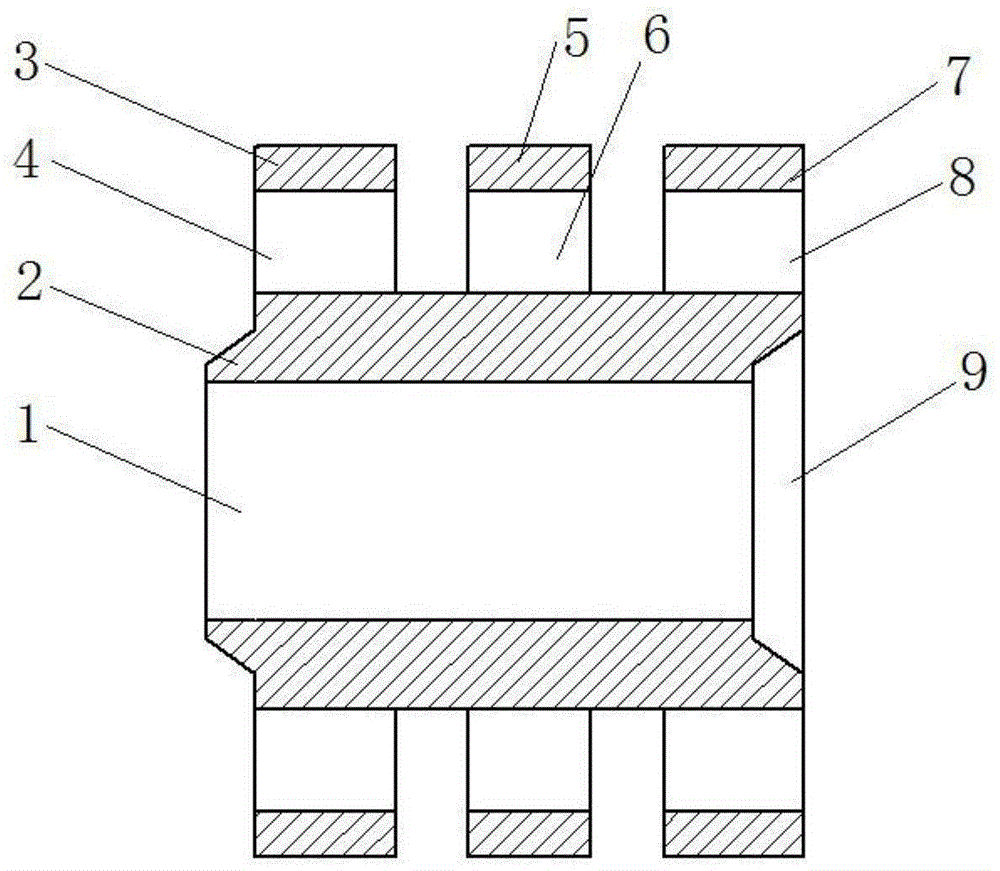

[0027] This embodiment provides a F304 / F304L double standard stainless steel material flange, the structure is as follows figure 1 , figure 2 As shown, it includes a through hole 1 and a flange piece. The flange piece is a disc-shaped structure. The through hole 1 is set on the central axis of the flange piece. Boss 2 and groove 9 are provided. The flange includes front flange 3, middle flange 5 and rear flange 7, and the three are arranged in parallel in turn. Front flange 3, middle flange 5 The diameter is equal to that of the rear flange 7, and the thickness of the front flange 3 is the same as that of the rear flange 7, and 4 fixing holes are evenly arranged on it, the front fixing hole 4, the middle fixing hole 6 and the rear fixing hole 8. The apertures are equal in size and corresponding in position.

[0028] The distance between the aforementioned front flange piece 3 and the middle flange piece 5 is equal to the distance between the middle flange piece 5 and the re...

Embodiment 2

[0030] This embodiment provides a production process of F304 / F304L double-standard stainless steel flange, the process steps are: melting - forging - heat treatment - trimming - ultrasonic testing - sampling analysis, wherein:

[0031] Melting: After the analysis is qualified, the alloy blank below 5000Kg is selected, and the vacuum arc remelting or electroslag remelting is adopted. The melting temperature is 2950°C. The chemical composition and mass percentage of the alloy blank are: Cr: 18.3%, Ni: 9.1%, C : 0.07%, Mo: 0.21%, Cu: 0.52%, Si: 0.89%, Nb: 0.14%, Ti: 0.097%, Ca: 0.15%, Se: 0.05%, Te: 0.15%, S: 0.015%, P : 0.021%, the rest is Fe and unavoidable impurities;

[0032] Forging: put the alloy billet smelted at high temperature into the furnace for heat preservation, the heat preservation temperature is 1050°C, and the heat preservation time is 7 hours, and then forge, the forging method adopts free forging, the forging ratio is controlled to 3.5, and the scale is remove...

Embodiment 3

[0039] This embodiment provides a production process of F304 / F304L double-standard stainless steel flange, the process steps are: melting - forging - heat treatment - trimming - ultrasonic testing - sampling analysis, wherein:

[0040] Melting: After the analysis is qualified, the alloy blank below 5000Kg is selected, and the vacuum arc remelting or electroslag remelting is adopted. The melting temperature is 3150°C. The chemical composition and mass percentage of the alloy blank are: Cr: 18.5%, Ni: 9.3%, C : 0.09%, Mo: 0.25%, Cu: 0.54%, Si: 0.93%, Nb: 0.16%, Ti: 0.099%, Ca: 0.17%, Se: 0.15%, Te: 0.19%, S: 0.025%, P : 0.023%, the rest is Fe and unavoidable impurities;

[0041] Forging: put the alloy billet smelted at high temperature into the furnace for heat preservation, the heat preservation temperature is 1090°C, and the heat preservation time is 5h, and then forge, the forging method adopts free forging, the forging ratio is controlled to 4.5, and the scale is removed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com